中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (12): 111-120.DOI: 10.13304/j.nykjdb.2022.0601

• 智慧农业 农机装备 • 上一篇

于淼1,2( ), 周海宾2, 丁京涛2, 程红胜2, 沈玉君1,2(

), 周海宾2, 丁京涛2, 程红胜2, 沈玉君1,2( ), 范盛远2, 张曦2, 王健2, 徐鹏翔2, 程琼仪2

), 范盛远2, 张曦2, 王健2, 徐鹏翔2, 程琼仪2

收稿日期:2022-07-18

接受日期:2022-11-22

出版日期:2023-12-15

发布日期:2023-12-12

通讯作者:

沈玉君

作者简介:于淼 E-mail:ym10946@163.com;

基金资助:

Miao YU1,2( ), Haibin ZHOU2, Jingtao DING2, Hongsheng CHENG2, Yujun SHEN1,2(

), Haibin ZHOU2, Jingtao DING2, Hongsheng CHENG2, Yujun SHEN1,2( ), Shengyuan FAN2, Xi ZHANG2, Jian WANG2, Pengxiang XU2, Qiongyi CHENG2

), Shengyuan FAN2, Xi ZHANG2, Jian WANG2, Pengxiang XU2, Qiongyi CHENG2

Received:2022-07-18

Accepted:2022-11-22

Online:2023-12-15

Published:2023-12-12

Contact:

Yujun SHEN

摘要:

餐厨垃圾原料复杂,导致其好氧堆肥原料混合过程仿真研究中存在参数不易获取的问题。该研究通过物理堆积试验与EDEM仿真试验结合的方法对餐厨垃圾接触参数进行了标定,通过Plackett-Burman(P-B)试验对9个待标定参数进行显著性筛选。结果表明,颗粒滚动摩擦系数、Johnso-Kendall-Roberts(JKR)表面能、颗粒与几何体间静摩擦系数对餐厨垃圾堆积角的影响显著;采用爬坡试验和Box-Behnken(B-B)试验,获得显著影响参数的最优值区间与最优值组合:餐厨垃圾-餐厨垃圾滚动摩擦系数为0.11、JKR表面能为0.13 J·m-2、餐厨垃圾-不锈钢静摩擦系数为0.73。仿真试验验证结果平均相对误差为4.3%,说明标定餐厨垃圾接触参数具有可靠性。研究结果可为餐厨垃圾处理和资源化利用设备的仿真研究提供参考。

中图分类号:

于淼, 周海宾, 丁京涛, 程红胜, 沈玉君, 范盛远, 张曦, 王健, 徐鹏翔, 程琼仪. 基于EDEM的餐厨垃圾组成颗粒间接触参数标定[J]. 中国农业科技导报, 2023, 25(12): 111-120.

Miao YU, Haibin ZHOU, Jingtao DING, Hongsheng CHENG, Yujun SHEN, Shengyuan FAN, Xi ZHANG, Jian WANG, Pengxiang XU, Qiongyi CHENG. Calibration of Interparticle Contact Parameters of Kitchen Waste Composition Based on EDEM[J]. Journal of Agricultural Science and Technology, 2023, 25(12): 111-120.

类型 Type | 尺寸(长×宽×高) Size (length×width× hight)/mm | 含水率 Moisture content/% | 密度 Density/(kg·m-3) |

|---|---|---|---|

| 米饭 Rice | 5.6×3.0×3.0 | 70 | 800 |

菜茎 Floret | 30.0×7.5×7.5 | ||

肉类 Meat | 20.0×15.0×2.0 |

表1 餐厨垃圾基础参数

Table 1 Basic parameters of kitchen waste

类型 Type | 尺寸(长×宽×高) Size (length×width× hight)/mm | 含水率 Moisture content/% | 密度 Density/(kg·m-3) |

|---|---|---|---|

| 米饭 Rice | 5.6×3.0×3.0 | 70 | 800 |

菜茎 Floret | 30.0×7.5×7.5 | ||

肉类 Meat | 20.0×15.0×2.0 |

参数 Parameter | 数值 Value |

|---|---|

| 泊松比Poisson’s ratio | 0.3 |

| 剪切模量Shear modulus/MPa | 7.9×1010 |

| 密度Density /kg·m-3 | 7 800 |

表2 不锈钢离散元参数

Table 2 Discrete element parameters of stainless steel

参数 Parameter | 数值 Value |

|---|---|

| 泊松比Poisson’s ratio | 0.3 |

| 剪切模量Shear modulus/MPa | 7.9×1010 |

| 密度Density /kg·m-3 | 7 800 |

参数符号 Parameter notation | 参数 Parameter | 参数水平 Parameter level | ||

|---|---|---|---|---|

| -1 | 0 | +1 | ||

| A | 餐厨垃圾泊松比 Kitchen waste poisson’s ratio | 0.250 | 0.325 | 0.400 |

| B | 餐厨垃圾剪切模量 Kitchen waste shear modulus/MPa | 1.0 | 5.5 | 10.0 |

| C | 餐厨-餐厨碰撞恢复系数 Kitchen waste-kitchen waste restitution coefficient | 0.35 | 0.55 | 0.75 |

| D | 餐厨-餐厨静摩擦系数 Kitchen waste-kitchen waste static friction coefficient | 0.20 | 0.62 | 1.04 |

| E | 餐厨-餐厨滚动摩擦系数 Kitchen waste-kitchen waste rolling friction coefficient | 0.05 | 0.10 | 0.15 |

| F | 餐厨-不锈钢碰撞恢复系数 Kitchen waste-stainless steel restitution coefficient | 0.4 | 0.6 | 0.8 |

| G | 餐厨-不锈钢静摩擦系数 Kitchen waste-stainless steel static friction coefficient | 0.50 | 0.75 | 1.00 |

| H | 餐厨-不锈钢滚动摩擦系数 Kitchen waste-stainless steel rolling friction coefficient | 0.50 | 0.75 | 1.00 |

| J | JKR表面能 JKR surface energy /(J·m-2) | 0.01 | 0.05 | 0.10 |

表3 餐厨垃圾离散元参数范围

Table 3 Discrete element parameter range of kitchen waste

参数符号 Parameter notation | 参数 Parameter | 参数水平 Parameter level | ||

|---|---|---|---|---|

| -1 | 0 | +1 | ||

| A | 餐厨垃圾泊松比 Kitchen waste poisson’s ratio | 0.250 | 0.325 | 0.400 |

| B | 餐厨垃圾剪切模量 Kitchen waste shear modulus/MPa | 1.0 | 5.5 | 10.0 |

| C | 餐厨-餐厨碰撞恢复系数 Kitchen waste-kitchen waste restitution coefficient | 0.35 | 0.55 | 0.75 |

| D | 餐厨-餐厨静摩擦系数 Kitchen waste-kitchen waste static friction coefficient | 0.20 | 0.62 | 1.04 |

| E | 餐厨-餐厨滚动摩擦系数 Kitchen waste-kitchen waste rolling friction coefficient | 0.05 | 0.10 | 0.15 |

| F | 餐厨-不锈钢碰撞恢复系数 Kitchen waste-stainless steel restitution coefficient | 0.4 | 0.6 | 0.8 |

| G | 餐厨-不锈钢静摩擦系数 Kitchen waste-stainless steel static friction coefficient | 0.50 | 0.75 | 1.00 |

| H | 餐厨-不锈钢滚动摩擦系数 Kitchen waste-stainless steel rolling friction coefficient | 0.50 | 0.75 | 1.00 |

| J | JKR表面能 JKR surface energy /(J·m-2) | 0.01 | 0.05 | 0.10 |

| 序号 No | 参数符号Parameter notation | 堆积角θ Repose angle θ/(°) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | K | L | ||

| 1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 35.29 |

| 2 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 31.52 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 25.37 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 38.61 |

| 5 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 44.92 |

| 6 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 27.09 |

| 7 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 29.24 |

| 8 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 31.19 |

| 9 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 28.74 |

| 10 | -1 | 1 | 1. | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 25.78 |

| 11 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 37.22 |

| 12 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 25.87 |

| 13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 31.56 |

| 14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 31.76 |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 29.32 |

| 16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 33.82 |

表4 Plackett-Burman 设计方案及结果

Table 4 Scheme and results of Plackett-Burman design

| 序号 No | 参数符号Parameter notation | 堆积角θ Repose angle θ/(°) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | K | L | ||

| 1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 35.29 |

| 2 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 31.52 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 25.37 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 38.61 |

| 5 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 44.92 |

| 6 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 27.09 |

| 7 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 29.24 |

| 8 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 31.19 |

| 9 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 28.74 |

| 10 | -1 | 1 | 1. | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 25.78 |

| 11 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 37.22 |

| 12 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 25.87 |

| 13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 31.56 |

| 14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 31.76 |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 29.32 |

| 16 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 33.82 |

方差来源 Variance source | 效应 Effect | P值 P value | 显著性排序 Significant ranking |

|---|---|---|---|

| 模型Model | — | 0.009 7** | — |

| A | -0.56 | 0.290 0 | 6 |

| B | 0.12 | 0.810 0 | 9 |

| C | 0.52 | 0.321 0 | 7 |

| D | -0.18 | 0.721 0 | 8 |

| E | 4.40 | 0.000 7** | 1 |

| F | 0.83 | 0.147 3 | 4 |

| G | -1.64 | 0.023 5* | 3 |

| H | 0.78 | 0.165 2 | 5 |

| J | 2.89 | 0.003 3** | 2 |

表5 Plackett-Burman试验参数显著性分析

Table 5 Analysis of significance parameters in Plackett-Burman design test

方差来源 Variance source | 效应 Effect | P值 P value | 显著性排序 Significant ranking |

|---|---|---|---|

| 模型Model | — | 0.009 7** | — |

| A | -0.56 | 0.290 0 | 6 |

| B | 0.12 | 0.810 0 | 9 |

| C | 0.52 | 0.321 0 | 7 |

| D | -0.18 | 0.721 0 | 8 |

| E | 4.40 | 0.000 7** | 1 |

| F | 0.83 | 0.147 3 | 4 |

| G | -1.64 | 0.023 5* | 3 |

| H | 0.78 | 0.165 2 | 5 |

| J | 2.89 | 0.003 3** | 2 |

序号 No. | 试验参数 Test parameter | 堆积角 Repose angle/(°) | 相对误差 Relative error/% | ||

|---|---|---|---|---|---|

| E | J | G | |||

| 1 | 0.05 | 0.01 | 1.0 | 27.29 | 31 |

| 2 | 0.07 | 0.04 | 0.9 | 28.32 | 28 |

| 3 | 0.09 | 0.07 | 0.8 | 31.73 | 10 |

| 4 | 0.11 | 0.10 | 0.7 | 36.62 | 7 |

| 5 | 0.13 | 0.13 | 0.6 | 45.92 | 15 |

| 6 | 0.15 | 0.16 | 0.5 | 50.10 | 26 |

表6 爬坡试验设计方案及仿真结果

Table 6 Scheme and results of climbing test

序号 No. | 试验参数 Test parameter | 堆积角 Repose angle/(°) | 相对误差 Relative error/% | ||

|---|---|---|---|---|---|

| E | J | G | |||

| 1 | 0.05 | 0.01 | 1.0 | 27.29 | 31 |

| 2 | 0.07 | 0.04 | 0.9 | 28.32 | 28 |

| 3 | 0.09 | 0.07 | 0.8 | 31.73 | 10 |

| 4 | 0.11 | 0.10 | 0.7 | 36.62 | 7 |

| 5 | 0.13 | 0.13 | 0.6 | 45.92 | 15 |

| 6 | 0.15 | 0.16 | 0.5 | 50.10 | 26 |

序号 No. | 试验参数 Test parameters | 堆积角 Angle of repose/(°) | ||

|---|---|---|---|---|

| E | J | G | ||

| 1 | 1(0.13) | -1(0.07) | 0(0.7) | 36.90 |

| 2 | 0(0.11) | -1 | -1(0.6) | 36.10 |

| 3 | -1(0.09) | 1(0.13) | 0 | 35.56 |

| 4 | -1 | -1 | 0 | 33.88 |

| 5 | 0 | 1 | 1(0.8) | 35.62 |

| 6 | 1 | 0(0.10) | 1 | 37.04 |

| 7 | -1 | 0 | -1 | 35.75 |

| 8 | 0 | 0 | 0 | 38.49 |

| 9 | 1 | 0 | -1 | 40.44 |

| 10 | -1 | 0 | 1 | 34.91 |

| 11 | 0 | 0 | 0 | 38.73 |

| 12 | 1 | 1 | 0 | 42.59 |

| 13 | 0 | 1 | -1 | 42.47 |

| 14 | 0 | 0 | 0 | 40.02 |

| 15 | 0 | -1 | 1 | 36.42 |

表7 Box-Behken 设计方案及仿真结果

Table 7 Scheme and results of Box-Behken design

序号 No. | 试验参数 Test parameters | 堆积角 Angle of repose/(°) | ||

|---|---|---|---|---|

| E | J | G | ||

| 1 | 1(0.13) | -1(0.07) | 0(0.7) | 36.90 |

| 2 | 0(0.11) | -1 | -1(0.6) | 36.10 |

| 3 | -1(0.09) | 1(0.13) | 0 | 35.56 |

| 4 | -1 | -1 | 0 | 33.88 |

| 5 | 0 | 1 | 1(0.8) | 35.62 |

| 6 | 1 | 0(0.10) | 1 | 37.04 |

| 7 | -1 | 0 | -1 | 35.75 |

| 8 | 0 | 0 | 0 | 38.49 |

| 9 | 1 | 0 | -1 | 40.44 |

| 10 | -1 | 0 | 1 | 34.91 |

| 11 | 0 | 0 | 0 | 38.73 |

| 12 | 1 | 1 | 0 | 42.59 |

| 13 | 0 | 1 | -1 | 42.47 |

| 14 | 0 | 0 | 0 | 40.02 |

| 15 | 0 | -1 | 1 | 36.42 |

方差来源 Variance source | 均方和 Mean sum of square | 自由度 Degree of freedom | 平方和 Quadratic sum | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 94.59 | 9 | 10.51 | 38.59 | 0.000 4** |

| X | 33.62 | 1 | 33.62 | 123.44 | 0.000 1** |

| Y | 17.82 | 1 | 17.82 | 65.43 | 0.000 5** |

| Z | 15.96 | 1 | 15.96 | 58.60 | 0.000 6** |

| XY | 6.28 | 1 | 6.28 | 23.04 | 0.004 9* |

| XZ | 1.03 | 1 | 1.03 | 3.78 | 0.109 4 |

| YZ | 12.85 | 1 | 12.85 | 47.19 | 0.001 0* |

| X2 | 4.34 | 1 | 4.34 | 15.92 | 0.010 4* |

| Y2 | 0.41 | 1 | 0.41 | 1.51 | 0.273 8 |

| Z2 | 3.08 | 1 | 3.08 | 11.32 | 0.020 0* |

| 失拟项 Lack of fit | 0.83 | 3 | 0.28 | — | 0.525 5 |

| 误差项 Pure error | 0.53 | 2 | 0.27 | 1.04 | — |

| 总和 Total | 95.96 | 14 | — | — | — |

表8 Box-Behnken试验设计回归模型方差分析

Table 8 ANOVA of Box-Behnken design quadratic model

方差来源 Variance source | 均方和 Mean sum of square | 自由度 Degree of freedom | 平方和 Quadratic sum | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 94.59 | 9 | 10.51 | 38.59 | 0.000 4** |

| X | 33.62 | 1 | 33.62 | 123.44 | 0.000 1** |

| Y | 17.82 | 1 | 17.82 | 65.43 | 0.000 5** |

| Z | 15.96 | 1 | 15.96 | 58.60 | 0.000 6** |

| XY | 6.28 | 1 | 6.28 | 23.04 | 0.004 9* |

| XZ | 1.03 | 1 | 1.03 | 3.78 | 0.109 4 |

| YZ | 12.85 | 1 | 12.85 | 47.19 | 0.001 0* |

| X2 | 4.34 | 1 | 4.34 | 15.92 | 0.010 4* |

| Y2 | 0.41 | 1 | 0.41 | 1.51 | 0.273 8 |

| Z2 | 3.08 | 1 | 3.08 | 11.32 | 0.020 0* |

| 失拟项 Lack of fit | 0.83 | 3 | 0.28 | — | 0.525 5 |

| 误差项 Pure error | 0.53 | 2 | 0.27 | 1.04 | — |

| 总和 Total | 95.96 | 14 | — | — | — |

方差来源 Variance source | 均方和 Mean sum of square | 自由度 Degree of freedom | 平方和 Quadratic sum | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 93.15 | 7 | 13.31 | 33.23 | <0.000 1** |

| X | 33.62 | 1 | 33.62 | 83.95 | <0.000 1** |

| Y | 17.82 | 1 | 17.82 | 44.50 | 0.000 3** |

| Z | 15.96 | 1 | 15.96 | 39.86 | 0.000 4** |

| XY | 6.28 | 1 | 6.28 | 15.67 | 0.005 5** |

| YZ | 12.85 | 1 | 12.85 | 32.09 | 0.000 8** |

| X2 | 4.16 | 1 | 4.16 | 10.38 | 0.014 6* |

| Y2 | 2.93 | 1 | 2.93 | 7.31 | 0.030 4* |

| 失拟项 Lack of fit | 2.27 | 5 | 0.45 | 1.70 | 0.410 0 |

| 误差项 Pure error | 0.53 | 2 | 0.27 | — | — |

| 总和 Total | 95.96 | 14 | — | — | — |

表9 Box-Behnken 试验设计优化模型方差分析

Table 9 AVOVA of Box-Behnken design modified model

方差来源 Variance source | 均方和 Mean sum of square | 自由度 Degree of freedom | 平方和 Quadratic sum | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 93.15 | 7 | 13.31 | 33.23 | <0.000 1** |

| X | 33.62 | 1 | 33.62 | 83.95 | <0.000 1** |

| Y | 17.82 | 1 | 17.82 | 44.50 | 0.000 3** |

| Z | 15.96 | 1 | 15.96 | 39.86 | 0.000 4** |

| XY | 6.28 | 1 | 6.28 | 15.67 | 0.005 5** |

| YZ | 12.85 | 1 | 12.85 | 32.09 | 0.000 8** |

| X2 | 4.16 | 1 | 4.16 | 10.38 | 0.014 6* |

| Y2 | 2.93 | 1 | 2.93 | 7.31 | 0.030 4* |

| 失拟项 Lack of fit | 2.27 | 5 | 0.45 | 1.70 | 0.410 0 |

| 误差项 Pure error | 0.53 | 2 | 0.27 | — | — |

| 总和 Total | 95.96 | 14 | — | — | — |

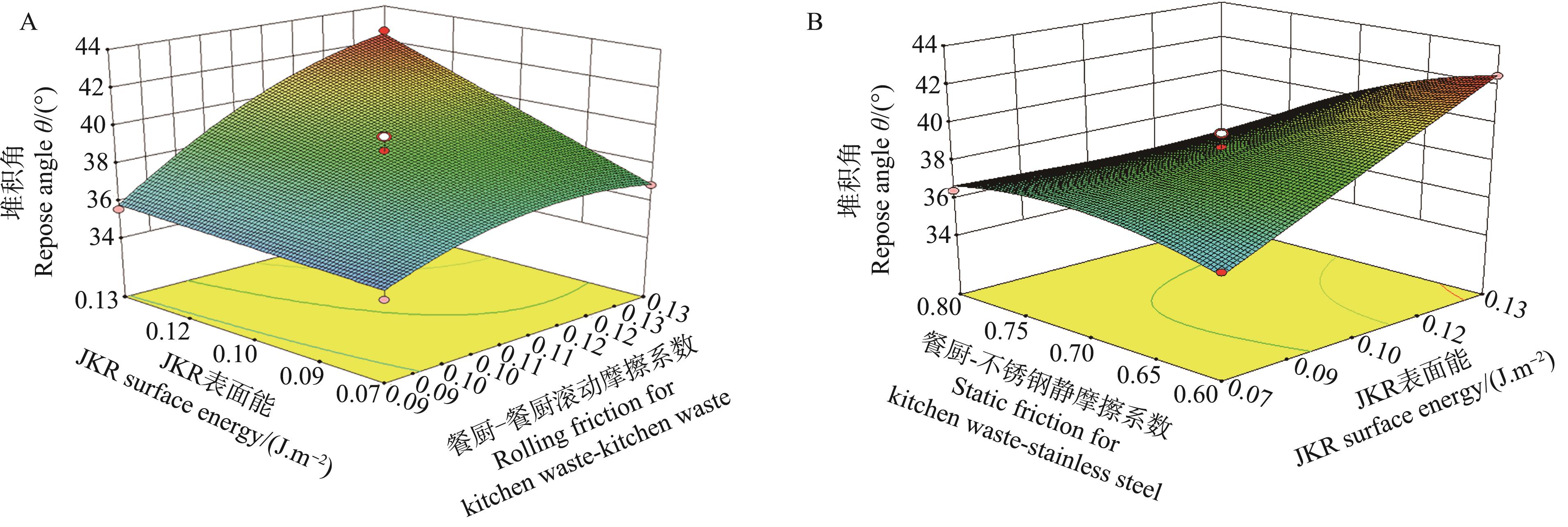

图5 JKR表面能、餐厨垃圾-餐厨垃圾滚动摩擦系数、餐厨垃圾-不锈钢静摩擦系数交互作用对堆积角的影响A: JKR表面能与餐厨-餐厨滚动摩擦系数的交互作用;B: 餐厨-不锈钢静摩擦系数与JKR表面能的交互作用

Fig. 5 Interaction of JKR surface energy, rolling friction for kitchen waste-kitchen waste and static friction for kitchen waste-stainless steel on the change of repose angleA: Interaction of JKR surface energy with rolling friction for kitchen waste-kitchen waste; B: Interaction of static friction for kitchen waste- stainless steel with JKR surface energy

| 1 | 魏珞宇,罗臣乾,张敏,等.农村有机生活垃圾沼气发酵工艺优化及菌群分析[J].中国沼气, 2019, 37(1): 27-30. |

| WEI L Y, LUO C Q, ZHANG M, et al.. Optimization of biogas fermentation process and microflora analysis of rural organic household waste [J]. China Biogas, 2019, 37(1): 27-30. | |

| 2 | 韩智勇,费勇强,刘丹,等.中国农村生活垃圾的产生量与物理特性分析及处理建议[J].农业工程学报, 2017, 33(15): 1-14. |

| HAN Z Y, FEI Y Q, LIU D, et al.. Yield and physical characteristics analysis of domestic waste in rural areas of China and its disposal proposal [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(15): 1-14. | |

| 3 | 靳琪.村镇生活垃圾收运处理模式评价研究[D].昆明: 昆明理工大学,2018. |

| JIN Q. The study of evaluation of domestic garbage collection, transportation and disposal mode in villages and towns [D]. Kunming: Kunming University of Science and Technology, 2018. | |

| 4 | 王浩璇,果霖,王一鸣,等.基于EDEM-Fluent仿真的餐厨垃圾渣液分离机设计与试验[J].食品与机械, 2021, 37(1): 130-136. |

| WANG H X, GUO L, WANG Y M, et al.. Design and test of the separator of kitchen waste residue liquid based on EDEM fluent simulation [J]. Food Mach., 2021, 37(1): 130-136. | |

| 5 | 曾智伟,马旭,曹秀龙,等.离散元法在农业工程研究中的应用现状和展望[J].农业机械学报, 2021, 52(4):1-20. |

| ZENG Z W, MA X, CAO X L, et al.. Critical review of applications of discrete element method in agricultural engineering [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(4): 1-20. | |

| 6 | 王国强,郝万军,王继军.离散单元法及其在EDEM上的实践[M].西安:西北工业大学出版社. 2010:1-49. |

| 7 | 马彦华,宋春东,宣传忠,等.苜蓿秸秆压缩仿真离散元模型参数标定[J].农业工程学报, 2020, 36(11): 22-30. |

| MA Y H, SONG C D, XUAN C Z, et al.. Parameters calibration of discrete element model for alfalfa straw compression simulation [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(11): 22-30. | |

| 8 | SANTOS K G, CAMPOS A V P, OLIVEIRA O S, et al.. Dem simulations of dynamic angle of repose of acerola residue: a parametric study using a response surface technique [J]. Blucher Chem. Eng. Proceed., 2015, 1(2): 11326-11333. |

| 9 | 罗帅,袁巧霞, GOUDA Shaban,等.基于JKR粘结模型的蚯蚓粪基质离散元法参数标定[J].农业机械学报, 2018, 49(4): 343-350. |

| LUO S, YUAN Q X, GOUDA S, et al.. Parameter calibration of earthworm manure matrix by discrete element method based on JKR bond model [J]. Trans. Chin. Soc. Agric. Mach., 2018, 49(4): 343-350. | |

| 10 | 王黎明,范盛远,程红胜,等.基于EDEM的猪粪接触参数标定[J].农业工程学报, 2020, 36(15): 95-102. |

| WANG L M, FAN S Y, CHENG H S, et al.. Calibration of pig manure contact parameters based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(15): 95-102. | |

| 11 | 田辛亮,丛旭,齐江涛,等.黑土区玉米秸秆-土壤混料离散元模型参数标定[J].农业机械学报, 2021, 52(10): 100- 108, 242. |

| TIAN X L, CONG X, QI J T, et al.. Parameter calibration of discrete element model for corn straw-soil mixture in black soil areas [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(10): 100-108, 242. | |

| 12 | 刘晓鹏,李建文,刘羽祚,等.颗粒状饲料接触参数标定及其流动性能分析[J].饲料工业, 2021, 42(19): 6-17. |

| LIU X P, LI J W, LIU Y Z, et al.. Contact parameters calibration and flowing property analysis of granular feed [J]. Feed Ind., 2021, 42(19): 6-17. | |

| 13 | 王刚,王倩,薛忠,等.基于离散元法的椰糠颗粒建模及仿真参数标定[J].热带作物学报, 2021, 42(9): 2704-2710. |

| WANG G, WANG Q, XUE Z, et al.. Modeling and simulation parameters calibration of coconut coir particles based on DEM [J]. Chin. J. Trop. Crops, 2021, 42(9): 2704-2710. | |

| 14 | 张仲君.分散式餐厨垃圾好氧处理技术与设备集成[D]. 北京:北京化工大学, 2021. |

| ZHANG Z J. Decentralized eat hutch garbage aerobic treatment technology and equipment integration [D]. Beijing:Beijing University of Chemical Industry, 2021. | |

| 15 | 潘丽爱,张贵林,石晶,等.餐厨垃圾特性的试验研究[J].粮油加工, 2009(9):154-156. |

| 16 | 田晓红,李光涛,张淑丽.谷物自然休止角测量方法的探究[J].粮食加工, 2010, 35(1): 68-71. |

| TIAN X H, LI G T, ZHANG S L. Determination of angle of repose [J]. Grain Process., 2010, 35(1): 68-71. | |

| 17 | JOHNSON K L, KENDALL K, ROBERTS A D. Surface energy and the contact of elastic solids [J]. Proc. R. Soc. Lond. A, 1971, 324 (158): 301-313. |

| 18 | 贾富国,韩燕龙,刘扬,等.稻谷颗粒物料堆积角模拟预测方法[J].农业工程学报, 2014, 30(11): 254-260. |

| JIA F G, HAN Y L, LIU Y, et al.. Simulation prediction method of repose angle for rice particle materials [J]. Trans. Chin. Soc. Agric. Eng., 2014, 30(11): 254-260. | |

| 19 | 胡国明.颗粒系统的离散元素法分析仿真:离散元素法的工业应用与EDEM软件简介[M]. 武汉:武汉理工大学出版社, 2010:10-31. |

| 20 | UCGUL M, FIELKE J M, SAUNDERS C. Three-dimensional discrete element modelling (DEM) of tillage: Accounting for soil cohesion and adhesion [J]. Biosyst. Eng., 2015, 129(1): 298-306. |

| 21 | 彭才望,许道军,贺喜,等.黑水虻处理的猪粪有机肥离散元仿真模型参数标定[J].农业工程学报, 2020, 36(17): 212-218. |

| PENG C W, XU D J, HE X, et al.. Parameter calibration of discrete element simulation model for pig manure organic fertilizer treated with Hermetia illucen [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(17): 212-218. | |

| 22 | 袁全春,徐丽明,邢洁洁,等.机施有机肥散体颗粒离散元模型参数标定[J].农业工程学报, 2018, 34(18): 21-27. |

| YUAN Q C, XU L M, XING J J, et al.. Parameter calibration of discrete element model of organic fertilizer particles for mechanical fertilization [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34 (18): 21-27. | |

| 23 | 韩伟,王绍宗,张倩,等.基于JKR接触模型的微米级颗粒离散元参数标定[J].中国粉体技术,2021,27(6):60-69. |

| HAN W, WANG S Z, ZHANG Q, et al.. Discrete element parameter calibration of micron sized powder particles based on JKR contact model [J]. China Powder Sci. Technol., 2021,27(6):60-69. | |

| 24 | 廖宜涛,王在腾,廖庆喜,等.果荚初期饲料油菜茎秆离散元接触模型参数标定[J].农业机械学报, 2020, 51(): 236-243. |

| LIAO Y T, WANG Z T, LIAO Q X, et al.. Calibration of discrete element model parameters of forage rape stalk at early pod stage [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(S1): 236-243. | |

| 25 | 邢洁洁,张锐,吴鹏,等.海南热区砖红壤颗粒离散元仿真模型参数标定[J].农业工程学报, 2020, 36(5): 158-166. |

| XING J J, ZHANG R, WU P, et al.. Parameter calibration of discrete element simulation model for latosol particles in hot areas of hainan province [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(5): 158-166. | |

| 26 | 武涛,黄伟凤,陈学深,等.考虑颗粒间黏结力的黏性土壤离散元模型参数标定[J].华南农业大学学报, 2017, 38(3): 93-98. |

| WU T, HUANG W F, CHEN X S, et al.. Calibration of discrete element model parameters for cohesive soil considering the cohesion between particles [J]. J. South China Agric. Univ., 2017, 38(3): 93-98. | |

| 27 | 韩燕龙,贾富国,唐玉荣,等.颗粒滚动摩擦系数对堆积特性的影响[J].物理学报, 2014, 63(17): 173-179. |

| HAN Y L, JIA F G, TANG Y R, et al.. Influence of granular coefficient of rolling friction on accumulation characteristics [J]. Acta Physica Sin., 2014, 63(17): 173-179. | |

| 28 | 吴爱祥,古德生,戴兴国.含水量对散体流动性的影响[J].中南矿冶学院学报, 1994,25(4): 455-459. |

| WU A X, GU D S, DAI X G. The influence of water content on the flow property of bulk solid [J]. J. Central South Univ., 1994,25(4): 455-459. |

| [1] | 王洪波, 樊志鹏, 乌兰图雅, 王春光, 马哲. 揉碎玉米秸秆螺旋输送仿真离散元模型参数标定[J]. 中国农业科技导报, 2023, 25(3): 96-106. |

| [2] | 宋世圣, 孙松林, 方芹, 彭才望, 周婷, 朱海英. 黑水虻生物转化餐厨垃圾有机肥离散元模型参数标定[J]. 中国农业科技导报, 2022, 24(6): 123-132. |

| [3] | 杨贵川, 张富贵, 郑乐, 王震, 孔曼曼, 章鑫鹏. 半夏块茎物理特性研究及离散元仿真参数标定[J]. 中国农业科技导报, 2022, 24(10): 99-108. |

| [4] | 尹靖凯, 龚小燕, 孙丽娜, 韩梦琦, 杨渊, 徐晓燕, 王小波. 黑水虻对餐厨垃圾养分转化研究[J]. 中国农业科技导报, 2021, 23(6): 154-159. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号