中国农业科技导报 ›› 2024, Vol. 26 ›› Issue (9): 93-104.DOI: 10.13304/j.nykjdb.2024.0150

高阳1( ), 李粤1,2(

), 李粤1,2( ), 位士全1, 黄椿1, 吴紫晗1, 魏晨辉1, 黄麒润1

), 位士全1, 黄椿1, 吴紫晗1, 魏晨辉1, 黄麒润1

收稿日期:2024-03-01

接受日期:2024-03-30

出版日期:2024-09-15

发布日期:2024-09-13

通讯作者:

李粤

作者简介:高阳 E-mail:gaoyang230910@163.com;

基金资助:

Yang GAO1( ), Yue LI1,2(

), Yue LI1,2( ), Shiquan WEI1, Chun HUANG1, Zihan WU1, Chenhui WEI1, Qirun HUANG1

), Shiquan WEI1, Chun HUANG1, Zihan WU1, Chenhui WEI1, Qirun HUANG1

Received:2024-03-01

Accepted:2024-03-30

Online:2024-09-15

Published:2024-09-13

Contact:

Yue LI

摘要:

针对目前香蕉秸秆粉碎效果不佳、能耗高、粉碎后秸秆腐化速度慢及腐熟程度低等问题,设计一款具有腐熟剂喷施装置的香蕉秸秆粉碎还田机。设计了直式异形甩刀,刀辊的排列方式为对称单螺旋排列,粉碎刀轴转速范围为1 500~1 860 r·min-1,喷施装置选用容积为180 L的药箱和喷射角为90°的扇形喷头,单喷头流量为0.8 L·min-1,4个喷头分别间隔370 mm固定于药杆。以机器前进速度和刀辊转速为自变量,以秸秆粉碎合格率和抛撒不均匀度为应变量进行二因素三水平的田间试验和进行对比试验。试验结果表明,机器前进速度为1.4 m·s-1,刀辊转速为1 860 r·min-1,此时香蕉秸秆粉碎合格率为93.08%,抛撒不均匀度为12.11%。实现了香蕉秸秆粉碎与腐熟的联合作业,相较于前代机具,不仅提升了秸秆的粉碎效果,还促进了秸秆有机质的分解,为后续香蕉秸秆腐熟还田机的研究提供技术参考。

中图分类号:

高阳, 李粤, 位士全, 黄椿, 吴紫晗, 魏晨辉, 黄麒润. 具有腐熟剂喷施装置的香蕉秸秆粉碎还田机的设计与试验[J]. 中国农业科技导报, 2024, 26(9): 93-104.

Yang GAO, Yue LI, Shiquan WEI, Chun HUANG, Zihan WU, Chenhui WEI, Qirun HUANG. Design and Experiment of a Banana Straw Crushing and Returning Machine with Rotting Agent Spraying Device[J]. Journal of Agricultural Science and Technology, 2024, 26(9): 93-104.

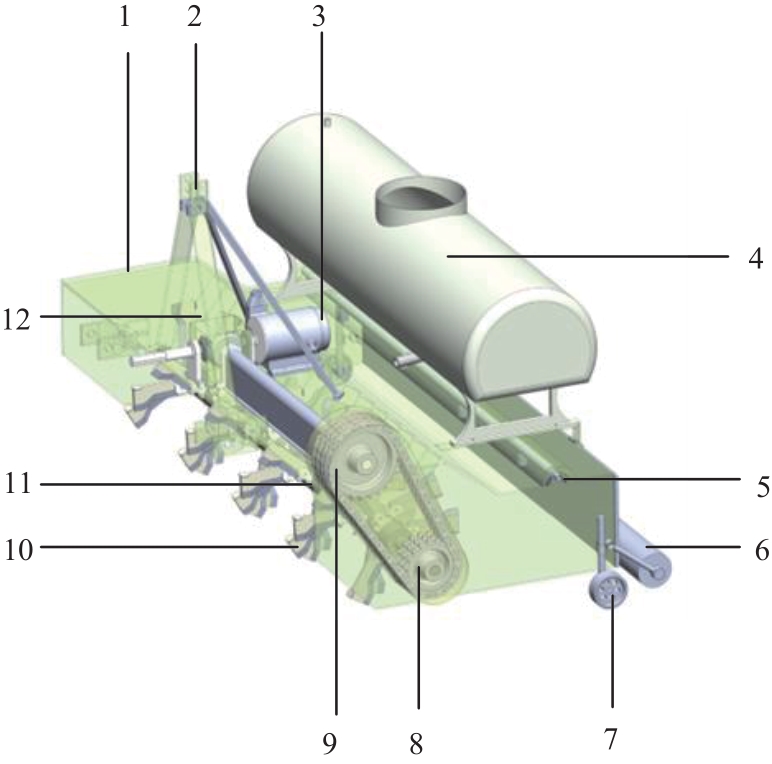

图1 整机结构注:1—机壳;2—悬挂装置;3—吸药泵;4—药箱;5—药杆固定槽;6—镇压辊;7—限深轮;8—从动链轮;9—主动链轮;10—粉碎甩刀;11—刀辊;12—定刀。

Fig. 1 Structure of the machineNote:1—Casing; 2—Suspension device; 3—Suction pump; 4—Medicine box; 5—Medicine pole fixed groove; 6—Suppression roller; 7—Depth limiting wheel; 8—Driven sprocket; 9—Active sprocket; 10—Crushing dump knife; 11—Knife roller; 12—Fixed knife.

| 参数 Parameter | 值 Value |

|---|---|

| 外形尺寸 Overall dimension/mm | 1 700×900×700 |

| 连接方式 Connection method | 三点悬挂 Three-point suspension |

| 整机质量 Overall quality of the machine/kg | 500 |

| 配套动力 Auxiliary power/kW | 60~100 |

| 作业幅宽 Working width/mm | 1 500 |

| 粉碎装置传动方式 Pulverizer drive type | 链传动 Chain drive |

| 甩刀数量 Number of dump knives | 48 |

| 定刀数量 Number of fixed knives | 17 |

| 刀辊转速 Knife roller speed/(r·min-1) | 1 500~1 900 |

| 喷头间距 Nozzle spacing/mm | 400 |

| 喷头偏转角度 Printhead deflection angle/(°) | 30~45 |

表1 主要技术参数

Table 1 Main technical parameters

| 参数 Parameter | 值 Value |

|---|---|

| 外形尺寸 Overall dimension/mm | 1 700×900×700 |

| 连接方式 Connection method | 三点悬挂 Three-point suspension |

| 整机质量 Overall quality of the machine/kg | 500 |

| 配套动力 Auxiliary power/kW | 60~100 |

| 作业幅宽 Working width/mm | 1 500 |

| 粉碎装置传动方式 Pulverizer drive type | 链传动 Chain drive |

| 甩刀数量 Number of dump knives | 48 |

| 定刀数量 Number of fixed knives | 17 |

| 刀辊转速 Knife roller speed/(r·min-1) | 1 500~1 900 |

| 喷头间距 Nozzle spacing/mm | 400 |

| 喷头偏转角度 Printhead deflection angle/(°) | 30~45 |

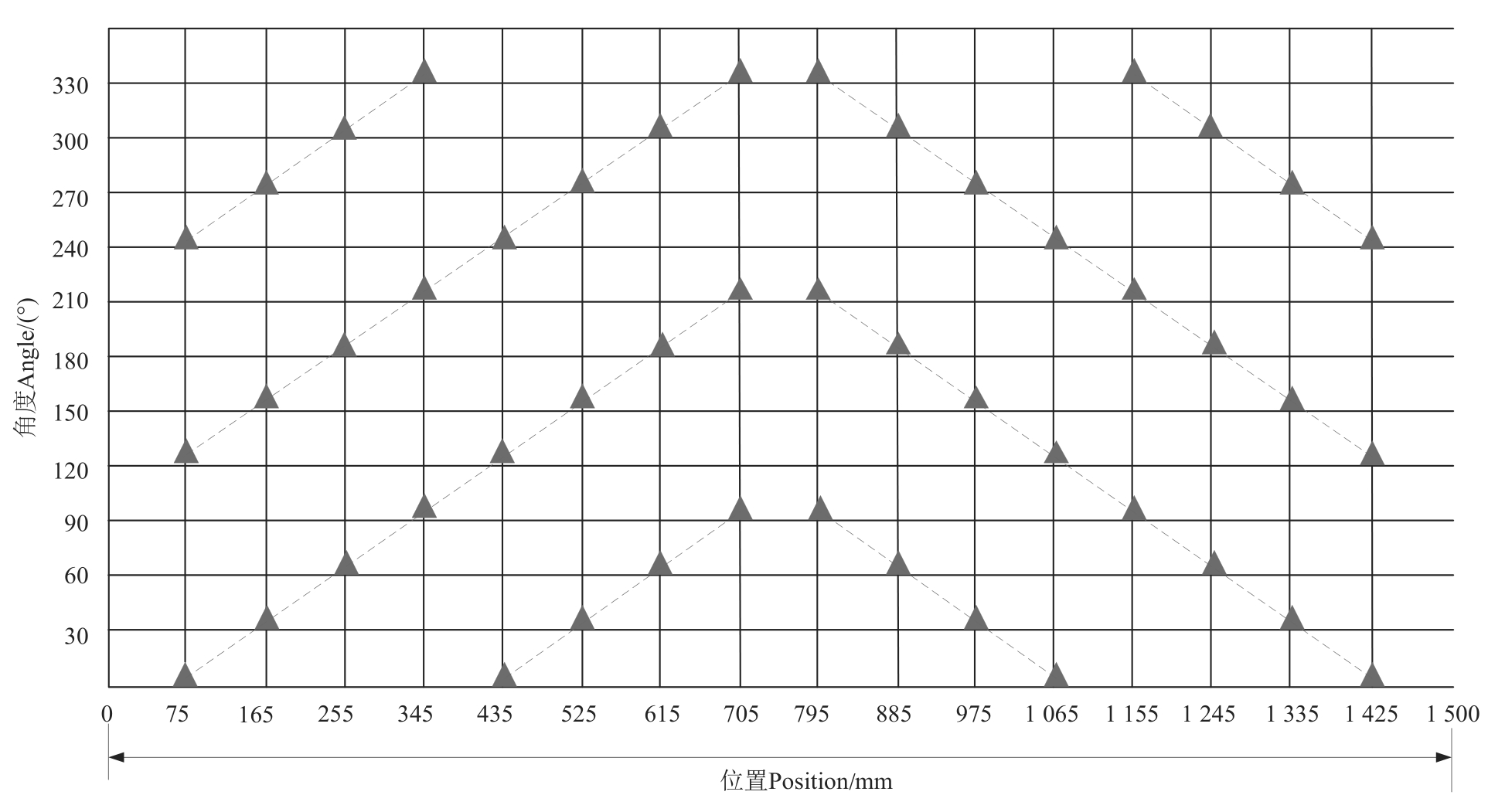

图6 甩刀在刀辊上的分布注:三角形位置表示甩刀在刀辊上的位置。

Fig. 6 Distribution of dump knives on the knife rollerNote: Triangle position indicates the position of the dump knife on the knife roller.

试验序号 Test No. | A:机器前进速度 Machine forward speed/(m·s-1) | B:粉碎刀辊转速 Crushing knife roller speed/(r·min-1) | Q:秸秆粉碎合格率 Straw crushing pass rate/% | Fb:抛撒不均匀度 Unevenness of spreading/% |

|---|---|---|---|---|

| 1 | 1.1 | 1 500 | 85.87 | 19.32 |

| 2 | 1.1 | 1 680 | 90.57 | 18.70 |

| 3 | 1.1 | 1 860 | 93.78 | 14.65 |

| 4 | 1.4 | 1 500 | 89.07 | 17.31 |

| 5 | 1.4 | 1 680 | 90.91 | 15.83 |

| 6 | 1.4 | 1 860 | 93.08 | 12.11 |

| 7 | 1.7 | 1 500 | 84.45 | 16.53 |

| 8 | 1.7 | 1 680 | 88.70 | 17.69 |

| 9 | 1.7 | 1 860 | 89.98 | 15.28 |

表2 田间试验方案和结果

Table 2 Field test scheme and results

试验序号 Test No. | A:机器前进速度 Machine forward speed/(m·s-1) | B:粉碎刀辊转速 Crushing knife roller speed/(r·min-1) | Q:秸秆粉碎合格率 Straw crushing pass rate/% | Fb:抛撒不均匀度 Unevenness of spreading/% |

|---|---|---|---|---|

| 1 | 1.1 | 1 500 | 85.87 | 19.32 |

| 2 | 1.1 | 1 680 | 90.57 | 18.70 |

| 3 | 1.1 | 1 860 | 93.78 | 14.65 |

| 4 | 1.4 | 1 500 | 89.07 | 17.31 |

| 5 | 1.4 | 1 680 | 90.91 | 15.83 |

| 6 | 1.4 | 1 860 | 93.08 | 12.11 |

| 7 | 1.7 | 1 500 | 84.45 | 16.53 |

| 8 | 1.7 | 1 680 | 88.70 | 17.69 |

| 9 | 1.7 | 1 860 | 89.98 | 15.28 |

指标 Index | 方差来源 Sources of variance | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| Q | A | 17.438 | 2 | 8.719 | 7.30 | 0.046 |

| B | 51.698 | 2 | 25.849 | 21.65 | 0.007 | |

| 误差 Pure error | 4.775 | 4 | 1.194 | |||

| Fb | A | 9.241 | 2 | 4.620 | 3.87 | 0.116 |

| B | 25.352 | 2 | 12.676 | 10.62 | 0.025 | |

| 误差 Pure error | 4.775 | 4 | 1.194 |

表3 方差分析

Table 3 Variance analysis

指标 Index | 方差来源 Sources of variance | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| Q | A | 17.438 | 2 | 8.719 | 7.30 | 0.046 |

| B | 51.698 | 2 | 25.849 | 21.65 | 0.007 | |

| 误差 Pure error | 4.775 | 4 | 1.194 | |||

| Fb | A | 9.241 | 2 | 4.620 | 3.87 | 0.116 |

| B | 25.352 | 2 | 12.676 | 10.62 | 0.025 | |

| 误差 Pure error | 4.775 | 4 | 1.194 |

处理方法 Treatment | 处理时间Treatment time/d | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 | |

粉碎并施用腐熟剂 Crushing and application of humus | 绿Green | 微黄Slightly yellow | 黄 Yellow | 黄 Yellow | 黄Yellow | 黄褐Ocher | 褐Brown | 褐Brown | 黑Black | 黑Black | 黑Black |

直接粉碎 Direct Crush | 绿Green | 绿 Green | 微黄Slightly yellow | 微黄Slightly yellow | 黄Yellow | 黄Yellow | 黄褐Ocher | 黄褐Ocher | 褐Brown | 褐Brown | 黑Black |

表4 还田后秸秆的颜色变化

Table 4 Color change of straw after returning to the field

处理方法 Treatment | 处理时间Treatment time/d | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 | |

粉碎并施用腐熟剂 Crushing and application of humus | 绿Green | 微黄Slightly yellow | 黄 Yellow | 黄 Yellow | 黄Yellow | 黄褐Ocher | 褐Brown | 褐Brown | 黑Black | 黑Black | 黑Black |

直接粉碎 Direct Crush | 绿Green | 绿 Green | 微黄Slightly yellow | 微黄Slightly yellow | 黄Yellow | 黄Yellow | 黄褐Ocher | 黄褐Ocher | 褐Brown | 褐Brown | 黑Black |

| 处理方法Treatment | 处理时间Treatment time/d | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 | |

粉碎并施用腐熟剂 Crushing and application of humus | 硬Hard | 微硬Slightly hard | 微硬Slightly hard | 微软Slightly soft | 微软Slightly soft | 软 Soft | 软烂Soft and rotten | 软烂Soft and rotten | 腐烂Putrefaction | 腐烂Putrefaction | 腐烂Putrefaction |

直接粉碎 Direct crushing | 硬Hard | 硬 Hard | 硬 Hard | 微硬Slightly hard | 微软Slightly soft | 微软Slightly soft | 软 Soft | 软 Soft | 软烂 Soft and rotten | 软烂 Soft and rotten | 腐烂Putrefaction |

表5 还田后秸秆的软化

Table 5 Softening of straw after returning to the field

| 处理方法Treatment | 处理时间Treatment time/d | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 12 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 | |

粉碎并施用腐熟剂 Crushing and application of humus | 硬Hard | 微硬Slightly hard | 微硬Slightly hard | 微软Slightly soft | 微软Slightly soft | 软 Soft | 软烂Soft and rotten | 软烂Soft and rotten | 腐烂Putrefaction | 腐烂Putrefaction | 腐烂Putrefaction |

直接粉碎 Direct crushing | 硬Hard | 硬 Hard | 硬 Hard | 微硬Slightly hard | 微软Slightly soft | 微软Slightly soft | 软 Soft | 软 Soft | 软烂 Soft and rotten | 软烂 Soft and rotten | 腐烂Putrefaction |

| 1 | 邹冬梅,范琼.世界香蕉生产、贸易现状与产业展望[J].广东农业科学, 2022, 49(7):131-140. |

| ZOU D M, FAN Q. Present situation of globle banana production and trade and prospect for banana industry [J]. Guangdong Agric. Sci., 2022,49(7):131-140. | |

| 2 | 王全永,欧燕芳.我国香蕉产业标准化现状和对策[J].中国标准化, 2021(3):147-152. |

| WANG Q Y, OU Y F. Present situation and countermeasures of banana industry standardization in China [J]. China Standard., 2021(3):147-152. | |

| 3 | 张喜瑞,胡旭航,刘俊孝,等.香蕉秸秆离散元仿真粘结模型参数标定与试验[J].农业机械学报, 2023,54(5):121-130. |

| ZANG X R, HU X H, LIU J X, et al.. Calibration and verification of bonding parameters of banana straw simulation model based on discrete element method [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(5):121-130. | |

| 4 | 李双,梁栋,张喜瑞,等.香蕉茎秆纤维提取刀片的改进设计[J].食品与机械, 2019,35(1):130-135. |

| LI S, LIANG D, ZHANG X R, et al.. Improved design of banana stalk fiber extraction blade [J]. Food Mach., 2019,35(1):130-135. | |

| 5 | 陈玉凤,王明林.秸秆还田机械化生产的优势及作业注意事项[J].农机使用与维修, 2022(11):110-112. |

| CHEN Y F, WANG M L. Advantages of mechanized production of straw returning and operation precautions [J]. Agric. Mach. Using Maintenance, 2022(11):110-112. | |

| 6 | 孙鹏,刘满意,王蓓蓓.香蕉秸秆不同还田模式对土壤微生物群落的影响[J].热带生物学报, 2021,12(1):57-62. |

| SUN P, LIU M Y, WANG B B. Effects of fresh harvested banana foliage on the soil microbial community structures [J]. J. Trop. Biol., 2021,12(1):57-62. | |

| 7 | 吴学尚,李粤,张喜瑞,等.甩刀式立式香蕉秸秆粉碎机的设计[J].农机化研究, 2014,36(4):83-86. |

| WU X S, LI Y, ZHANG X R, et al.. The design of the vertical flail banana stalk crushing machine [J]. J. Agric. Mech. Res., 2014,36(4):83-86. | |

| 8 | 李志强,李粤,贺宁波,等.纵向双辊式香蕉秸秆粉碎还田机的设计与试验[J].中国农机化学报, 2020,41(3):180-184. |

| LI Z Q, LI Y, HE N B, et al.. Design and test of longitudinal double roller banana straw crushing and returning machine [J]. J. Chin. Agric. Mech., 2020,41(3):180-184. | |

| 9 | 裴培,李佳新,邓晓玉,等.生物质香蕉秸秆应用于包装材料开发的潜力探究[J].绿色包装, 2021(12):21-26. |

| PEI P, LI J X, DENG X Y, et al.. Research on the Potential of banana straw biomass on the development of packaging materials [J]. Green Packaging, 2021(12):21-26. | |

| 10 | 刘国欢,邝继云,李超,等.香蕉秸秆资源化利用的研究进展[J].可再生能源, 2012,30(5):64-68. |

| LIU G H, KUANG J Y, LI C, et al.. Research progress on utilization of banana stalk waste [J]. Renew. Energy Resour.,2012,30(5):64-68. | |

| 11 | 郭超凡,李粤,姚德宇,等.仿生香蕉秸秆粉碎装置关键部件作业参数优化与试验[J].中国农机化学报, 2022,43(1):93-100. |

| GUO C F, LI Y, YAO D Y, et al.. Optimization and experiment of operating parameters of key components of bionic banana straw crushing devices [J]. J. Chin. Agric. Mechan., 2022,43(1):93-100. | |

| 12 | 赵灿,杨帆,汝绍锋,等.覆土式秸秆粉碎还田机的设计与分析[J].海南大学学报(自然科学版), 2021,39(2):185-191. |

| ZHAO C, YANG F, RU S F, et al.. Design and analysis of soil-covered straw grinder [J]. J. Hainan Univ. ( Nat. Sci.), 2021,39(2):185-191. | |

| 13 | 胡双燕,胡敏娟.可降解穴盘切割刀具优化设计与有限元分析[J].中国农机化学报, 2021,42(9):44-52. |

| HU S Y, HU M J. Optimized design and finite element analysis of cutting tools for degradable cavity trays [J]. J. Chin. Agric. Mechan., 2021,42(9):44-52. | |

| 14 | 宋雅婷. 1XHJ-1600型卧式香蕉假茎粉碎还田机关键部件的优化设计与试验研究[D].海口:海南大学, 2016. |

| SONG Y T. Design and optimization of key components & test of horizontal banana straw crushing machine [D]. Haikou: Hainan University, 2016. | |

| 15 | 王毅超.二次抛送式棉秸秆粉碎还田机设计与试验[D].乌鲁木齐:新疆农业大学, 2020. |

| WANG Y C. Design and test of secondary feeding type cotton straw crushing and returning machine [D]. Urumqi: Xinjiang Agricultural University, 2020. | |

| 16 | 郑智旗,何进,李洪文,等.动定刀支撑滑切式秸秆粉碎装置设计与试验[J].农业机械学报, 2016,47(S1):108-116. |

| ZHENG Z Q, HE J, LI H W, et al.. Design and experiment of straw-chopping device with chopping and fixed knife supported slide cutting [J]. Trans. Chin. Soc. Agric. Mach., 2016,47(S1):108-116. | |

| 17 | 姬江涛,李庆军,蔡苇.刀具布置对茎秆切碎还田机振动的影响分析[J].农机化研究, 2003(4):63-64. |

| JI J T, LI Q J, CAI W. Influence analysis of cutter arrangement on the vibration of field straw chopper [J]. J. Agric. Mech. Res., 2003(4):63-64. | |

| 18 | 陈园胜.液体腐熟剂变量喷施装置的设计与研究[D].武汉:湖北工业大学,2017. |

| CHEN Y S. Design and research on variable spraying device of liquid putrefactive [D]. Wuhan:Hubei University of Technology, 2017. | |

| 19 | 杨兆文,陈培敏,刘茂玉,等. 保护性耕作机械第6部分:秸秆粉碎还田机: [S].北京:中国标准出版社,2021. |

| 20 | 郝文录,刘恒新,朱良,等. 农业机械试验条件 测定方法的一般规定: [S]. 北京:中国标准出版社,2008. |

| 21 | 王自强,李粤,张喜瑞,等.沟齿式香蕉假茎粉碎还田机设计与试验[J].农机化研究, 2018,40(12):55-59. |

| WANG Z Q, LI Y, ZHANG X R, et al.. Design and experiment on banana stalks disintegrator with double shafts [J]. J. Agric. Mech. Res., 2018,40(12):55-59. | |

| 22 | 赵昌胜.高速工具钢在模具制造中的应用及热处理[J].模具制造, 2011,11(11):88-90. |

| ZHAO C S. Application and heat treatment of high-speed tool steel in die & mold manufacture [J]. Die Mould Manufacture, 2011,11(11):88-90. | |

| 23 | 张喜瑞,王自强,李粤,等.滑切防缠式香蕉秸秆还田机设计与试验[J].农业工程学报, 2018,34(3):26-34. |

| ZHANG X R, WANG Z Q, LI Y, et al.. Design and experiment of sliding-cutting and anti-twining returning device for banana straw [J]. Trans. Chin. Soc. Agric. Eng., 2018,34(3):26-34. | |

| 24 | 戴飞,张锋伟,赵春花,等.快速腐熟秸秆还田机设计与试验[J].农业机械学报, 2010,41(4):47-51. |

| DAI F, ZHANG F W, ZHAO C H, et al.. Design and experiment on straw returning machine with fast decomposing inoculant spray equipment [J]. Trans. Chin. Soc. Agric. Mach., 2010,41(4):47-51. |

| [1] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [2] | 潘梦诗, 郭文阳, 周留柱, 邓丽, 苗建利, 徐宏光, 张宗源, 亓兰达. 贝莱斯芽孢杆菌菌剂对花生白绢病的田间防效及作用机理研究[J]. 中国农业科技导报, 2022, 24(11): 130-136. |

| [3] | 张凤奎, 张宏, 兰海鹏, 于福锋, 李忠杰, 李平. 基于CFD-EDM耦合的气吸式红枣捡拾机气力输送装置仿真分析[J]. 中国农业科技导报, 2021, 23(7): 107-116. |

| [4] | 何远灵1,邢泽炳1,2*,侯华铭1,吴晓东1. 智能化农业机械装备的发展现状及展望(英文)[J]. 中国农业科技导报, 2019, 21(6): 8-19. |

| [5] | 刘东,肖宏儒*,金月,杨光. 基于ANSYS的鸡毛菜茎秆切割的有限元分析及验证试验[J]. 中国农业科技导报, 2018, 20(11): 85-93. |

| [6] | 葛宜元1,王金武2*,李亚芹1,魏天路1. 水稻高秆翻埋快腐还田机研究[J]. , 2014, 16(6): 81-88. |

| [7] | 黄永宝1,纪延光2*. 基于因子分析的我国农业机械发展分析研究[J]. , 2014, 16(4): 95-101. |

| [8] | 李桂兰. 俄罗斯农业科技发展动态[J]. , 2002, 4(5): 70-73. |

| [9] | . 深化改革促进转制|持续创新抢占先机[J]. , 2001, 3(2): 63-65. |

| [10] | 原国家科委. 产前领域[J]. , 2000, 2(2): 9-14. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号