中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (3): 95-103.DOI: 10.13304/j.nykjdb.2023.0662

钟国良1( ), 万霖1(

), 万霖1( ), 车刚1, 唐浩2, 曲天奇1, 张骐麟1

), 车刚1, 唐浩2, 曲天奇1, 张骐麟1

收稿日期:2023-09-04

接受日期:2023-11-16

出版日期:2025-03-15

发布日期:2025-03-14

通讯作者:

万霖

作者简介:钟国良 E-mail:1076866915@qq.com;

基金资助:

Guoliang ZHONG1( ), Lin WAN1(

), Lin WAN1( ), Gang CHE1, Hao TANG2, Tianqi QU1, Qilin ZHANG1

), Gang CHE1, Hao TANG2, Tianqi QU1, Qilin ZHANG1

Received:2023-09-04

Accepted:2023-11-16

Online:2025-03-15

Published:2025-03-14

Contact:

Lin WAN

摘要:

针对稻谷热风干燥过程中能量消耗高、干燥效率低的问题,以‘稻花香’稻谷为研究对象,测定各初始含水率下的稻谷在不同干燥参数下的干燥能耗和干燥效率,确定不同参数水平下的最优方案。多因素正交试验研究表明,对稻谷干燥速率的影响从强到弱为热风温度、热风风速、初始含水率。对单位干燥能耗的影响从强到弱为:热风温度、初始含水率、热风风速。最优的干燥参数为热风温度50 ℃、热风风速0.7 m·s-1、初始含水率19%、干燥速率为5.28%·h-1、干燥能耗为5 565.03 kJ·kg-1。因此,优化干燥流程和干燥参数,既能提升干燥速率又可减少干燥能耗。

中图分类号:

钟国良, 万霖, 车刚, 唐浩, 曲天奇, 张骐麟. 干燥参数对稻谷热风干燥速率及能耗的影响[J]. 中国农业科技导报, 2025, 27(3): 95-103.

Guoliang ZHONG, Lin WAN, Gang CHE, Hao TANG, Tianqi QU, Qilin ZHANG. Influence of Drying Parameters on Hot Air Drying Rate and Energy Consumption of Rice[J]. Journal of Agricultural Science and Technology, 2025, 27(3): 95-103.

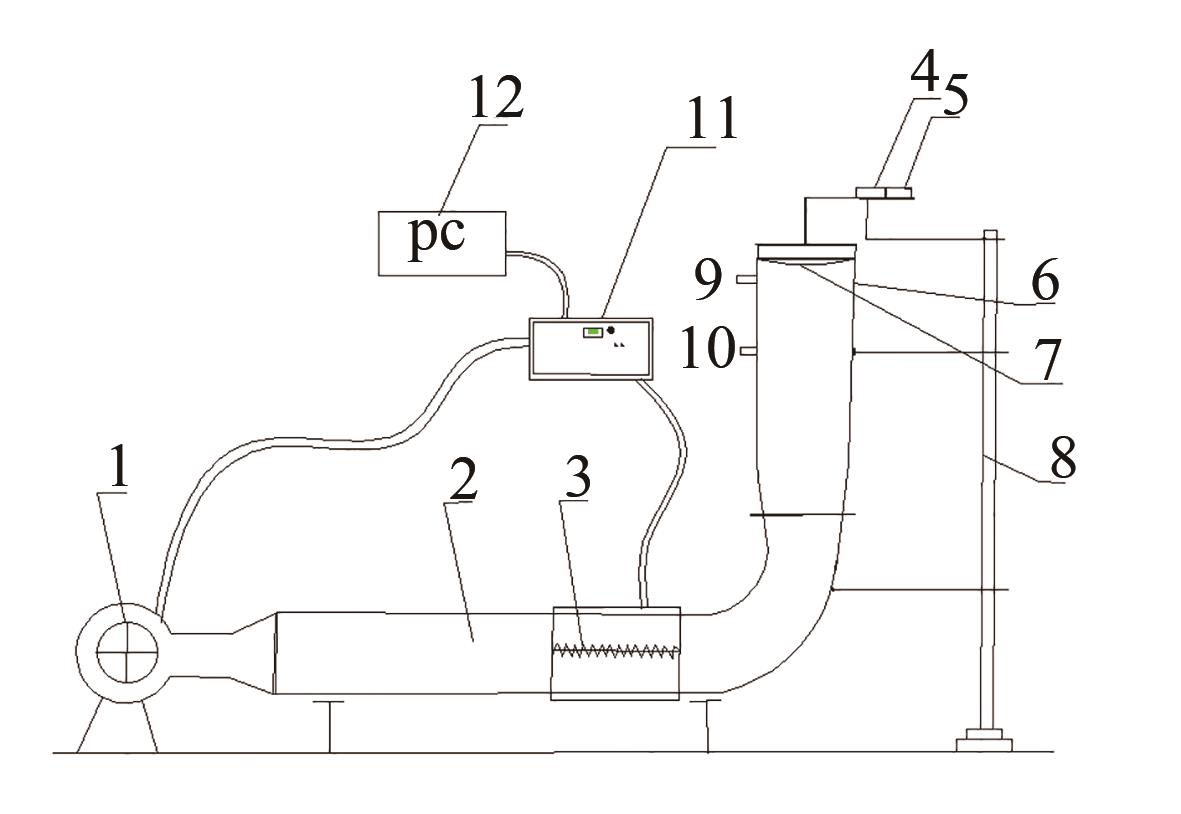

图1 GHS-Ⅱ型薄层干燥试验台结构注:1—风机;2—风道;3—加热器;4—温度显示器;5—质量天平;6—干燥筒;7—干燥盘;8—支架;9—风速传感器;10—温度传感器;11—控制柜;12—数据采集系统。

Fig. 1 Structure of GHS-Ⅱ thin layer drying test benchNote: 1—Fan;2—Air duct; 3—Heater; 4—Temperature display; 5—Mass balance; 6—Drying cylinder; 7—Drying tray; 8—Support; 9—Wind speed sensor; 10—Temperature sensor; 11—Control cabinet; 12—Data collection system.

序号 Serial number | 水平 Level | X1:热风温度 Wind temperature/℃ | X2:风速 Wind speed/(m·s-1) | X3:初始含水率 Initial water content/% |

|---|---|---|---|---|

| +γ | +1.682 | 50 | 0.8 | 23 |

| 1 | +1 | 48 | 0.7 | 22 |

| 0 | 0 | 45 | 0.5 | 21 |

| -1 | -1 | 42 | 0.3 | 20 |

| -γ | -1.682 | 40 | 0.2 | 19 |

表1 三元二次回归正交试验因素编码

Table 1 Encoding of factors in ternary quadratic regression orthogonal experiment

序号 Serial number | 水平 Level | X1:热风温度 Wind temperature/℃ | X2:风速 Wind speed/(m·s-1) | X3:初始含水率 Initial water content/% |

|---|---|---|---|---|

| +γ | +1.682 | 50 | 0.8 | 23 |

| 1 | +1 | 48 | 0.7 | 22 |

| 0 | 0 | 45 | 0.5 | 21 |

| -1 | -1 | 42 | 0.3 | 20 |

| -γ | -1.682 | 40 | 0.2 | 19 |

编号 Number | X1:热风温度 Wind temperature/℃ | X2:风速 Wind speed/(m·s-1) | X3:初始含水率 Initial water content/% | Y1 干燥速率 Drying rate/(%·h-1) | Y2 单位干燥能耗 Unit drying energy consumption/(kJ·kg-1) |

|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 4.536 | 7 833.33 |

| 2 | 1 | 1 | -1 | 5.184 | 7 472.22 |

| 3 | 1 | -1 | 1 | 3.552 | 8 027.78 |

| 4 | 1 | -1 | -1 | 4.056 | 7 020 |

| 5 | -1 | 1 | 1 | 3.648 | 6 111.11 |

| 6 | -1 | 1 | -1 | 4.32 | 6 027.78 |

| 7 | -1 | -1 | 1 | 3.144 | 6 166.67 |

| 8 | -1 | -1 | -1 | 3.24 | 5 888.89 |

| 9 | γ | 0 | 0 | 5.28 | 6 972.22 |

| 10 | -γ | 0 | 0 | 3.31 | 6 750 |

| 11 | 0 | γ | 0 | 4.56 | 6 527.78 |

| 12 | 0 | -γ | 0 | 3.67 | 7 527.78 |

| 13 | 0 | 0 | γ | 4.652 | 6 844.44 |

| 14 | 0 | 0 | -γ | 4.032 | 5 394.44 |

| 15 | 0 | 0 | 0 | 4.94 | 6 972.22 |

| 16 | 0 | 0 | 0 | 4.344 | 7 000 |

| 17 | 0 | 0 | 0 | 4.44 | 7 966.67 |

| 18 | 0 | 0 | 0 | 4.56 | 6 944.44 |

| 19 | 0 | 0 | 0 | 4.28 | 7 138.89 |

| 20 | 0 | 0 | 0 | 4.416 | 6 972.22 |

| 21 | 0 | 0 | 0 | 4.9 | 7 138.89 |

| 22 | 0 | 0 | 0 | 4.248 | 7 427.78 |

| 23 | 0 | 0 | 0 | 4.052 | 6 772.22 |

表2 二次回归正交旋转组合试验及结果

Table 2 Quadratic regression orthogonal rotation combination experiment and results

编号 Number | X1:热风温度 Wind temperature/℃ | X2:风速 Wind speed/(m·s-1) | X3:初始含水率 Initial water content/% | Y1 干燥速率 Drying rate/(%·h-1) | Y2 单位干燥能耗 Unit drying energy consumption/(kJ·kg-1) |

|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 4.536 | 7 833.33 |

| 2 | 1 | 1 | -1 | 5.184 | 7 472.22 |

| 3 | 1 | -1 | 1 | 3.552 | 8 027.78 |

| 4 | 1 | -1 | -1 | 4.056 | 7 020 |

| 5 | -1 | 1 | 1 | 3.648 | 6 111.11 |

| 6 | -1 | 1 | -1 | 4.32 | 6 027.78 |

| 7 | -1 | -1 | 1 | 3.144 | 6 166.67 |

| 8 | -1 | -1 | -1 | 3.24 | 5 888.89 |

| 9 | γ | 0 | 0 | 5.28 | 6 972.22 |

| 10 | -γ | 0 | 0 | 3.31 | 6 750 |

| 11 | 0 | γ | 0 | 4.56 | 6 527.78 |

| 12 | 0 | -γ | 0 | 3.67 | 7 527.78 |

| 13 | 0 | 0 | γ | 4.652 | 6 844.44 |

| 14 | 0 | 0 | -γ | 4.032 | 5 394.44 |

| 15 | 0 | 0 | 0 | 4.94 | 6 972.22 |

| 16 | 0 | 0 | 0 | 4.344 | 7 000 |

| 17 | 0 | 0 | 0 | 4.44 | 7 966.67 |

| 18 | 0 | 0 | 0 | 4.56 | 6 944.44 |

| 19 | 0 | 0 | 0 | 4.28 | 7 138.89 |

| 20 | 0 | 0 | 0 | 4.416 | 6 972.22 |

| 21 | 0 | 0 | 0 | 4.9 | 7 138.89 |

| 22 | 0 | 0 | 0 | 4.248 | 7 427.78 |

| 23 | 0 | 0 | 0 | 4.052 | 6 772.22 |

参数 Parameter | 系数 Coefficient | F值 F value | P值 P value |

|---|---|---|---|

| 模型Model | 5.940 0 | 4.660 0 | 0.006 4 |

| X1 | 2.900 0 | 20.460 0 | 0.000 6 |

| X2 | 1.970 0 | 13.950 0 | 0.002 5 |

| X3 | 0.056 4 | 0.398 1 | 0.539 0 |

| X1X2 | 0.034 8 | 0.246 2 | 0.628 1 |

| X1X3 | 0.018 4 | 0.130 2 | 0.724 0 |

| X2X3 | 0.064 8 | 0.457 8 | 0.510 5 |

| X1² | 0.219 3 | 1.550 0 | 0.235 2 |

| X2² | 0.521 3 | 3.680 0 | 0.077 2 |

| X3² | 0.161 7 | 1.140 0 | 0.304 6 |

残差平方和 Sum of squared residuals | 1.150 0 | ||

纯误差平方和 Sum of squares of pure errors | 0.693 4 | ||

| 决定系数R2 | 0.763 4 | ||

| 校正决定系数Adj R2 | 0.599 5 | ||

| 预测决定系数Pre R2 | -0.236 1 | ||

| 变异系数C.V./% | 8.890 0 | ||

表3 干燥速率回归模型系数显著性检验及方差分析

Table 3 Significance test and analysis of variance of drying rate regression model coefficient

参数 Parameter | 系数 Coefficient | F值 F value | P值 P value |

|---|---|---|---|

| 模型Model | 5.940 0 | 4.660 0 | 0.006 4 |

| X1 | 2.900 0 | 20.460 0 | 0.000 6 |

| X2 | 1.970 0 | 13.950 0 | 0.002 5 |

| X3 | 0.056 4 | 0.398 1 | 0.539 0 |

| X1X2 | 0.034 8 | 0.246 2 | 0.628 1 |

| X1X3 | 0.018 4 | 0.130 2 | 0.724 0 |

| X2X3 | 0.064 8 | 0.457 8 | 0.510 5 |

| X1² | 0.219 3 | 1.550 0 | 0.235 2 |

| X2² | 0.521 3 | 3.680 0 | 0.077 2 |

| X3² | 0.161 7 | 1.140 0 | 0.304 6 |

残差平方和 Sum of squared residuals | 1.150 0 | ||

纯误差平方和 Sum of squares of pure errors | 0.693 4 | ||

| 决定系数R2 | 0.763 4 | ||

| 校正决定系数Adj R2 | 0.599 5 | ||

| 预测决定系数Pre R2 | -0.236 1 | ||

| 变异系数C.V./% | 8.890 0 | ||

参数 Parameter | 系数 Coefficient | F值 F value | P值 P value |

|---|---|---|---|

| 模型Model | 6.507×106 | 2.830 0 | 0.043 4 |

| X1 | 3.125×106 | 12.240 0 | 0.003 9 |

| X2 | 1.316×105 | 0.515 5 | 0.485 5 |

| X3 | 1.272×106 | 4.980 0 | 0.043 8 |

| X1X2 | 380 3.66 | 0.014 9 | 0.904 7 |

| X1X3 | 1.270×105 | 0.497 2 | 0.493 2 |

| X2X3 | 884 35.36 | 0.346 4 | 0.566 3 |

| X1² | 662 27.12 | 0.259 4 | 0.619 1 |

| X2² | 504.25 | 0.002 0 | 0.965 2 |

| X3² | 1.697×106 | 6.65 | 0.022 9 |

残差平方和 Sum of squared residuals | 2.304×106 | ||

纯误差平方和 Sum of squares of pure errors | 1.015×106 | ||

| 决定系数R2 | 0.662 2 | ||

| 校正决定系数Adj R2 | 0.428 3 | ||

| 预测决定系数Pre R2 | -0.915 3 | ||

| 变异系数CV/% | 7.310 0 | ||

表4 单位干燥能耗回归模型系数显著性检验及方差分析

Table 4 Significance test and analysis of variance for regression model coefficients of unit drying energy consumption

参数 Parameter | 系数 Coefficient | F值 F value | P值 P value |

|---|---|---|---|

| 模型Model | 6.507×106 | 2.830 0 | 0.043 4 |

| X1 | 3.125×106 | 12.240 0 | 0.003 9 |

| X2 | 1.316×105 | 0.515 5 | 0.485 5 |

| X3 | 1.272×106 | 4.980 0 | 0.043 8 |

| X1X2 | 380 3.66 | 0.014 9 | 0.904 7 |

| X1X3 | 1.270×105 | 0.497 2 | 0.493 2 |

| X2X3 | 884 35.36 | 0.346 4 | 0.566 3 |

| X1² | 662 27.12 | 0.259 4 | 0.619 1 |

| X2² | 504.25 | 0.002 0 | 0.965 2 |

| X3² | 1.697×106 | 6.65 | 0.022 9 |

残差平方和 Sum of squared residuals | 2.304×106 | ||

纯误差平方和 Sum of squares of pure errors | 1.015×106 | ||

| 决定系数R2 | 0.662 2 | ||

| 校正决定系数Adj R2 | 0.428 3 | ||

| 预测决定系数Pre R2 | -0.915 3 | ||

| 变异系数CV/% | 7.310 0 | ||

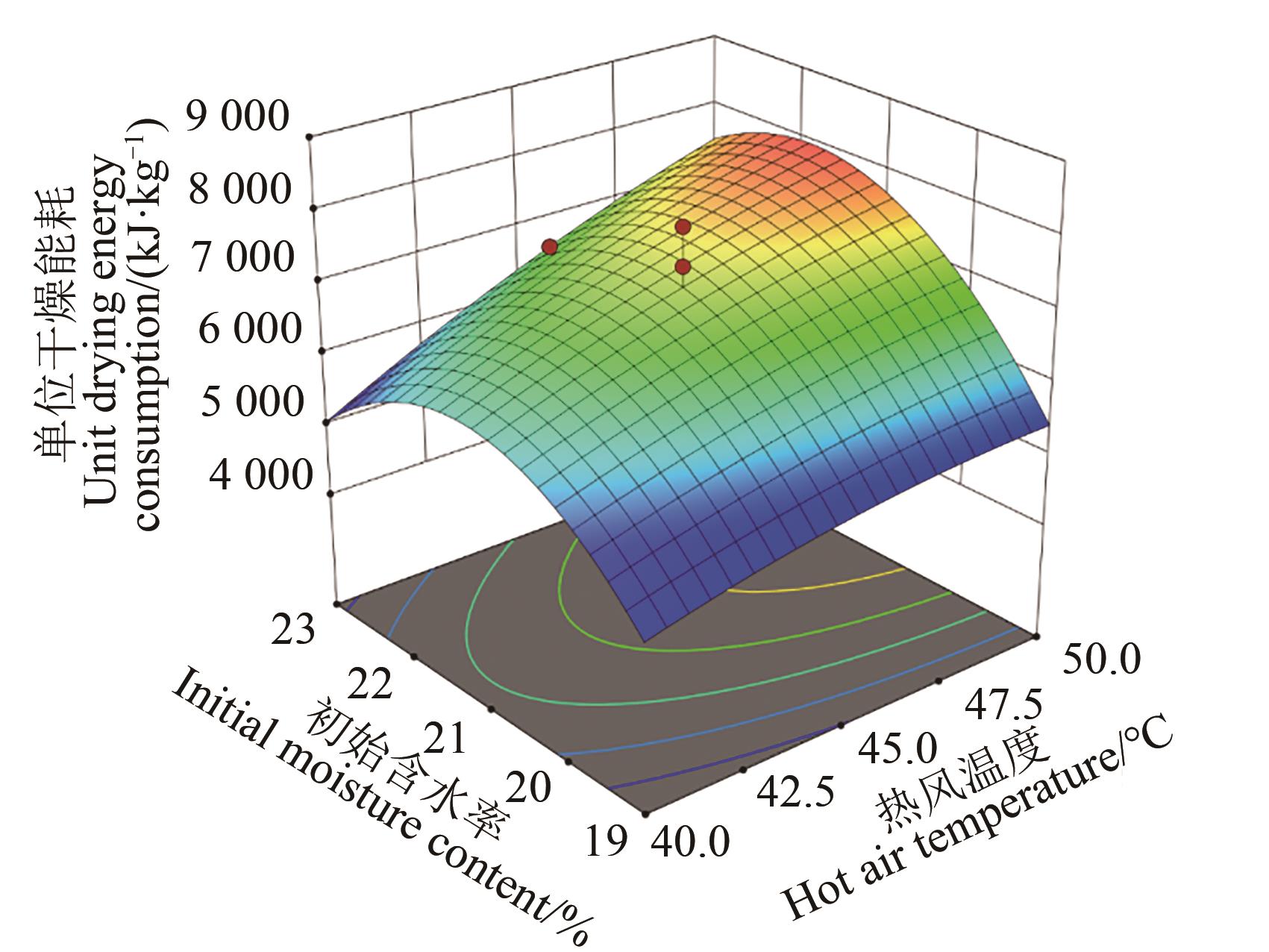

图9 热风温度和初始含水率交互作用对单位干燥能耗的影响

Fig. 9 Effect of the interaction between hot air temperature and initial moisture content on unit drying energy consumption

| 1 | 车刚,高瑞丽,万霖,等.水稻负压混流干燥室结构优化设计与试验[J].农业工程学报,2021,37(4):87-96. |

| CHE G, GAO R L, WAN L, et al.. Optimized design and experimental study on rice negative pressure mixed flow drying chamber [J]. Trans. Chin. Soc. Agric. Eng., 2021,37(4):87-96. | |

| 2 | 周浩天.空气源热泵冷暖两联供系统运行策略研究[D].绵阳:西南科技大学,2022. |

| ZHOU H T. Research on the operation strategy of air source heat pump combined cooling and heating system [D]. Mianyang: Southwest University of Science and Technology, 2022. | |

| 3 | 国务院关于印发“十四五”节能减排综合工作方案的通知[Z]. 中华人民共和国国务院公报, 国发〔2021〕33号. |

| 4 | MUSTAFFAR A, PHAN A, BDDOHOO K. Hybrid heat pipe screw dryer: a novel, continuous and highly energy-efficient drying technology [J]. Chem. Eng Proces, 2018, 128: 199-215. |

| 5 | 陈坤杰,陈青春,张银.中国谷物干燥加工中的能源消耗状况(英文)[J].农业工程学报, 2005, 21(5): 173-177. |

| CHEN K J, CHEN Q C, ZHANG Y. Energy consumption for grain drying in China [J]. Trans. Chin. Soc. Agric. Eng., 2005,21(5):173-177. | |

| 6 | 白桂培.可适用于木材干燥的机械热泵系统的设计及性能分析[D].南京:南京航空航天大学,2017. |

| BAI G P. Design and performance research of mechanical heat pump system for wood drying [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017. | |

| 7 | 张德元. 浅谈干燥设备系统的节能减排[J].化工机械,2009,36(3):195-199. |

| ZHANG D Y. Saving energy and reducing pollutangts in the drying systems [J]. Chem. Engin. Mach., 2009,36(3):195-199. | |

| 8 | RAFAEL P A, MAURI F, GISELE T S. Exergy analysis applied to the design of grain dryers with air flow recirculation [C]// An ASABE Meeting Presentation. St. Joseph, Mich.: ASABE, 2012:12-13. |

| 9 | THOMAS Z, HASAN J, MARCO S. Increasing the energy efficiency of batch-type drying with partial air recirculation [J]. Chemie Ingenieur Technik, 2016, 88(1-2): 208-214. |

| 10 | JOKINIEMI H T, AHOKAS J M. Drying process optimisation in a mixed-flow batch grain dryer [J]. Biosys. Eng., 2014, 124: 209-220. |

| 11 | DEFENDI R O, PARAISO P R, JORGE L M D M. Optimization study of soybean intermittent drying in fixed-bed drying of soybean intermittent drying in fixed-bed drying technology [J]. Drying Technol., 2017, 35(1): 125-137. |

| 12 | 胡万里,李长友,徐凤英.稻谷薄层快速干燥工艺的试验[J].农业机械学报, 2007(4): 103-106. |

| HU W L, LI C Y, XU F Y. Experimental study on fast dry craft of rough rice thin layer [J].Trans. Chin. Soc. Agric. Mach., 2007(4): 103-106. | |

| 13 | 郜坤.谷物干燥过程热质交换及能耗研究[D].北京:华北电力大学,2019. |

| GAO K. Study of heat and mass exchange and energy consumption of during grain drying [D].Beijing:North China Electric Power University,2019. | |

| 14 | 王桂英.粮食热风干燥冷凝增效节能机理与技术的研究[D].长春:吉林大学, 2022. |

| WANG G Y. Stduy of the energy saving mechanism and technology of hot air drying condensation increasing efficiency of grain [D]. Changchun: Jilin University,2022. | |

| 15 | 李秀琴.节能环保型粮食干燥机的设计研究[J].中国设备工程, 2019(4): 198-199. |

| 16 | 赵锡和,龙成树,张进疆,等.秋季稻谷热泵变风速干燥及干燥箱火用分析[J].食品与机械,2016, 32(6): 95-99. |

| ZHAO X H, LONG C S, ZHANG J J . et al .. Analysis on drying box exergy and variable air velocity drying of autumn rice [J]. Food Mach., 2016, 32(6): 95-99. | |

| 17 | 车刚,王洪超,万霖,等.水稻干燥变温混配装置设计与试验[J].农业机械学报,2022,53(2):386-392, 411. |

| CHE G, WANG H C, WAN L, et al.. Design and test of varying temperature mixing device on paddy rice drying [J].Trans. Chin. Soc. Agric. Mach., 2022,53(2):386-392, 411. | |

| 18 | RATTHASAK P, PHADUNGSAK R, DULYACHOT C. Energy and exergy analyses in drying process of porous media using hot air [J]. Int. Commun. Heat Mass Transfer, 2010,37:372-378. |

| 19 | 姚专,王岚,秦卫国. 油料 水分及挥发物含量测定: [S].北京:中国标准出版社,2009. |

| 20 | 高东明,罗钢.干燥参数对苜蓿各含水率阶段干燥特性及能耗的影响[J].江苏大学学报(自然科学版),2020,41( 6) :685-693. |

| GAO D M, LUO G. Effect of drying parameters on drying characteristics and energy consumption during alfalfa drying process [J]. J. Jiangsu Univ. (Nat. Sci.), 2020,41( 6) :685-693. | |

| 21 | 张译文,张燕梁,万霖,等.3种干燥方法对荞麦干燥特性及品质的影响[J].食品与机械,2019,35(10):197-200. |

| ZHANG Y W, ZHANG Y L, WAN L, et al.. Effects of three drying methods on the drying characteristics and quality of buck wheat [J] . Food Mach., 2019,35(10):197-200. | |

| 22 | 陈正发,车刚,万霖,等.稻谷四向通风混流干燥段数值模拟与试验[J].农业工程学报,2022,38(24):237-247. |

| CHEN Z F, CHE G, WAN L, et al.. Numerical simulation and experiment of four-way ventilation mixed flow drying section for rice [J]. Trans. Chin. Soc. Agric. Eng., 2022,38(24):237-247. | |

| 23 | 万霖,王洪超,车刚.嵌入旋转气腔式水稻穴直播排种器设计与试验[J].农业机械学报,2019,50(11):74-84. |

| WAN L, WANG H C, CHE G, et al.. Design and test of rice hill-drop seed metering device embedded with rotating air cavity [J]. Trans. Chin. Soc. Agric. Mach., 2019,50(11):74-84. |

| [1] | 刘大为, 秦锋, 廖骞, 王修善, 谢方平, 李铁辉. 南方籼稻热风干燥特性及其工艺参数优化[J]. 中国农业科技导报, 2024, 26(8): 93-102. |

| [2] | 杨伊琳, 丁俊雄, 吴小华, 王鹏, 孙东亮, 于馨尧, 张振涛, 李栋. 基于响应曲面法优化香菇热风干燥工艺参数[J]. 中国农业科技导报, 2023, 25(6): 154-164. |

| [3] | 陈平录, 肖石华, 许静, 刘木华. 收割机提升搅龙中干燥稻谷的CFD-DEM数值模拟[J]. 中国农业科技导报, 2022, 24(5): 93-101. |

| [4] | 史扬杰, 奚小波, 袁日灿, 单翔, 张琦, 赵其东, 张瑞宏. CO2冷阱微波真空干燥装置设计与试验[J]. 中国农业科技导报, 2021, 23(6): 97-104. |

| [5] | 罗燕,李武强,万芳新,黄晓鹏*. 基于Weibull分布函数的桔梗切片热风干燥特性[J]. 中国农业科技导报, 2020, 22(8): 132-140. |

| [6] | 彭春晖1,任奕林1*,李宝军1,周广生2,刘永红3. 生物炭基肥挤压成型工艺参数优化[J]. 中国农业科技导报, 2019, 21(5): 74-84. |

| [7] | 刘羽平,张拓,刘妤*. 稻谷颗粒模型离散元接触参数标定与试验[J]. 中国农业科技导报, 2019, 21(11): 70-76. |

| [8] | 徐富贤,熊洪,张林,郭晓艺,朱永川,周兴兵,刘茂. 冬水田施氮对杂交中稻氮、磷、钾含量及干物质积累与分配的影响[J]. , 2012, 14(2): 118-126. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号