中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (5): 113-121.DOI: 10.13304/j.nykjdb.2023.0937

陈桥( ), 肖明玮, 罗陈迪, 高嘉正, 欧阳春凡, 曾春林, 李文涛, 周学成(

), 肖明玮, 罗陈迪, 高嘉正, 欧阳春凡, 曾春林, 李文涛, 周学成( )

)

收稿日期:2023-12-28

接受日期:2024-03-22

出版日期:2025-05-15

发布日期:2025-05-20

通讯作者:

周学成

作者简介:陈桥 E-mail:az1016875977@163.com;

基金资助:

Qiao CHEN( ), Mingwei XIAO, Chendi LUO, Jiazheng GAO, Chunfan OUYANG, Chunlin ZENG, Wentao LI, Xuecheng ZHOU(

), Mingwei XIAO, Chendi LUO, Jiazheng GAO, Chunfan OUYANG, Chunlin ZENG, Wentao LI, Xuecheng ZHOU( )

)

Received:2023-12-28

Accepted:2024-03-22

Online:2025-05-15

Published:2025-05-20

Contact:

Xuecheng ZHOU

摘要:

针对火龙果生长环境复杂、生长姿态多样、枝条内茎剪切强度大、果蒂附近果皮易损伤等采摘难题,设计了一种椭圆夹爪剪切式火龙果采摘末端执行器,能够对不同生长姿态下的火龙果进行无损采摘。椭圆夹爪可以将火龙果果实与枝条分隔,保护果实的完整;通过在椭圆夹爪上开V型槽来适应不同倾角的火龙果,防止枝条对夹持动作的阻碍;采用先剪后拉的方法采摘火龙果。对夹持和剪切机构进行力学分析,通过剪切试验测得最小剪切力为33.5 N,对动力源进行选型。建立了剪切后火龙果拉力采摘模型,经过有限元分析和果园人工剪切后的拉力试验对比,测得平均拉力为20 N,不会对果实造成损伤。构建了物理样机,并对其进行了15次夹持试验和25次果园实地剪切试验,结果表明,末端执行器的可采摘范围远大于现有火龙果定位精度,采摘火龙果倾角为50°~90°,平均采摘时间为3.1 s,采摘成功率为92%,切下的叶片平均长度为55.3 mm,能够满足采摘需求。

中图分类号:

陈桥, 肖明玮, 罗陈迪, 高嘉正, 欧阳春凡, 曾春林, 李文涛, 周学成. 椭圆夹爪剪切式火龙果采摘末端执行器设计[J]. 中国农业科技导报, 2025, 27(5): 113-121.

Qiao CHEN, Mingwei XIAO, Chendi LUO, Jiazheng GAO, Chunfan OUYANG, Chunlin ZENG, Wentao LI, Xuecheng ZHOU. Design of Shear End Effector for Dragon Fruit Picking Based on Oval Claw[J]. Journal of Agricultural Science and Technology, 2025, 27(5): 113-121.

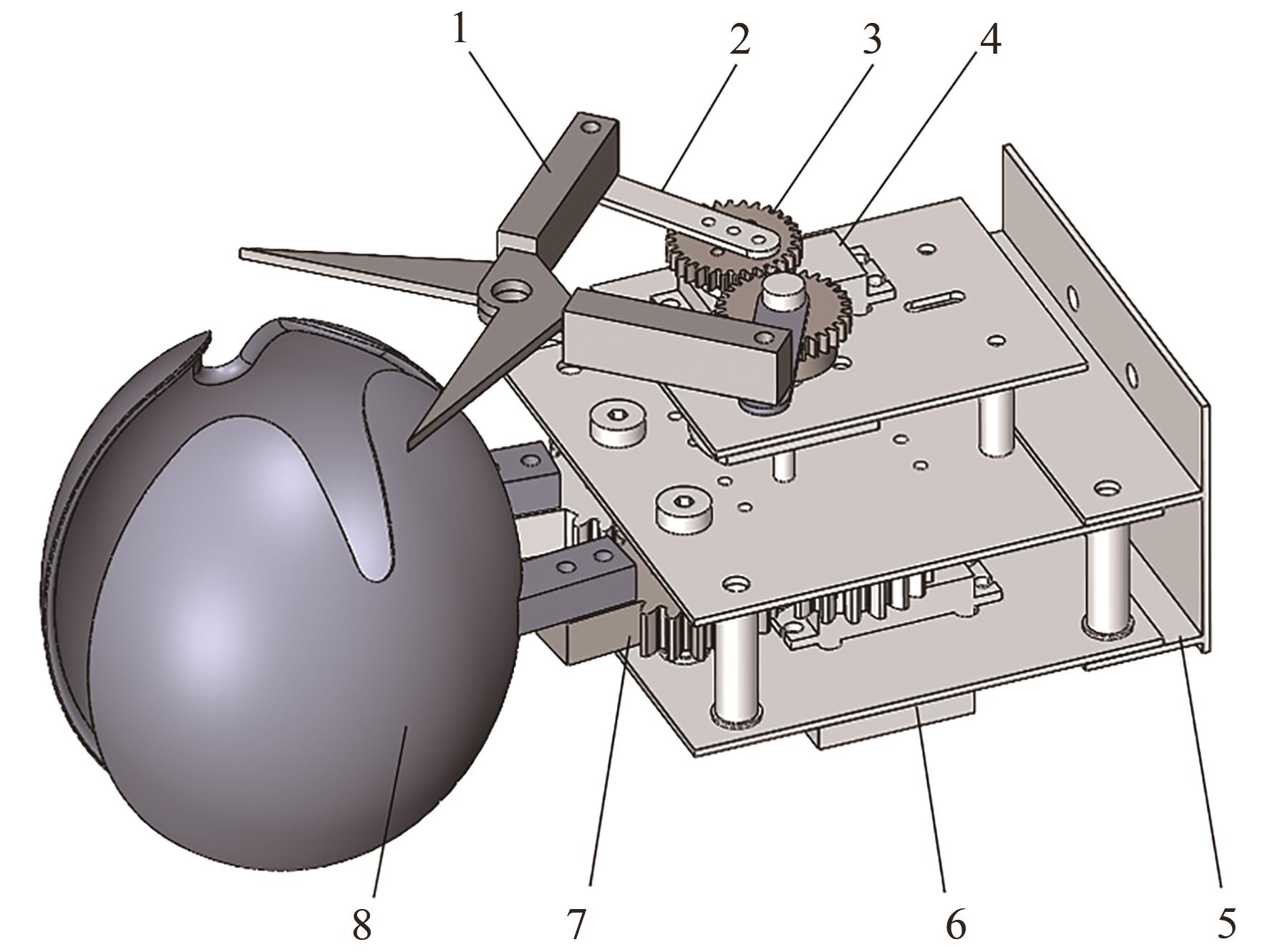

图1 火龙果采摘末端执行器机构注:1—剪刀;2—连杆;3—剪切驱动齿轮;4—剪切驱动舵机;5—手腕连接件;6—夹持驱动舵机;7—剪切驱动齿轮;8—椭圆夹爪。

Fig. 1 Structure of the end effector of dragon fruit pickingNote:1—Scissors; 2—Connecting rod; 3—Gear wheel; 4—Steering engine; 5—Mechanical arm connector; 6—Steering engine; 7—Gear wheel; 8—Oval jaw.

序号 Number | 果梗直径 Stem diameter/mm | 加载速度Loading speed/ (mm·min-1) | 最大剪切力 Maximum shear force/N |

|---|---|---|---|

| 1 | 4.24 | 10 | 35.64 |

| 2 | 5.24 | 10 | 46.67 |

| 3 | 5.47 | 10 | 44.89 |

| 4 | 4.56 | 10 | 67.10 |

| 5 | 4.05 | 10 | 38.03 |

| 6 | 4.5 | 10 | 34.56 |

| 7 | 4.05 | 20 | 38.17 |

| 8 | 5.23 | 20 | 63.82 |

| 9 | 5.10 | 20 | 46.38 |

| 10 | 4.65 | 20 | 47.12 |

| 11 | 4.70 | 20 | 51.89 |

| 12 | 4.53 | 20 | 44.23 |

| 13 | 4.10 | 50 | 32.06 |

| 14 | 4.93 | 50 | 61.29 |

| 15 | 5.04 | 50 | 45.78 |

| 16 | 4.91 | 50 | 43.84 |

| 17 | 4.83 | 50 | 39.37 |

| 18 | 4.48 | 50 | 48.46 |

| 19 | 4.11 | 80 | 35.04 |

| 20 | 4.90 | 80 | 46.97 |

| 21 | 4.95 | 80 | 43.54 |

| 22 | 5.10 | 80 | 41.60 |

| 23 | 4.63 | 80 | 44.44 |

| 24 | 4.20 | 80 | 48.46 |

表1 火龙果单刀剪切试验结果

Table 1 Results of single knife shear test of dragon fruit

序号 Number | 果梗直径 Stem diameter/mm | 加载速度Loading speed/ (mm·min-1) | 最大剪切力 Maximum shear force/N |

|---|---|---|---|

| 1 | 4.24 | 10 | 35.64 |

| 2 | 5.24 | 10 | 46.67 |

| 3 | 5.47 | 10 | 44.89 |

| 4 | 4.56 | 10 | 67.10 |

| 5 | 4.05 | 10 | 38.03 |

| 6 | 4.5 | 10 | 34.56 |

| 7 | 4.05 | 20 | 38.17 |

| 8 | 5.23 | 20 | 63.82 |

| 9 | 5.10 | 20 | 46.38 |

| 10 | 4.65 | 20 | 47.12 |

| 11 | 4.70 | 20 | 51.89 |

| 12 | 4.53 | 20 | 44.23 |

| 13 | 4.10 | 50 | 32.06 |

| 14 | 4.93 | 50 | 61.29 |

| 15 | 5.04 | 50 | 45.78 |

| 16 | 4.91 | 50 | 43.84 |

| 17 | 4.83 | 50 | 39.37 |

| 18 | 4.48 | 50 | 48.46 |

| 19 | 4.11 | 80 | 35.04 |

| 20 | 4.90 | 80 | 46.97 |

| 21 | 4.95 | 80 | 43.54 |

| 22 | 5.10 | 80 | 41.60 |

| 23 | 4.63 | 80 | 44.44 |

| 24 | 4.20 | 80 | 48.46 |

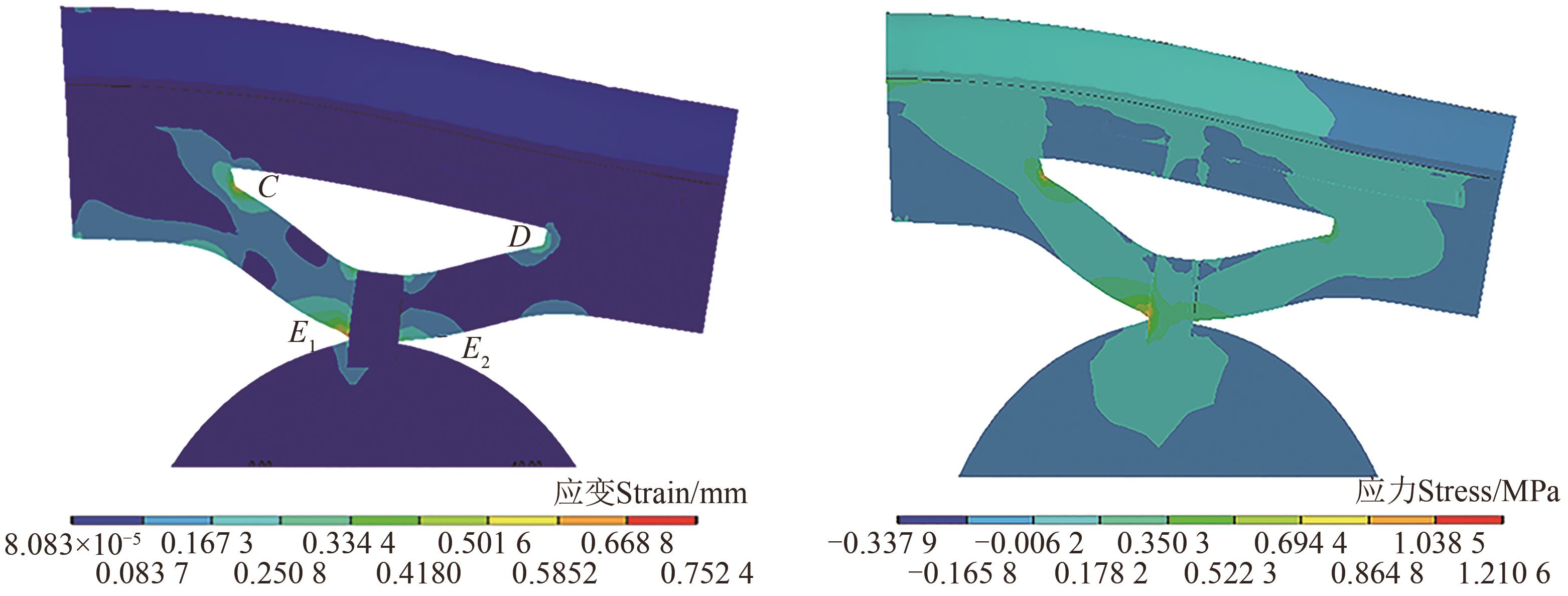

图8 剪切后的火龙果受拉的应力应变分布A:等效应变分布;B:垂直受拉应力分布

Fig. 8 Stress-strain distribution of the strained dragon fruit after shearA: Equivalent strain distribution; B:Vertical tensile stress

序号 Number | 果实尺寸 Fruit size/mm | 切痕长度 Cut length/mm | 拉力 Tension/N | 叶片组织长度 Leaf tissue length/mm |

|---|---|---|---|---|

| 1 | 63.7×81.0 | 43.3 | 16.0 | 58.4 |

| 2 | 67.3×76.3 | 45.4 | 25.5 | 40.7 |

| 3 | 61.0×73.6 | 49.0 | 25.5 | 40.8 |

| 4 | 73.4×90.3 | 54.2 | 22.0 | 54.1 |

| 5 | 66.2×93.1 | 47.2 | 18.0 | 33.1 |

| 6 | 70.8×81.1 | 50.1 | 22.5 | 58.9 |

| 7 | 62.0×78.4 | 46.8 | 18.0 | 41.6 |

| 8 | 64.5×77.0 | 54.2 | 17.0 | 38.3 |

| 9 | 61.0×71.1 | 46.5 | 20.0 | 45.4 |

| 10 | 71.5×79.8 | 58.0 | 23.0 | 63.7 |

| 11 | 83.0×100.5 | 47.4 | 21.0 | 43.1 |

| 12 | 86.0×104.0 | 51.3 | 19.0 | 53.6 |

| 13 | 87.0×105.1 | 55.2 | 23.5 | 59.4 |

| 14 | 89.0×107.3 | 48.1 | 22.0 | 55.3 |

| 15 | 78.3×99.4 | 45.3 | 16.5 | 32.5 |

| 16 | 75.8×94.2 | 40.6 | 20.5 | 41.7 |

| 17 | 70.0×90.0 | 52.1 | 17.5 | 53.7 |

| 18 | 73.0×92.0 | 46.2 | 15.5 | 32.1 |

| 19 | 67.0×88.1 | 44.3 | 17.0 | 47.6 |

| 20 | 64.5×84.3 | 43.5 | 19.5 | 46.3 |

表2 切后火龙果拉力测量试验结果

Table 2 Test results of cutting dragon fruit tension

序号 Number | 果实尺寸 Fruit size/mm | 切痕长度 Cut length/mm | 拉力 Tension/N | 叶片组织长度 Leaf tissue length/mm |

|---|---|---|---|---|

| 1 | 63.7×81.0 | 43.3 | 16.0 | 58.4 |

| 2 | 67.3×76.3 | 45.4 | 25.5 | 40.7 |

| 3 | 61.0×73.6 | 49.0 | 25.5 | 40.8 |

| 4 | 73.4×90.3 | 54.2 | 22.0 | 54.1 |

| 5 | 66.2×93.1 | 47.2 | 18.0 | 33.1 |

| 6 | 70.8×81.1 | 50.1 | 22.5 | 58.9 |

| 7 | 62.0×78.4 | 46.8 | 18.0 | 41.6 |

| 8 | 64.5×77.0 | 54.2 | 17.0 | 38.3 |

| 9 | 61.0×71.1 | 46.5 | 20.0 | 45.4 |

| 10 | 71.5×79.8 | 58.0 | 23.0 | 63.7 |

| 11 | 83.0×100.5 | 47.4 | 21.0 | 43.1 |

| 12 | 86.0×104.0 | 51.3 | 19.0 | 53.6 |

| 13 | 87.0×105.1 | 55.2 | 23.5 | 59.4 |

| 14 | 89.0×107.3 | 48.1 | 22.0 | 55.3 |

| 15 | 78.3×99.4 | 45.3 | 16.5 | 32.5 |

| 16 | 75.8×94.2 | 40.6 | 20.5 | 41.7 |

| 17 | 70.0×90.0 | 52.1 | 17.5 | 53.7 |

| 18 | 73.0×92.0 | 46.2 | 15.5 | 32.1 |

| 19 | 67.0×88.1 | 44.3 | 17.0 | 47.6 |

| 20 | 64.5×84.3 | 43.5 | 19.5 | 46.3 |

尺寸 Size/mm | 数量 Quantity | +x方向 +x direction/mm | +y方向 +y direction/mm | +z方向 +z direction/ mm |

|---|---|---|---|---|

| 90x×68 | 5 | [19.0,33.0] | [0,22.0] | [-26.2,+49.8] |

| 98×78 | 5 | [15.0,31.5] | [0,17.0] | [-18.0,+44.2] |

| 110×90 | 5 | [9.0,20.5] | [0,15.0] | [-8.4,+38.8] |

表3 采摘范围试验结果

Table 3 Clamp test results

尺寸 Size/mm | 数量 Quantity | +x方向 +x direction/mm | +y方向 +y direction/mm | +z方向 +z direction/ mm |

|---|---|---|---|---|

| 90x×68 | 5 | [19.0,33.0] | [0,22.0] | [-26.2,+49.8] |

| 98×78 | 5 | [15.0,31.5] | [0,17.0] | [-18.0,+44.2] |

| 110×90 | 5 | [9.0,20.5] | [0,15.0] | [-8.4,+38.8] |

| 1 | 王蔚婕,唐道邦,曹清明,等.火龙果的营养价值及加工现状[J].中国食物与营养,2019,25(4):27-30. |

| WANG W J, TANG D B, CAO Q M, et al.. Research advancement of nutritional value and processing of pitaya [J]. Food Nutr. China, 2019,25(4):27-30. | |

| 2 | 李靓,朱涵彬,袁晓晴,等.火龙果营养成分及保健功能的研究[J].现代食品,2020,5(10):26-28. |

| LI J, ZHU H B, YUAN X Q, et al.. Study on nutritional composition and healthy function of pitaya fruit [J]. Mod. Food, 2020,5(10):26-28. | |

| 3 | 徐磊磊,金琰,侯媛媛,等.我国火龙果市场与产业调查分析报告[J].农产品市场,2021(8):43-45. |

| XU L L, JIN Y, HOU Y Y, et al.. Chinese dragon fruit market and Industry survey and analysis report [J]. Agric. Products Market., 2021(8): 43-45. | |

| 4 | 卜令昕.结构化果园苹果收获机器人关键技术研究[D].杨凌:西北农林科技大学,2021. |

| BU L X. Key technologies of robotic apple harvester in constructed orchard [D]. Yangling: Northwest A&F University, 2021. | |

| 5 | 苗玉彬,郑家丰.苹果采摘机器人末端执行器恒力柔顺机构研制[J].农业工程学报,2019,35(10):19-25. |

| MIAO Y B, ZHENG J F. Development of compliant constant-force mechanism for end effector of apple picking robot [J]. Trans. Chin. Soc. Agric. Eng., 2019,35(10):19-25. | |

| 6 | 于丰华,周传琦,杨鑫,等.日光温室番茄采摘机器人设计与试验[J].农业机械学报,2022,53(1):41-49. |

| YU F H, ZHOU C Q, YANG X, et al.. Design and experiment of tomato picking robot in solar greenhouse [J]. Trans. Chin. Soc. Agric. Mach., 2022,53(1):41-49. | |

| 7 | HOHIMER C J, WANG H, BHUSAL S, et al.. Design and field evaluation of a robotic apple harvesting system with a 3D-Printed Soft-Robotic End-Effector [J]. Trans. ASABE, 2019,62(2):405-414. |

| 8 | XIE H. Optimization and experimental study of structural parameters of compliant end-effector for robotic cherry tomato harvesting [J]. Appl. Eng. Agric., 2022,38(3):617-625. |

| 9 | GOULART R, JARVIS D, WALSH K B. Evaluation of end effectors for robotic harvesting of mango fruit [J]. Sustainability, 2023, 15(8): 6769. |

| 10 | 魏博,何金银,石阳,等.欠驱动式柑橘采摘末端执行器设计与试验[J].农业机械学报,2021,52(10):120-128. |

| WEI B, HE J Y, SHI Y, et al.. Design and experiment of underactuated end-effector for Citrus picking [J].Trans. Chin. Soc. Agric. Mach., 2021,52(10):120-128. | |

| 11 | 虞浪,俞高红,吴浩宇,等. 欠驱动关节型柑橘采摘末端执行器设计与试验[J]. 农业工程学报,2023,17(39): 1-10. |

| YU L, YU G H, WU H Y, et al.. Design and experiment of the end-effector with underactuated articular for citrus picking [J]. Trans. Chin. Soc. Agric. Eng., 2023, 39(17): 29-38. | |

| 12 | 邓小雷,罗忠祎,庞景权,等.仿生无损吸取式苹果采摘装置的设计与试验[J].中国农业大学学报,2019,24(10):100-108. |

| DENG X L, LUO Z Y, PANG J Q, et al.. Design and experiment of bionic nondestructive handheld suction apple picker [J]. J. China Agric. Univ., 2019,24(10):100-108. | |

| 13 | ZHANG K X, LAMMERS K, CHU P Y, et al.. System design and control of an apple harvesting robot [J/OL]. Mechatronics, 2021,79:102644 [2024-09-23]. . |

| 14 | 姬江涛,李梦松,赵凯旋,等.双孢菇柔性仿形采摘末端执行器设计与试验[J].农业机械学报,2023,54(1):104-115. |

| JI J T, LI M S, ZHAO K X, et al.. Design and experiment of flexible profiling picking end-effector for Agaricus bisporus [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(1):104-115. | |

| 15 | 戎毫.基于果梗分离采摘方式的猕猴桃采摘末端执行器研制[D].杨凌:西北农林科技大学,2019. |

| RONG H. Development of end-effector for picking kiwi fruit based on fruit stem separation and picking method [D]. Yangling: Northwest A & F University, 2019. | |

| 16 | 陈真真.南疆苹果采摘机械系统末端执行器的设计与研究[D].塔里木:塔里木大学,2016. |

| CHEN Z Z. Design and research of end-effector of apple picking mechanical system in southern Xinjiang [D]. Turim: Tarim University,2016. | |

| 17 | 李健,戴楚彦,王扬威,等.基于草莓轮廓曲线的单指软体采摘抓手设计与优化[J].浙江大学学报(工学版). 2022,56(6):1088-1096, 1134. |

| LI J, DAI C Y, WANG Y W, et al.. Design and optimization of single-finger soft grasp based on strawberry curve [J]. J. Zhejiang Univ. (Eng. Technol.), 2022,56(6):1088-1096, 1134. | |

| 18 | 鲍秀兰,马志涛,马萧杰,等.丘陵果园自然环境下柑橘采摘机器人设计与试验[J].农业机械学报,2024,55(4):124-135. |

| BAO X L, MA Z T, MA X J, et al.. Design and experiment of citrus picking robot in hilly orchard natural environment [J]. Trans. Chin. Soc. Agric. Mach., 2024,55(4):124-135. | |

| 19 | 吴华昕.黄瓜智能采摘机器人关键技术研究[D].扬州:扬州大学,2021. |

| WU H X. Research on key technologies of cucumber intelligent picking robot [D]. Yangzhou: Yangzhou University, 2021. | |

| 20 | HABEGGER R, BERGAMO E, SCHWAB W, et al.. Impact of intensive modification of sweet pepper plants on performance of end effectors for autonomous harvesting [J]. Eur. J. Hortic. Sci., 2021,86(4):354-359. |

| 21 | 肖旭. 柑橘采摘机器人的采摘关键技术研究与试验[D].长沙:湖南农业大学, 2022. |

| XIAO X. Research and experiment on picking key technology of citrus picking robot [D]. Changsha:Hunan Agricultural University, 2022. | |

| 22 | 王毅. 柑橘采摘机器人咬合式末端执行器关键技术研究[D].重庆:重庆大学, 2019. |

| WANG Y. Research on key technologies of occluding end-effector for citrus picking robot [D]. Chongqing: Chongqing University, 2019. | |

| 23 | 陈建能,李杭,刘林敏,等.分体刀具式名优茶采摘末端执行器设计与试验优化[J]. 农业机械学报,2024,55(1): 39-46, 195. |

| CHEN J N, LI H, LIU L M, et al.. Design and experimental optimization of end effector for picking famous premium tea with split-cutter [J]. Trans. Chin. Soc. Agric. Mach., 2024,55(1):39-46, 195. | |

| 24 | 徐丽明,刘旭东,张凯良,等.脐橙采摘机器人末端执行器设计与试验[J].农业工程学报,2018,34(12):53-61. |

| XU L M, LIU X D, ZHANG K L, et al.. Design and test of end-effector for navel orange picking robot [J]. Trans. Chin. Soc. Agric. Eng., 2018,34(12):53-61. | |

| 25 | 罗茂珍,刘艳芝,张雪松,等.火龙果的特征特性及其温室盆栽配套技术[J].果树实用技术与信息,2021,(1):24-29. |

| 26 | 张瀚,杨福孙,胡文斌,等.火龙果果实生长及内含物变化规律[J].江苏农业科学,2022,50(11):161-168. |

| ZHANG H, YANG F S, HU W B, et al.. Changes of fruit growth and contents of pitaya [J]. Jiangsu Agric. Sci., 2022, 50(11): 161-168. | |

| 27 | 张跃跃.火龙果采摘机器人末端执行器关键技术的研究与设计[D]. 南京:南京林业大学, 2023. |

| ZHANG Y Y. Research and design of key technologies of end-effector for dragon fruit picking robot [D]. Nanjing: Nanjing Forestry University, 2023. | |

| 28 | 周佳良. 基于深度学习的复杂采摘环境下火龙果位姿识别与控制系统研究[D]. 南京:南京林业大学, 2023. |

| ZHOU J L. Research on position recognition and control system of dragon fruit in complex picking environment based on deep learning [D]. Nanjing:Nanjing Forestry University, 2023. | |

| 29 | ZHOU J, ZHANG Y, WANG J. RDE-YOLOv7: An improved model based on YOLOv7 for better performance in detecting dragon fruits [J/OL]. Agronomy, 2023,13(4):1042 [2024-09-23]. . |

| [1] | 郑杰, 陈红, 孟令剑, 李善军, 马露畅. 不同类型灌水器滴头对沼液抗堵塞性能的影响[J]. 中国农业科技导报, 2022, 24(7): 108-116. |

| [2] | 王忠云1,喻阳华2*,王芊姿1. 养分管理措施对干热河谷火龙果土壤肥力的影响[J]. 中国农业科技导报, 2020, 22(11): 176-186. |

| [3] | 王冰洁1,潘波1,姜蕾1,林勇1*,赵帅2,莫宇星2. 植保无人机作业参数对雾滴在火龙果树冠层沉积分布的影响[J]. 中国农业科技导报, 2020, 22(10): 101-109. |

| [4] | 王毅,张茂,刘波,刘洒,何宇,许洪斌*. 柑橘采摘机器人末端执行器夹持机构设计与实验[J]. 中国农业科技导报, 2019, 21(4): 61-69. |

| [5] | 张哲1,王毅1,2*,付舜1,马冀桐1. 基于咬合型末端执行器的柑橘采摘机器人采摘姿态研究[J]. 中国农业科技导报, 2018, 20(5): 75-82. |

| [6] | 王毅1,2,付舜2,张哲2,马冀桐2,许洪斌1,2*. 柑橘采摘机器人末端执行器设计与试验[J]. 中国农业科技导报, 2018, 20(1): 69-77. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号