Journal of Agricultural Science and Technology ›› 2022, Vol. 24 ›› Issue (3): 120-129.DOI: 10.13304/j.nykjdb.2020.1036

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Kaiyi SHAO( ), Zhiyou NIU(

), Zhiyou NIU( ), Chongyang YU, Wentao WU

), Chongyang YU, Wentao WU

Received:2020-12-06

Accepted:2021-03-03

Online:2022-03-15

Published:2022-03-14

Contact:

Zhiyou NIU

通讯作者:

牛智有

作者简介:邵恺怿 E-mail: shao_kaiyi@163.com;

基金资助:CLC Number:

Kaiyi SHAO, Zhiyou NIU, Chongyang YU, Wentao WU. Measurement and Analysis on Suspension Velocity of Aquaculture Pellets Feed[J]. Journal of Agricultural Science and Technology, 2022, 24(3): 120-129.

邵恺怿, 牛智有, 于重洋, 吴文涛. 水产颗粒饲料悬浮速度测定与分析[J]. 中国农业科技导报, 2022, 24(3): 120-129.

品种 Variety | 粒径 Particle size/mm | 密度 Density /(kg·m-3) | 含水率 Moisture content/% |

|---|---|---|---|

膨化饲料 Extruded feed | 1.00 | 531.91 | 9.04 |

| 2.00 | 501.21 | 10.05 | |

| 3.00 | 476.19 | 9.50 | |

| 4.00 | 458.72 | 9.19 | |

颗粒饲料 Pellet feed | 2.00 | 1 192.86 | 9.80 |

| 3.00 | 1 133.33 | 9.21 | |

| 4.00 | 1 081.25 | 8.23 |

Table 1 Characteristic of aquaculture pellets feed samples

品种 Variety | 粒径 Particle size/mm | 密度 Density /(kg·m-3) | 含水率 Moisture content/% |

|---|---|---|---|

膨化饲料 Extruded feed | 1.00 | 531.91 | 9.04 |

| 2.00 | 501.21 | 10.05 | |

| 3.00 | 476.19 | 9.50 | |

| 4.00 | 458.72 | 9.19 | |

颗粒饲料 Pellet feed | 2.00 | 1 192.86 | 9.80 |

| 3.00 | 1 133.33 | 9.21 | |

| 4.00 | 1 081.25 | 8.23 |

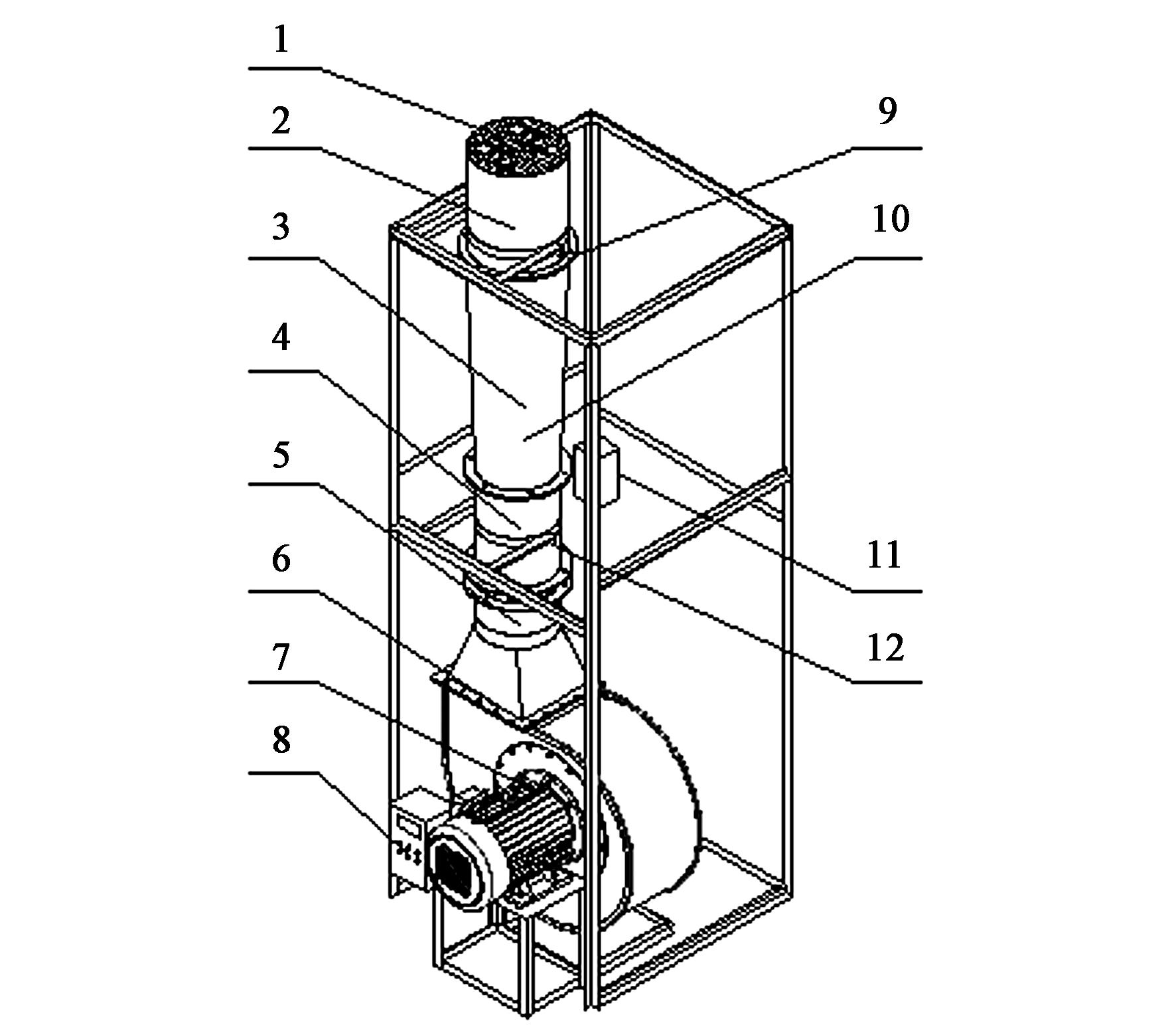

Fig.1 Test bed for determination of suspension velocityNote:1—Obstructive net; 2—Upper airflow-steadying pipe; 3—Tapered observed pipe; 4—Lower airflow-steadying pipe; 5—Pipe filled with grille; 6—Conduit coupler; 7—Fan; 8—Frequency converter; 9—Flanges; 10—L type pitot tube; 11—KXYL-600B Intelligent pressure air-volume anemometer; 12—Entrance gate.

差异源 Variance source | 平方和 SS | 自由度 df | 均方 MS | F | 显著性 Significance |

|---|---|---|---|---|---|

| 修正模型Modified model | 109.501 | 19 | 5.763 | 601.654 | |

| 截距Interpolation | 1 565.342 | 1 | 1 565.342 | 163 414.753 | |

| 含水率Moisture content | 0.957 | 4 | 0.239 | 24.976 | ** |

| 粒径Particle size | 108.493 | 3 | 36.164 | 3 775.395 | ** |

| 粒径×含水率Particle size×moisture content | 0.051 | 12 | 0.004 | 0.445 | |

| 误差 Error | 0.766 | 80 | 0.010 | ||

| 总计Total | 1 675.609 | 100 | |||

| 修正后总计Rvised total | 110.267 | 99 |

Table 2 Variance analysis of suspension velocity parameters for extruded feed

差异源 Variance source | 平方和 SS | 自由度 df | 均方 MS | F | 显著性 Significance |

|---|---|---|---|---|---|

| 修正模型Modified model | 109.501 | 19 | 5.763 | 601.654 | |

| 截距Interpolation | 1 565.342 | 1 | 1 565.342 | 163 414.753 | |

| 含水率Moisture content | 0.957 | 4 | 0.239 | 24.976 | ** |

| 粒径Particle size | 108.493 | 3 | 36.164 | 3 775.395 | ** |

| 粒径×含水率Particle size×moisture content | 0.051 | 12 | 0.004 | 0.445 | |

| 误差 Error | 0.766 | 80 | 0.010 | ||

| 总计Total | 1 675.609 | 100 | |||

| 修正后总计Rvised total | 110.267 | 99 |

差异源 Variance source | 平方和 SS | 自由度 df | 均方 MS | F | 显著性 Significance |

|---|---|---|---|---|---|

| 修正模型Modified model | 40.575 | 14 | 2.898 | 109.339 | |

| 截距Interpolation | 2 536.102 | 1 | 2 536.102 | 95 678.052 | |

| 含水率Moisture content | 2.319 | 4 | 0.580 | 21.868 | ** |

| 粒径Particle size | 38.065 | 2 | 19.032 | 718.022 | ** |

| 粒径×含水率Particle size×moisture content | 0.192 | 8 | 0.024 | 0.904 | |

| 误差 Error | 1.590 | 60 | 0.027 | ||

| 总计Total | 2 578.267 | 75 | |||

| 修正后总计Revised total | 42.165 | 74 |

Table 3 Variance analysis of suspension velocity parameters of pellet feed

差异源 Variance source | 平方和 SS | 自由度 df | 均方 MS | F | 显著性 Significance |

|---|---|---|---|---|---|

| 修正模型Modified model | 40.575 | 14 | 2.898 | 109.339 | |

| 截距Interpolation | 2 536.102 | 1 | 2 536.102 | 95 678.052 | |

| 含水率Moisture content | 2.319 | 4 | 0.580 | 21.868 | ** |

| 粒径Particle size | 38.065 | 2 | 19.032 | 718.022 | ** |

| 粒径×含水率Particle size×moisture content | 0.192 | 8 | 0.024 | 0.904 | |

| 误差 Error | 1.590 | 60 | 0.027 | ||

| 总计Total | 2 578.267 | 75 | |||

| 修正后总计Revised total | 42.165 | 74 |

品种 Variety | 评价指标 Evaluation index | 模型类型 Model type | |||

|---|---|---|---|---|---|

| 一阶Linear | 双因素交互2FI | 二阶Quadratic | 三阶Cubic | ||

膨化饲料 Extruded feed | 预测决定系数Pred R2 | 0.990 7 | 0.990 8 | 0.990 8 | 0.991 4 |

| 变异系数CV | 2.52 | 2.49 | 2.46 | 2.33 | |

颗粒饲料 Pellet feed | 预测决定系数Pred R2 | 0.954 0 | 0.955 1 | 0.953 1 | 0.950 6 |

| 变异系数CV | 2.72 | 2.68 | 2.70 | 2.73 | |

Table 4 Statistical results of each model

品种 Variety | 评价指标 Evaluation index | 模型类型 Model type | |||

|---|---|---|---|---|---|

| 一阶Linear | 双因素交互2FI | 二阶Quadratic | 三阶Cubic | ||

膨化饲料 Extruded feed | 预测决定系数Pred R2 | 0.990 7 | 0.990 8 | 0.990 8 | 0.991 4 |

| 变异系数CV | 2.52 | 2.49 | 2.46 | 2.33 | |

颗粒饲料 Pellet feed | 预测决定系数Pred R2 | 0.954 0 | 0.955 1 | 0.953 1 | 0.950 6 |

| 变异系数CV | 2.72 | 2.68 | 2.70 | 2.73 | |

| 项目Item | 值Value | |

|---|---|---|

| 膨化饲料Extruded feed | 颗粒饲料Pellet feed | |

| 平均值Mean | 3.96 | 5.81 |

| 变异系数CV | 2.33 | 2.68 |

| 决定系数R2 | 0.993 1 | 0.959 1 |

| 调整后决定系数Adj R2 | 0.992 4 | 0.957 3 |

| 预测决定系数Pred R2 | 0.991 4 | 0.955 1 |

| 精密度Adep precision | 105.037 | 62.391 |

Table 5 Analysis of error in regression model

| 项目Item | 值Value | |

|---|---|---|

| 膨化饲料Extruded feed | 颗粒饲料Pellet feed | |

| 平均值Mean | 3.96 | 5.81 |

| 变异系数CV | 2.33 | 2.68 |

| 决定系数R2 | 0.993 1 | 0.959 1 |

| 调整后决定系数Adj R2 | 0.992 4 | 0.957 3 |

| 预测决定系数Pred R2 | 0.991 4 | 0.955 1 |

| 精密度Adep precision | 105.037 | 62.391 |

方差来源 Source | 平方和 SS | 自由度 df | 均方 MS | F | P |

|---|---|---|---|---|---|

| 模型Model | 109.61 | 9 | 12.18 | 1 436.66 | <0.000 1 |

| D | 6.190 000 | 1 | 6.190 000 | 730.21 | <0.000 1 |

| M | 0.100 000 | 1 | 0.100 000 | 11.89 | 0.000 9 |

| DM | 0.032 000 | 1 | 0.032 000 | 3.77 | 0.055 3 |

| D2 | 0.033 000 | 1 | 0.033 000 | 3.88 | 0.051 8 |

| M2 | 0.007 609 | 1 | 0.007 609 | 0.90 | 0.346 0 |

| D2M | 0.007 199 | 1 | 0.007 199 | 0.85 | 0.359 2 |

| DM2 | 0.005 086 | 1 | 0.005 086 | 0.60 | 0.440 6 |

| D3 | 0.110 000 | 1 | 0.110 000 | 13.38 | 0.000 4 |

| M3 | 0.000 555 | 1 | 0.000 555 | 0.04 | 0.834 1 |

Table 6 Variance analysis in regression model for extruded feed

方差来源 Source | 平方和 SS | 自由度 df | 均方 MS | F | P |

|---|---|---|---|---|---|

| 模型Model | 109.61 | 9 | 12.18 | 1 436.66 | <0.000 1 |

| D | 6.190 000 | 1 | 6.190 000 | 730.21 | <0.000 1 |

| M | 0.100 000 | 1 | 0.100 000 | 11.89 | 0.000 9 |

| DM | 0.032 000 | 1 | 0.032 000 | 3.77 | 0.055 3 |

| D2 | 0.033 000 | 1 | 0.033 000 | 3.88 | 0.051 8 |

| M2 | 0.007 609 | 1 | 0.007 609 | 0.90 | 0.346 0 |

| D2M | 0.007 199 | 1 | 0.007 199 | 0.85 | 0.359 2 |

| DM2 | 0.005 086 | 1 | 0.005 086 | 0.60 | 0.440 6 |

| D3 | 0.110 000 | 1 | 0.110 000 | 13.38 | 0.000 4 |

| M3 | 0.000 555 | 1 | 0.000 555 | 0.04 | 0.834 1 |

方差来源 Source | 平方和 SS | 自由度 df | 均方 MS | F | P |

|---|---|---|---|---|---|

| 模型Model | 40.490 | 3 | 13.500 | 554.31 | <0.000 1 |

| D | 38.190 | 1 | 38.190 | 1 568.42 | <0.000 1 |

| M | 2.300 | 1 | 2.300 | 94.38 | <0.000 1 |

| DM | 0.078 | 1 | 0.078 | 3.20 | 0.077 8 |

Table 7 Variance analysis in regression model for pellet feed

方差来源 Source | 平方和 SS | 自由度 df | 均方 MS | F | P |

|---|---|---|---|---|---|

| 模型Model | 40.490 | 3 | 13.500 | 554.31 | <0.000 1 |

| D | 38.190 | 1 | 38.190 | 1 568.42 | <0.000 1 |

| M | 2.300 | 1 | 2.300 | 94.38 | <0.000 1 |

| DM | 0.078 | 1 | 0.078 | 3.20 | 0.077 8 |

| 1 | 麦康森.转变增长方式是我国水产养殖持续发展的必由之路[J].渔业信息与战略,2012,27(1):1-6. |

| MAI K S. Change of growth pattern and sustainable development of aquaculture in China [J]. Fishery Inf. Strategy, 2012, 27(1):1-6. | |

| 2 | 孔令杰,尹海富.黑龙江省水产膨化饲料应用现状及前景[J].渔业经济研究,2005(3):7-9. |

| 3 | 周世明.自动投饵机的种类、结构原理及使用维护技术[J].科学养鱼,2018(9):72-73. |

| 4 | 陈晓龙,田昌凤,杨家鹏,等.高密度养殖池塘自动气力投饲机的设计试验[J].渔业现代化,2016,43(5):18-22. |

| CHEN X L, TIAN C F, YANG J P, et al.. Research on pneumatic automatic feeding machine for intensive pond aquaculture [J]. Fishery Modern., 2016, 43(5):18-22. | |

| 5 | 杨伦,谢一华.气力输送工程[M].北京:机械工业出版社,2006:82-89. |

| 6 | 苏微,高筱钧,任闯,等.种子颗粒群的悬浮速度模拟预测方法[J].华南农业大学学报,2016, 37(1):110-116. |

| SU W, GAO X J, REN C, et al.. A simulation prediction method of suspension speed of seed particle swarm [J]. J. South China Agric.Univ., 2016, 37(1):110-116. | |

| 7 | 邓春香.谷物清选风车运动学和动力学特性研究及参数优化[D].长沙:湖南农业大学,2005. |

| DENG C X. Studied on the movement and dynamic characteristic of cereal cleaning windmill and optimized parameters [D]. Changsha: Hunan Agricultural University, 2005. | |

| 8 | 马征,李耀明,徐立章.油菜脱出物悬浮速度及摩擦与浸润特性的测定与分析[J].农业工程学报,2011,27(9):13-17. |

| MA Z, LI Y M, XU L Z. Testing and analysis on rape excursion components characteristics in floating, friction and wettability [J]. Trans. Chin. Soc. Agric. Eng., 2011, 27(9):13-17. | |

| 9 | 陈立,廖庆喜,宗望远,等.油菜联合收获机脱出物空气动力学特性测定[J].农业机械学报,2012, 43():125-130. |

| CHEN L, LIAO Q X, ZONG W Y, et al.. Aerodynamic characteristics measurement of extraction components for rape combine harvester [J]. Trans. Chin. Soc. Agric. Mach., 2012, 43 ():125-130. | |

| 10 | 郭辉,邢少康,郭伟宏,等.红花悬浮与收集试验[J].农机化研究,2020, 42(6):166-170. |

| GUO H, XING S K, GUO W H, et al.. Safflower suspension and collection test [J]. J. Agric. Mechan. Res., 2020, 42(6):166-170. | |

| 11 | 高连兴,张文,杜鑫,等.花生脱壳机脱出物的漂浮系数试验[J].农业工程学报,2012,28(2):289-292. |

| GAO L X, ZHANG W, DU X, et al.. Experiment on aerodynamic characteristics of threshed mixtures of peanut shelling machine [J]. Trans. Chin. Soc. Agric. Eng., 2012, 28(2):289-292. | |

| 12 | 张继成,陈海涛,纪文艺,等.大豆脱出物悬浮速度试验研究[J].农机化研究,2013,35(4):127-131. |

| ZHANG J C, CHEN H T, JI W Y, et al.. Experimental study on floating velocity of soybean extraction [J]. J. Agric. Mechan. Res., 2013, 35(4):127-131. | |

| 13 | 吴明聪,陈树人,卞丽娜,等.不同刈割期秧草收割物悬浮速度的测定与分析[J].安徽农业大学学报,2014,41(3):507-512. |

| WU M C, CHEN S R, BIAN L N, et al.. Measurement and analysis on suspension velocity of cut medicago falcate components in different harvesting periods [J]. J. Anhui Agric.Univ., 2014, 41(3):507-512. | |

| 14 | 王维,王亚妮,田智辉,等.物料悬浮速度试验台的设计与试验[J].中国农机化学报,2016,37(6):44-46. |

| WANG W, WANG Y N, TIAN Z H, et al.. Research on design and experimental of material suspension velocity test bench [J]. J. Chin. Agric. Mechan., 2016, 37(6):44-46. | |

| 15 | 马秋成,卢安舸,高连兴,等.莲子物料空气动力学特性与壳仁分离装置试验[J].农业工程学报,2015,31(6):297-303. |

| MA Q C, LU A G, GAO L X, et al.. Aerodynamic characteristics of lotus seed mixtures and test on pneumatic separating device for lotus seed kernel and contaminants [J]. Trans. Chin. Soc. Agric. Eng., 2015, 31(6):297-303. | |

| 16 | 刘艳艳,李耀明,徐立章,等.水稻悬浮速度试验研究[J].农机化研究,2010,32(2):149-155. |

| LIU Y Y, LI Y M, XU L Z, et al.. Experimental study on rice floating velocity [J]. J. Agric. Mechan. Res., 2010, 32(2):149-155. | |

| 17 | 彭建恩.物料悬浮速度的研究[J].粮食科技与经济,2001(4):36-37. |

| 18 | 于福峰,李平,张凤奎,等.红枣悬浮速度特性试验测定与分析[J].中国农机化学报,2020,41(6):99-105. |

| YU F F, LI P, ZHANG F K, et al.. Experimental determination and analysis of suspension velocity characteristics for red jujube [J]. J. Chin. Agric. Mechan., 2020, 41(6):99-105. | |

| 19 | 张佳,庄卫东,陈彬.农业物料悬浮速度试验台的研制[J].黑龙江八一农垦大学学报,1998,10(3):56-59. |

| ZHANG J, ZHUANG W D, CHEN B. The development of the test-bed for stuff of agriculture in suspension speed [J]. J. Heilongjiang Bayi Univ. Agric., 1998, 10(3):56-59. | |

| 20 | 连萌.物料悬浮速度测试装置试验研究[J].黄河水利职业技术学院学报,2020,32(3):37-43. |

| LIAN M. Research on material suspension speed testing device experiment [J]. J. Yellow Riv. Conserv. Tech. Inst., 2020, 32(3):37-43. | |

| 21 | 侯华铭,崔清亮,郭玉明,等.气吹式粮油作物脱出物清选悬浮速度测量装置设计与试验[J].农业工程学报,2018,34(16):43-49. |

| HOU H M, CUI Q L, GUO Y M, et al.. Design and test of air-sweeping suspension velocity testing device for cleaning threshed materials of grain and oil crops [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(16):43-49. | |

| 22 | 中华人民共和国卫生部.食品中水分的测定: [S].北京:中国标准出版社,2010. |

| 23 | 李秀荣,米彩林.牧草种子悬浮速度测定方法: [S].北京:机械工业出版社,2007. |

| 24 | 谢蕾蕾.SPSS统计分析实用教程[M].北京:人民邮电出版社,2013:111-205. |

| 25 | 葛宜元.实验设计方法与Design-Expert软件应用[M].哈尔滨:哈尔滨工业大学出版社,2014:81-85. |

| 26 | 李莉,张赛,何强,等.响应面法在试验设计与优化中的应用[J].实验室研究与探索,2015,34(8):41-45. |

| LI L, ZHANG S, HE Q, et al.. Application of response surface methodology in experiment design and optimization [J]. Res. Explor. Lab., 2015, 34(8):41-45. |

| No related articles found! |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号