Journal of Agricultural Science and Technology ›› 2022, Vol. 24 ›› Issue (5): 93-101.DOI: 10.13304/j.nykjdb.2021.0056

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Pinglu CHEN( ), Shihua XIAO, Jing XU(

), Shihua XIAO, Jing XU( ), Muhua LIU

), Muhua LIU

Received:2021-01-17

Accepted:2021-04-11

Online:2022-05-15

Published:2022-06-06

Contact:

Jing XU

通讯作者:

许静

作者简介:陈平录 E-mail:cpl757@163.com;

基金资助:CLC Number:

Pinglu CHEN, Shihua XIAO, Jing XU, Muhua LIU. CFD-DEM Simulation of Paddy Drying in Lifting Screw Conveyor of Harvester[J]. Journal of Agricultural Science and Technology, 2022, 24(5): 93-101.

陈平录, 肖石华, 许静, 刘木华. 收割机提升搅龙中干燥稻谷的CFD-DEM数值模拟[J]. 中国农业科技导报, 2022, 24(5): 93-101.

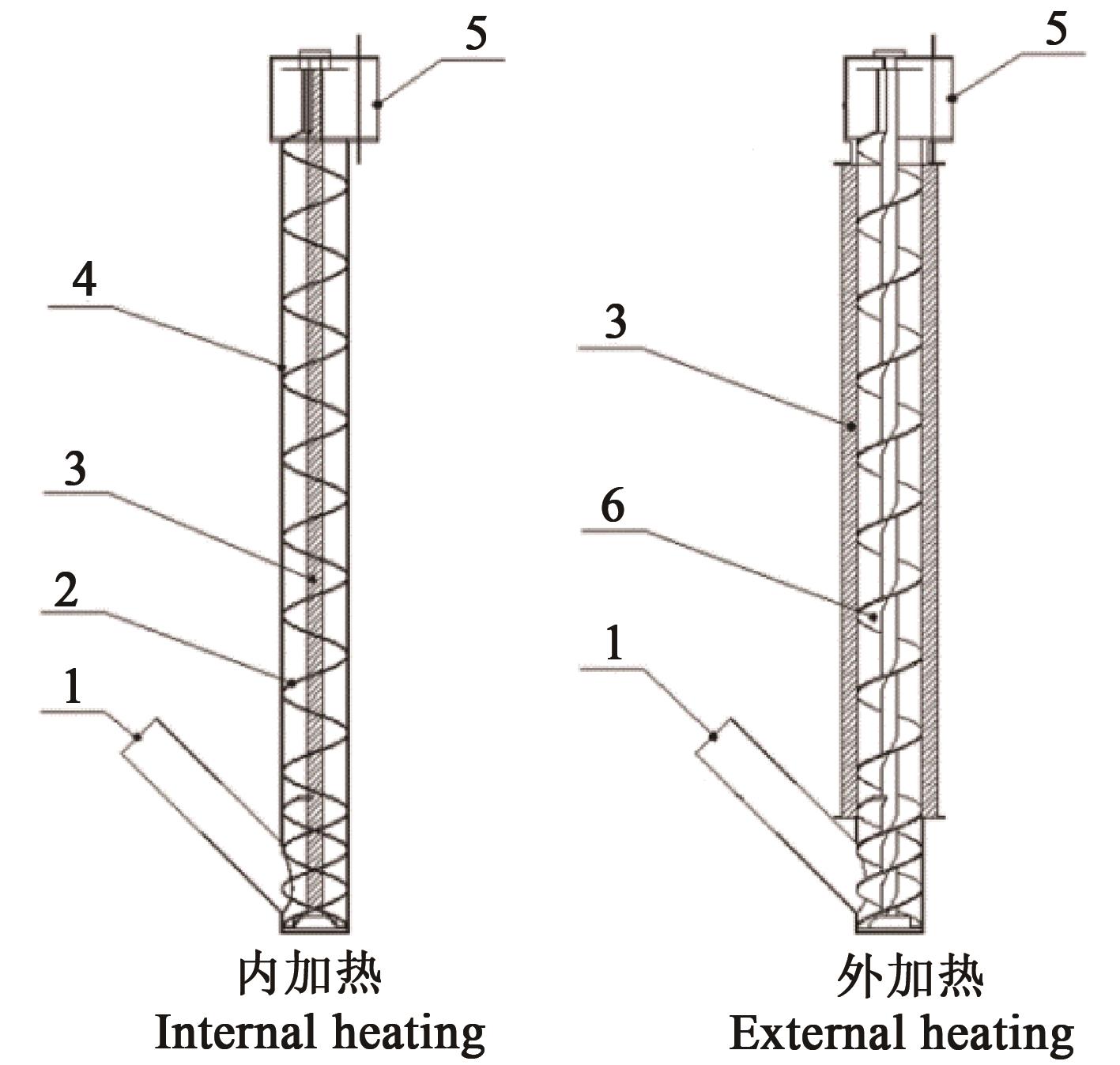

Fig.1 Structure of drying device in combine harvesterNote:1—Inlet (hot air inlet); 2—Shaftless screw conveyor; 3—Infrared heating tube; 4—Shell; 5—Outlet (exhaust outlet); 6—Screw conveyor.

| 材料 Material | 密度Density/(kg·m-3) | 弹性模量Hear modulus/(N·m-2) | 泊松比 Poisson’s ratio |

|---|---|---|---|

| 稻谷 Paddy | 1 086 | 8.65×107 | 0.25 |

| 钢 steel | 7 850 | 7×109 | 0.29 |

Table 1 Material parameters of particle model

| 材料 Material | 密度Density/(kg·m-3) | 弹性模量Hear modulus/(N·m-2) | 泊松比 Poisson’s ratio |

|---|---|---|---|

| 稻谷 Paddy | 1 086 | 8.65×107 | 0.25 |

| 钢 steel | 7 850 | 7×109 | 0.29 |

接触形式 Form of contact | 恢复系数 Coefficient of restitution | 静摩擦系数 Coefficient of static friction | 动摩擦系数 Coefficient of rolling friction |

|---|---|---|---|

| 稻谷-稻谷Paddy-paddy | 0.40 | 0.81 | 0.01 |

| 稻谷-钢Paddy-steel | 0.56 | 0.35 | 0.02 |

Table 2 Contact parameters of particle model

接触形式 Form of contact | 恢复系数 Coefficient of restitution | 静摩擦系数 Coefficient of static friction | 动摩擦系数 Coefficient of rolling friction |

|---|---|---|---|

| 稻谷-稻谷Paddy-paddy | 0.40 | 0.81 | 0.01 |

| 稻谷-钢Paddy-steel | 0.56 | 0.35 | 0.02 |

| 1 | 唐庆春,赵立欣.2019年黑龙江省稻米市场形势分析及后市展望[J].农业展望,2020,16(4):3-6. |

| TANG Q C, ZHAO L X. Analysis of rice market situation and future prospects in Heilongjiang Province in 2019 [J]. Agric. Prospects, 2020, 16(4):3-6. | |

| 2 | 姚瑶.基于自回热理论的稻谷流化床干燥系统设计与研究[D].南京:南京航空航天大学,2017. |

| YAO Y. Design and research of rice fluidized bed drying system based on self-regenerative theory [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017. | |

| 3 | GAO W Z, FENG L M, LIU Z J. Design and analysis of engine exhaust gas energy recovery system [J]. Environ. Sci. Eng., 2008, 2(12):1-5. |

| 4 | 李素云,夏朝勇,朱文学.红外辐射在谷物干燥中的应用[J].粮食与食品工业,2007,14(1):44-46. |

| LI S Y, XIA C Y, ZHU W X. Application of infrared radiation in drying grain [J]. Cereal Food Ind., 2007, 14(1):44-46. | |

| 5 | 夏朝勇,朱文学,张仲欣,等.红外对流组合干燥稻谷试验[J].农业机械学报,2006,37(8):235-238. |

| 6 | 姜亚南.基于余热回收的粮食烘干系统的设计与实现[J].安徽农业科学,2016,44(26):228-230. |

| JIANG Y N. Design and implementation of grain drying system based on waste heat recovery [J]. J. Anhui Agric. Sci., 2016, 44(26):228-230. | |

| 7 | 白继伟,罗书强,叶进,等.多功能拖拉机发动机余热利用系统设计[J].农机化研究,2008,12:195-197. |

| BAI J W, LUO S Q, YE J, et al.. Design of multi-functional tractor engine waste heat utilization system [J]. J. Agric. Mechan. Res., 2008, 12:195-197. | |

| 8 | 吕欢.全太阳能木材干燥室性能测试及流场模拟优化[D].北京:北京林业大学, 2016. |

| LYU H. Performance test and flow field simulation optimization of all-solar wood drying chamber [D]. Beijing: Beijing Forestry University, 2016. | |

| 9 | 王仕琪.花生干燥过程中湿热传递机理及实验研究[D].郑州:河南工业大学,2020. |

| WANG S Q. Mechanism and experimental study of moisture and heat transfer in peanut drying process [D]. Zhengzhou: Henan University of Technology, 2020. | |

| 10 | 汪喜波,胡琼,肖波,等.稻谷红外辐射与对流联合干燥过程的模型模拟[J].农业机械学报,2013,44(9):145-151. |

| WANG X B, HU Q, XIAO B, et al.. Simulation of drying process of rice by combination of infrared radiation and convection [J]. Trans. Chin. Soc. Agric. Mach., 2013, 44(9):145-151. | |

| 11 | 高敏.稻谷籽粒热风干燥过程中热质传递模拟[D].天津:天津科技大学, 2017. |

| GAO M. Simulation of heat and mass transfer in rice grain during hot air drying [D]. Tianjin: Tianjin University of Science and Technology, 2017. | |

| 12 | WANG Z, HURTER S, YOU Z, et al.. Influences of negative pressure on air-leakage of coalseam gas extraction: Laboratory and CFD-DEM simulations [J/OL]. J. Pet. Sci. Eng., 2021, 196:107731 [2021-02-28]. . |

| 13 | SHAHAB G, RAHMAT S, REZA Z, et al.. Review and implementation of CFD-DEM applied to chemical process systems [J/OL]. Chem. Eng. Sci., 2020, 221:115646 [2021-02-28]. . |

| 14 | 马华庆,赵永志.喷动流化床中杆状颗粒混合特性的CFD-DEM模拟[J].浙江大学学报(工学版),2020, 54(7):1347-1354. |

| MA H Q, ZHAO Y Z. CFD-DEM investigation on mixing of rod-like particles in spout-fluid bed [J]. J. Zhejiang Univ. (Eng. Sci.), 2020, 54(7):1347-1354. | |

| 15 | 李云川,赵崤隆,石平平,等.基于CFD-DEM耦合的土壤渗透性数值分析[J].江苏农业科学,2020,48(16): 255-259. |

| LI Y C, ZHAO Y L, SHI P P, et al.. Numerical analysis of soil permeability based on CFD-DEM coupling [J]. Jiangsu Agric. Sci., 2020, 48(16):255-259. | |

| 16 | HOBBS A. Simulation of an aggregate dryer using coupled CFD and DEM methods [J]. Int. J. Computational Fluid Dynamics, 2009, 23(2):199-207. |

| 17 | 石林榕,吴建民,赵武云,等.基于CFD-EDEM耦合的小区玉米帘式滚筒干燥箱数值模拟[J].干旱地区农业研究,2014,32(6):273-278. |

| SHI L R, WU J M, ZHAO W Y, et al.. Numerical simulation of corn curtain drying oven based on CFD-EDEM coupling [J]. Agric. Res. Arid Areas, 2014, 32(6):273-278. | |

| 18 | 虞文俊,吴瑞梅,李红,等.基于Fluent-EDEM耦合的茶叶红外杀青机滚筒内流场数值模拟[J].食品与机械,2019,35(8):104-109. |

| YU W J, WU R M, LI H, et al.. Numerical simulation of flow field in tea infrared cleaning machine drum based on fluent and EDEM coupling [J]. Food Mach., 2019, 35(8):104-109. | |

| 19 | 胡国明.颗粒系统的离散元素法分析仿真[M].武汉:武汉理工大学出版社,2010:87-88. |

| HU G M. Analysis and Simulation of Particle System by Discrete Element Method [M]. Wuhan: Wuhan University of Technology Press, 2010:87-88. | |

| 20 | 朱兰.基于HDG的混合网格法的应用研究[D].成都:电子科技大学,2017. |

| ZHU L. Application research of hybrid mesh method based on HDG [D]. Chengdou: University of Electronic Science and Technology of China, 2017. | |

| 21 | 原建博,李骅,吴崇友,等.基于离散单元法的水稻籽粒快速颗粒建模研究[J].南京农业大学学报,2018,41(6):1151-1158. |

| YUAN J B, LI H, WU C Y, et al.. Fast grain modeling of rice based on discrete element method [J]. J. Nanjing Agric.Univ., 2018, 41(6):1151-1158. | |

| 22 | 王润发.粮食红外线辅助热风干燥工艺系统设计[D].广州:华南农业大学,2016. |

| WANG R F. Design of grain infrared assisted hot air drying process system [D]. Guangzhou: South China Agricultural University, 2016. | |

| 23 | 王珊珊.稻谷籽粒干燥玻璃化转变过程数值模拟[D].天津:天津科技大学,2019. |

| WANG S S. Numerical simulation of drying vitrification process of rice grain [D]. Tianjin: Tianjin University of Science and Technology, 2019. | |

| 24 | 郑刚,孙丽琴.不同干燥温度和干燥风速对稻谷品质的影响研究[J].粮油食品科技,2020,28(4):173-176. |

| ZHENG G, SUN L Q. Study on the effect of different drying temperature and drying wind speed on rice quality [J]. Sci. Technol. Cereals Oils Food, 2020, 28(4):173-176. |

| [1] | ZHOU Shuxian, SHI Yixin, JIANG Ping. Design and Test Verification of Two-stage Jet Mixer Based on CFD [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 86-96. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号