Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (7): 87-96.DOI: 10.13304/j.nykjdb.2022.0008

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Dejun ZHANG1( ), Xiaoming ZHANG2, Di WU1, Shuyun LIN2, Taihua ZHANG1, Weiping XU1(

), Xiaoming ZHANG2, Di WU1, Shuyun LIN2, Taihua ZHANG1, Weiping XU1( )

)

Received:2022-01-04

Accepted:2022-05-23

Online:2023-07-15

Published:2023-08-25

Contact:

Weiping XU

张德俊1( ), 张小明2, 吴荻1, 林蜀云2, 张太华1, 徐卫平1(

), 张小明2, 吴荻1, 林蜀云2, 张太华1, 徐卫平1( )

)

通讯作者:

徐卫平

作者简介:张德俊 E-mail:2459917487@qq.com;

基金资助:CLC Number:

Dejun ZHANG, Xiaoming ZHANG, Di WU, Shuyun LIN, Taihua ZHANG, Weiping XU. Simulation of Pepper Cleaning Based on DEM-CFD Coupling[J]. Journal of Agricultural Science and Technology, 2023, 25(7): 87-96.

张德俊, 张小明, 吴荻, 林蜀云, 张太华, 徐卫平. 基于DEM-CFD耦合的辣椒清选仿真研究[J]. 中国农业科技导报, 2023, 25(7): 87-96.

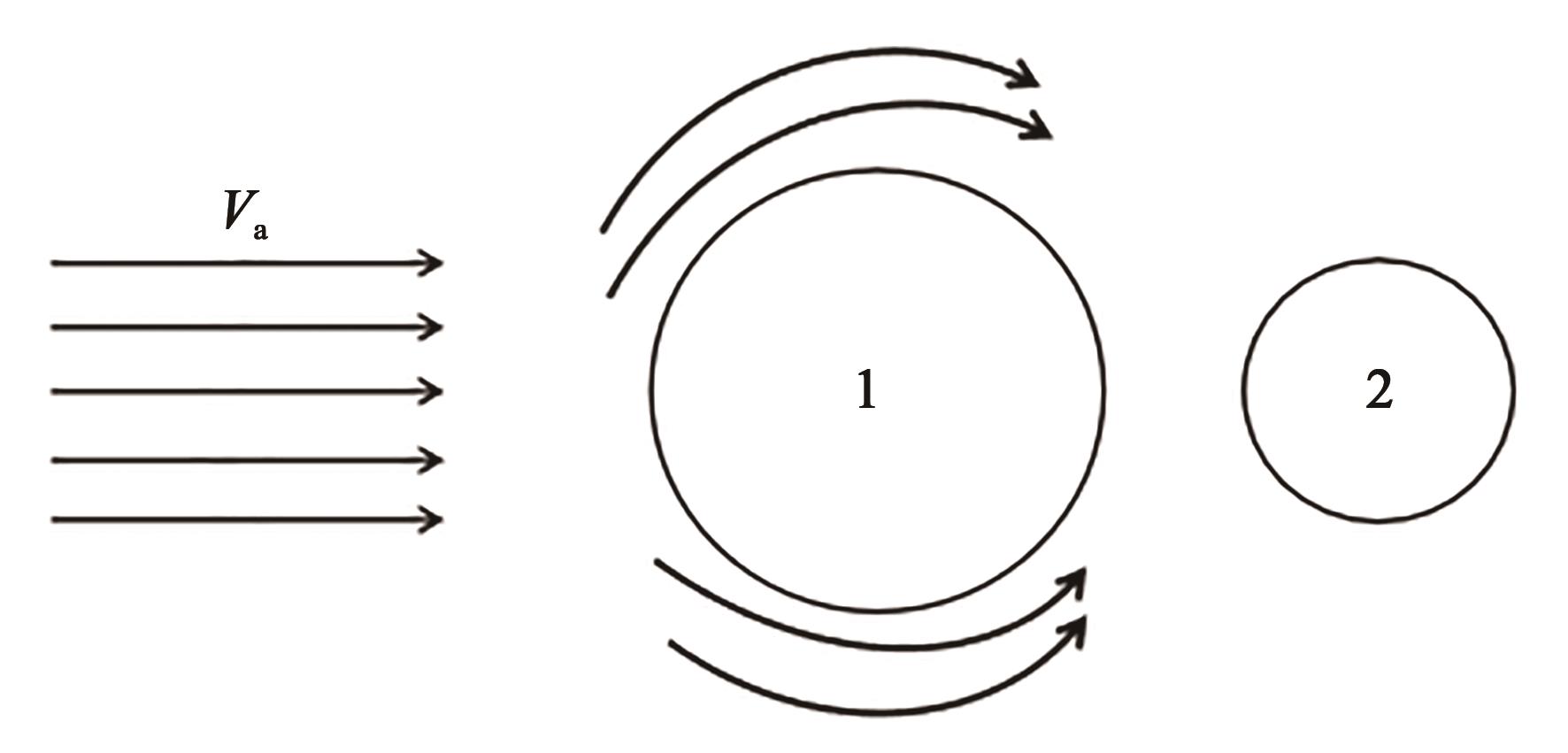

Fig. 4 Simplified principle of wind-selected particle wind-blocking effectNote: 1 is particles group of continuous motion at the front segment; 2 is particles group of continuous motion at the end segment.

| 材料 Material | 辣椒 pepper | 辣椒叶 pepper leaf | 辣椒茎秆 pepper stick | 钢 Steel |

|---|---|---|---|---|

| 泊松比 Poisson ratio | 0.34 | 0.28 | 0.41 | 0.29 |

| 剪切模量 Modulus of shear/ | 2.51e6 | 1.02e6 | 1.27e6 | 7.99e10 |

| 密度 Density/(kg/ | 790.89 | 598.95 | 1 074.43 | 7 860.00 |

Table 1 Physical parameters of the material

| 材料 Material | 辣椒 pepper | 辣椒叶 pepper leaf | 辣椒茎秆 pepper stick | 钢 Steel |

|---|---|---|---|---|

| 泊松比 Poisson ratio | 0.34 | 0.28 | 0.41 | 0.29 |

| 剪切模量 Modulus of shear/ | 2.51e6 | 1.02e6 | 1.27e6 | 7.99e10 |

| 密度 Density/(kg/ | 790.89 | 598.95 | 1 074.43 | 7 860.00 |

| 材料 Material | 恢复系数 Recovery coefficient | 静摩擦系数 Coefficient of static friction | 滑动摩擦系数 Coefficient of sliding friction |

|---|---|---|---|

| 辣椒-辣椒 pepper-pepper | 0.410 0 | 0.53 | 0.46 |

| 辣椒-辣椒叶 pepper-pepper leaves | 0.250 0 | 0.43 | 0.35 |

| 辣椒-辣椒茎秆 pepper-pepper sticks | 0.360 0 | 0.49 | 0.42 |

| 辣椒-钢 pepper-Steel | 0.430 0 | 0.56 | 0.31 |

| 辣椒叶-辣椒叶 pepper leaves-pepper leaves | 0.000 2 | 0.86 | 0.82 |

| 辣椒叶-辣椒茎秆 pepper leaves-pepper Sticks | 0.130 0 | 0.70 | 0.59 |

| 辣椒叶-钢 pepper leaves-Steel | 0.000 6 | 0.60 | 0.47 |

| 辣椒茎秆-辣椒茎秆 pepper sticks-pepper sticks | 0.390 0 | 0.76 | 0.67 |

| 辣椒茎秆-钢 pepper sticks-Steel | 0.370 0 | 0.54 | 0.38 |

Table 2 Material contact coefficient of related particles

| 材料 Material | 恢复系数 Recovery coefficient | 静摩擦系数 Coefficient of static friction | 滑动摩擦系数 Coefficient of sliding friction |

|---|---|---|---|

| 辣椒-辣椒 pepper-pepper | 0.410 0 | 0.53 | 0.46 |

| 辣椒-辣椒叶 pepper-pepper leaves | 0.250 0 | 0.43 | 0.35 |

| 辣椒-辣椒茎秆 pepper-pepper sticks | 0.360 0 | 0.49 | 0.42 |

| 辣椒-钢 pepper-Steel | 0.430 0 | 0.56 | 0.31 |

| 辣椒叶-辣椒叶 pepper leaves-pepper leaves | 0.000 2 | 0.86 | 0.82 |

| 辣椒叶-辣椒茎秆 pepper leaves-pepper Sticks | 0.130 0 | 0.70 | 0.59 |

| 辣椒叶-钢 pepper leaves-Steel | 0.000 6 | 0.60 | 0.47 |

| 辣椒茎秆-辣椒茎秆 pepper sticks-pepper sticks | 0.390 0 | 0.76 | 0.67 |

| 辣椒茎秆-钢 pepper sticks-Steel | 0.370 0 | 0.54 | 0.38 |

| 风速 Wind speed/(m·s-1) | 含杂率最大值 Maximum impurity rate/% | 平均含杂率 Average impurity rate/% | 平均损失率 Average loss rate/% |

|---|---|---|---|

| 15 | 22.234 | 11.774 | 0.959 |

| 20 | 8.713 | 4.624 | 1.798 |

| 25 | 3.554 | 1.676 | 6.476 |

Table 3 Simulation results at different wind speeds

| 风速 Wind speed/(m·s-1) | 含杂率最大值 Maximum impurity rate/% | 平均含杂率 Average impurity rate/% | 平均损失率 Average loss rate/% |

|---|---|---|---|

| 15 | 22.234 | 11.774 | 0.959 |

| 20 | 8.713 | 4.624 | 1.798 |

| 25 | 3.554 | 1.676 | 6.476 |

| 1 | 牟玉梅,毛妃凤,张绍刚.贵州省辣椒产业现状与发展建议[J].中国蔬菜,2020(2):10-12. |

| 2 | 杜涛.贵州从“辣椒大省”迈向“辣椒强省”[N].中国食品报,2021-09-27(002). |

| 3 | 谭春亮,王科社,范涛,等.风选机的气流场分析与优化设计[J].北京机械工业学院学报,2006(1):20-23. |

| TAN C L, WANG K S, FAN T, et al.. Simulation analysis of flow field of air classifier [J]. J. Beijing Institute Machinery Industry, 2006(1):20-23. | |

| 4 | 敬志臣,韩正晟,高爱民,等.小区小麦联合收获机清选系统的仿真分析[J].甘肃农业大学学报,2010(3):140-144, 155. |

| JING Z C, HAN Z C, GAO A M, et al.. Simulation analysis of the district wheat combine harvester cleaning system [J]. J. Gansu Agric.Univ., 2010(3):140-144, 155. | |

| 5 | 李兴凯,韩正晟,戴飞,等.基于EDEM的小区育种小麦脱粒装置作业参数仿真研究[J].干旱地区农业研究,2016(4):292-298. |

| LI X K, HAN Z C, DAI F, et al.. Simulation research on working parameters of threshing device on plot-bred wheat based on EDEM [J]. Agric. Res. Arid Areas., 2016(4):292-298. | |

| 6 | 张凤奎,张宏,兰海鹏,等.基于CFD-EDM耦合的气吸式红枣捡拾机气力输送装置仿真分析[J].中国农业科技导报,2021(7):107-116. |

| ZHANG F K, ZHANG H, LAN H P, et al.. Simulation analysis of pneumatic conveying device of air-suction jujube picker based on CFD-EDM coupling [J]. J. Agric. Sci. Technol., 2021(7):107-116. | |

| 7 | 郭柄江,马学东,刘正海,等.风筛式谷物清选模拟研究及参数讨论[J].农机化研究,2021(2):10-15. |

| GUO B J, MA X D, LIU Z H, et al.. Simulation study and parameters discussion on wind-sieve type grain cleaning [J]. J. Agric. Mechanization Res., 2021(2):10-15. | |

| 8 | 丁贺贺,石加联,马学东,等.基于DEM-CFD耦合的谷物垂直气流风选仿真试验[J]. 甘肃农业大学学报,2019(6):190-197. |

| DING H H, SHI J L, MA X D, et al.. Simulation experiment of grain vertical air separation based on DEM-CFD coupling [J]. J. Gansu Agric. Univ., 2019 (6):190-197. | |

| 9 | 刘正海,马学东,陈广慧,等.基于DEM-FLUENT耦合仿真谷物颗粒风选研究[J]. 农机化研究,2020,42(7):50-56. |

| LIU Z H, MA X D, CHEN G H, et al.. Study on wind-selection of cereal grains based on DEM-FLUENT coupling simulation [J]. J. Agric. Mechanization Res., 2020, 42(7):50-56. | |

| 10 | LEI X, LIAO Y, LIAO Q. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat [J]. Comp. Elect. Agric., 2016,131:29-39. |

| 11 | ADEMA A T, YANG Y, BOOM R. Discrete element method-computational fluid dynamic simulation of the materials flow in an iron-making blast furnace [J]. ISIJ Int., 2010,50(7):954-961. |

| 12 | WIACEK J. Geometrical parameters of binary granular mixtures with size ratio and volume fraction: experiments and dem simulations [J]. Granular Matter, 2016,18(3): 42. |

| 13 | DUAN C, CHENG S, WU L, et al.. CFD-DEM simulation of fluid-solid flow of a tapered column separation bed [J]. Int. J. Mining Sci. Technol., 2015,25(5):855-859. |

| 14 | 赵永志,程易.水平滚筒内二元颗粒体系径向分离模式的数值模拟研究[J].物理学报,2008(1):322-328. |

| ZHAO Y Z, CHENG Y. Numerical simulation of radial segregation patterns of binary granular systems in a rotating horizontal drum [J]. Acta Physiol. Sin., 2008(1):322-328. | |

| 15 | 王国欣,师清翔,刘师多,等.物料状态对圆筒式短茎秆清理装置性能的影响[J]. 农业机械学报,2002(4):52-54. |

| WANG G X, SHI Q X, LIU S D, et al.. Effects of the state of materials on performance of a drum device of short stem cleaning [J]. Trans. Chin. Soc. Agric. Mach., 2002(4):52-54. | |

| 16 | 陈广慧,李军,滕杰,等.基于EDEM-Fluent耦合的风筛式清选装置仿真及分析[J].中国农机化学报,2020,41(5):69-73. |

| CHEN G H, LI J, TENG J, et al.. Simulation and analysis of wind screen cleaning device based on EDEM-Fluent coupling [J]. J. Chin. Agric. Mechanization., 2020, 41(5):69-73. | |

| 17 | 黄深闯,杨望,杨坚,等.甘蔗茎秆-蔗叶系统有限元建模方法研究[J].农机化研究,2018,40(6):19-23. |

| HUANG S B, YANG W, YANG J, et al.. Study on finite element modeling method of sugarcane stalk-sugarcane leaf system [J]. J. Agric. Mechanization Res., 2018,40(6):19-23. | |

| 18 | 郭无极,杨望,温翔,等.切段式甘蔗收割机排杂仿真建模方法研究[J].农机化研究,2020,42(8):6-12. |

| GUO W J, YANG W, WEN X, et al.. Research on simulation modeling method of sugarcane harvester’s removing impurities operation [J]. J. Agric. Mechanization Res., 2020,42(8):6-12. | |

| 19 | 刘文政,何进,李洪文,等.基于离散元的微型马铃薯仿真参数标定[J].农业机械学报,2018,49(5):125-135, 142. |

| LIU W Z, HE J, LI H W, et al.. Calibration of simulation parameters for potato minituber based on EDEM [J]. Trans. Chin. Soc. Agric. Mach., 2018,49(5):125-135, 142. | |

| 20 | 张涛,刘飞,赵满全,等.玉米秸秆接触物理参数测定与离散元仿真标定[J].中国农业大学学报,2018,23(4):120-127. |

| ZHANG T, LIU F, ZHAO M Q, et al.. Determination of corn stalk contact parameters and calibration of discrete element method simulation [J]. J. China Agric. Univ., 2018, 23(4):120-127. | |

| 21 | 邹道钟,周卫华,马晓荣,等.分级式板椒清选系统的优化设计与试验[J].农机化研究,2022(9):129-132, 137. |

| ZOU D Z, ZHOU W H, MA X R, et al.. Design of cleaning system of pepper harvester [J]. J. Agric. Mechanization Res., 2022(9):129-132, 137. | |

| 22 | 赵飞龙,赵永满.辣椒收获机风机清选液压系统的设计研究[J].新疆农机化,2019(4):18-19, 23. |

| ZHAO F L, ZHAO Y M. Design and study on cleaning hydraulic system of pepper harvester fan [J]. Xinjiang Agric. Mechanization,2019 (4):18-19, 23. | |

| 23 | 韩丹丹,张东兴,杨丽,等.基于EDEM-CFD耦合的内充气吹式排种器优化与试验[J].农业机械学报,2017,(11):43-51. |

| HAN D D, ZHANG D X, YANG L, et al.. Optimization and experiment of inside-filling air-blowing seed metering device based on EDEM-CFD [J]. Trans. Chin. Soc. Agric. Mach., 2017,48(48):43-51. | |

| 24 | 丁力,杨丽,武德浩,等.基于DEM-CFD耦合的玉米气吸式排种器仿真与试验[J]. 农业机械学报,2018,(11):48-57. |

| DING L, YANG L, WU D H, et al.. Simulation and experiment of corn air suction seed metering device based on DEM-CFD coupling method [J]. Trans. Chin. Soc. Agric. Mach., 2018,49(49):48-57. | |

| 25 | YUAN J, WU C, LI H, et al.. Movement rules and screening characteristics of rice-threshed mixture separation through a cylinder sieve [J]. Comp. Elect. Agric., 2018,154:320-329. |

| 26 | 蒋恩臣,孙占峰,潘志洋,等.基于CFD-DEM的收获机分离室内谷物运动模拟与试验[J].农业机械学报,2014,45(4):117-122. |

| 27 | 王立军,李义博,郑招辉,等.玉米收获机清选装置内杂余抛送器设计与试验[J]. 农业机械学报,2019,50(50):124-136. |

| WANG L J, LI Y B, ZHENG Z H, et al.. Design and experiment of mechanism of throwing impurity in cleaning device of maize grain harvester [J]. Trans. Chin. Soc. Agric. Mach., 2019,50(50):124-136. | |

| 28 | 刘向军,石磊,徐旭常.稠密气固两相流欧拉-拉格朗日法的研究现状[J].计算力学学报,2007(2):166-172. |

| LIU X J, SHI L, XU X C. Activities of dense particle-gas two-phase flow modeling in Eulerian-Lagrangian approach [J]. Chin. J. Comp. Mechanics, 2007(2): 166-172. | |

| 29 | ZHOU Y, WANG H, ZHOU Bet al.. Dem-aided direct shear testing of granular sands incorporating realistic particle shape [J]. Granular Matter, 2018,20(3):55-55. |

| No related articles found! |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号