Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (11): 90-102.DOI: 10.13304/j.nykjdb.2022.0237

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Fake SHAN1( ), Shuo KANG1, Jianxi ZHU2, Yongwei WANG1, Jun WANG1(

), Shuo KANG1, Jianxi ZHU2, Yongwei WANG1, Jun WANG1( )

)

Received:2022-03-28

Accepted:2022-06-06

Online:2023-11-15

Published:2023-11-20

Contact:

Jun WANG

单发科1( ), 康朔1, 朱建锡2, 王永维1, 王俊1(

), 康朔1, 朱建锡2, 王永维1, 王俊1( )

)

通讯作者:

王俊

作者简介:单发科 E-mail: 21913001@zju.edu.cn;

基金资助:CLC Number:

Fake SHAN, Shuo KANG, Jianxi ZHU, Yongwei WANG, Jun WANG. Study on Tillage Fertilizer Mixing Effect Under Vertical Smashing Rotary Tillage and Rotary Tillage Based on EDEM[J]. Journal of Agricultural Science and Technology, 2023, 25(11): 90-102.

单发科, 康朔, 朱建锡, 王永维, 王俊. 基于EDEM的粉垄和旋耕作业混肥效果研究[J]. 中国农业科技导报, 2023, 25(11): 90-102.

| 耕作方式 Tillage method | 耕作幅宽 Tillage width/m | 最大耕深 Tillage depth/cm | l a d e s p e e d /(r·min-1) 刀具转速 B | 前进速度 Speed/(m·s-1) | n g l e /(°) 倾斜角度 A |

|---|---|---|---|---|---|

| 粉垄 Vertical smashing rotary tillage | 1.2 | 40 | 0~500 | 0~0.5 | -10~10 |

| 旋耕 Rotary tillage | 1.7 | 20 | 0~600 | 0~0.4 | — |

Table 1 Tillage parameters

| 耕作方式 Tillage method | 耕作幅宽 Tillage width/m | 最大耕深 Tillage depth/cm | l a d e s p e e d /(r·min-1) 刀具转速 B | 前进速度 Speed/(m·s-1) | n g l e /(°) 倾斜角度 A |

|---|---|---|---|---|---|

| 粉垄 Vertical smashing rotary tillage | 1.2 | 40 | 0~500 | 0~0.5 | -10~10 |

| 旋耕 Rotary tillage | 1.7 | 20 | 0~600 | 0~0.4 | — |

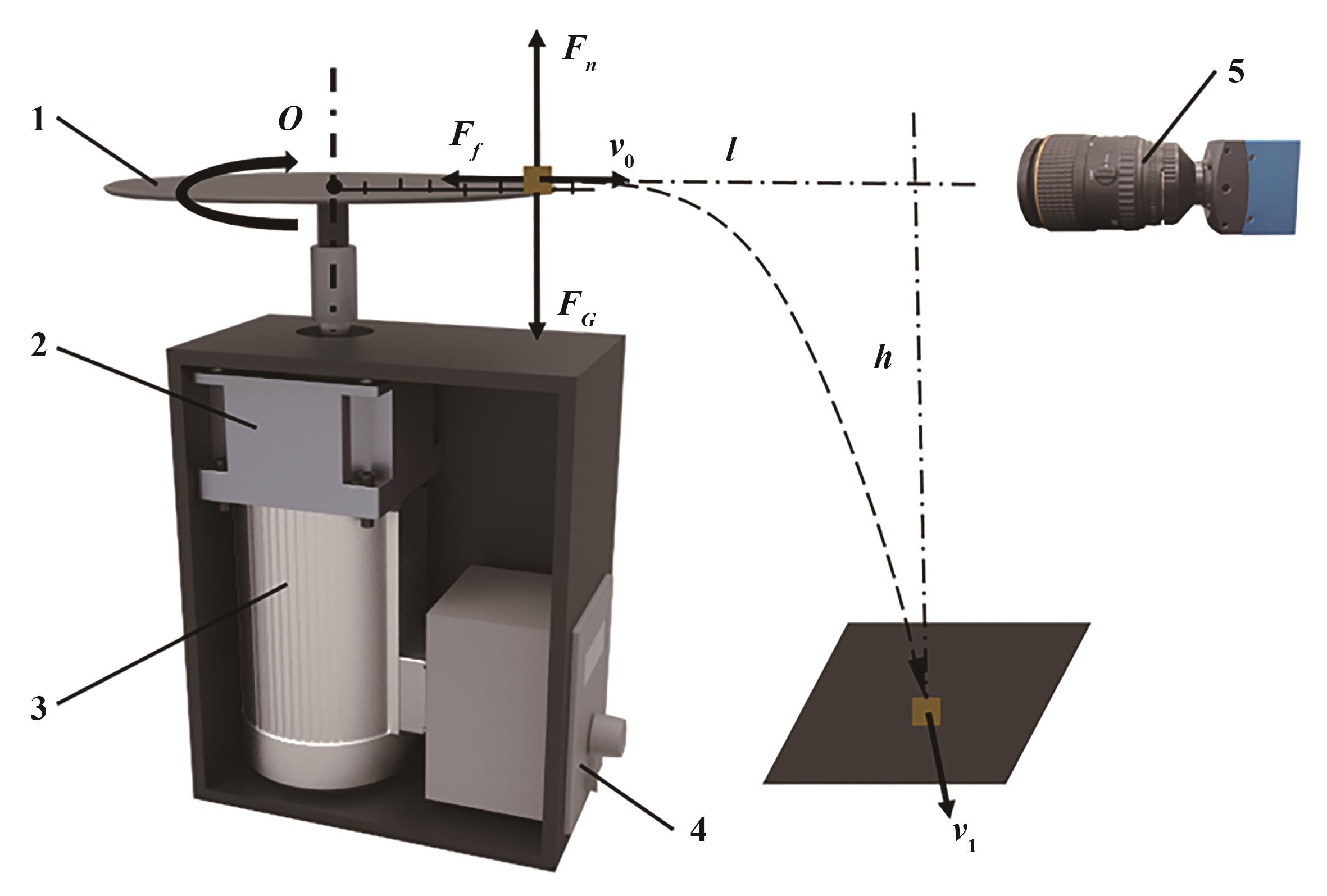

Fig. 1 Coefficient measuring platform and measuring principleNote: 1—Platform (materials could be replaced); 2—Speed reducer; 3—Electrical mach; 4—Speed regulator; 5—Camera with high-speed.

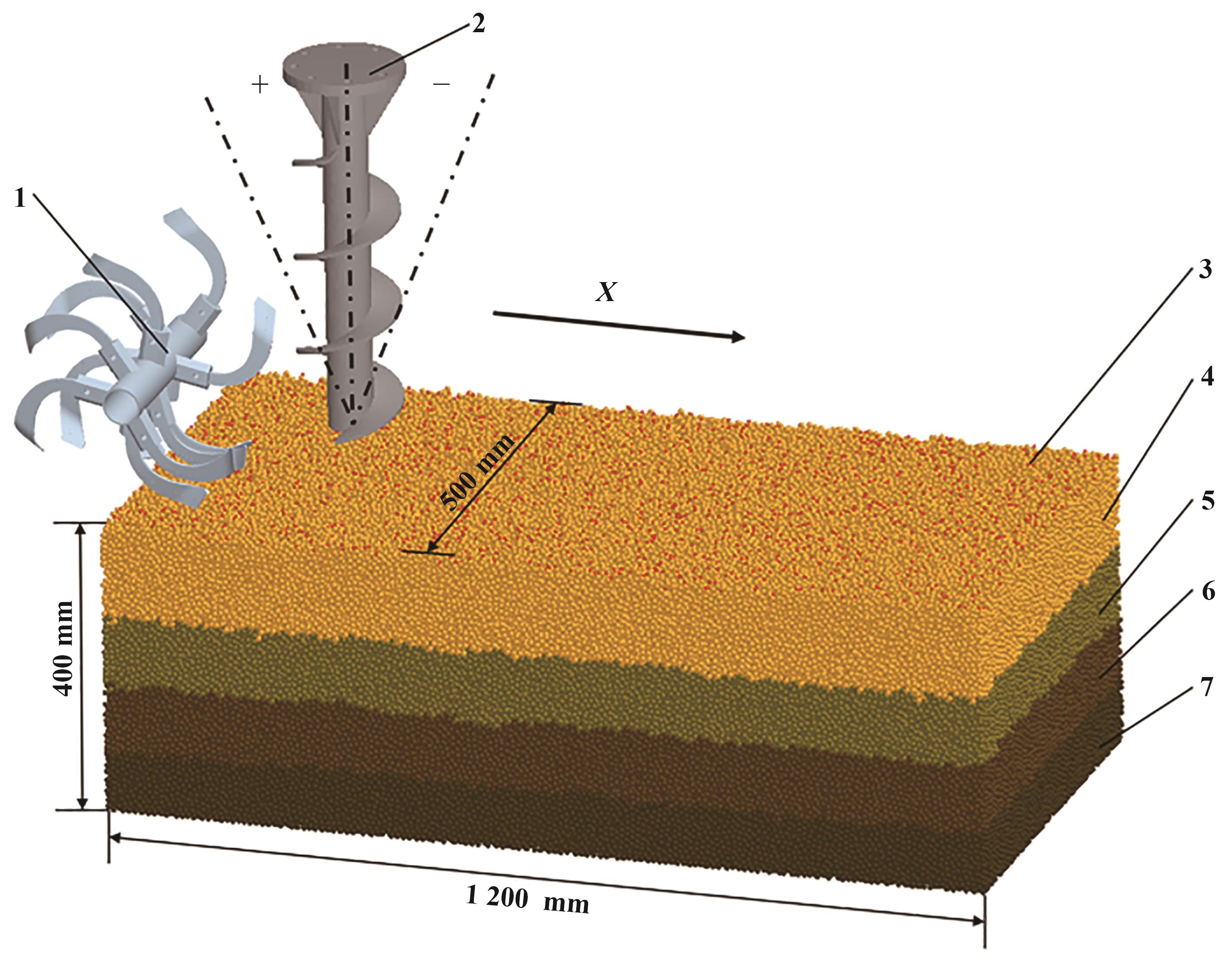

Fig. 2 3D simulation model of tillage processNote: 1—Rotary blade; 2—Powder ridge blade; 3—Fertilizer particles; 4~7 is soil particles at 0—10, 10—20, 20—30, 30—40 cm layers, respectively.

| 耕作方式 Tillage method | 序号 No. | o t a r y s p e e d /(r·min-1) 转速 R | p e e d /(m·s-1) 前进速度 S | n g l e /(°) 倾斜角度 A | 变异系数 Coefficient of variation |

|---|---|---|---|---|---|

| 粉垄耕作 Vertical smashing rotary tillage | 1 | 200(-1) | 0.2(-1) | -10(-1) | 0.766 1 |

| 2 | 400(+1) | 0.2(-1) | -10(-1) | 0.679 6 | |

| 3 | 200(-1) | 0.4(+1) | -10(-1) | 0.766 3 | |

| 4 | 400(+1) | 0.4(+1) | -10(-1) | 0.714 9 | |

| 5 | 200(-1) | 0.2(-1) | 10(+1) | 0.585 0 | |

| 6 | 400(+1) | 0.2(-1) | 10(+1) | 0.685 2 | |

| 7 | 200(-1) | 0.4(+1) | 10(+1) | 0.643 8 | |

| 8 | 400(+1) | 0.4(+1) | 10(+1) | 0.701 4 | |

| 9 | 132(-1.68) | 0.3(0) | 0(0) | 0.872 1 | |

| 10 | 468(+1.68) | 0.3(0) | 0(0) | 0.657 0 | |

| 11 | 300(0) | 0.13(-1.68) | 0(0) | 0.473 2 | |

| 12 | 300(0) | 0.47(+1.68) | 0(0) | 0.567 8 | |

| 13 | 300(0) | 0.3(0) | -16.8(-1.68) | 0.580 7 | |

| 14 | 300(0) | 0.3(0) | 16.8(+1.68) | 0.570 6 |

Tab. 2 Design of optimization test

| 耕作方式 Tillage method | 序号 No. | o t a r y s p e e d /(r·min-1) 转速 R | p e e d /(m·s-1) 前进速度 S | n g l e /(°) 倾斜角度 A | 变异系数 Coefficient of variation |

|---|---|---|---|---|---|

| 粉垄耕作 Vertical smashing rotary tillage | 1 | 200(-1) | 0.2(-1) | -10(-1) | 0.766 1 |

| 2 | 400(+1) | 0.2(-1) | -10(-1) | 0.679 6 | |

| 3 | 200(-1) | 0.4(+1) | -10(-1) | 0.766 3 | |

| 4 | 400(+1) | 0.4(+1) | -10(-1) | 0.714 9 | |

| 5 | 200(-1) | 0.2(-1) | 10(+1) | 0.585 0 | |

| 6 | 400(+1) | 0.2(-1) | 10(+1) | 0.685 2 | |

| 7 | 200(-1) | 0.4(+1) | 10(+1) | 0.643 8 | |

| 8 | 400(+1) | 0.4(+1) | 10(+1) | 0.701 4 | |

| 9 | 132(-1.68) | 0.3(0) | 0(0) | 0.872 1 | |

| 10 | 468(+1.68) | 0.3(0) | 0(0) | 0.657 0 | |

| 11 | 300(0) | 0.13(-1.68) | 0(0) | 0.473 2 | |

| 12 | 300(0) | 0.47(+1.68) | 0(0) | 0.567 8 | |

| 13 | 300(0) | 0.3(0) | -16.8(-1.68) | 0.580 7 | |

| 14 | 300(0) | 0.3(0) | 16.8(+1.68) | 0.570 6 |

| 耕作方式 Tillage method | 序号 No. | o t a r y s p e e d /(r·min-1) 转速 R | p e e d /(m·s-1) 前进速度 S | n g l e /(°) 倾斜角度 A | 变异系数 Coefficient of variation |

|---|---|---|---|---|---|

| 粉垄耕作 Vertical smashing rotary tillage | 15 | 300(0) | 0.3(0) | 0(0) | 0.394 7 |

| 16 | 300(0) | 0.3(0) | 0(0) | 0.369 7 | |

| 17 | 300(0) | 0.3(0) | 0(0) | 0.345 2 | |

| 18 | 300(0) | 0.3(0) | 0(0) | 0.439 7 | |

| 19 | 300(0) | 0.3(0) | 0(0) | 0.449 7 | |

| 20 | 300(0) | 0.3(0) | 0(0) | 0.401 2 | |

| 旋耕耕作 Rotary tillage | 1 | 300(-1) | 0.1(-1) | — | 0.673 4 |

| 2 | 500(+1) | 0.1(-1) | — | 0.727 0 | |

| 3 | 300(-1) | 0.3(+1) | — | 0.618 3 | |

| 4 | 500(+1) | 0.3(+1) | — | 0.526 9 | |

| 5 | 258(-1.68) | 0.2(0) | — | 0.669 7 | |

| 6 | 541(+1.68) | 0.2(0) | — | 0.639 5 | |

| 7 | 400(0) | 0.06(-1.68) | — | 0.637 1 | |

| 8 | 400(0) | 0.34(+1.68) | — | 0.579 5 | |

| 9 | 400(0) | 0.2(0) | — | 0.501 0 | |

| 10 | 400(0) | 0.2(0) | — | 0.530 1 | |

| 11 | 400(0) | 0.2(0) | — | 0.510 9 | |

| 12 | 400(0) | 0.2(0) | — | 0.499 3 | |

| 13 | 400(0) | 0.2(0) | — | 0.529 8 |

Table 2 Design of optimization test

| 耕作方式 Tillage method | 序号 No. | o t a r y s p e e d /(r·min-1) 转速 R | p e e d /(m·s-1) 前进速度 S | n g l e /(°) 倾斜角度 A | 变异系数 Coefficient of variation |

|---|---|---|---|---|---|

| 粉垄耕作 Vertical smashing rotary tillage | 15 | 300(0) | 0.3(0) | 0(0) | 0.394 7 |

| 16 | 300(0) | 0.3(0) | 0(0) | 0.369 7 | |

| 17 | 300(0) | 0.3(0) | 0(0) | 0.345 2 | |

| 18 | 300(0) | 0.3(0) | 0(0) | 0.439 7 | |

| 19 | 300(0) | 0.3(0) | 0(0) | 0.449 7 | |

| 20 | 300(0) | 0.3(0) | 0(0) | 0.401 2 | |

| 旋耕耕作 Rotary tillage | 1 | 300(-1) | 0.1(-1) | — | 0.673 4 |

| 2 | 500(+1) | 0.1(-1) | — | 0.727 0 | |

| 3 | 300(-1) | 0.3(+1) | — | 0.618 3 | |

| 4 | 500(+1) | 0.3(+1) | — | 0.526 9 | |

| 5 | 258(-1.68) | 0.2(0) | — | 0.669 7 | |

| 6 | 541(+1.68) | 0.2(0) | — | 0.639 5 | |

| 7 | 400(0) | 0.06(-1.68) | — | 0.637 1 | |

| 8 | 400(0) | 0.34(+1.68) | — | 0.579 5 | |

| 9 | 400(0) | 0.2(0) | — | 0.501 0 | |

| 10 | 400(0) | 0.2(0) | — | 0.530 1 | |

| 11 | 400(0) | 0.2(0) | — | 0.510 9 | |

| 12 | 400(0) | 0.2(0) | — | 0.499 3 | |

| 13 | 400(0) | 0.2(0) | — | 0.529 8 |

| 属性参数 Property parameter | 土壤 Soil | 化肥 Fertilizer | 刀具 Blade | |||

|---|---|---|---|---|---|---|

| 0—10 cm | 10—20 cm | 20—30 cm | 30—40 cm | |||

| 弹性模量 Elastic modulus | 1.820 1×107 | 5.248 4×107 | 6.004 1×107 | 10.457 8×107 | 7.9×1010 | 2.05×1011 |

| 剪切模量 Shear modulus | 0.719 5×107 | 2.016 3×107 | 2.173 7×107 | 3.79 67×107 | 3.16×1010 | 7.9×1010 |

| 泊松比 Poisson ratio | 0.26 | 0.30 | 0.38 | 0.38 | 0.25 | 0.3 |

e n s i t y /(kg·cm-3) 密度 D | 1 414 | 1 559 | 1 602 | 1 613 | 1 670 | 7 861 |

| 含水率 Water content/% | 17.71 | 18.79 | 18.83 | 18.66 | — | — |

Table 3 Material property parameter

| 属性参数 Property parameter | 土壤 Soil | 化肥 Fertilizer | 刀具 Blade | |||

|---|---|---|---|---|---|---|

| 0—10 cm | 10—20 cm | 20—30 cm | 30—40 cm | |||

| 弹性模量 Elastic modulus | 1.820 1×107 | 5.248 4×107 | 6.004 1×107 | 10.457 8×107 | 7.9×1010 | 2.05×1011 |

| 剪切模量 Shear modulus | 0.719 5×107 | 2.016 3×107 | 2.173 7×107 | 3.79 67×107 | 3.16×1010 | 7.9×1010 |

| 泊松比 Poisson ratio | 0.26 | 0.30 | 0.38 | 0.38 | 0.25 | 0.3 |

e n s i t y /(kg·cm-3) 密度 D | 1 414 | 1 559 | 1 602 | 1 613 | 1 670 | 7 861 |

| 含水率 Water content/% | 17.71 | 18.79 | 18.83 | 18.66 | — | — |

| 接触材料 Contact material | 接触参数 Contact parameter | ||

|---|---|---|---|

| 碰撞恢复系数 Coefficient of restitution | 滑动摩擦系数 Dynamic friction factor | 滚动摩擦系数 Coefficient of rolling friction | |

| 土壤-土壤 Soil-soil | 0.103 3 | 0.894 7 | 0.153 5 |

| 土壤-刀具 Soil-blade | 0.139 0 | 0.827 9 | 0.158 4 |

| 化肥-土壤 Fertilizer-soil | 0.066 5 | 0.908 2 | 0.640 0 |

| 化肥-刀具 Fertilizer-blade | 0.293 3 | 0.590 1 | 0.480 5 |

Table 4 Material contact parameter

| 接触材料 Contact material | 接触参数 Contact parameter | ||

|---|---|---|---|

| 碰撞恢复系数 Coefficient of restitution | 滑动摩擦系数 Dynamic friction factor | 滚动摩擦系数 Coefficient of rolling friction | |

| 土壤-土壤 Soil-soil | 0.103 3 | 0.894 7 | 0.153 5 |

| 土壤-刀具 Soil-blade | 0.139 0 | 0.827 9 | 0.158 4 |

| 化肥-土壤 Fertilizer-soil | 0.066 5 | 0.908 2 | 0.640 0 |

| 化肥-刀具 Fertilizer-blade | 0.293 3 | 0.590 1 | 0.480 5 |

| 参数 Parameter | 土层 Soil layer/cm | ||||

|---|---|---|---|---|---|

| 10—20 | 20—30 | 30—40 | |||

| 法向接触刚度 Normal contact stiffness/(N·m-3) | 5.44×107 | 6.22×107 | 1.08×108 | ||

| 切向接触刚度 Tangential contact stiffness/(N·m-3) | 3.63×107 | 4.15×107 | 7.22×107 | ||

| 法向临界应力 Normal critical stress/Pa | 18 776.67 | 30 949.74 | 41 502.30 | ||

| 切向临界应力 Tangential critical stress/Pa | 12 517.78 | 20 633.16 | 27 668.20 | ||

| 土壤颗粒黏结半径 Bonding radius/mm | — | 4.386 3 | — | ||

| 生成黏结键总数 Total number of bonding bonds | — | 1 294 607 | — | ||

Table 5 Bonding model parameter

| 参数 Parameter | 土层 Soil layer/cm | ||||

|---|---|---|---|---|---|

| 10—20 | 20—30 | 30—40 | |||

| 法向接触刚度 Normal contact stiffness/(N·m-3) | 5.44×107 | 6.22×107 | 1.08×108 | ||

| 切向接触刚度 Tangential contact stiffness/(N·m-3) | 3.63×107 | 4.15×107 | 7.22×107 | ||

| 法向临界应力 Normal critical stress/Pa | 18 776.67 | 30 949.74 | 41 502.30 | ||

| 切向临界应力 Tangential critical stress/Pa | 12 517.78 | 20 633.16 | 27 668.20 | ||

| 土壤颗粒黏结半径 Bonding radius/mm | — | 4.386 3 | — | ||

| 生成黏结键总数 Total number of bonding bonds | — | 1 294 607 | — | ||

| 耕作方式 Tillage method | 变异来源 Variation source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | P值P value |

|---|---|---|---|---|---|

| 粉垄耕作Vertical smashing rotary tillage | 模型 Model | 0.39 | 9 | 0.043 | 0.000 3** |

| A | 9.97×10-3 | 1 | 9.97×10-3 | 0.131 6 | |

| B | 6.44×10-3 | 1 | 6.44×10-3 | 0.216 4 | |

| C | 9.26×10-3 | 1 | 9.26×10-3 | 0.144 5 | |

| AB | 4.71×10-5 | 1 | 4.71×10-5 | 0.912 4 | |

| AC | 9.02×10-3 | 1 | 9.02×10-3 | 0.149 3 | |

| BC | 5.57×10-4 | 1 | 5.57×10-4 | 0.706 1 | |

| A2 | 0.290 | 1 | 0.290 | <0.000 1** | |

| B2 | 0.043 | 1 | 0.043 | 0.006 8** | |

| C2 | 0.079 | 1 | 0.079 | 0.001 0** | |

| 失拟项 Lack term | 0.029 | 5 | 5.79×10-3 | 0.092 1 | |

| 纯误差 Pure error | 8.00×10-3 | 5 | 1.60×10-3 | ||

| 旋耕耕作Rotary tillage | 模型 Model | 0.066 | 5 | 0.013 | 0.000 5** |

| A | 8.12×10-4 | 1 | 8.12×10-4 | 0.309 5 | |

| B | 0.014 | 1 | 0.014 | 0.002 6** | |

| AB | 5.25×10-3 | 1 | 5.25×10-3 | 0.027 1* | |

| A2 | 0.035 | 1 | 0.035 | 0.000 2** | |

| B2 | 0.016 | 1 | 0.016 | 0.001 8** | |

| 失拟项 Lack term | 3.83×10-3 | 3 | 1.28×10-3 | 0.237 8 | |

| 纯误差 Pure error | 9.045×10-4 | 4 | 2.26×10-4 |

Table 6 Model analysis of variance

| 耕作方式 Tillage method | 变异来源 Variation source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | P值P value |

|---|---|---|---|---|---|

| 粉垄耕作Vertical smashing rotary tillage | 模型 Model | 0.39 | 9 | 0.043 | 0.000 3** |

| A | 9.97×10-3 | 1 | 9.97×10-3 | 0.131 6 | |

| B | 6.44×10-3 | 1 | 6.44×10-3 | 0.216 4 | |

| C | 9.26×10-3 | 1 | 9.26×10-3 | 0.144 5 | |

| AB | 4.71×10-5 | 1 | 4.71×10-5 | 0.912 4 | |

| AC | 9.02×10-3 | 1 | 9.02×10-3 | 0.149 3 | |

| BC | 5.57×10-4 | 1 | 5.57×10-4 | 0.706 1 | |

| A2 | 0.290 | 1 | 0.290 | <0.000 1** | |

| B2 | 0.043 | 1 | 0.043 | 0.006 8** | |

| C2 | 0.079 | 1 | 0.079 | 0.001 0** | |

| 失拟项 Lack term | 0.029 | 5 | 5.79×10-3 | 0.092 1 | |

| 纯误差 Pure error | 8.00×10-3 | 5 | 1.60×10-3 | ||

| 旋耕耕作Rotary tillage | 模型 Model | 0.066 | 5 | 0.013 | 0.000 5** |

| A | 8.12×10-4 | 1 | 8.12×10-4 | 0.309 5 | |

| B | 0.014 | 1 | 0.014 | 0.002 6** | |

| AB | 5.25×10-3 | 1 | 5.25×10-3 | 0.027 1* | |

| A2 | 0.035 | 1 | 0.035 | 0.000 2** | |

| B2 | 0.016 | 1 | 0.016 | 0.001 8** | |

| 失拟项 Lack term | 3.83×10-3 | 3 | 1.28×10-3 | 0.237 8 | |

| 纯误差 Pure error | 9.045×10-4 | 4 | 2.26×10-4 |

| 耕作方式 Tillage method | 土层 Soil layer/cm | 仿真化肥颗粒数 Number of simulated fertilizer particles | 每层占比 Proportion/% | 实际化肥颗粒数 Actual number of fertilizer particles | 每层占比 Proportion/% | 误差 Error/% |

|---|---|---|---|---|---|---|

| 旋耕 Rotary tillage | 0—10 | 88 | 55.70 | 293 | 60.16 | 4.47 |

| 10—20 | 62 | 39.24 | 149 | 30.60 | 8.65 | |

| 20—30 | 8 | 5.06 | 45 | 9.24 | 4.18 | |

| 粉垄 Vertical smashing rotary tillage | 0—10 | 60 | 41.67 | 150 | 33.63 | 8.03 |

| 10—20 | 48 | 33.33 | 159 | 35.65 | 2.32 | |

| 20—30 | 27 | 18.75 | 81 | 18.16 | 0.59 | |

| 30—40 | 9 | 6.25 | 56 | 12.56 | 6.31 |

Tab. 7 Simulation and verification results of fertilizer particle distribution

| 耕作方式 Tillage method | 土层 Soil layer/cm | 仿真化肥颗粒数 Number of simulated fertilizer particles | 每层占比 Proportion/% | 实际化肥颗粒数 Actual number of fertilizer particles | 每层占比 Proportion/% | 误差 Error/% |

|---|---|---|---|---|---|---|

| 旋耕 Rotary tillage | 0—10 | 88 | 55.70 | 293 | 60.16 | 4.47 |

| 10—20 | 62 | 39.24 | 149 | 30.60 | 8.65 | |

| 20—30 | 8 | 5.06 | 45 | 9.24 | 4.18 | |

| 粉垄 Vertical smashing rotary tillage | 0—10 | 60 | 41.67 | 150 | 33.63 | 8.03 |

| 10—20 | 48 | 33.33 | 159 | 35.65 | 2.32 | |

| 20—30 | 27 | 18.75 | 81 | 18.16 | 0.59 | |

| 30—40 | 9 | 6.25 | 56 | 12.56 | 6.31 |

| 1 | 吴建富,王海辉,刘经荣,等.长期施用不同肥料稻田土壤养分的剖面分布特征[J].江西农业大学学报,2001, 23(1): 54-56. |

| WU J F, WANG H H, LIU J R, et al.. The characters of the profile distribution of nutrients in rice fields after long-term application of different fertilizers [J]. J. Jiangxi Agric. Univ., 2001, 23(1): 54-56. | |

| 2 | 杨庆璐,黄幸媛,王庆杰,等.玉米空间分层施肥装置结构优化与试验[J].农业机械学报,2020, 51(S1): 175-185. |

| YANG Q L, HUANG X Y, WANG Q J, et al.. Structure optimization and experiment of corn layered fertilization device [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(S1): 175-185. | |

| 3 | ZHANG J, LI F, LIAO P, et al.. Smash ridge tillage strongly influence soil functionality, physiology and rice yield [J]. Saudi J. Biol. Sci., 2020, 28(2), 1297-1307. |

| 4 | 韦本辉,申章佑,周佳,等.粉垄耕作改良盐碱地效果及机理[J].土壤,2020, 52(4):699-703. |

| WEI B H, SHEN Z Y, ZHOU J, et al.. Study on effect and mechanism of improving saline-alkali soil by fenlong tillage [J]. Soils, 2020, 52(4): 699-703. | |

| 5 | 韦本辉,吴延勇,甘秀芹,等.粉垄栽培甘蔗试验增产效果[J].中国农业科学,2011, 44(21): 4544-4550. |

| WEI B H, WU Y Y, GAN X Q, et al.. Yield increase of smash-ridging cultivation of sugarcane [J]. Sci. Agric. Sin., 2011, 44(21): 4544-4550. | |

| 6 | 石丽红,李超,唐海明,等.长期施肥方式对双季稻根系生理特性与产量的影响[J].中国农业大学学报 2021, 26(9): 18-29. |

| SHI L H, LI C, TANG H M, et al.. Effects of different long-term fertilizer management on physiological characteristic of root and yield of rice in double-cropping rice paddy field [J]. J. Chin. Agric. Univ. 2021, 26(9): 18-29. | |

| 7 | 张拥兵,黄军保,李卓,等.限根栽培下不同施肥方式对葡萄果实品质的影响 [J].山西农业科学,2021,49(9): 1110-1113. |

| ZHANG Y B, HUANG J B, LI Z, et al.. Effects of different fertilizer treatments on grape fruit quality under root restriction cultivation [J]. J. Shanxi Agric. Sci., 2021, 49(9): 1110-1113. | |

| 8 | 雷金银,雷晓婷,周丽娜,等.耕作措施对缓坡耕地土壤养分分布及肥料利用率的影响[J].农业工程学报,2020, 36(18): 127-134. |

| LEI J Y, LEI X T, ZHOU L N, et al.. Effects of tillage measures on soil nutrients distribution and fertilizer use efficiency on gentle slope farmland [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(18): 127-134. | |

| 9 | 李超,施伟,姚应方,等.基于离散元的间歇式施肥器的施肥过程[J].江苏农业科学,2021, 49(1): 166-170. |

| LI C, SHI W, YAO Y F, et al.. Fertilization process of batch fertilizer applicator based on discrete element method [J]. Jiangsu Agric. Sci., 2021, 49(1): 166-170. | |

| 10 | 赵春,吴雪梅.基于EDEM离散元法的土肥混合过程分析[J].中国农机化学报,2019, 40(7): 178-182. |

| ZHAO C, WU X M. Analysis of soil fertilizer mixing process based on EDEM discrete element method [J]. J. Chin. Agric. Mechan., 2019, 40(7): 178-182. | |

| 11 | 刘彩玲,黎艳妮,宋建农,等.基于EDEM的离心甩盘撒肥器性能分析与试验[J].农业工程学报,2017,33(14): 32-39. |

| LIU C L, LI Y N, SONG J N, et al.. Performance analysis and experiment on fertilizer spreader with centrifugal swing disk based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(14): 32-39. | |

| 12 | 曾智伟,马旭,曹秀龙,等.离散元法在农业工程研究中的应用现状和展望[J].农业机械学报,2021,52(4): 1-20. |

| ZENG Z W, MA X, CAO X L, et al.. Critical review of applications of discrete element method in agricultural engineering [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(4): 1-20. | |

| 13 | 赵淑红,刘汉朋,侯磊涛,等.基于离散元法的免耕深施肥分段式玉米播种开沟器研制[J].农业工程学报,2021, 37(13): 1-10. |

| ZHAO S H, LIU H P, HOU L T, et al.. Development of deep fertilizing no-tillage segmented maize sowing opener using discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(13): 1-10. | |

| 14 | 胡建平,赵军,潘浩然,等.基于离散元的双轴旋耕机功耗预测模型[J].农业机械学报,2020, 51(S1): 9-16. |

| HU J P, ZHAO J, PAN H R, et al.. Prediction model of double axis rotary power consumption based on discrete element method [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(S1): 9-16. | |

| 15 | 祝英豪,夏俊芳,曾荣,等.基于离散元的稻板田旋耕功耗预测模型研究[J].农业机械学报,2020, 51(10): 42-50. |

| ZHU Y H, XIA J F, ZENG R, et al.. Prediction model of rotary tillage power consumption in paddy stubble field based on discrete element method [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(10): 42-50. | |

| 16 | 周华,李栋,刘政源,等.秸秆旋埋还田后空间分布效果仿真与试验[J].农业机械学报,2019, 50(9): 69-77. |

| ZHOU H, LI D, LIU Z Y, et al.. Simulation and experiment of spatial distribution effect after straw incorporation into soil by rotary burial [J]. Trans. Chin. Soc. Agric. Mach., 2019, 50(9): 69-77. | |

| 17 | 熊平原,杨洲,孙志全,等.基于离散元法的旋耕刀三向工作阻力仿真分析与试验[J].农业工程学报,2018, 34(18): 113-121. |

| XIONG P Y, YANG Z, SUN Z Q, et al.. Simulation analysis and experiment for three-axis working resistances of rotary blade based on discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(18): 113-121. | |

| 18 | 方会敏,姬长英,张庆怡,等.基于离散元法的旋耕刀受力分析[J].农业工程学报,2016, 32(21): 54-59. |

| FANG H M, JI C Y, ZHANG Q Y, et al.. Force analysis of rotary blade based on distinct element method [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(21): 54-59. | |

| 19 | 郝文录,刘恒新,朱良,等. 农业机械试验条件 测定方法的一般规定: [S].北京:中国标注出版社,2008. |

| 20 | SHI Y Y, XIN S, WANG X C, et al.. Numerical simulation and field tests of minimum-tillage planter with straw smashing and strip laying based on EDEM software [J]. Comput. Electron. Agric., 2019, 166: 105021. |

| 21 | 鲍士旦.土壤农化分析[M].第3版.北京:中国农业出版社,2000:1-495. |

| 22 | 石林榕,赵武云,孙伟.基于离散元的西北旱区农田土壤颗粒接触模型和参数标定[J].农业工程学报,2017, 33(21): 181-187. |

| SHI L R, ZHAO W Y, SUN W. Parameter calibration of soil particles contact model of farmland soil in northwest arid region based on discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(21): 181-187. | |

| 23 | 王宪良,胡红,王庆杰,等.基于离散元的土壤模型参数标定方法[J].农业机械学报,2017, 48(12): 78-85. |

| WANG X L, HU H, WANG Q J, et al.. Calibration method of soil contact characteristic parameters based on DEM theory [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(12): 78-85. | |

| 24 | 石林榕,吴建民,赵武云,等.基于离散单元法农田土壤单轴压缩模型的建立及参数校核[J].中国农业大学学报,2015, 20(4): 174-182. |

| SHI L R, WU J M, ZHAO W Y, et al.. Establishment and parameter verification of farmland soil model in uniaxial compression based on discrete element method [J]. J. Chin. Agric. Univ., 2015, 20(4): 174-182. | |

| 25 | 孙景彬,刘琪,杨福增,等.黄土高原坡地土壤与旋耕部件互作离散元仿真参数标定[J].农业机械学报,2022, 53(1): 63-73. |

| SUN J B, LIU Q, YANG F Z, et al.. Calibration of discrete element simulation parameters of sloping soil on loess plateau and its interaction with rotary tillage components [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(1): 63-73. | |

| 26 | UCGUL M, SAUNDERS C. Simulation of tillage forces and furrow profile during soil-mouldboard plough interaction using discrete element modelling [J]. Biosyst. Eng., 2020, 190:58-70. |

| 27 | 张锋伟,宋学锋,张雪坤,等.玉米秸秆揉丝破碎过程力学特性仿真与试验[J].农业工程学报,2019, 35(9): 58-65. |

| ZHANG F W, SONG X F, ZHANG X K, et al.. Simulation and experiment on mechanical characteristics of kneading and crushing process of corn straw [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(9): 58-65. | |

| 28 | 郝建军,龙思放,李浩,等.机收麻山药离散元模型构建及其仿真参数标定[J].农业工程学报,2019, 35(20): 34-42. |

| HAO J J, LONG S F, LI H, et al.. Development of discrete element model and calibration of simulation parameters for mechanically-harvested yam [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(20): 34-42. | |

| 29 | 肖茂华,汪开鑫,杨望,等.基于东方蝼蛄爪趾的仿生旋耕刀设计与试验[J].农业机械学报,2021, 52(2): 55-63. |

| XIAO M H, WANG K X, YANG W, et al.. Design and experiment of bionic rotary blade based on claw toe of Gryllotalpa orientalis Burmeister [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(2): 55-63. | |

| 30 | 郝建军,龙思放,李建昌,等.麻山药种植田砂壤土流动性离散元模型颗粒放尺效应[J].农业工程学报,2020, 36(21): 56-64. |

| HAO J J, LONG S F, LI J C, et al.. Effect of granular ruler in discrete element model of sandy loam fluidity in Ma yam planting field [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(21): 56-64. | |

| 31 | MAKANGE N R. Prediction of cutting forces and soil behavior with discrete element simulation [J]. Comput. Electron. Agric., 2020, 179: 105848. |

| 32 | 陈新予,史宇亮,陈明东.基于离散元法的甘薯起垄机旋耕刀抛土性能仿真试验[J].农业工程,2021,11(2): 117-120. |

| CHEN X Y, SHI Y L, CHEN M D. Simulation experiment on throwing performance of rotary blade of sweet potato ridger based on discrete element method [J]. Agric. Eng., 2021, 11(2): 117-120. | |

| 33 | 鲍洋清.基于DEM的新型仿生深松铲的研制[D].泰安:山东农业大学,2018. |

| BAO Y Q. Development of a new bionic subsoiler based on DEM [D]. Tai’an: Shandong Agricultural University, 2018. | |

| 34 | 高亮.基于DEM法的旋耕刀具耕作过程分析与研究[D].石家庄:河北科技大学,2017. |

| GAO L. The analysis and research about rotary knife cultivation process based on DEM [D]. Shijiazhuang: Hebei University of Science & Technology, 2017. |

| [1] | Hongbo WANG, Zhipeng FAN, Wulantuya, Chunguang WANG, Zhe MA. Parameter Calibration of Discrete Element Model for Simulation of Crushed Corn Stalk Screw Conveying [J]. Journal of Agricultural Science and Technology, 2023, 25(3): 96-106. |

| [2] | Jianwei YAN, Song WEI, Dongjun HU, Qihe LIU, Fuigui ZHANG. Parameter Calibration of Radish Seeds with Different Filling Particle Radius by DEM [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 119-128. |

| [3] | XIANG Wei1,2, WU Mingliang1*, LYU Jiangnan2, MA Lan2, QUAN Wei1, LIU Jiajie2, XIAO Le3. Simulation and Experiment on Hole-forming Performance of Hole-forming Mechanism for Rape Seedling Transplanting Based on EDEM [J]. Journal of Agricultural Science and Technology, 2019, 21(7): 70-81. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号