Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (1): 181-192.DOI: 10.13304/j.nykjdb.2023.0384

• FOOD QUALITY & PROCESSING AND STORAGE • Previous Articles

Xue WANG( ), Xing ZHENG(

), Xing ZHENG( ), Jiamiao REN, Yazhou ZHAO, Wenjun PENG(

), Jiamiao REN, Yazhou ZHAO, Wenjun PENG( )

)

Received:2023-05-17

Accepted:2024-01-17

Online:2025-01-15

Published:2025-01-21

Contact:

Wenjun PENG

通讯作者:

彭文君

作者简介:王雪 E-mail:wangxue41996@163.com基金资助:CLC Number:

Xue WANG, Xing ZHENG, Jiamiao REN, Yazhou ZHAO, Wenjun PENG. Optimization of Extraction Conditions for Volatile Components in Jujube Honey Based on Plackett-Burman Design and Response Surface Method[J]. Journal of Agricultural Science and Technology, 2025, 27(1): 181-192.

王雪, 郑星, 任佳淼, 赵亚周, 彭文君. 基于Plackett-Burman设计和响应面法优化枣花蜂蜜挥发性成分的萃取条件[J]. 中国农业科技导报, 2025, 27(1): 181-192.

指标 Index | 波美度 Baume | 固形物含量 Solid content/(g·100 g-1) | 水分含量 Moisture content/% | pH |

|---|---|---|---|---|

| 值Value | 42.80±0.10 | 81.20±0.10 | 17.10±0.20 | 3.63±0.05 |

Table 1 Basic Physical and Chemical Indicators of Jujube Honey Samples

指标 Index | 波美度 Baume | 固形物含量 Solid content/(g·100 g-1) | 水分含量 Moisture content/% | pH |

|---|---|---|---|---|

| 值Value | 42.80±0.10 | 81.20±0.10 | 17.10±0.20 | 3.63±0.05 |

| 因素Factor | 水平Level | |

|---|---|---|

| -1 | +1 | |

A:萃取温度 Extraction temperature/℃ | 50 | 70 |

B:萃取时间 Extraction time/min | 40 | 60 |

C:样品量 Sample amount/g | 4 | 6 |

D:去离子水添加量 Addition of deionized water/g | 0.0 | 1.0 |

E:氯化钠添加量 Addition of sodium chloride/g | 0.0 | 0.6 |

F:搅拌速度 Stirring speed/(r·min-1) | 500 | 800 |

Table 2 Plackett-Burman experimental design

| 因素Factor | 水平Level | |

|---|---|---|

| -1 | +1 | |

A:萃取温度 Extraction temperature/℃ | 50 | 70 |

B:萃取时间 Extraction time/min | 40 | 60 |

C:样品量 Sample amount/g | 4 | 6 |

D:去离子水添加量 Addition of deionized water/g | 0.0 | 1.0 |

E:氯化钠添加量 Addition of sodium chloride/g | 0.0 | 0.6 |

F:搅拌速度 Stirring speed/(r·min-1) | 500 | 800 |

| 因素Factor | 水平Level | ||

|---|---|---|---|

| -1 | 0 | 1 | |

A:萃取温度 Extraction temperature/℃ | 50 | 60 | 70 |

B:萃取时间 Extraction time/min | 40 | 50 | 60 |

C:样品量 Sample amount/g | 4 | 5 | 6 |

Table 3 Level of respond surface analysis expermental factor

| 因素Factor | 水平Level | ||

|---|---|---|---|

| -1 | 0 | 1 | |

A:萃取温度 Extraction temperature/℃ | 50 | 60 | 70 |

B:萃取时间 Extraction time/min | 40 | 50 | 60 |

C:样品量 Sample amount/g | 4 | 5 | 6 |

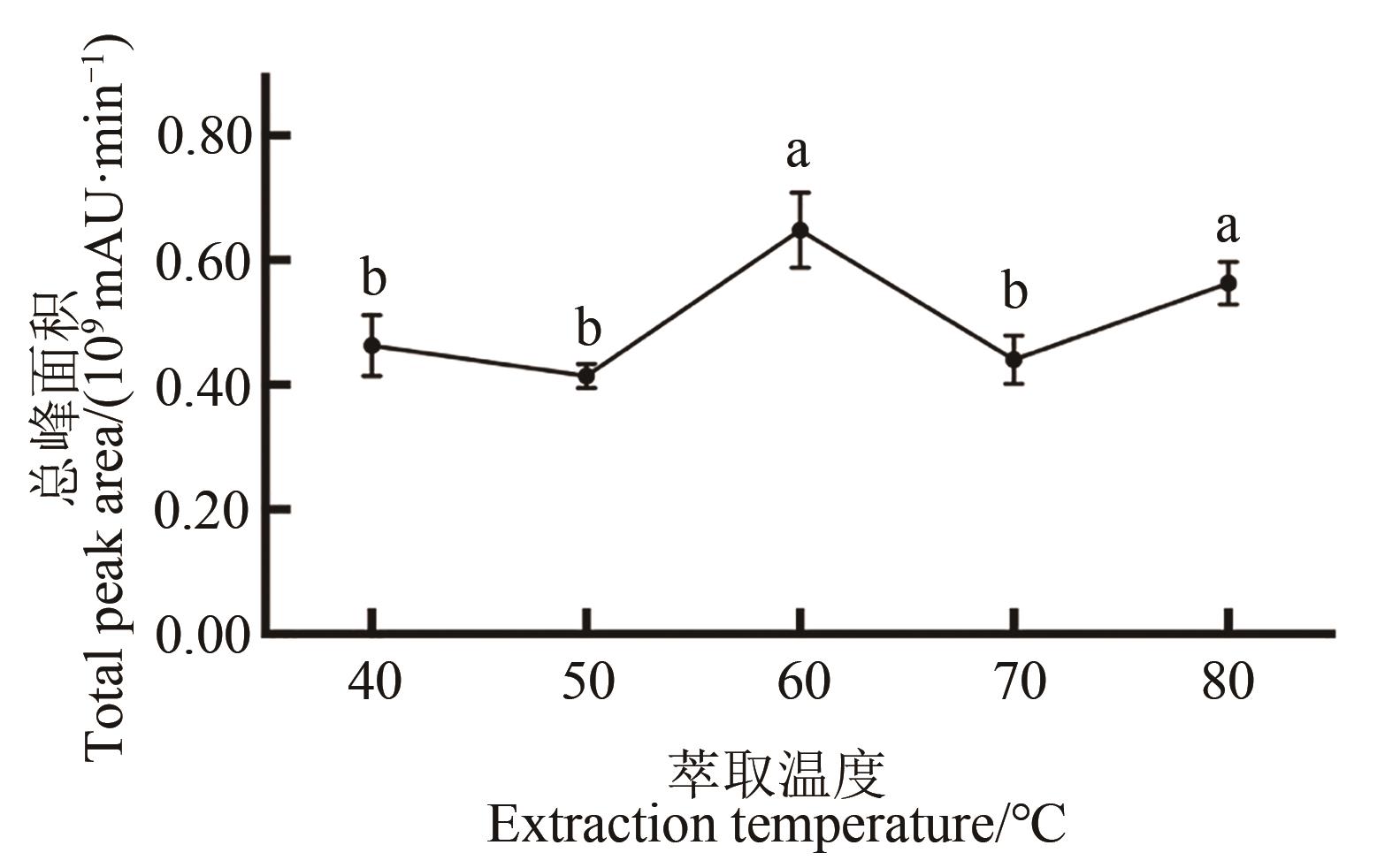

Fig. 1 Extraction effect of volatile substances of jujube honey under different extraction temperaturesNote:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

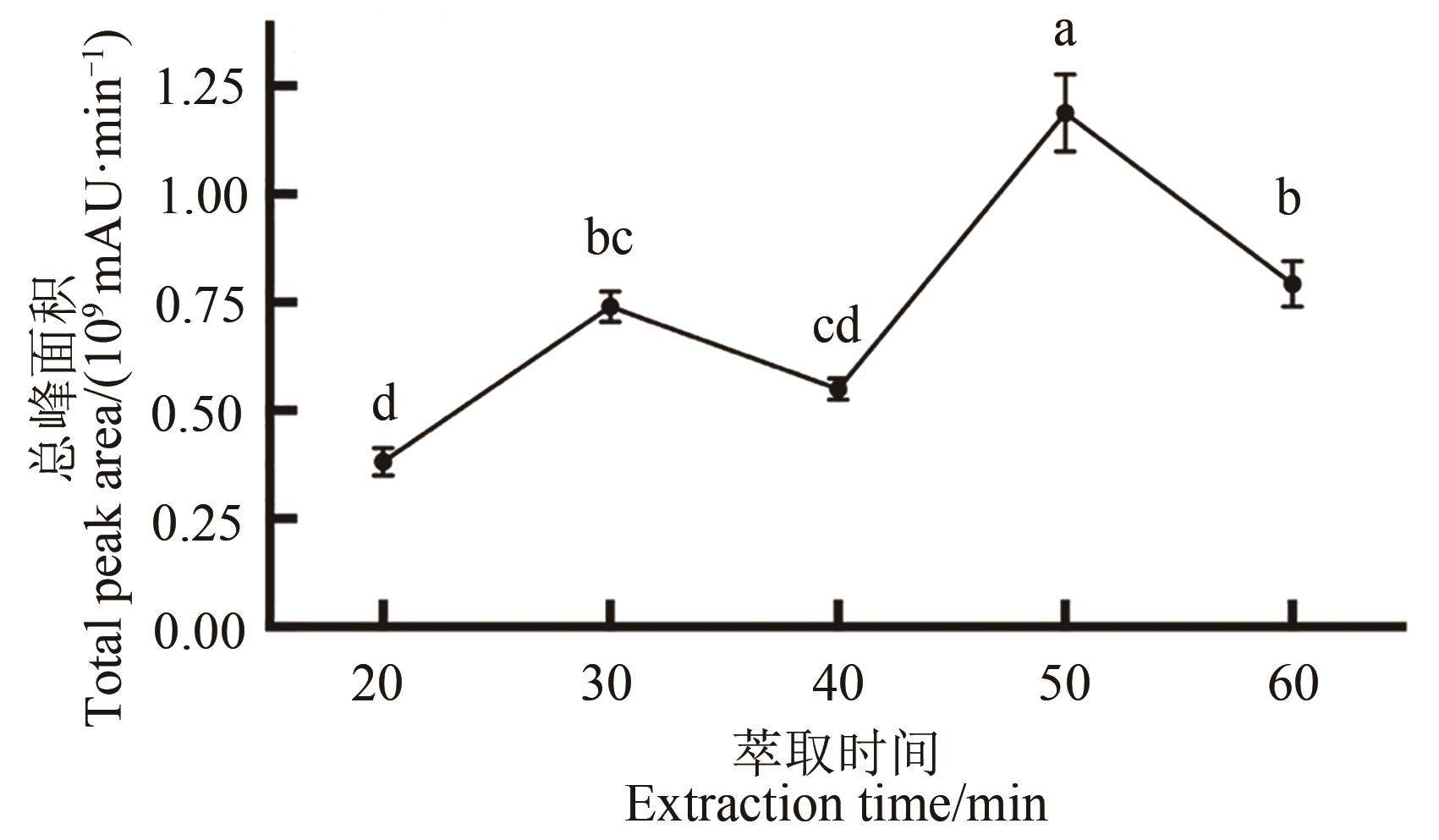

Fig. 2 Extraction effect of volatiles substances of jujube honey under different extraction timesNote:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

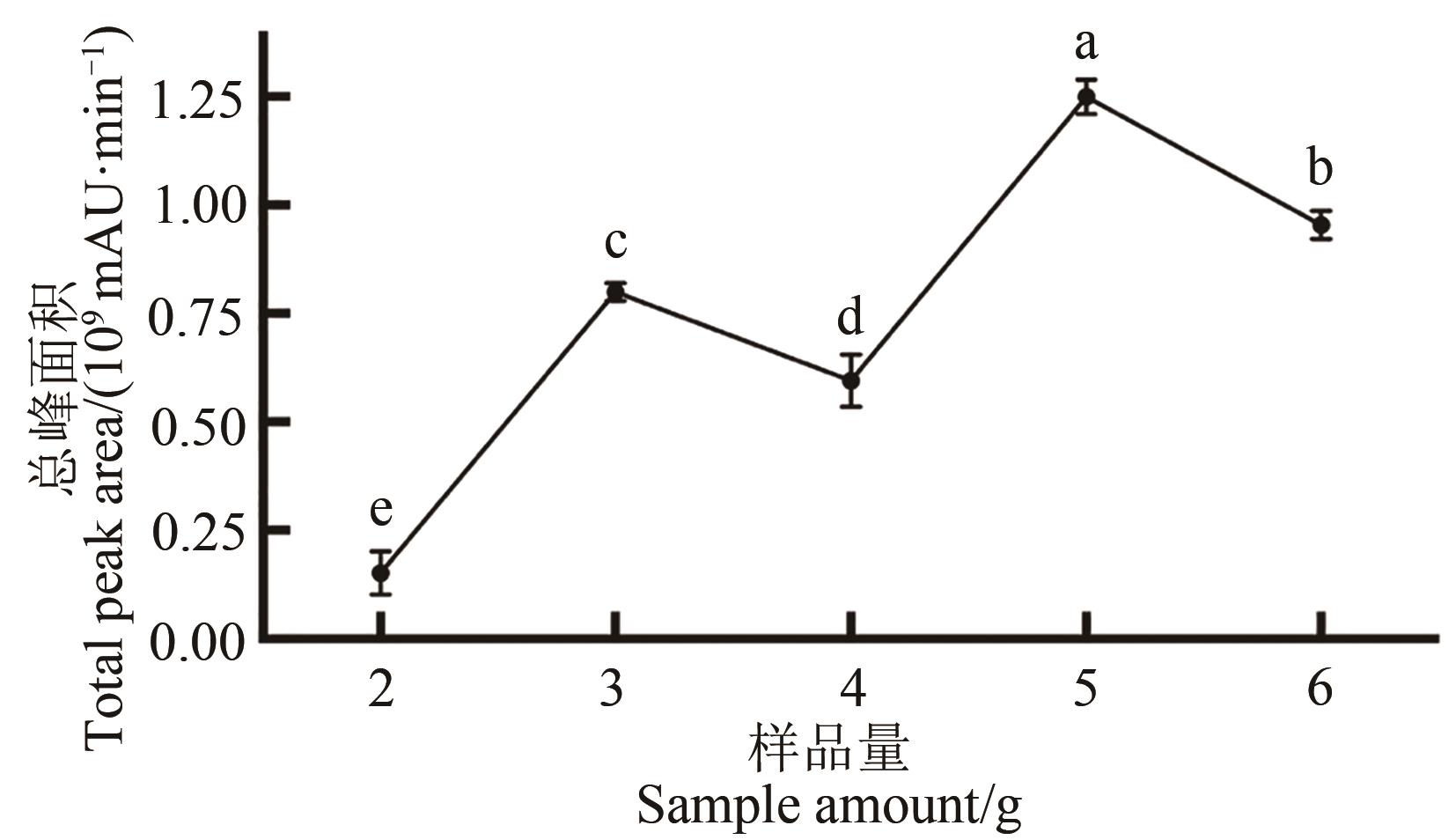

Fig. 3 Extraction effect of volatile substances of jujube honey under different sample amountsNote:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

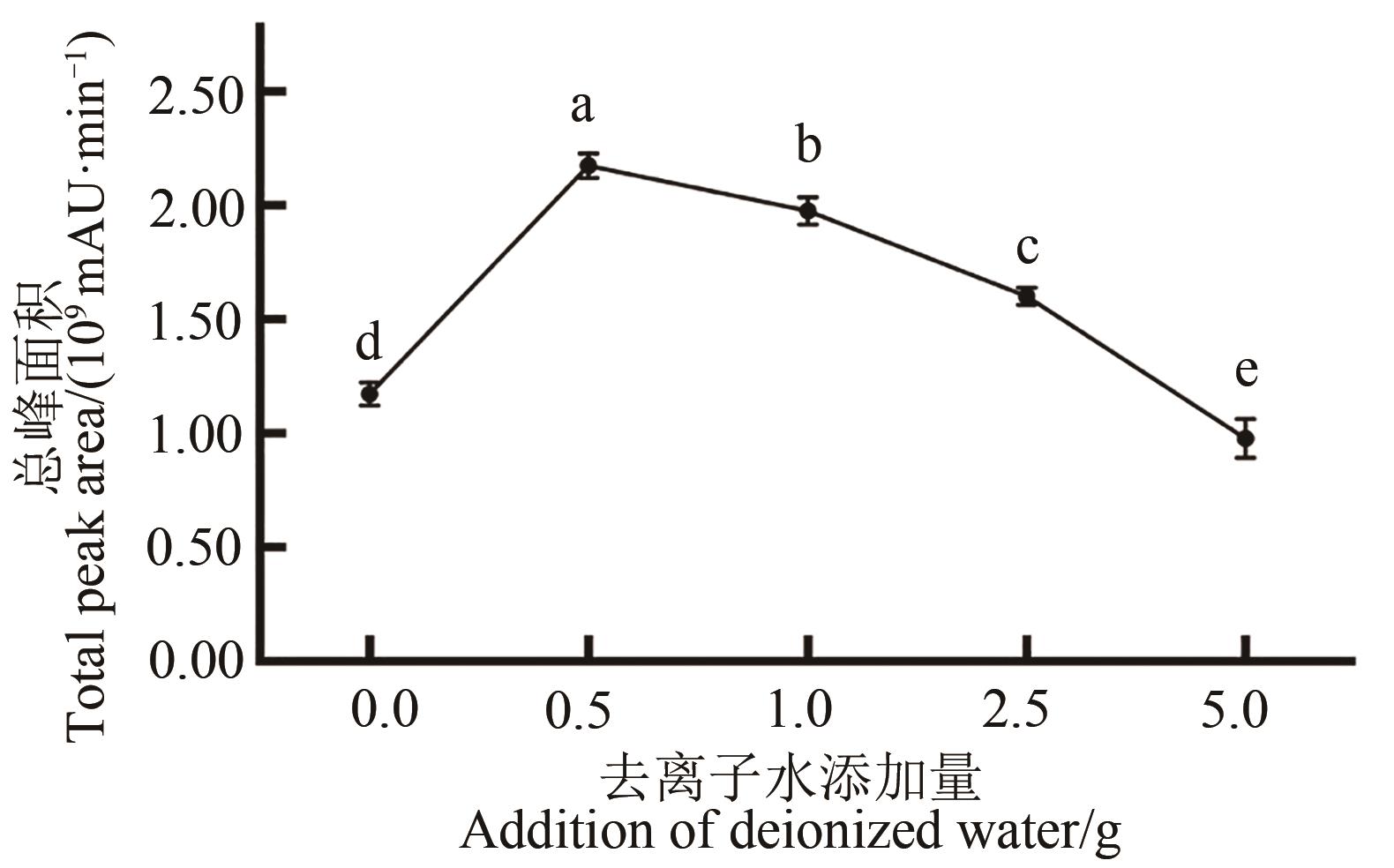

Fig. 4 Extraction effect of volatile substances of jujube honey under different deionized water additionsNote:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

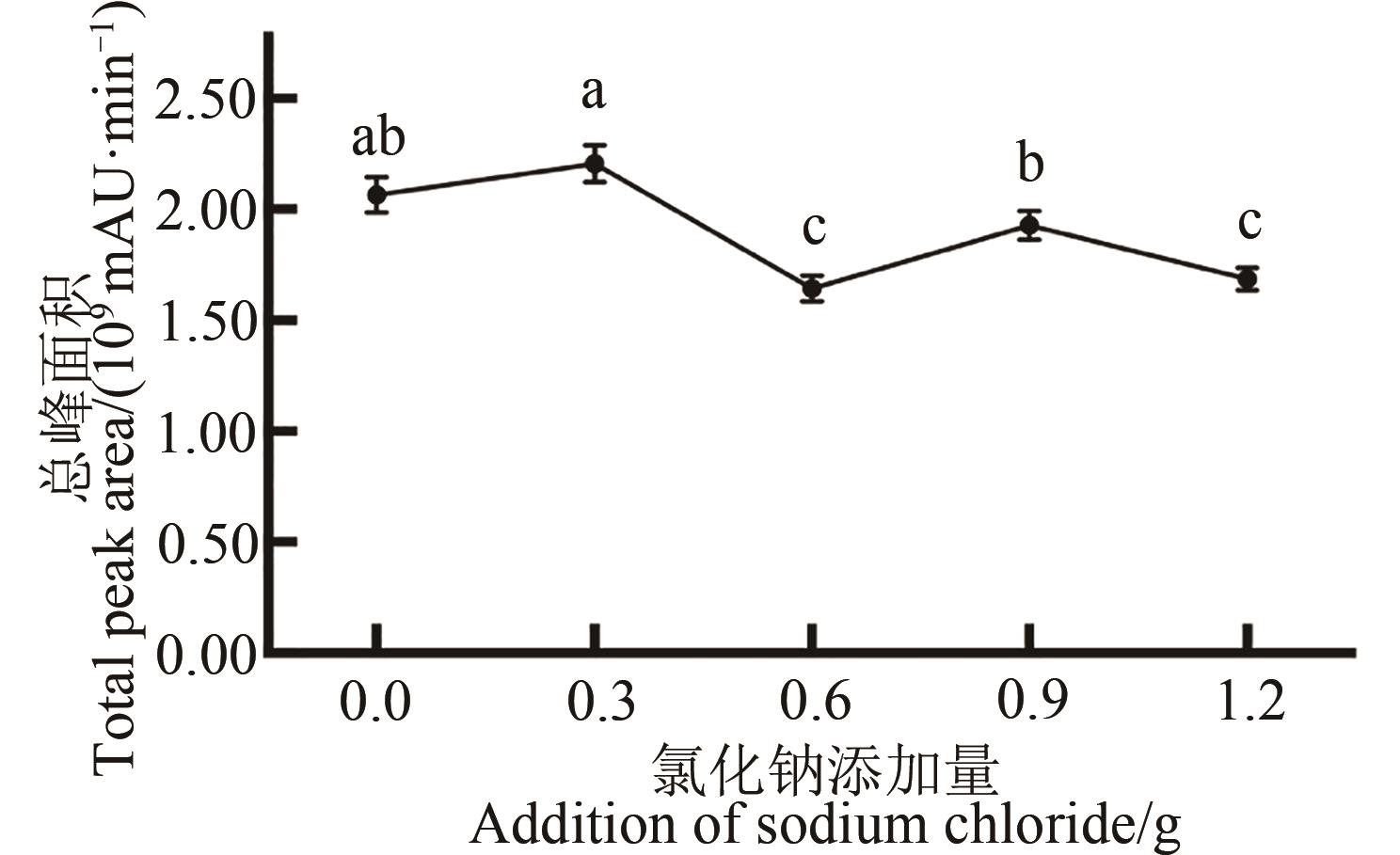

Fig. 5 Extraction effect of volatile substances of jujube honey under different sodium chloride additionsNote:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

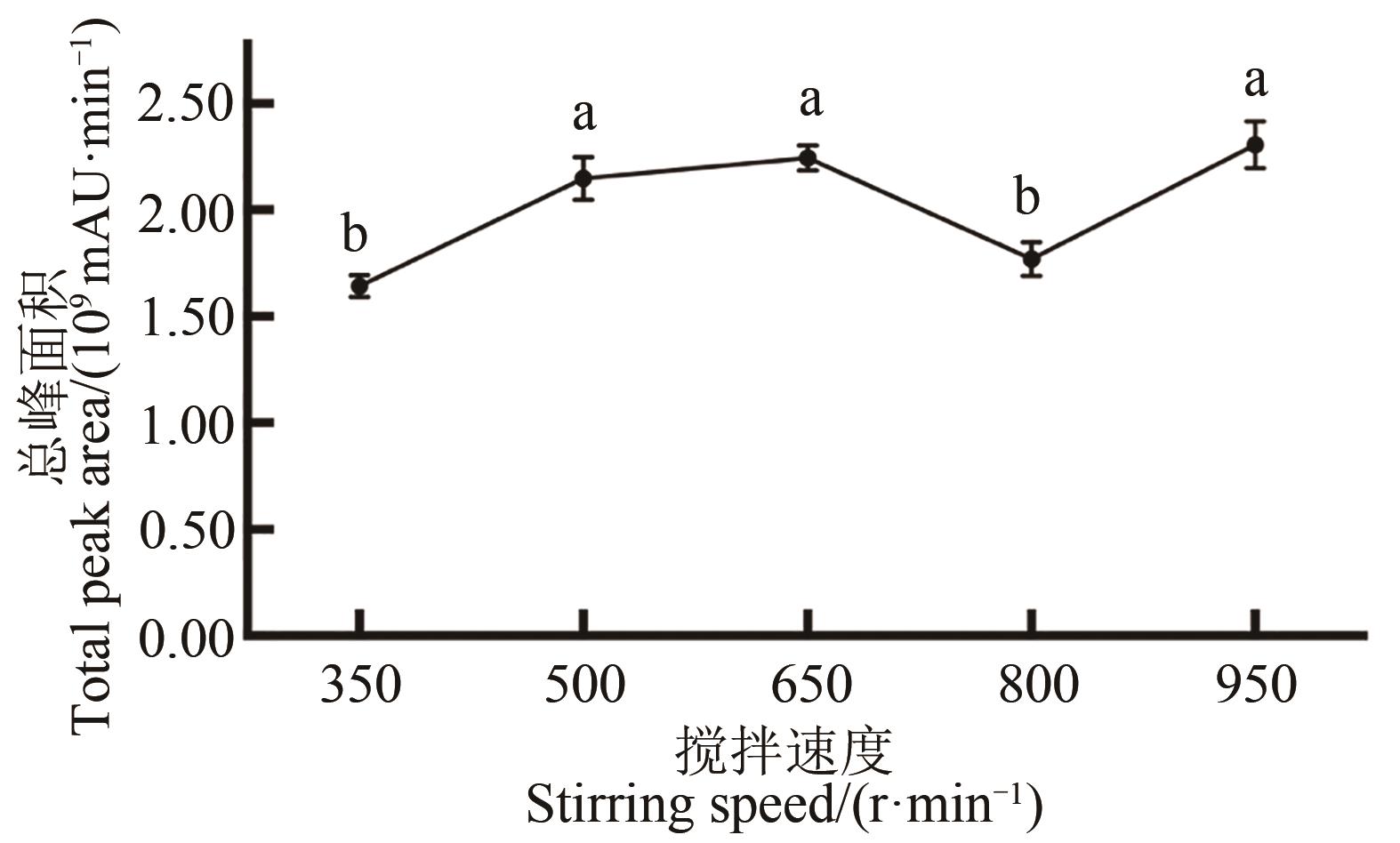

Fig. 6 Extraction effect of volatile substances of jujube honey under different stirring speedsNote:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

试验号 Test number | A:萃取温度 Extraction temperature/℃ | B:萃取时间 Extraction time/min | C:样品量 Sample amount/g | D:去离子水添加量 Addition of deionized water/g | E:氯化钠添加量 Addition of sodium chloride/g | F:搅拌速度 Stirring speed/(r·min-1) | 总峰面积 Total peak area/(mAU•min-1) |

|---|---|---|---|---|---|---|---|

| 1 | 70 | 60 | 4 | 1.0 | 0.6 | 500 | 2 164 313 333 |

| 2 | 70 | 60 | 6 | 0.0 | 0.6 | 800 | 1 985 202 493 |

| 3 | 50 | 40 | 4 | 1.0 | 0.6 | 800 | 1 083 938 267 |

| 4 | 70 | 40 | 6 | 1.0 | 00 | 800 | 788 256 575 |

| 5 | 50 | 60 | 4 | 0.0 | 0.0 | 800 | 14 213 104 785 |

| 6 | 50 | 40 | 6 | 1.0 | 0.6 | 500 | 704 139 893 |

| 7 | 50 | 40 | 4 | 0.0 | 0.0 | 500 | 844 452 565 |

| 8 | 50 | 60 | 6 | 1.0 | 0.0 | 800 | 661 973 145 |

| 9 | 70 | 40 | 4 | 0.0 | 0.6 | 800 | 1 363 575 350 |

| 10 | 70 | 40 | 6 | 0.0 | 0.0 | 500 | 777 127 905 |

| 11 | 70 | 60 | 4 | 1.0 | 0.0 | 500 | 2 157 547 652 |

| 12 | 50 | 60 | 6 | 0.0 | 0.0 | 500 | 409 948 561 |

Table 4 Plackett-Burman test design and results

试验号 Test number | A:萃取温度 Extraction temperature/℃ | B:萃取时间 Extraction time/min | C:样品量 Sample amount/g | D:去离子水添加量 Addition of deionized water/g | E:氯化钠添加量 Addition of sodium chloride/g | F:搅拌速度 Stirring speed/(r·min-1) | 总峰面积 Total peak area/(mAU•min-1) |

|---|---|---|---|---|---|---|---|

| 1 | 70 | 60 | 4 | 1.0 | 0.6 | 500 | 2 164 313 333 |

| 2 | 70 | 60 | 6 | 0.0 | 0.6 | 800 | 1 985 202 493 |

| 3 | 50 | 40 | 4 | 1.0 | 0.6 | 800 | 1 083 938 267 |

| 4 | 70 | 40 | 6 | 1.0 | 00 | 800 | 788 256 575 |

| 5 | 50 | 60 | 4 | 0.0 | 0.0 | 800 | 14 213 104 785 |

| 6 | 50 | 40 | 6 | 1.0 | 0.6 | 500 | 704 139 893 |

| 7 | 50 | 40 | 4 | 0.0 | 0.0 | 500 | 844 452 565 |

| 8 | 50 | 60 | 6 | 1.0 | 0.0 | 800 | 661 973 145 |

| 9 | 70 | 40 | 4 | 0.0 | 0.6 | 800 | 1 363 575 350 |

| 10 | 70 | 40 | 6 | 0.0 | 0.0 | 500 | 777 127 905 |

| 11 | 70 | 60 | 4 | 1.0 | 0.0 | 500 | 2 157 547 652 |

| 12 | 50 | 60 | 6 | 0.0 | 0.0 | 500 | 409 948 561 |

项 Term | 效应 Effect | 系数 Coefficient | 标准误差 Standard error | t值 t value | P值 P value |

|---|---|---|---|---|---|

常量 Constant | 1 196 815 581 | 100 987 228 | 11.85 | 0.000 | |

A:萃取温度 Extraction temperature | 685 043 400 | 342 521 700 | 100 987 228 | 3.39* | 0.019 |

B:萃取时间 Extraction time | 539 800 851 | 269 900 426 | 100 987 228 | 2.67* | 0.044 |

C:样品量 Sample amout | -618 081 512 | -309 040 756 | 100 987 228 | -3.06* | 0.028 |

D:去离子水添加量 Addition of deionized water | 126 425 252 | 63 212 626 | 100 987 228 | 0.63 | 0.559 |

E:氯化钠添加量 Addition of sodium chloride | 176 741 596 | 88 370 798 | 100 987 228 | 0.88 | 0.422 |

F:搅拌速度 Stirring speed | 41 121 066 | 20 560 533 | 100 987 228 | 0.20 | 0.847 |

Table 5 Estimated effects and coefficients for total peak area and their significance test

项 Term | 效应 Effect | 系数 Coefficient | 标准误差 Standard error | t值 t value | P值 P value |

|---|---|---|---|---|---|

常量 Constant | 1 196 815 581 | 100 987 228 | 11.85 | 0.000 | |

A:萃取温度 Extraction temperature | 685 043 400 | 342 521 700 | 100 987 228 | 3.39* | 0.019 |

B:萃取时间 Extraction time | 539 800 851 | 269 900 426 | 100 987 228 | 2.67* | 0.044 |

C:样品量 Sample amout | -618 081 512 | -309 040 756 | 100 987 228 | -3.06* | 0.028 |

D:去离子水添加量 Addition of deionized water | 126 425 252 | 63 212 626 | 100 987 228 | 0.63 | 0.559 |

E:氯化钠添加量 Addition of sodium chloride | 176 741 596 | 88 370 798 | 100 987 228 | 0.88 | 0.422 |

F:搅拌速度 Stirring speed | 41 121 066 | 20 560 533 | 100 987 228 | 0.20 | 0.847 |

试验号 Test number | A:萃取温度 Extraction temperature/℃ | B:萃取时间 Extraction time/min | C:样品量 Sample amout/g | 总峰面积 Total peak area/(mAU•min-1) |

|---|---|---|---|---|

| 1 | 50 | 40 | 5 | 1 567 557 487 |

| 2 | 60 | 40 | 5 | 1 932 456 712 |

| 3 | 50 | 60 | 5 | 1 346 186 065 |

| 4 | 70 | 60 | 5 | 2 052 983 463 |

| 5 | 50 | 50 | 4 | 1 630 325 323 |

| 6 | 70 | 50 | 4 | 1 805 337 729 |

| 7 | 50 | 50 | 6 | 1 709 197 022 |

| 8 | 70 | 50 | 6 | 1 968 466 135 |

| 9 | 60 | 40 | 4 | 1 311 696 261 |

| 10 | 60 | 60 | 4 | 1 798 610 819 |

| 11 | 60 | 40 | 6 | 1 673 851 366 |

| 12 | 60 | 60 | 6 | 1 585 792 904 |

| 13 | 60 | 50 | 5 | 2 155 122 427 |

| 14 | 60 | 50 | 5 | 2 172 382 193 |

| 15 | 60 | 50 | 5 | 2 124 892 245 |

Table 6 Design and results of response surface experiments

试验号 Test number | A:萃取温度 Extraction temperature/℃ | B:萃取时间 Extraction time/min | C:样品量 Sample amout/g | 总峰面积 Total peak area/(mAU•min-1) |

|---|---|---|---|---|

| 1 | 50 | 40 | 5 | 1 567 557 487 |

| 2 | 60 | 40 | 5 | 1 932 456 712 |

| 3 | 50 | 60 | 5 | 1 346 186 065 |

| 4 | 70 | 60 | 5 | 2 052 983 463 |

| 5 | 50 | 50 | 4 | 1 630 325 323 |

| 6 | 70 | 50 | 4 | 1 805 337 729 |

| 7 | 50 | 50 | 6 | 1 709 197 022 |

| 8 | 70 | 50 | 6 | 1 968 466 135 |

| 9 | 60 | 40 | 4 | 1 311 696 261 |

| 10 | 60 | 60 | 4 | 1 798 610 819 |

| 11 | 60 | 40 | 6 | 1 673 851 366 |

| 12 | 60 | 60 | 6 | 1 585 792 904 |

| 13 | 60 | 50 | 5 | 2 155 122 427 |

| 14 | 60 | 50 | 5 | 2 172 382 193 |

| 15 | 60 | 50 | 5 | 2 124 892 245 |

来源 Source | 自由度 df | 平方和 Sum of squares | 均方 Mean squares | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 9 | 9.915×1017 | 1.102×1017 | 6.54 | 0.026 |

| A | 1 | 2.835×1017 | 2.835×1017 | 16.83 | 0.009** |

| B | 1 | 1.110×1016 | 1.110×1016 | 0.66 | 0.454 |

| C | 1 | 1.914×1016 | 1.914×1016 | 1.14 | 0.335 |

| AB | 1 | 2.922×1016 | 2.922×1016 | 1.73 | 0.245 |

| AC | 1 | 1.775×1015 | 1.775×1015 | 0.11 | 0.759 |

| BC | 1 | 8.265×1016 | 8.265×1016 | 4.91 | 0.078 |

| A2 | 1 | 5.324×1016 | 5.324×1016 | 3.16 | 0.136 |

| B2 | 1 | 3.456×1017 | 3.456×1017 | 20.51 | 0.006** |

| C2 | 1 | 2.352×1017 | 2.352×1017 | 13.96 | 0.014* |

| 残差 Residual error | 5 | 8.423×1016 | 1.685×1016 | ||

| 纯误差 Pure error | 2 | 1.156×1015 | 5.778×1014 | ||

| 总变异 Cor. total | 14 | 1.076×1018 |

Table 7 Results of regression analysis

来源 Source | 自由度 df | 平方和 Sum of squares | 均方 Mean squares | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 9 | 9.915×1017 | 1.102×1017 | 6.54 | 0.026 |

| A | 1 | 2.835×1017 | 2.835×1017 | 16.83 | 0.009** |

| B | 1 | 1.110×1016 | 1.110×1016 | 0.66 | 0.454 |

| C | 1 | 1.914×1016 | 1.914×1016 | 1.14 | 0.335 |

| AB | 1 | 2.922×1016 | 2.922×1016 | 1.73 | 0.245 |

| AC | 1 | 1.775×1015 | 1.775×1015 | 0.11 | 0.759 |

| BC | 1 | 8.265×1016 | 8.265×1016 | 4.91 | 0.078 |

| A2 | 1 | 5.324×1016 | 5.324×1016 | 3.16 | 0.136 |

| B2 | 1 | 3.456×1017 | 3.456×1017 | 20.51 | 0.006** |

| C2 | 1 | 2.352×1017 | 2.352×1017 | 13.96 | 0.014* |

| 残差 Residual error | 5 | 8.423×1016 | 1.685×1016 | ||

| 纯误差 Pure error | 2 | 1.156×1015 | 5.778×1014 | ||

| 总变异 Cor. total | 14 | 1.076×1018 |

| 1 | 王琪琦,杜欣玥,高西贝,等.蜂蜜功能活性及药用价值研究进展[J].食品安全质量检测学报,2022,13(18):5849-5854. |

| WANG Q Q, DU X Y, GAO X B, et al.. Research progress on functional activities and medicinal value of honey [J]. J. Food Saf. Qual., 2022, 13(18):5849-5854. | |

| 2 | 任佳淼,赵亚周,田文礼,等.不同蜜源蜂蜜的挥发性成分分析[J].中国食品学报,2016,16(3):225-236. |

| REN J M, ZHAO Y Z, TIAN W L, et al.. Analysis of volatile components in honeys from different nectar sources [J]. Chin. J. Food Sci., 2016, 16(3):225-236. | |

| 3 | SILVA P M, LUCIANO V A, MONIA S, et al.. Stability of volatile compounds of honey during prolonged storage [J]. J. Food Sci Technol., 2020, 57(3):1167-1182. |

| 4 | LLOMPART M, CELEIRO M, GARCÍA-JARES C, et al.. Environmental applications of solid-phase microextraction [J]. Trac Trends Anal. Chem., 2019, 112:1-12. |

| 5 | 邹雪梅,张馨予,陈芳,等.南果梨香气顶空固相微萃取条件优化及成分分析[J].辽宁农业科学,2022(4):30-33. |

| ZOU X M, ZHANG X Y, CHEN F, et al.. Optimization of the headspace solid phase microextraction conditions and composition analysis of Nanguo Pear aroma [J]. Liaoning Agric. Sci., 2022(4):30-33. | |

| 6 | 江新凤,李琛,曹挥华,等.基于顶空固相微萃取-气相色谱-质谱法分析不同嫩度河红茶香气的差异[J].食品安全质量检测学报,2022,13(22):7305-7313. |

| JIANG X F, LI C, CAO H H, et al.. Analysis of characteristic aroma components of different tenderness of Hekou black tea based on headspace solid-phase microextraction-gas chromatography-mass spectrometry [J]. J. Food Saf. Qual., 2022, 13(22):7305-7313. | |

| 7 | KAKONIEN V, VENSKUTONIS P R, EKSTERYT V. Composition of volatile compounds of honey of various floral origin and beebread collected in Lithuania [J]. Food Chem., 2008, 111(4):988-997. |

| 8 | 蔡秋萍,陆大鹏.优化顶空固相微萃取-气相色谱-质谱联用方法测定蜂蜜挥发性成分的研究[J].食品安全导刊,2022(7):112-115. |

| CAI Q P, LU D P. Optimization of headspace solid-phase microextraction-gas chromatography-mass spectrometry for the determination of volatile components in honey [J]. China Food Saf. Magazine, 2022(7):112-115. | |

| 9 | 魏泉增,臧蓓蕾,肖付刚.不同蜜源蜂蜜挥发性成分差异分析[J].食品研究与开发,2020,41(15):143-149. |

| WEI Q Z, ZANG B L, XIAO F G. Analysis of volatile components of honey from different honey sources [J]. Food Res. Dev., 2020, 41(15):143-149. | |

| 10 | NEGGAD A, BENKACI-ALI F, ALSAFRA Z, et al.. Headspace solid phase microextraction coupled to GC/MS for the analysis of volatiles of honeys from arid and mediterranean areas of algeria [J/OL]. Chem. Biodiversity, 2019, 16(10):267 [2023-04-20]. . |

| 11 | IGOR J, ZVONIMIR M, MALENICA S M. Screening of natural organic volatiles from Prunus mahaleb L. honey : coumarin and vomifoliol as nonspecific biomarkers [J]. Molecules, 2011, 16(3):2507-2518. |

| 12 | HUANG J F, OU Y X, ZHANG D F, et al.. Optimization of the culture condition of bacillus mucilaginous using Agaricus bisporus industrial wastewater by Plackett-Burman combined with Box-Behnken response surface method [J/OL]. AMB Express, 2018, 8:7 [2023-04-20]. . |

| 13 | SPADI A, ANGELONI G, GUERRINI L, et al.. Using a Plackett-Burman design to maximise yield of rosemary essential oil by distillation [J/OL]. Ind. Crop Prod., 2021, 166:113488 [2023-04-20]. . |

| 14 | WEN Y Q, XUE C H, XU L L, et al.. Application of Plackett-Burman design in screening of natural antioxidants suitable for anchovy oil [J/OL]. Antioxidants, 2019, 8(12):627 [2023-04-20]. . |

| 15 | MA L, WANG L, TANG J, et al.. Optimization of arsenic extraction in rice samples by Plackett-Burman design and response surface methodology [J]. Food Chem., 2016, 204(1):283-288. |

| 16 | 欧阳嘉,林衍,于东盛,等.Plackett-Burman设计和响应曲面法优化除磷陶粒的制备[J].环境工程学报,2017,11(4):2291-2298. |

| OUYANG J, LIN Y, YU D S, et al.. Plackett-Burman design and response surface method to optimize the preparation of phosphorus removal ceramsite [J]. Chin. J. Environ. Eng., 2017, 11(4):2291-2298. | |

| 17 | 张雅昆,王亭亭,张洪艳,等.Plackett-Burman结合Box-Behnken响应面法优化赪桐中类叶升麻苷纯化工艺及其稳定性分析[J].中国饲料,2023(9):38-44. |

| ZHANG Y K, WANG T T, ZHANG H Y, et al.. Optimization of purification process and stability of acteoside from clerodendrum japonicum by Plackett-Burman combined with Box-Behnken response surface method [J]. China Feed, 2023(9):38-44. | |

| 18 | 李达,孙慕白,苗欣宇,等.Plackett-Burman试验联用响应面法优化枯草芽孢杆菌产α-淀粉酶培养基营养成分[J].中国调味品,2022,47(1):81-86, 97. |

| LI D, SUN M B, MIAO X Y, et al.. Optomization of nutritional components of culture medium for α-amylase produced by bacillus subtilis using Plackett-Burman [J]. China Condiment, 2022, 47(1):81-86, 97. | |

| 19 | BIANCHI F, MANGIA A, MATTAROZZI M, et al.. Characterization of the volatile profile of thistle honey using headspace solid-phase microextraction and gas chromatography-mass spectrometry [J]. Food Chem., 2011, 129(3):1030-1036. |

| 20 | 孙海达,范秀章,昝宏强.顶空固相微萃取-气相色谱串联质谱联用测定雷山云雾绿茶中挥发性物质[J].现代食品,2022,28(23):99-103. |

| SUN H D, FAN X Z, ZAN H Q. Determination of volatile aroma components in Leishan Cloud-Mist tea by HS-SPME-GC-MS [J]. Mod. Food, 2022, 28(23):99-103. | |

| 21 | 严学芬,许应芬,李海燕,等.基于顶空固相微萃取法-气相色谱-质谱法和相对气味活度值分析13种凤凰单丛茶香气成分[J].食品安全质量检测学报,2022,13(17):5459-5467. |

| YAN X F, XU Y F, LI H Y, et al.. Analysis of aroma components of 13 kinds of Fenghuang Dancong tea based on headspace solid phase microextraction-gas chromatography-mass spectrometry and relative odor activity value [J]. J. Food Saf. Qual., 2022, 13(17):5459-5467. | |

| 22 | 王桃红,祖铁红,郑军红,等.紫穗槐蜂蜜理化指标及挥发性成分测定与分析[J].食品与发酵工业,2022,48(13):285-291. |

| WANG T H, ZU T H, ZHENG J H, et al.. Determination and analysis of physicochemical parameters and volatile compounds in Amorpha fruticosa honey [J]. Food Ferment. Ind., 2022, 48(13):285-291. | |

| 23 | ZACARONI L M, DE-SALES P F, CARDOSO M D G, et al.. Response surface optimization of SPME extraction conditions for the analysis of volatile compounds in Brazilian sugar cane spirits by HS-SPME-GC-MS [J]. J. I. Brewing, 2017, 123(2):226-231. |

| 24 | MAES C, BROSTAUX Y, BOUQUILLON S, et al.. Use of new glycerol-based dendrimers for essential oils encapsulation: optimization of stirring time and rate using a Plackett-Burman design and a surface response methodology [J/OL]. Foods (Basel, Switzerland), 2021, 10(2):207 [2023-04-20]. . |

| 25 | 李美萍,李蓉,丁鹏霞,等.HS-SPME条件优化并结合GC-MS分析新鲜及不同干燥方式香菜的挥发性成分[J].食品工业科技,2019,40(7):228-236, 247. |

| LI M P, LI R, DING P X, et al.. Optimization of HS-SPME condition and analysis of volatile compounds in fresh and different drying coriander by GC-MS [J]. Sci. Technol. Food Ind., 2019, 40(7)228-236,247. | |

| 26 | 相懿芳,夏邦华,邹昊博,等.基于响应面分析法优化顶空-固相微萃取与气相色谱-质谱法检测黑龙江野生鳜挥发性风味物质[J].食品安全质量检测学报,2023,14(1):211-219. |

| XIANG Y F, XIA B H, ZOU H B, et al.. Optimization of headspace-solid phase microextraction based on response surface analysis and gas chromatography-mass spectrometry for the determination of volatile flavor substances in Heilongjiang wild Siniperca chuatsi [J]. J. Food Saf. Qual., 2023, 14(1):211-219. | |

| 27 | 张鹏云,李蓉,龙春霞,等.HS-SPME-GC-MS技术分析麦卢卡蜂蜜中的挥发性成分[J].食品工业,2019,40(9):255-260. |

| ZHANG P Y, LI R, LONG C X, et al.. Analysis of the volatile compounds from manuka honey by HSSPME-GC-MS combing with retention index [J]. Food Ind., 2019, 40(9):255-260. | |

| 28 | 帅佳琪,吕长平,秧拯民,等.SPME-GC-MS测定‘凤丹’牡丹籽油挥发物组成时固相微萃取条件的响应面优化[J].中国油脂,2023,48(4):57-62. |

| SHUAI J Q, LYU C P, YANG Z M, et al.. Response surface optimization of solid phase microextraction condition for the determination of volatiles in Fengdan seed oil by SPME-GC-MS [J]. China Oil Fats, 2023, 48(4):57-62. | |

| 29 | 初众,王海茹,张彦军,等.HS-SPME-GC-MS技术分析香草兰果皮的挥发性成分[J].食品科学,2016,37(6):126-131. |

| CHU Z, WANG H R, ZHANG Y J, et al.. GC-MS analysis of volatiles in vanilla husk extracted by headspace solid-phase microextraction [J]. Food Sci., 2016, 37(6):126-131. | |

| 30 | RUI M A, XL A, HT B, et al.. Odor-active volatile compounds profile of triploid rainbow trout with different marketable sizes [J]. Aquacult. Rep., 2020, (17):100312-100312. |

| 31 | 刘晓成,魏俊桃,纪晓梅,等.柑橘纤维及乳化剂提高麻酱蘸料稳定性的研究[J].中国调味品,2022,47(3):97-101. |

| LIU X C, WEI J T, JI X M, et al.. Study on improving the stability of sesame dipping sauce with citrus fiber and emulsifie [J]. China Condiment, 2022, 47(3):97-101. | |

| 32 | 陈源,杨道富,范丽华,等.响应面法优化微波提取茂谷橘橙皮总黄酮工艺[J].中国食品学报,2013,13(4):80-86. |

| CHEN Y, YANG D F, FAN L H, et al..Studies on optimization of the technology for extracting total flavonoids from murcott peel by response surface methodology [J]. Chin. J. Food Sci., 2013, 13(4):80-86. | |

| 33 | 李翔,凌云坤,蒋方国,等.基于Plackett-Burman试验和响应面法优化松茸牛肉酱生产工艺[J].食品工业,2020,41(12):58-62. |

| LI X, LING Y K, JIANG F G, et al.. Optimization of production process of tricholoma matsutake beef sauce based on Plackett-Burman design and response surface method [J]. Food Ind., 2020, 41(12):58-62. |

| [1] | Jinrong LI, Tong ZHOU, Yiqi LIN, Zuohua HUANG, Liangjing SHENG, Feiping ZHANG, Songqing WU. Optimization of Serratia marcescens BRC-CXG2 Fermentation Medium Based on Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 133-143. |

| [2] | LI Siqingaowa, WANG Chunguang, DU Haifeng, JIN Eerdumutu. Research on Cutting Performance of Convex Arc Blade [J]. Journal of Agricultural Science and Technology, 2021, 23(12): 94-100. |

| [3] | HUANG Weiwei1, BI Shenglei2, YANG Di3, LIU Yu1, XIN Nahui1, LI Yuyuan1, ZHANG Naiqun1*. Study on the Collecting Method of Heterotrophic Chlorella Cells [J]. Journal of Agricultural Science and Technology, 2021, 23(1): 186-193. |

| [4] | DAI Yangjun1, HU Jian1,2, ZHOU Ying2, ZUO Bo1, SHI Yixue1. Optimization of Compound Enzymolysis Process of Dried Figs by Plackett-Burman Design and Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2018, 20(7): 146-153. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号