Journal of Agricultural Science and Technology ›› 2024, Vol. 26 ›› Issue (9): 72-82.DOI: 10.13304/j.nykjdb.2024.0176

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Jiaxin ZHENG1( ), Shishun WANG1, Fan TANG1, Longtu ZHU1, Ji LUO2, Wenchai YANG1(

), Shishun WANG1, Fan TANG1, Longtu ZHU1, Ji LUO2, Wenchai YANG1( )

)

Received:2024-03-08

Accepted:2024-05-19

Online:2024-09-15

Published:2024-09-13

Contact:

Wenchai YANG

郑嘉鑫1( ), 王世顺1, 汤凡1, 朱龙图1, 罗骥2, 杨文彩1(

), 王世顺1, 汤凡1, 朱龙图1, 罗骥2, 杨文彩1( )

)

通讯作者:

杨文彩

作者简介:郑嘉鑫E-mail:zhengjiaxin_0628@126.com

基金资助:CLC Number:

Jiaxin ZHENG, Shishun WANG, Fan TANG, Longtu ZHU, Ji LUO, Wenchai YANG. Design of a Harvesting Machine for Panax notoginseng Stems and Leaves Under the Forest and Simulation Experiment of a Reciprocating Cutting Blade[J]. Journal of Agricultural Science and Technology, 2024, 26(9): 72-82.

郑嘉鑫, 王世顺, 汤凡, 朱龙图, 罗骥, 杨文彩. 林下三七茎叶采收机设计及往复式割刀仿真试验[J]. 中国农业科技导报, 2024, 26(9): 72-82.

| 参数Parameter | 数值Value |

|---|---|

垄高 Ridge height/cm | 27~30 |

垄底宽度 Ridge bottom width/cm | 143~145 |

垄顶宽度 Ridge top width/cm | 128~130 |

垄与树干的距离 Distance between ridge and trunk/cm | 28~35 |

垄面距硬碰支架最高处距离 Distance between the ridge surface and the highest point of the hard collision bracket/cm | 163~170 |

荫棚支架垄底之间距离 Distance between the bottom of the shade shed support ridge/cm | 165~168 |

荫棚支架垄顶之间距离 Distance between the ridge tops of the shade shed brackets/cm | 153~155 |

Table 1 Planting parameter for Panax notoginseng under the forest

| 参数Parameter | 数值Value |

|---|---|

垄高 Ridge height/cm | 27~30 |

垄底宽度 Ridge bottom width/cm | 143~145 |

垄顶宽度 Ridge top width/cm | 128~130 |

垄与树干的距离 Distance between ridge and trunk/cm | 28~35 |

垄面距硬碰支架最高处距离 Distance between the ridge surface and the highest point of the hard collision bracket/cm | 163~170 |

荫棚支架垄底之间距离 Distance between the bottom of the shade shed support ridge/cm | 165~168 |

荫棚支架垄顶之间距离 Distance between the ridge tops of the shade shed brackets/cm | 153~155 |

| 参数Parameter | 数值Value |

|---|---|

剪切处茎秆直径 Stem diameter at cutting point/mm | 3.1~4.5 |

根部到叶脉高度 Root to vein height/mm | 7.6~16 |

花高 Flower height/cm | 8.2~18 |

茎秆-茎秆之间的滚动摩擦 Rolling friction between stems | 0.697~0.782 |

茎秆-茎秆之间的滑动摩擦 Sliding friction between stems | 0.286~0.352 |

Table 2 Basic physical parameters of Panax notoginseng stem

| 参数Parameter | 数值Value |

|---|---|

剪切处茎秆直径 Stem diameter at cutting point/mm | 3.1~4.5 |

根部到叶脉高度 Root to vein height/mm | 7.6~16 |

花高 Flower height/cm | 8.2~18 |

茎秆-茎秆之间的滚动摩擦 Rolling friction between stems | 0.697~0.782 |

茎秆-茎秆之间的滑动摩擦 Sliding friction between stems | 0.286~0.352 |

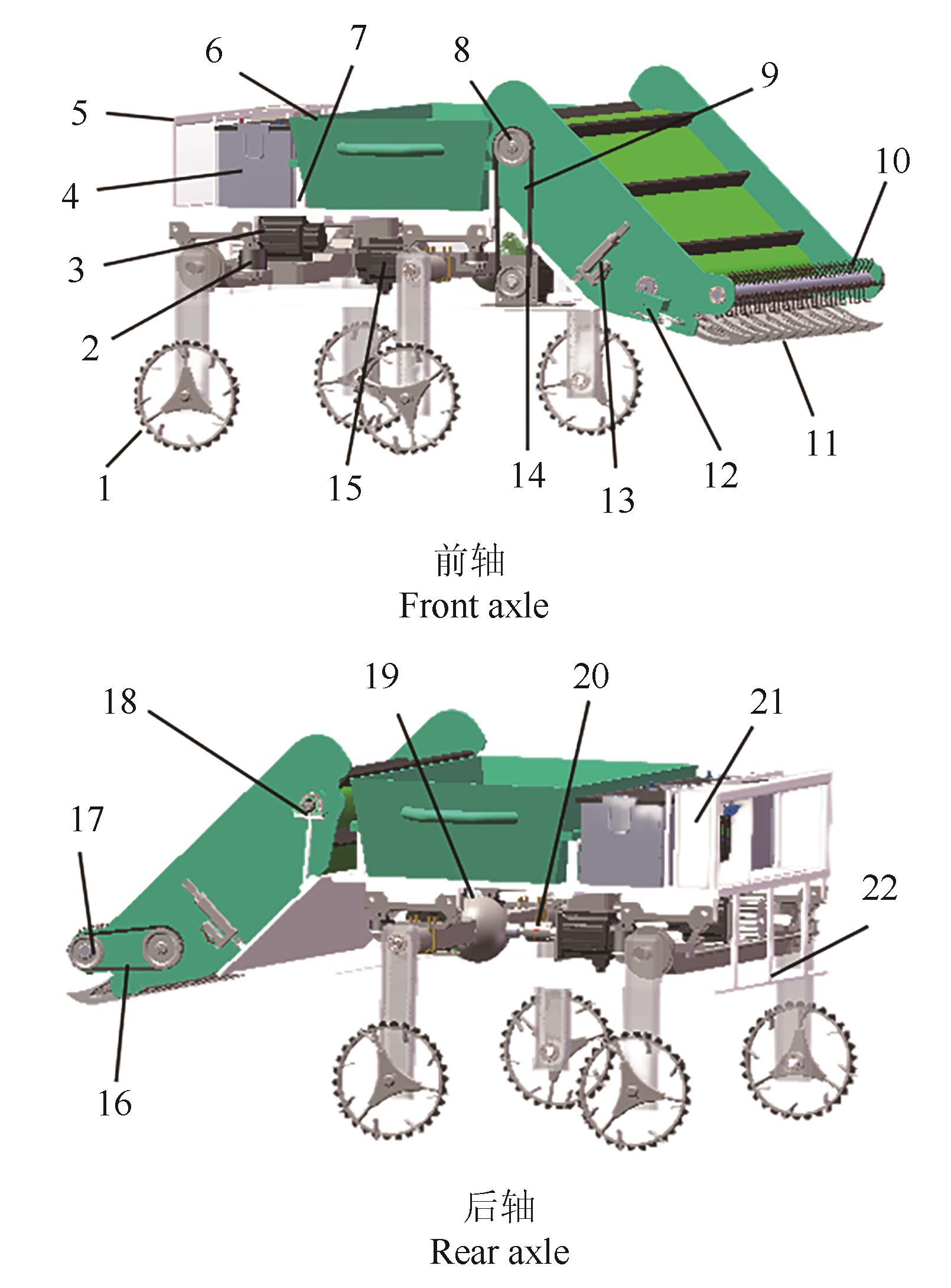

Fig. 1 Panax notoginseng stem and leaf harvester underNote:1—Rice rotation; 2—Hydraulic transmission device; 3—Steering motor; 4—Lithium ion batteries; 5—Handrails; 6—Pulling collection box; 7—Walking motor; 8—With wheels; 9—Belt; 10—Conveyor belt guard plate; 11—Reel reel; 12—Reciprocating cutter; 13—Gear assembly box; 14—Push rod motor; 15—Blade cutting motor; 16—Belt; 17—Pulley; 18—Bearing seat; 19—Differential; 20—Plum key; 21—Control box; 22—Rack.the forest

| 参数Parameter | 数值Value |

|---|---|

整体尺寸 Overall size/cm | 240×130 ×100 |

割幅宽度 Cutting width/cm | 130 |

底轮间距 Bottom wheel spacing/cm | 145 |

前进速度 Forward speed/(m·s‒1) | 0~2 |

输送带转速 Conveyor belt speed/(r·min‒1) | 0~100 |

推杆电机行程 Push rod motor stroke/cm | 0~10 |

割刀往复行程 Cutting blade reciprocating stroke/cm | 35 |

动力类型 Power type | 锂电 Lithium battery |

控制方式 Control mode | 遥控 remote control |

Table 3 Device design parameters

| 参数Parameter | 数值Value |

|---|---|

整体尺寸 Overall size/cm | 240×130 ×100 |

割幅宽度 Cutting width/cm | 130 |

底轮间距 Bottom wheel spacing/cm | 145 |

前进速度 Forward speed/(m·s‒1) | 0~2 |

输送带转速 Conveyor belt speed/(r·min‒1) | 0~100 |

推杆电机行程 Push rod motor stroke/cm | 0~10 |

割刀往复行程 Cutting blade reciprocating stroke/cm | 35 |

动力类型 Power type | 锂电 Lithium battery |

控制方式 Control mode | 遥控 remote control |

编号 Code | 三七茎秆纵向位移 Longitudinal displacement of Panax notoginseng stem | 三七茎秆横向位移 Lateral displacement of Panaxnotoginseng stem | 最大拉力 Maximum tensile force/N | ||||

|---|---|---|---|---|---|---|---|

平均值 Average | 50 | 50.11 | 0.11 | 3.04 | 2.76 | 0.28 | 18.35 |

| 1 | 50 | 50.11 | 0.11 | 3.3 | 2.96 | 0.34 | 18.42 |

| 2 | 50 | 50.15 | 0.15 | 2.47 | 2.28 | 0.19 | 19.89 |

| 3 | 50 | 50.17 | 0.17 | 2.73 | 2.53 | 0.2 | 22.27 |

| 4 | 50 | 50.07 | 0.07 | 3.85 | 3.58 | 0.27 | 15.58 |

| 5 | 50 | 50.06 | 0.06 | 2.86 | 2.44 | 0.42 | 15.58 |

Table 4 Basic parameters of Panax notoginseng stem tensile test

编号 Code | 三七茎秆纵向位移 Longitudinal displacement of Panax notoginseng stem | 三七茎秆横向位移 Lateral displacement of Panaxnotoginseng stem | 最大拉力 Maximum tensile force/N | ||||

|---|---|---|---|---|---|---|---|

平均值 Average | 50 | 50.11 | 0.11 | 3.04 | 2.76 | 0.28 | 18.35 |

| 1 | 50 | 50.11 | 0.11 | 3.3 | 2.96 | 0.34 | 18.42 |

| 2 | 50 | 50.15 | 0.15 | 2.47 | 2.28 | 0.19 | 19.89 |

| 3 | 50 | 50.17 | 0.17 | 2.73 | 2.53 | 0.2 | 22.27 |

| 4 | 50 | 50.07 | 0.07 | 3.85 | 3.58 | 0.27 | 15.58 |

| 5 | 50 | 50.06 | 0.06 | 2.86 | 2.44 | 0.42 | 15.58 |

项目 Item | 参数 Parameter | 数值 Value |

|---|---|---|

茎秆 Stem | 泊松比 Poisson’s ratio | 0.39 |

弹性模量 Elastic modulus/MPa | 0.26×103 | |

密度 Density/(g | 1.01 | |

茎秆-切割器滑动摩擦 Stem-cutter sliding friction | 0.287 | |

茎秆-切割器滚动摩擦 Stem-cutter rolling friction | 0.743 | |

茎秆含水率 Stem moisture content/% | 82.34 | |

切割器Cutter | 泊松比 Poisson’s ratio | 0.29 |

弹性模量 Elastic modulus/MPa | 2.07×105 | |

密度 Density/(kg | 7 801 |

Table 5 Model material parameter

项目 Item | 参数 Parameter | 数值 Value |

|---|---|---|

茎秆 Stem | 泊松比 Poisson’s ratio | 0.39 |

弹性模量 Elastic modulus/MPa | 0.26×103 | |

密度 Density/(g | 1.01 | |

茎秆-切割器滑动摩擦 Stem-cutter sliding friction | 0.287 | |

茎秆-切割器滚动摩擦 Stem-cutter rolling friction | 0.743 | |

茎秆含水率 Stem moisture content/% | 82.34 | |

切割器Cutter | 泊松比 Poisson’s ratio | 0.29 |

弹性模量 Elastic modulus/MPa | 2.07×105 | |

密度 Density/(kg | 7 801 |

水平 Level | 因素factor | ||

|---|---|---|---|

X1:切割速度 Cutting speed /(mm | X2:切割倾角 Cutting inclination angle/(°) | X3:刀型 Knife type | |

| -1 | 0.45 | 90 | 梯形刀片 Trapezoidal blade |

| 0 | 0.60 | 92 | 三角形刀片 Triangle blade |

| 1 | 0.75 | 94 | 矩形刀片 Rectangular blade |

Table 6 Factor of simulation test

水平 Level | 因素factor | ||

|---|---|---|---|

X1:切割速度 Cutting speed /(mm | X2:切割倾角 Cutting inclination angle/(°) | X3:刀型 Knife type | |

| -1 | 0.45 | 90 | 梯形刀片 Trapezoidal blade |

| 0 | 0.60 | 92 | 三角形刀片 Triangle blade |

| 1 | 0.75 | 94 | 矩形刀片 Rectangular blade |

试验编号 Test number | 因素水平 Factor level | 最大切割力/N Maximum cutting force/N | ||

|---|---|---|---|---|

| X1 | X2 | X3 | ||

| 1 | 0 | 0 | 0 | 25.6 |

| 2 | -1 | -1 | 0 | 12.8 |

| 3 | 1 | -1 | 0 | 36.6 |

| 4 | 0 | 1 | -1 | 61.3 |

| 5 | 0 | 0 | 0 | 20.4 |

| 6 | 1 | 1 | 0 | 61.1 |

| 7 | 0 | -1 | 1 | 19.2 |

| 8 | 0 | 0 | 0 | 27.0 |

| 9 | 1 | 0 | -1 | 71.7 |

| 10 | 0 | 1 | 1 | 54.5 |

| 11 | 0 | 0 | 0 | 19.0 |

| 12 | 0 | -1 | -1 | 19.6 |

| 13 | -1 | 1 | 0 | 46.5 |

| 14 | -1 | 0 | 1 | 57.4 |

| 15 | 1 | 0 | 1 | 62.3 |

| 16 | 0 | 0 | 0 | 28.4 |

Table 7 Orthogonal experimental design and result

试验编号 Test number | 因素水平 Factor level | 最大切割力/N Maximum cutting force/N | ||

|---|---|---|---|---|

| X1 | X2 | X3 | ||

| 1 | 0 | 0 | 0 | 25.6 |

| 2 | -1 | -1 | 0 | 12.8 |

| 3 | 1 | -1 | 0 | 36.6 |

| 4 | 0 | 1 | -1 | 61.3 |

| 5 | 0 | 0 | 0 | 20.4 |

| 6 | 1 | 1 | 0 | 61.1 |

| 7 | 0 | -1 | 1 | 19.2 |

| 8 | 0 | 0 | 0 | 27.0 |

| 9 | 1 | 0 | -1 | 71.7 |

| 10 | 0 | 1 | 1 | 54.5 |

| 11 | 0 | 0 | 0 | 19.0 |

| 12 | 0 | -1 | -1 | 19.6 |

| 13 | -1 | 1 | 0 | 46.5 |

| 14 | -1 | 0 | 1 | 57.4 |

| 15 | 1 | 0 | 1 | 62.3 |

| 16 | 0 | 0 | 0 | 28.4 |

方差来源 Source of variance | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F | P |

|---|---|---|---|---|---|

失拟项 Misfit term | 269.60 | 3 | 89.87 | 5.22 | 0.072 1 |

模型 model | 5 954.48 | 9 | 661.61 | 13.68 | 0.001 2 |

| X1 | 1 178.55 | 1 | 1 178.55 | 24.38 | 0.001 7 |

| X2 | 2 284.88 | 1 | 2 284.88 | 47.26 | 0.000 2 |

| X3 | 65.55 | 1 | 65.55 | 1.36 | 0.282 4 |

| X1X2 | 21.16 | 1 | 21.16 | 0.44 | 0.529 4 |

| X1X3 | 597.80 | 1 | 597.80 | 12.36 | 0.009 8 |

| X2X3 | 10.24 | 1 | 10.24 | 0.21 | 0.659 3 |

| X1² | 875.83 | 1 | 875.83 | 18.11 | 0.003 8 |

| X2² | 2.35 | 1 | 2.35 | 0.05 | 0.831 7 |

| X3² | 804.47 | 1 | 804.47 | 16.64 | 0.004 7 |

Table 8 Analysis of variance results

方差来源 Source of variance | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F | P |

|---|---|---|---|---|---|

失拟项 Misfit term | 269.60 | 3 | 89.87 | 5.22 | 0.072 1 |

模型 model | 5 954.48 | 9 | 661.61 | 13.68 | 0.001 2 |

| X1 | 1 178.55 | 1 | 1 178.55 | 24.38 | 0.001 7 |

| X2 | 2 284.88 | 1 | 2 284.88 | 47.26 | 0.000 2 |

| X3 | 65.55 | 1 | 65.55 | 1.36 | 0.282 4 |

| X1X2 | 21.16 | 1 | 21.16 | 0.44 | 0.529 4 |

| X1X3 | 597.80 | 1 | 597.80 | 12.36 | 0.009 8 |

| X2X3 | 10.24 | 1 | 10.24 | 0.21 | 0.659 3 |

| X1² | 875.83 | 1 | 875.83 | 18.11 | 0.003 8 |

| X2² | 2.35 | 1 | 2.35 | 0.05 | 0.831 7 |

| X3² | 804.47 | 1 | 804.47 | 16.64 | 0.004 7 |

| 1 | 国家药典委员会.中华人民共和国药典(一部)[M].北京:中国医药科技出版社,2020:155. |

| 2 | 朱赞,袁希平,甘淑,等.高分1号数据用于云南文山三七种植信息提取[J].浙江农林大学学报,2020,37(1):129-135. |

| ZHU Z, YUAN X P, GAN S, et al.. GF-1 remote sensing data for Panax notoginseng planting information extraction in Wenshan, Yunnan Province [J]. J. Zhejiang A&F Univ., 2020,37 (1): 129-135. | |

| 3 | 史婷婷,张小波,郭兰萍,等.基于决策树模型的文山三七种植面积估算方法研究[J].中国中药杂志,2017,42(22):4358-4361. |

| SHI T T, ZHANG X B, GUO L P, et al.. Study on extraction method of Panax notoginseng plots in Wenshan of Yunnan province based on decision tree model [J]. China J. Chin. Materia Medica, 2017,42 (22): 4358-4361. | |

| 4 | 解开婷,张兆国,王法安,等.土壤与三七根茎黏附数学模型构建与验证[J]. 农业工程学报, 2022, 38(S1): 131-141. |

| XIE K T, ZHANG Z G, WANG F A, et al.. Mathematical model construction and verification of soil and Panax notoginseng root adhesion [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(S1): 131-141. | |

| 5 | 张兆国,薛浩田,王一驰,等.基于离散元法的三七仿生挖掘铲设计与试验[J].农业机械学报,2022,53(5):100-111. |

| ZHANG Z G, XUE H T, WANG Y C, et al.. Design and experiment of Panax notoginseng bionic excavating shovel based on EDEM [J]. Trans. Chin. Soc. Agric., 2022, 53(5): 100-111. | |

| 6 | 张兆国,王法安,张永成,等.自走式三七收获机设计与试验[J].农业机械学报, 2016, 47(S1): 234-240. |

| ZHANG Z G, WANG F A, ZHANG Y C, et al.. Design and experiment of self-propelled Panax notoginseng harvester [J]. Trans. Chin. Soc. Agric., 2016, 47(S1): 234-240. | |

| 7 | 王法安.三七收获机的设计与试验研究[D].昆明:昆明理工大学, 2017. |

| WANG F A. The design and experimental study of Panax notoginseng harvester [D]. Kunming: Kunming University of Science and Technology, 2017. | |

| 8 | 张兆国,王一驰,李汉青,等.液压控制履带自走式温室三七收获机设计与试验[J].农业机械学报, 2021,52(6):127-135, 158. |

| ZHANG Z G, WANG Y C, LI H Q, et al.. Design and test of hydraulic control tracked self-propelled greenhouse Panax notoginseng harvester [J]. Trans. Chin. Soc. Agric., 2021, 52(6): 127-135, 158. | |

| 9 | 张兆国,徐红伟,薛浩田,等.三七茎秆离散元参数标定与试验[J].农业机械学报,2023,54(11):61-70, 91. |

| ZHANG Z G, XU H W, XUE H T, et al.. Calibration and experiment of discrete element parameters for Panax notoginseng stem [J]. Trans. Chin. Soc. Agric. Mach., 2023, 54(11): 61-70, 91. | |

| 10 | 崔振猛,张兆国,王法安,等.4SD-1700型悬挂式三七收获机设计与试验[J] .农机化研究,2019,41(2):134-139. |

| CUI Z M, ZHANG Z G, WANG F A, et al.. Design and test of the 4 SD - 1700 model suspension type Panax notoginseng harvester [J]. J. Agric. Mechanization Res., 2019, 41 (2): 134-139. | |

| 11 | 唐金鑫.温室三七收获机挖掘装置优化与土槽试验[D].昆明:昆明理工大学,2021. |

| TANG J X. Optimization of excavation device and soil tank test for greenhouse Panax notoginseng harvester [D]. Kunming: Kunming University of Science and Technology, 2021. | |

| 12 | 于进川,张兆国,武占东,等.悬挂式三年生三七挖掘收获机的研制及试验[J] .农机化研究,2016,38(4):130-133, 164. |

| YU J C, ZHANG Z G, WU Z D, et al.. Development and testing of a suspended three-year Panax notoginseng excavator harvester [J]. J. Agric. Mechan. Res., 2016,38 (4): 130-133, 164. | |

| 13 | 赵菲菲.牵引式三七收获机的设计与试验研究[D].昆明:昆明理工大学,2016. |

| ZHAO F F. Design and experimental research of a traction type Panax notoginseng harvester [D]. Kunming: Kunming University of Science and Technology, 2016. | |

| 14 | 张永成.自走式三七收获机的设计与试验研究[D].昆明:昆明理工大学,2016. |

| ZHANG Y C. Design and experimental research on self-propelled Panax notoginseng harvester [D]. Kunming: Kunming University of Science and Technology, 2016. | |

| 15 | 薛浩田.三七联合收获机整机设计及关键部件的仿真试验[D].昆明:昆明理工大学, 2022. |

| XUE H T. Complete machine design and simulation test of key components of Sanqi combine harvester [D]. Kunming: Kunming University of Science and Technology, 2022. | |

| 16 | 韦勇,秦广明,金月,等.叶菜收获机械的研究现状及发展趋势[J].农业开发与装备,2016(8):98-100. |

| 17 | 王俊,杜冬冬,胡金冰,等.蔬菜机械化收获技术及其发展[J].农业机械学报,2014,45(2):81-87. |

| WANG J, DU D D, HU J B, et al.. Vegetable mechanized harvesting technology and its development [J].Trans. Chin. Soc. Agric., 2014, 45 (2): 81-87. | |

| 18 | 杨光,肖宏儒,宋志禹,等.叶类蔬菜收获环节机械化还需跨过几道坎[J].蔬菜,2018(6):1-8. |

| 19 | 宫元娟,冯雨龙,李创业,等.韭菜收割机械研究现状及发展趋势[J].农机化研究,2018,40(10):262-268. |

| GONG Y J, FENG Y L, LI C Y, et al.. Research actuality of leek harvester and its developing countermeasures [J]. J. Agric. Mechan. Res., 2018, 40 (10): 262-268. | |

| 20 | JANG S W, LEE E H, KIM W B. Analysis of research and development papers of lettuce in Korea [J]. Korean J. Hortic. Sci. Technol., 2007, 25(3): 295-303. |

| 21 | NANG V N, YAMANE S. Development of prototype harvester for head lettuce [J]. Eng. Agric. Env. Food, 2015, 8(1): 18-25. |

| 22 | 伍渊远.温室芹菜收获机的设计[D].宁夏:宁夏大学,2018. |

| WU Y Y. Design of greenhouse celery harvester [D]. Ningxia: Ningxia University, 2018. | |

| 23 | 卢建强,秦广明,赵映,等.一种蔬菜有序收获机: CN201410281685.1[P].2016-02-03. |

| 24 | 于英杰,王剑,赖庆辉,等.手持振动梳刷式小粒咖啡采摘装置设计与试验[J].农业机械学报,2021,52(9) :124-133. |

| YU Y J, WANG J, LAI Q H, et al.. Design and experiment of hand-held vibrating comb-type Coffea arabica L. harvester [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52( 9): 124-133. | |

| 25 | 史增录,唐学鹏,鄢金山,等.往复式切割装置摆环机构的刚柔耦合仿真及分析[J].干旱地区农业研究,2018,36(3):292-296. |

| SHI Z L, TANG X P, YAN J S, et al.. Rigid-flexible coupling simulation and analysis of sway ring mechanism in reciprocating cutting device [J]. Agric. Res. Arid Areas, 2018, 36( 3):292-296. | |

| 26 | 郑永东,岑海堂,张天放,等.向日葵收割装置的设计与仿真研究[J].中国农机化学报,2017,38(12):1-3, 29. |

| ZHENG Y D, CEN H T, ZHANG T F, et al.. Research progress of domestic and foreign TMR feeding technologies and mixers [J]. J. Chin. Agric. Mechan., 2017, 38(12): 1-3, 29. | |

| 27 | 金诚谦,齐彦栋,刘岗微,等.大豆联合收获机拨禾轮作用机理分析与参数优化[J].农业机械学报,2023,54(6):104-113. |

| JIN C Q, QI Y D, LIU G W, et al.. Mechanism analysis and parameter optimization of soybean combine harvester reel [J]. Trans. Chin. Soc. Agric. Mach., 2023, 54(6): 104-113. | |

| 28 | 张博文,李爱潮,郑志安,等.川麦冬往复切割式剪果装置设计与仿真试验[J].农业机械学报, 2023, 54 (S2):81-90. |

| ZHANG B W, LI A C, ZHENG Z A, et al.. Design and simulation experiments of reciprocating cutting tuber temoval device for Ophiopogon japonicus [J]. Trans. Chin. Soc. Agric. Mach., 2023, 54(S2): 81-90. | |

| 29 | 王佳,李绍波,陈春皓,等.葡萄茎秆切割装置作业参数优化与试验[J].中国农机化学报,2023,44(2):37-45. |

| WANG J, LI S B, CHEN C H, et al.. Optimization and test of operating parameters of grape stem cutting device [J]. J. Chin. Agric. Mechan., 2023, 44(2): 37-45. | |

| 30 | 张克平,黄建龙,杨 敏,等.冬小麦籽粒受挤压特性的有限元分析及试验验证[J].农业工程学报,2010,26 (6):352-356. |

| ZHANG K P, HUANG J L, YANG M, et al.. Finite element analysis and experimental verification of winter wheat grain compression characteristics [J].Trans. Chin. Soc. Agric. Eng., 2010, 26(6): 352-356. | |

| 31 | 崔涛,刘佳,张东兴,等.基于ANSYS和ADAMS玉米茎秆柔性体仿真[J].农业机械学报,2012,43 ( Z1):112-115. |

| CUI T, LIU J, ZHANG D X, et al.. Simulation of corn stemflexible body based on ANSYS and ADAMS [J]. Trans. Chin. Soc. Agric. Mach., 2012,43 ( Z1):112-115. | |

| 32 | 张荣荣,李小昱,王为,等.基于有限元方法的板栗破壳力学特性分析[J].农业工程学报,2008,24 (9):84-88. |

| ZHANG R R, LI X Y, WANG W, et al.. Mechanical properties analysis of Chinese chestnut broken shell based on finite element method [J]. Trans. Chin. Soc. Agric. Eng., 2008, 24 (9): 84-88. | |

| 33 | 刘兆朋.圆盘式苎麻切割器的设计及试验研究[D].长沙:湖南农业大学,硕士学位论文,2011. |

| LIU Z P. Design and experimental study of disc type ramiecutter [D].Changsha: Hunan Agricultural University, Master Dissertation, 2011. | |

| 34 | 李延龄.六面体有限元网格自动剖分技术研究[D].郑州:机械科学研究院,2002. |

| LI Y L. Research on automatic meshing of hexahedral finite element mesh [D]. Zhengzhou: Zhengzhou Institute of Mechanical Science, 2002. | |

| 35 | 陆亮,涂宇.整杆式巨菌草双圆盘切割装置动力学研究与参数优化[J].中国农机化学报,2023,44(3);41-48. |

| LU L, TU Y. Kinetics research and parameter optimization of the whole-rod giant Juncao double-disc cutting device [J]. J. Chin. Agric. Mechan., 2023, 44(3):41-48. |

| [1] | ZHANG Fengkui, ZHANG Hong, LAN Haipeng, YU Fufeng, LI Zhongjie, LI Ping. Simulation Analysis of Pneumatic Conveying Device of Air-suction Jujube Picker Based on CFD-EDM Coupling [J]. Journal of Agricultural Science and Technology, 2021, 23(7): 107-116. |

| [2] | XU Mingxian, WANG Lihai*, SHI Xiaolong, LIU Tienan, ZHANG Guanghui, MENG Qingkai. Design and Experimental Verification of A Woodland Cleaning Device for Eucalyptus Plantations [J]. Journal of Agricultural Science and Technology, 2019, 21(4): 70-78. |

| [3] | LI Xiao-dong, FANG Xian-fa, HAN Zeng-de*, ZHANG Zi-rui, LIU Gui-ming, CUI Jun-we. Dynamic Simulation of Sweet Sorghum Cutting Based on ANSYS/LS-DYNA [J]. , 2015, 17(3): 70-76. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号