Journal of Agricultural Science and Technology ›› 2024, Vol. 26 ›› Issue (6): 72-81.DOI: 10.13304/j.nykjdb.2023.0828

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Yafeng LIU1( ), Zhichao FANG1,2(

), Zhichao FANG1,2( ), Haifeng XIA1, Yongbo QU1, Mingliang WU1,2

), Haifeng XIA1, Yongbo QU1, Mingliang WU1,2

Received:2023-11-10

Accepted:2024-01-19

Online:2024-06-15

Published:2024-06-12

Contact:

Zhichao FANG

柳亚峰1( ), 方志超1,2(

), 方志超1,2( ), 夏海峰1, 曲永波1, 吴明亮1,2

), 夏海峰1, 曲永波1, 吴明亮1,2

通讯作者:

方志超

作者简介:柳亚峰 E-mail:liuyafeng1222@163.com;

基金资助:CLC Number:

Yafeng LIU, Zhichao FANG, Haifeng XIA, Yongbo QU, Mingliang WU. Design and Experiment of a Opposite Roller Extrusion Type Allium chinense Harvester[J]. Journal of Agricultural Science and Technology, 2024, 26(6): 72-81.

柳亚峰, 方志超, 夏海峰, 曲永波, 吴明亮. 对辊拨刷式藠头收获机设计与试验[J]. 中国农业科技导报, 2024, 26(6): 72-81.

| 参数 Parameter | 数值 Value |

|---|---|

| 外形尺寸(长×宽×高) Shape size(length×width×high)/m | 2.0×1.9×1.5 |

| 作业幅宽 Operating width/m | 1.6 |

| 前进速度 Forward speed/(m·s-1) | 0.2~0.6 |

| 最大挖掘深度 Digging depth/m | 0.3 |

| 生产率 Productivity/(hm2·h-1) | 1.152~3.456 |

| 整机质量 Total weight/kg | 450 |

| 配套动力 Mating power/kW | 50~70 |

Table 1 Technical parameters of double roller extrusion type Allium chinense harvester

| 参数 Parameter | 数值 Value |

|---|---|

| 外形尺寸(长×宽×高) Shape size(length×width×high)/m | 2.0×1.9×1.5 |

| 作业幅宽 Operating width/m | 1.6 |

| 前进速度 Forward speed/(m·s-1) | 0.2~0.6 |

| 最大挖掘深度 Digging depth/m | 0.3 |

| 生产率 Productivity/(hm2·h-1) | 1.152~3.456 |

| 整机质量 Total weight/kg | 450 |

| 配套动力 Mating power/kW | 50~70 |

Fig. 1 Structure of Allium chinense harvesterNote:1—Excavation shovel; 2—Swinging sieve; 3—Adjustable connecting rod; 4—Connecting rod; 5—Suspension bracket; 6—Body frame; 7—Transmission shaft; 8—Depth adjustment handwheel; 9—Feeding roller; 10—Crushing roller; 11—Depth wheel; 12—Laying grid.

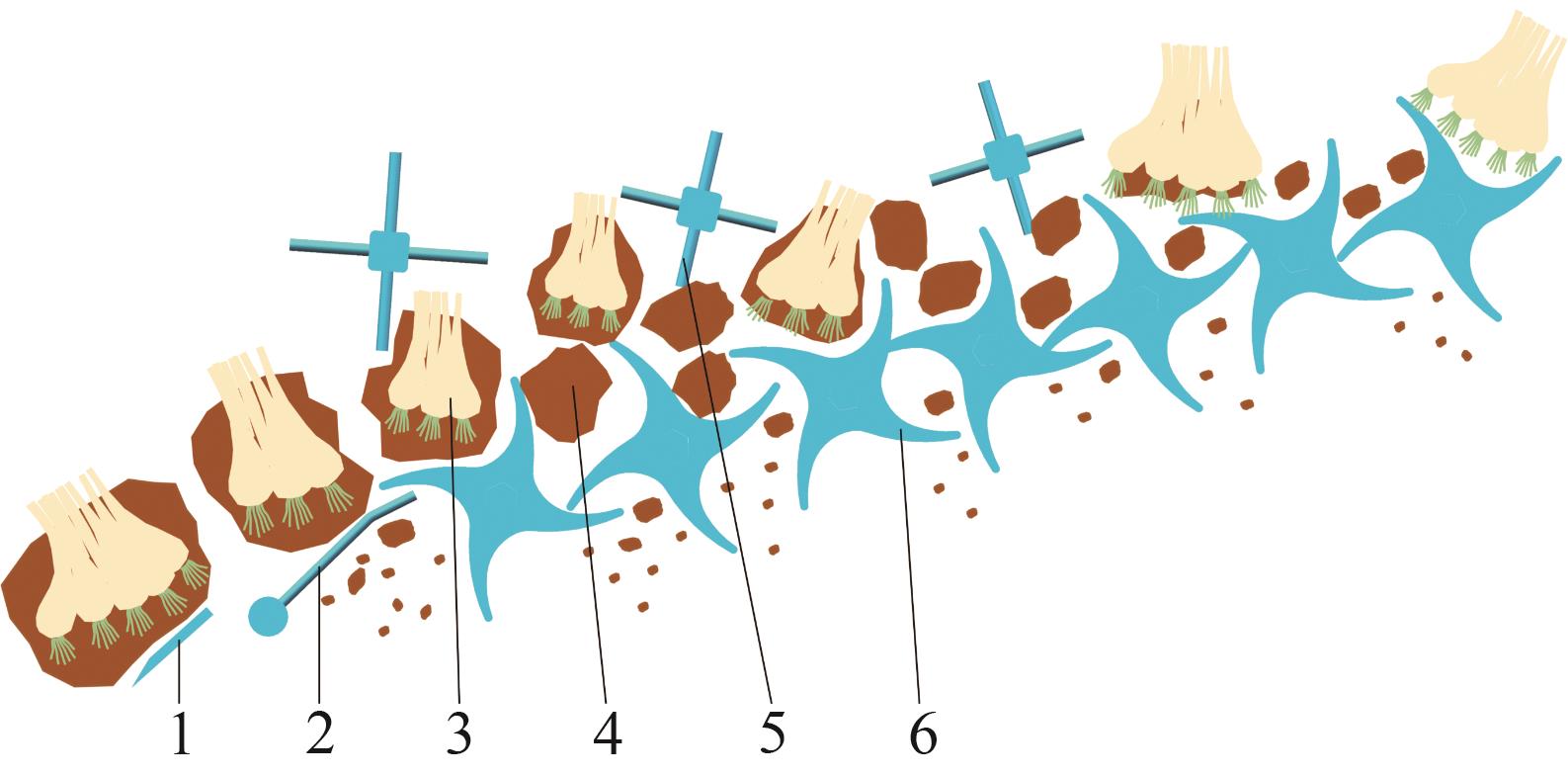

Fig. 2 Schematic diagram of opposite roller extrusion separationNote:1—Excavation shovel; 2—Swinging sieve; 3—Allium chinense; 4—Soil; 5—Crushing roller; 6—Feeding roller.

水平 Level | 因素 Factor | ||

|---|---|---|---|

X1:前进速度 Forward speed/(m·s-1) | X2:转速差 Rotation difference/(r·min-1) | X3:旋转半径 Rotation radius/mm | |

| -1 | 0.2 | 40 | 40 |

| 0 | 0.4 | 60 | 50 |

| 1 | 0.6 | 80 | 60 |

Table 2 Experimental factors and levels

水平 Level | 因素 Factor | ||

|---|---|---|---|

X1:前进速度 Forward speed/(m·s-1) | X2:转速差 Rotation difference/(r·min-1) | X3:旋转半径 Rotation radius/mm | |

| -1 | 0.2 | 40 | 40 |

| 0 | 0.4 | 60 | 50 |

| 1 | 0.6 | 80 | 60 |

试验号 Test number | X1 | X2 | X3 | Y1/% | Y2/% |

|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 88.0 | 2.90 |

| 2 | 0 | 1 | -1 | 86.0 | 2.16 |

| 3 | 0 | -1 | -1 | 85.9 | 1.58 |

| 4 | 0 | 0 | 0 | 90.2 | 1.99 |

| 5 | 0 | 0 | 0 | 89.5 | 1.89 |

| 6 | 1 | 1 | 0 | 90.6 | 2.47 |

| 7 | 0 | 0 | 0 | 89.9 | 1.84 |

| 8 | 0 | 0 | 0 | 90.0 | 2.05 |

| 9 | -1 | 1 | 0 | 89.1 | 2.43 |

| 10 | 0 | -1 | 1 | 86.2 | 2.36 |

| 11 | 1 | 0 | -1 | 86.2 | 2.29 |

| 12 | 0 | 1 | 1 | 89.1 | 2.63 |

| 13 | 0 | 0 | 0 | 90.5 | 2.10 |

| 14 | -1 | -1 | 0 | 88.1 | 1.61 |

| 15 | -1 | 0 | -1 | 85.7 | 1.91 |

| 16 | -1 | 0 | 1 | 86.1 | 2.52 |

| 17 | 1 | -1 | 0 | 89.3 | 2.19 |

Table 3 Test scheme and results

试验号 Test number | X1 | X2 | X3 | Y1/% | Y2/% |

|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 88.0 | 2.90 |

| 2 | 0 | 1 | -1 | 86.0 | 2.16 |

| 3 | 0 | -1 | -1 | 85.9 | 1.58 |

| 4 | 0 | 0 | 0 | 90.2 | 1.99 |

| 5 | 0 | 0 | 0 | 89.5 | 1.89 |

| 6 | 1 | 1 | 0 | 90.6 | 2.47 |

| 7 | 0 | 0 | 0 | 89.9 | 1.84 |

| 8 | 0 | 0 | 0 | 90.0 | 2.05 |

| 9 | -1 | 1 | 0 | 89.1 | 2.43 |

| 10 | 0 | -1 | 1 | 86.2 | 2.36 |

| 11 | 1 | 0 | -1 | 86.2 | 2.29 |

| 12 | 0 | 1 | 1 | 89.1 | 2.63 |

| 13 | 0 | 0 | 0 | 90.5 | 2.10 |

| 14 | -1 | -1 | 0 | 88.1 | 1.61 |

| 15 | -1 | 0 | -1 | 85.7 | 1.91 |

| 16 | -1 | 0 | 1 | 86.1 | 2.52 |

| 17 | 1 | -1 | 0 | 89.3 | 2.19 |

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 53.68 | 9 | 5.96 | 52.16 | <0.000 1** |

| 3.25 | 1 | 3.25 | 28.43 | 0.001 1** | |

| 3.51 | 1 | 3.51 | 30.70 | 0.000 9** | |

| 3.92 | 1 | 3.92 | 34.28 | 0.000 6** | |

| 0.02 | 1 | 0.02 | 0.19 | 0.670 7 | |

| 0.49 | 1 | 0.49 | 4.28 | 0.077 2 | |

| 1.96 | 1 | 1.96 | 17.14 | 0.004 3** | |

| 1.15 | 1 | 1.15 | 10.05 | 0.015 7* | |

| 0.21 | 1 | 0.20 | 1.82 | 0.219 0 | |

| 37.83 | 1 | 37.83 | 330.80 | <0.000 1** | |

| 残差 Residual | 0.800 5 | 7 | 0.114 4 | ||

| 失拟 Lack of fit | 0.252 5 | 3 | 0.084 2 | 0.614 4 | 0.640 9 |

| 误差 Error | 0.548 | 4 | 0.137 | ||

| 总和 Sum | 54.48 | 16 |

Table 4 Variance analysis for root-soil separation rate

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 53.68 | 9 | 5.96 | 52.16 | <0.000 1** |

| 3.25 | 1 | 3.25 | 28.43 | 0.001 1** | |

| 3.51 | 1 | 3.51 | 30.70 | 0.000 9** | |

| 3.92 | 1 | 3.92 | 34.28 | 0.000 6** | |

| 0.02 | 1 | 0.02 | 0.19 | 0.670 7 | |

| 0.49 | 1 | 0.49 | 4.28 | 0.077 2 | |

| 1.96 | 1 | 1.96 | 17.14 | 0.004 3** | |

| 1.15 | 1 | 1.15 | 10.05 | 0.015 7* | |

| 0.21 | 1 | 0.20 | 1.82 | 0.219 0 | |

| 37.83 | 1 | 37.83 | 330.80 | <0.000 1** | |

| 残差 Residual | 0.800 5 | 7 | 0.114 4 | ||

| 失拟 Lack of fit | 0.252 5 | 3 | 0.084 2 | 0.614 4 | 0.640 9 |

| 误差 Error | 0.548 | 4 | 0.137 | ||

| 总和 Sum | 54.48 | 16 |

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 1.990 0 | 9 | 0.220 7 | 97.00 | 0.000 1** |

| 0.238 0 | 1 | 0.238 0 | 29.08 | 0.001** | |

| 0.475 3 | 1 | 0.475 3 | 58.07 | 0.000 1** | |

| 0.762 6 | 1 | 0.762 6 | 93.17 | <0.000 1** | |

| 0.072 9 | 1 | 0.072 9 | 8.91 | 0.020 4* | |

| 0 | 1 | 0 | 0 | 1.000 0 | |

| 0.024 0 | 1 | 0.024 0 | 2.94 | 0.130 4 | |

| 0.188 8 | 1 | 0.188 8 | 23.07 | 0.002 0** | |

| 0.000 5 | 1 | 0.000 5 | 0.06 | 0.814 4 | |

| 0.202 4 | 1 | 0.202 4 | 24.73 | 0.001 6** | |

| 残差Residual | 0.057 3 | 7 | 0.008 2 | ||

| 失拟Lack of fit | 0.010 4 | 3 | 0.003 5 | 0.294 8 | 0.828 3 |

| 误差Error | 0.046 9 | 4 | 0.011 7 | ||

| 总和Sum | 2.040 0 | 16 |

Table 5 Variance analysis for damage rate of rhizome

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 1.990 0 | 9 | 0.220 7 | 97.00 | 0.000 1** |

| 0.238 0 | 1 | 0.238 0 | 29.08 | 0.001** | |

| 0.475 3 | 1 | 0.475 3 | 58.07 | 0.000 1** | |

| 0.762 6 | 1 | 0.762 6 | 93.17 | <0.000 1** | |

| 0.072 9 | 1 | 0.072 9 | 8.91 | 0.020 4* | |

| 0 | 1 | 0 | 0 | 1.000 0 | |

| 0.024 0 | 1 | 0.024 0 | 2.94 | 0.130 4 | |

| 0.188 8 | 1 | 0.188 8 | 23.07 | 0.002 0** | |

| 0.000 5 | 1 | 0.000 5 | 0.06 | 0.814 4 | |

| 0.202 4 | 1 | 0.202 4 | 24.73 | 0.001 6** | |

| 残差Residual | 0.057 3 | 7 | 0.008 2 | ||

| 失拟Lack of fit | 0.010 4 | 3 | 0.003 5 | 0.294 8 | 0.828 3 |

| 误差Error | 0.046 9 | 4 | 0.011 7 | ||

| 总和Sum | 2.040 0 | 16 |

试验号 Test number | Y1:根土分离率 Rhizome soil separation rate/% | Y2:根茎损伤率 Rhizome damage rate/% |

|---|---|---|

| 1 | 88.9 | 1.81 |

| 2 | 87.9 | 1.73 |

| 3 | 89.6 | 1.87 |

| 4 | 88.5 | 1.78 |

| 5 | 87.7 | 1.71 |

| 平均值 Average value | 88.5 | 1.78 |

| 预测值 Prediction value | 89.3 | 1.73 |

| 相对误差 Relative error | 0.89 | 2.89 |

Table.6 Comparison of model prediction and validation test results

试验号 Test number | Y1:根土分离率 Rhizome soil separation rate/% | Y2:根茎损伤率 Rhizome damage rate/% |

|---|---|---|

| 1 | 88.9 | 1.81 |

| 2 | 87.9 | 1.73 |

| 3 | 89.6 | 1.87 |

| 4 | 88.5 | 1.78 |

| 5 | 87.7 | 1.71 |

| 平均值 Average value | 88.5 | 1.78 |

| 预测值 Prediction value | 89.3 | 1.73 |

| 相对误差 Relative error | 0.89 | 2.89 |

| 1 | 袁祖华,彭莹.长江流域藠头高产栽培技术[J].长江蔬菜,2015(13):39-41. |

| 2 | 陈学军,程和生,万新建,等.绿色食品藠头栽培技术规程[J].江西农业学报,2009,21(8):97-98. |

| CHEN X J, CHENG H S, WAN X J, et al.. Cultivation technology regulation of green food crop Allium chinensis [J]. Acta Agric. Jiangxi, 2009, 21(8): 97-98. | |

| 3 | 王龙,刘浩,胡海波.中药薤白基源植物的历史变迁[J].中华中医药杂志,2017,32(6):2422-2424. |

| WANG L, LIU H, HU H B. History of origin plants of Chinese herbal medicine Bulbus Allii macrostemi [J]. China J. Trad. Chin. Med. Pharm., 2017, 32(6): 2422-2424. | |

| 4 | 张兆国,李彦彬,王海翼,等.马铃薯机械化收获关键技术与装备研究进展[J].云南农业大学学报(自然科学),2021,36(6):1092-1103. |

| ZHANG Z G, LI Y B, WANG H Y, et al.. Research progress on key technology and equipment of potato mechanized harvest [J]. J. Yunnan Agric. Univ. (Nat. Sci.), 2021, 36(6): 1092-1103. | |

| 5 | 陈中玉,高连兴, CHEN Charles,等.中美花生收获机械化技术现状与发展分析[J].农业机械学报,2017,48(4):1-21. |

| CHEN Z Y, GAO L X, CHEN C, et al.. Development course of peanut harvest mechanization technology of the united states and enlightenment to China [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(4): 1-21. | |

| 6 | 王申莹,胡志超, CHEN Charles,等.牵引式甜菜联合收获机自动对行系统设计与台架试验[J].农业机械学报,2020,51(4): 103-112, 163. |

| WANG S Y, HU Z C, CHEN C, et al.. Bench test and analysis on performance of autofollow row for traction sugar beet combine harvester [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(4): 103-112, 163. | |

| 7 | 李涛,周进,徐文艺,等. 4UGS2 型双行甘薯收获机的研制[J]. 农业工程学报,2018,34(11):26-33. |

| LI T, ZHOU J, XU W Y, et al.. Development of 4UGS2 type double-row sweet potato harvester [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(11): 26-33. | |

| 8 | 侯加林,陈彦宇,李玉华,等.铲筛组合式大葱挖掘抖土疏整装置设计与试验[J].农业工程学报,2021,37(18):29-39. |

| HOU J L, CHEN Y Y, LI Y H, et al.. Design and experiment of shovel-screen combined green onion digging, shaking, and soil tillage device [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(18): 29-39. | |

| 9 | 宋江,邱胜蓝,王新忠. 4B-1200型平贝母药材收获机的设计与试验[J].农业工程学报,2015,31(8):34-41. |

| SONG J, QIU S L, WANG X Z. Design and test on 4B-1200 type bulbus Fritillariae ussuriensis medicinal material harvester [J]. Trans. Chin. Soc. Agric. Eng., 2015, 31(8): 34-41. | |

| 10 | 张兆国,王法安,张永成,等.自走式三七收获机设计与试验[J]. 农业机械学报,2016,47(S1):234-240. |

| ZHANG Z G, WANG F A, ZHANG Y C, et al.. Design and experiment of self-propelled Panax notoginseng harvester [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(S1): 234-240. | |

| 11 | 陈学深,马旭,武涛,等.虎杖根系脱土装置设计与试验[J].农业机械学报, 2015,46(7):59-65. |

| CHEN X S, MA X, WU T, et al.. Design and experiment of Roots-Soil separating device of knotweeds [J]. Trans. Chin. Soc. Agric. Mach., 2015, 46(7): 59-65. | |

| 12 | 杨发展,杨云鹏,李维华,等.悬挂式山药收获机振动挖掘碎土装置设计与试验[J].农业机械学报,,2020,,51(6):104-111. |

| YANG F Z, YANG Y P, LI W H, et al.. Structural design and experiment on vibrating soil breaking device of mounted yam harvester [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(6): 104-111. | |

| 13 | 吕金庆,杨晓涵,吕伊宁,等.马铃薯挖掘机升运分离过程块茎损伤机理分析与试验[J].农业机械学报,2020,51(1):103-113. |

| LYU J Q, YANG X H, LYU Y N, et al.. Analysis and experiment of potato damage in process of lifting and separating potato excavator [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(1): 103-113. | |

| 14 | 魏忠彩,苏国粱,李学强,等.基于离散元的马铃薯收获机波浪形筛面参数优化与试验[J].农业机械学报,2020,51(10):109-122. |

| WEI Z C, SU G L, LI X Q, et al.. Parameter optimization and test of potato harvester wavy sieve based on EDEM [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(10): 109-122. | |

| 15 | 万里鹏程,李永磊,赵虎,等.根茎类作物单摆铲栅收获装置渐变抛掷特性[J].农业工程学报,2021,37(24):9-21. |

| WAN L P C, LI Y L, ZHAO H, et al.. Gradient throwing characteristics of oscillating slat shovel for rhizome crop harvesters [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(24): 9-21. | |

| 16 | 张兆国,薛浩田,王一驰,等.基于离散元法的三七仿生挖掘铲设计与试验[J].农业机械学报,2022,53(5):100-111. |

| ZHANG Z G, XUE H T, WANG Y C, et al.. Design and experiment of Panax notoginseng bionic excavating shovel based on EDEM [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(5): 100-111. | |

| 17 | 曲永波,方志超,吴明亮,等.振动和拨辊推送式藠头收获机研制[J]. 农业工程学报,2022,38(19):51-59. |

| QU Y B, FANG Z C, WU M L, et al.. Development of vibrating and roller pushing type Allium chinense harvester [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(19): 51-59. | |

| 18 | 康建明,李树君,杨学军,等.正弦指数曲线型开沟刀片结构参数优化[J].农业机械学报,2016,47(11):91-99, 17. |

| KANG J M, LI S J, YANG X J, et al.. Structure parameters optimization of sine exponential curve type ditching blade [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(11): 91-99, 17. | |

| 19 | 吴建民,李辉,孙伟,等.拨指轮式马铃薯挖掘机试验[J].农业工程学报,2011,27(7):173-177. |

| WU J M, LI H, SUN W, et al.. Experiment on poke finger wheel type potato digger [J]. Trans. Chin. Soc. Agric. Eng., 2011, 27(7): 173-177. | |

| 20 | 代振维,吴明亮,方志超,等.抛送辊式百合收获机的设计与试验[J].农业工程学报,2023,39(12):20-29. |

| DAI Z W, WU M L, FANG Z C, et al.. Design and test of a throwing roller type lily bulb harvester [J]. Trans. Chin. Soc. Agric. Eng., 2023, 39(12): 20-29. | |

| 21 | 管春松,崔志超,高庆生,等.双轴旋耕碎土试验台设计与分层耕作试验[J].农业工程学报,2021,37(10):28-37. |

| GUAN C S, CUI Z C, GAO Q S, et al.. Design of biaxial rotary tillage soil test bench and layered tillage test [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(10): 28-37. | |

| 22 | 陈桂斌,王庆杰,李问盈,等.对辊差速式块状有机肥破碎施肥装置设计与试验[J].农业机械学报,2021,52(12):65-76. |

| CHEN G B, WANG Q J, Li W Y, et al.. Design and experiment of double roller differential speed crushing fertilizer device for block organic fertilizer [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(12): 65-76. | |

| 23 | 杨然兵,杨红光,尚书旗,等.拨辊推送式马铃薯收获机设计与试验[J].农业机械学报,2016,47(7):119-126. |

| YANG R B, YANG H G, SHANG S Q, et al.. Design and experiment of vertical circular separating and conveying device for potato combine harvester [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(7): 119-126. | |

| 24 | 吕金庆,孙贺,兑瀚,等.粘重土壤下马铃薯挖掘机分离输送装置改进设计与试验[J].农业机械学报,2017,48(11):146-155. |

| LV J Q, SUN H, DUI H, et al.. Design and experiment on conveyor separation device of potato digger under heavy soil condition [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(11): 146-155. |

| [1] | Fengguang HE, Zihong CHEN, Ganran DENG, Tenghui LI, Sili ZHOU, Guojie LI, Zhende CUI, Shuang ZHENG, Ling LI, Shuangmei QIN, Xiang WANG, Shaoying YANG, Deqiang ZHOU. Design and Performance of Cutting Depth Monitoring System for Sugarcane Harvester Cutter [J]. Journal of Agricultural Science and Technology, 2024, 26(5): 101-109. |

| [2] | Fengguang HE, Ganran DENG, Zhende CUI, Shuang ZHENG, Guojie LI, Ling LI, Shuangmei QIN. Operating Performance of Self-propelled Silage Cassava Stem and Leaf Harvester [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 109-115. |

| [3] | WEI Tianlu1§, DU Shuang2§, GE Yiyuan2*, JIANG Yongcheng2, WANG Junfa2, LIU Dongxu2. Optimum Design and Experiment of Cutter of Chopping Roller of Green Forage Harvester [J]. Journal of Agricultural Science and Technology, 2020, 22(12): 77-87. |

| [4] | YANG Anming1, WU Mingliang1,2*, LYU Jiangnan3, XIANG Wei3. Design and Experiment on Chopping System of Forage Ramie Harvester [J]. Journal of Agricultural Science and Technology, 2020, 22(10): 110-118. |

| [5] | LI Jinfeng, LIU Xianxi, ZHANG Kaixing*. Grain Combine Harvester Cutter and Whole Machine Smoothness Simulation Analysis Based on ADAMS [J]. Journal of Agricultural Science and Technology, 2019, 21(1): 62-69. |

| [6] | XIE Chao1, LIU Dawei1,2, LI Xu1,2, XIE Fangping1,2*, WANG Xunwei1, XIE Jinfan1. Structure Optimization and Experiment on Cyclone Separation-Purification Device for Small Rice Combine Harvester [J]. Journal of Agricultural Science and Technology, 2018, 20(5): 54-63. |

| [7] | YANG Hongguang1,2, YANG Ranbing1,2*, SHANG Shuqi1,2, LIU Zhishen1, NI Zhiwei1. Design and Experiment of Vibration Digging Type Potato Harvester [J]. Journal of Agricultural Science and Technology, 2017, 19(8): 55-62. |

| [8] | CHEN Changlin, SHI Lei*, ZHANG Yutong, KONG Fanting, XIE Qing, . Design and Test of Cotton-boll Separation and Collection System from Stripper Cotton Harvester [J]. Journal of Agricultural Science and Technology, 2017, 19(11): 68-73. |

| [9] | XIE Feng, GUO Jin-bing, LIAO Na, LIU Yun-dong, GUAN Cheng-jun*. Kinematics Simulation Analysis of the Sugarcane #br# Harvester Cutter based on Adams [J]. Journal of Agricultural Science and Technology, 2016, 18(4): 87-92. |

| [10] | CHEN Qing-wen, HAN Zeng-de*, CUI Jun-wei, WANG Guo-xin, QIAO Xiao-dong, ZHANG Zi. Development Status and Trend Current Situation of Self-propelled Combine Harvester [J]. , 2015, 17(1): 109-114. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号