中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (3): 162-171.DOI: 10.13304/j.nykjdb.2023.0724

• 食品质量 加工储运 • 上一篇

饶文俊( ), 李信, 欧阳玲花, 祝水兰, 袁林峰, 周巾英(

), 李信, 欧阳玲花, 祝水兰, 袁林峰, 周巾英( )

)

收稿日期:2023-09-28

接受日期:2023-12-04

出版日期:2025-03-15

发布日期:2025-03-14

通讯作者:

周巾英

作者简介:饶文俊 E-mail:1171416511@qq.com;

基金资助:

Wenjun RAO( ), Xin LI, Linghua OUYANG, Shuilan ZHU, Linfeng YUAN, Jinying ZHOU(

), Xin LI, Linghua OUYANG, Shuilan ZHU, Linfeng YUAN, Jinying ZHOU( )

)

Received:2023-09-28

Accepted:2023-12-04

Online:2025-03-15

Published:2025-03-14

Contact:

Jinying ZHOU

摘要:

为探究焙炒程度对黑芝麻风味的影响,采用气相色谱-离子迁移谱(gas chromatography-ion mobility spectrometry,GC-IMS)对未焙炒、轻度焙炒、中度焙炒和重度焙炒的黑芝麻进行风味差异分析。结果表明,不同焙炒程度黑芝麻样品可通过GC-IMS技术得到较好地区分。GC-IMS共定性出52种挥发性风味物质,其中醛酮类、酯类物质对焙炒黑芝麻风味贡献较大,随着焙炒过程的进行其种类和含量逐渐增加;吡嗪类、吡咯类、呋喃类物质是焙炒黑芝麻的主体香味,呈现出浓郁的坚果香、焙烤香和焦香,这些物质在焙炒后期含量较高。通过多元统计分析能够有效地判别不同焙炒程度的黑芝麻样品。并筛选出13种差异香气化合物,根据这13种差异化合物进行聚类分析,聚类结果与GC-IMS结果相似。综上,利用GC-IMS技术,构建了不同焙炒程度黑芝麻风味指纹谱图,为黑芝麻焙炒工艺优化、产品品质提升提供了理论参考。

中图分类号:

饶文俊, 李信, 欧阳玲花, 祝水兰, 袁林峰, 周巾英. 基于GC-IMS技术对不同焙炒程度黑芝麻风味差异分析[J]. 中国农业科技导报, 2025, 27(3): 162-171.

Wenjun RAO, Xin LI, Linghua OUYANG, Shuilan ZHU, Linfeng YUAN, Jinying ZHOU. Analysis of Flavor Differences of Black Sesame Seeds at Different Roasting Levels Based on GC-IMS Technique[J]. Journal of Agricultural Science and Technology, 2025, 27(3): 162-171.

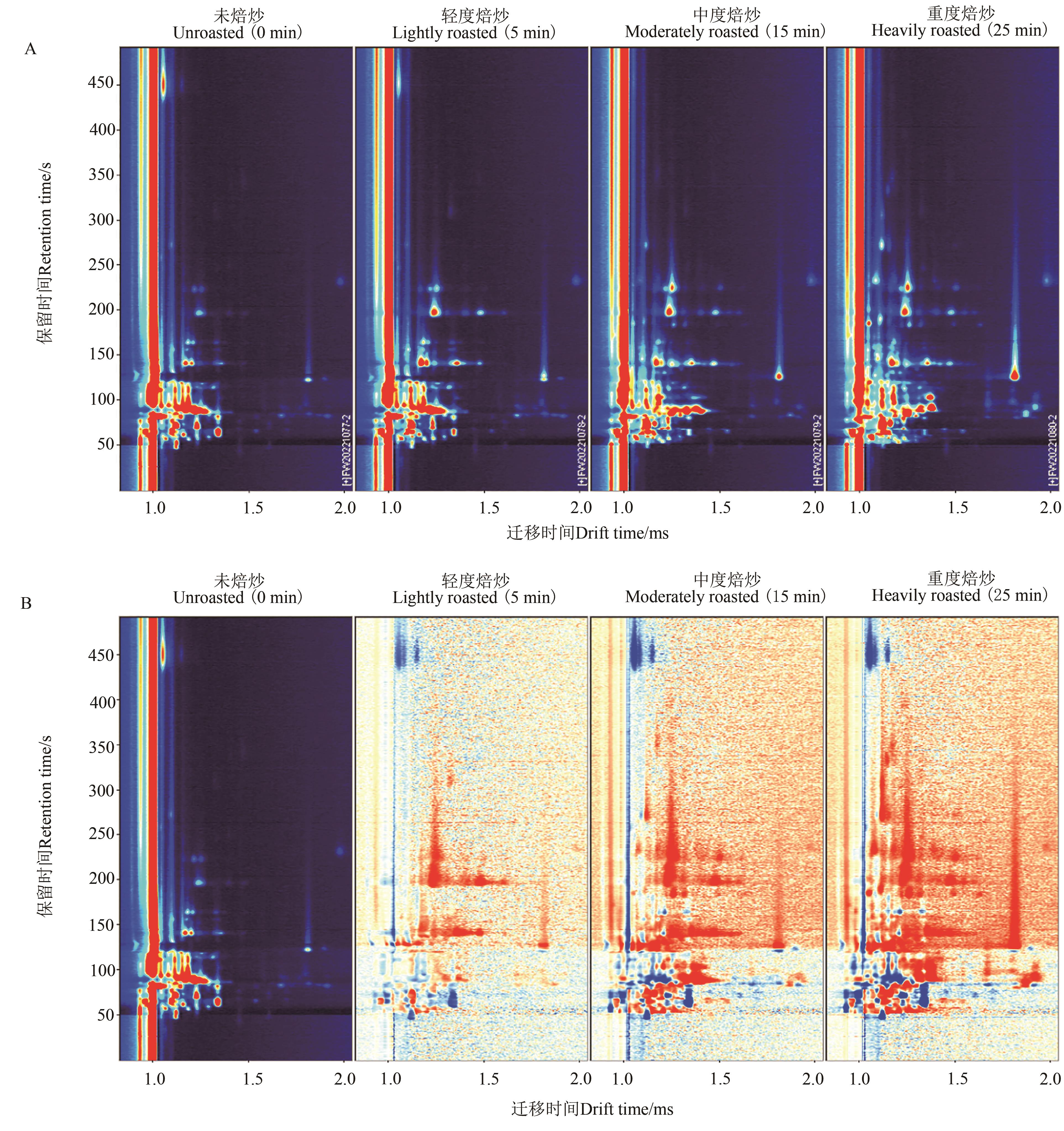

图1 不同焙炒程度黑芝麻GC-IMS谱图A:二维俯视图;B:差异化谱图

Fig. 1 GC-IMS spectra of black sesame seeds with different roasting degreesA: Two-dimensional top view; B: Differentiated spectra

类别 Category | 序号 Number | 化合物 Compound | 分子式 Formula | 分子量 Molecular weight | 保留指数 Retention index | 保留时间 Retention time/s | 迁移时间 Drift time/ms |

|---|---|---|---|---|---|---|---|

醇类 Alcohols | 1 | 异戊醇M IsopentanolM | C5H12O | 88.1 | 1 175.7 | 200.266 | 1.235 87 |

| 2 | 异戊醇D IsopentanolD | C5H12O | 88.1 | 1 171.6 | 197.360 | 1.483.00 | |

| 3 | 异丁醇M IsobutanolM | C4H10O | 74.1 | 1 074.2 | 143.581 | 1.168 44 | |

| 4 | 异丁醇D IsobutanolD | C4H10O | 74.1 | 1 069.8 | 141.561 | 1.357 66 | |

| 5 | 乙醇M EthanolM | C2H6O | 46.1 | 950.6 | 97.198 | 1.041 28 | |

| 6 | 乙醇D EthanolD | C2H6O | 46.1 | 951.8 | 97.446 | 1.115 54 | |

| 7 | 异丙醇 Isopropanol | C3H8O | 60.1 | 939.9 | 94.965 | 1.077 68 | |

| 8 | 正己醇 Hexanol | C6H14O | 102.2 | 871.6 | 81.759 | 1.341 59 | |

酸类 Acids | 9 | 乙酸 Acetate | C2H4O2 | 60.1 | 1 405.8 | 452.560 | 1.055 86 |

酯类 Esters | 10 | 丁酸丙酯 Propyl butyrate | C7H14O2 | 130.2 | 1 151.8 | 184.079 | 1.265 62 |

| 11 | 丙酸丙酯 Propyl propanoate | C6H12O2 | 116.2 | 1 071.2 | 142.192 | 1.197 91 | |

| 12 | 2-甲基丙酸乙酯 Ethyl isobutyrate | C6H12O2 | 116.2 | 970 | 101.417 | 1.183 97 | |

| 13 | 乙酸甲酯 Methyl acetate | C3H6O2 | 74.1 | 874.7 | 82.308 | 1.036 91 | |

| 14 | 乙酸乙酯 Ethyl acetate | C4H8O2 | 88.1 | 907.7 | 88.478 | 1.324 66 | |

| 15 | 乙酸异戊酯 Isoamyl acetate | C7H14O2 | 130.2 | 873.5 | 82.095 | 1.297 05 | |

| 16 | 戊酸乙酯 Ethyl valerate | C7H14O2 | 130.2 | 890.0 | 85.113 | 1.253 35 | |

| 17 | 丁酸甲酯 Methyl butyrate | C5H10O2 | 102.1 | 718.4 | 58.444 | 1.154 01 | |

| 18 | 丁酸乙酯 Ethyl butanoate | C6H12O2 | 116.2 | 788.8 | 68.192 | 1.20033 | |

| 19 | γ-丁内酯 γ-butyrolactone | C4H6O2 | 86.1 | 898.0 | 86.633 | 1.088 01 | |

| 20 | 3-甲基丁酸乙酯 Ethyl isovalerate | C7H14O2 | 130.2 | 1 068.3 | 140.824 | 1.254 44 | |

| 21 | 乙酸异丙酯 Isopropyl acetate | C5H10O2 | 102.1 | 918.6 | 90.629 | 1.176 39 | |

| 22 | γ-己内酯 γ-caprolactone | C6H10O2 | 114.1 | 1 047.5 | 130.843 | 1.172 63 | |

醛类 Aldehydes | 23 | (Z)-6-壬烯醛 (Z)-6-nonenal | C9H16O | 140.2 | 1 106 | 158.983 | 1.169 99 |

| 24 | 异戊醛 Isovaleraldehyde | C5H10O | 86.1 | 956.4 | 98.439 | 1.189 79 | |

| 25 | 丁醛 Butyraldehyde | C4H8O | 72.1 | 888.4 | 84.816 | 1.123 24 | |

| 26 | 洋茉莉醛丙二醇缩醛 Piperonal propylene glycol acetal | C11H12O4 | 208.2 | 756.8 | 63.582 | 1.127 38 | |

| 27 | 反式-2-戊烯醛 (E)-2-pentenal | C5H8O | 84.1 | 749.2 | 62.528 | 1.093 80 | |

| 28 | 正戊醛 Valeraldehyde | C5H10O | 86.1 | 695.2 | 55.546 | 1.189 90 | |

| 29 | 正己醛 Hexanal | C6H12O | 100.2 | 790.8 | 68.485 | 1.233 89 | |

酮类 Ketones | 30 | 环戊酮 Cyclopentanone | C5H8O | 84.1 | 1 161.5 | 190.304 | 1.107 73 |

| 31 | 2-戊酮M Pentan-2-oneM | C5H10O | 86.1 | 984.8 | 104.891 | 1.118 45 | |

| 32 | 2-戊酮D Pentan-2-oneD | C5H10O | 86.1 | 975.5 | 102.658 | 1.371 79 | |

| 33 | 乙酸基丙酮 1-acetoxyacetone | C5H8O3 | 116.1 | 873.5 | 82.095 | 1.188 67 | |

| 34 | 异丙叉丙酮 Mesityl oxide | C6H10O | 98.1 | 810.6 | 71.530 | 1.126 07 | |

| 35 | 3-羟基-2-丁酮 Acetoin | C4H8O2 | 88.1 | 729.5 | 59.893 | 1.061 38 | |

| 36 | 2,3-戊二酮 2,3-pentanedione | C5H8O2 | 100.1 | 670.7 | 52.648 | 1.206 11 | |

| 37 | 甲基异丁基甲酮4-methyl-2-pentanone | C6H12O | 100.2 | 1 010.5 | 114.861 | 1.185 35 | |

吡嗪类 Pyrazines | 38 | 2,5-二甲基吡嗪2,5-dimethylpyrazine | C6H8N2 | 108.1 | 1 262.3 | 272.901 | 1.107 73 |

| 39 | 2-甲基吡嗪 Methylpyrazine | C5H6N2 | 94.1 | 1 218.5 | 233.471 | 1.087 13 | |

吡咯类 Pyrroles | 40 | 2-乙酰基吡咯M 2-acetylpyrroleM | C6H7NO | 109.1 | 1 080.2 | 146.358 | 1.097 10 |

| 41 | N-甲基吡咯烷酮 N-methylpyrrolidone | C5H9NO | 99.1 | 1 037.7 | 126.411 | 1.086 11 | |

| 42 | 2-乙酰基吡咯D 2-acetylpyrroleD | C6H7NO | 109.1 | 1 068.3 | 140.824 | 1.471 97 | |

呋喃类 Furans | 43 | 2-戊基呋喃 2-amylfuran | C9H14O | 138.2 | 1 209.9 | 226.415 | 1.251 89 |

| 44 | 2-正丁基呋喃 2-butylfuran | C8H12O | 124.2 | 1 116.5 | 164.412 | 1.180 85 | |

| 45 | 2,5-二甲基呋喃 2,5-dimethylfuran | C6H8O | 96.1 | 923.0 | 91.490 | 1.371 79 | |

| 46 | 四氢呋喃 Tetrahydrofuran | C4H8O | 72.1 | 862.2 | 80.086 | 1.234 93 | |

萜类 Terpenes | 47 | α-松油烯 α-terpinene | C10H16 | 136.2 | 1 006.5 | 113.221 | 1.238 01 |

| 48 | 柠檬烯 Limonene | C10H16 | 136.2 | 1 009.3 | 114.365 | 1.315 01 | |

其他 Others | 49 | 丙硫醇 1-propanethiol | C3H8S | 76.2 | 830.5 | 74.705 | 1.161 24 |

| 50 | 1,4-二氧六环 1,4-dioxane | C4H8O2 | 88.1 | 731.6 | 60.157 | 1.121 59 | |

| 51 | 邻二甲苯 O-xylene | C8H10 | 106.2 | 1 153.2 | 184.909 | 1.050 52 | |

| 52 | 苯甲醚 Anisole | C7H8O | 108.1 | 902.9 | 87.555 | 1.044 01 |

表1 不同焙炒程度黑芝麻风味物质定性结果 (续表Continued)

Table 1 Qualitative results of flavor substances of black sesame at different roasting levels

类别 Category | 序号 Number | 化合物 Compound | 分子式 Formula | 分子量 Molecular weight | 保留指数 Retention index | 保留时间 Retention time/s | 迁移时间 Drift time/ms |

|---|---|---|---|---|---|---|---|

醇类 Alcohols | 1 | 异戊醇M IsopentanolM | C5H12O | 88.1 | 1 175.7 | 200.266 | 1.235 87 |

| 2 | 异戊醇D IsopentanolD | C5H12O | 88.1 | 1 171.6 | 197.360 | 1.483.00 | |

| 3 | 异丁醇M IsobutanolM | C4H10O | 74.1 | 1 074.2 | 143.581 | 1.168 44 | |

| 4 | 异丁醇D IsobutanolD | C4H10O | 74.1 | 1 069.8 | 141.561 | 1.357 66 | |

| 5 | 乙醇M EthanolM | C2H6O | 46.1 | 950.6 | 97.198 | 1.041 28 | |

| 6 | 乙醇D EthanolD | C2H6O | 46.1 | 951.8 | 97.446 | 1.115 54 | |

| 7 | 异丙醇 Isopropanol | C3H8O | 60.1 | 939.9 | 94.965 | 1.077 68 | |

| 8 | 正己醇 Hexanol | C6H14O | 102.2 | 871.6 | 81.759 | 1.341 59 | |

酸类 Acids | 9 | 乙酸 Acetate | C2H4O2 | 60.1 | 1 405.8 | 452.560 | 1.055 86 |

酯类 Esters | 10 | 丁酸丙酯 Propyl butyrate | C7H14O2 | 130.2 | 1 151.8 | 184.079 | 1.265 62 |

| 11 | 丙酸丙酯 Propyl propanoate | C6H12O2 | 116.2 | 1 071.2 | 142.192 | 1.197 91 | |

| 12 | 2-甲基丙酸乙酯 Ethyl isobutyrate | C6H12O2 | 116.2 | 970 | 101.417 | 1.183 97 | |

| 13 | 乙酸甲酯 Methyl acetate | C3H6O2 | 74.1 | 874.7 | 82.308 | 1.036 91 | |

| 14 | 乙酸乙酯 Ethyl acetate | C4H8O2 | 88.1 | 907.7 | 88.478 | 1.324 66 | |

| 15 | 乙酸异戊酯 Isoamyl acetate | C7H14O2 | 130.2 | 873.5 | 82.095 | 1.297 05 | |

| 16 | 戊酸乙酯 Ethyl valerate | C7H14O2 | 130.2 | 890.0 | 85.113 | 1.253 35 | |

| 17 | 丁酸甲酯 Methyl butyrate | C5H10O2 | 102.1 | 718.4 | 58.444 | 1.154 01 | |

| 18 | 丁酸乙酯 Ethyl butanoate | C6H12O2 | 116.2 | 788.8 | 68.192 | 1.20033 | |

| 19 | γ-丁内酯 γ-butyrolactone | C4H6O2 | 86.1 | 898.0 | 86.633 | 1.088 01 | |

| 20 | 3-甲基丁酸乙酯 Ethyl isovalerate | C7H14O2 | 130.2 | 1 068.3 | 140.824 | 1.254 44 | |

| 21 | 乙酸异丙酯 Isopropyl acetate | C5H10O2 | 102.1 | 918.6 | 90.629 | 1.176 39 | |

| 22 | γ-己内酯 γ-caprolactone | C6H10O2 | 114.1 | 1 047.5 | 130.843 | 1.172 63 | |

醛类 Aldehydes | 23 | (Z)-6-壬烯醛 (Z)-6-nonenal | C9H16O | 140.2 | 1 106 | 158.983 | 1.169 99 |

| 24 | 异戊醛 Isovaleraldehyde | C5H10O | 86.1 | 956.4 | 98.439 | 1.189 79 | |

| 25 | 丁醛 Butyraldehyde | C4H8O | 72.1 | 888.4 | 84.816 | 1.123 24 | |

| 26 | 洋茉莉醛丙二醇缩醛 Piperonal propylene glycol acetal | C11H12O4 | 208.2 | 756.8 | 63.582 | 1.127 38 | |

| 27 | 反式-2-戊烯醛 (E)-2-pentenal | C5H8O | 84.1 | 749.2 | 62.528 | 1.093 80 | |

| 28 | 正戊醛 Valeraldehyde | C5H10O | 86.1 | 695.2 | 55.546 | 1.189 90 | |

| 29 | 正己醛 Hexanal | C6H12O | 100.2 | 790.8 | 68.485 | 1.233 89 | |

酮类 Ketones | 30 | 环戊酮 Cyclopentanone | C5H8O | 84.1 | 1 161.5 | 190.304 | 1.107 73 |

| 31 | 2-戊酮M Pentan-2-oneM | C5H10O | 86.1 | 984.8 | 104.891 | 1.118 45 | |

| 32 | 2-戊酮D Pentan-2-oneD | C5H10O | 86.1 | 975.5 | 102.658 | 1.371 79 | |

| 33 | 乙酸基丙酮 1-acetoxyacetone | C5H8O3 | 116.1 | 873.5 | 82.095 | 1.188 67 | |

| 34 | 异丙叉丙酮 Mesityl oxide | C6H10O | 98.1 | 810.6 | 71.530 | 1.126 07 | |

| 35 | 3-羟基-2-丁酮 Acetoin | C4H8O2 | 88.1 | 729.5 | 59.893 | 1.061 38 | |

| 36 | 2,3-戊二酮 2,3-pentanedione | C5H8O2 | 100.1 | 670.7 | 52.648 | 1.206 11 | |

| 37 | 甲基异丁基甲酮4-methyl-2-pentanone | C6H12O | 100.2 | 1 010.5 | 114.861 | 1.185 35 | |

吡嗪类 Pyrazines | 38 | 2,5-二甲基吡嗪2,5-dimethylpyrazine | C6H8N2 | 108.1 | 1 262.3 | 272.901 | 1.107 73 |

| 39 | 2-甲基吡嗪 Methylpyrazine | C5H6N2 | 94.1 | 1 218.5 | 233.471 | 1.087 13 | |

吡咯类 Pyrroles | 40 | 2-乙酰基吡咯M 2-acetylpyrroleM | C6H7NO | 109.1 | 1 080.2 | 146.358 | 1.097 10 |

| 41 | N-甲基吡咯烷酮 N-methylpyrrolidone | C5H9NO | 99.1 | 1 037.7 | 126.411 | 1.086 11 | |

| 42 | 2-乙酰基吡咯D 2-acetylpyrroleD | C6H7NO | 109.1 | 1 068.3 | 140.824 | 1.471 97 | |

呋喃类 Furans | 43 | 2-戊基呋喃 2-amylfuran | C9H14O | 138.2 | 1 209.9 | 226.415 | 1.251 89 |

| 44 | 2-正丁基呋喃 2-butylfuran | C8H12O | 124.2 | 1 116.5 | 164.412 | 1.180 85 | |

| 45 | 2,5-二甲基呋喃 2,5-dimethylfuran | C6H8O | 96.1 | 923.0 | 91.490 | 1.371 79 | |

| 46 | 四氢呋喃 Tetrahydrofuran | C4H8O | 72.1 | 862.2 | 80.086 | 1.234 93 | |

萜类 Terpenes | 47 | α-松油烯 α-terpinene | C10H16 | 136.2 | 1 006.5 | 113.221 | 1.238 01 |

| 48 | 柠檬烯 Limonene | C10H16 | 136.2 | 1 009.3 | 114.365 | 1.315 01 | |

其他 Others | 49 | 丙硫醇 1-propanethiol | C3H8S | 76.2 | 830.5 | 74.705 | 1.161 24 |

| 50 | 1,4-二氧六环 1,4-dioxane | C4H8O2 | 88.1 | 731.6 | 60.157 | 1.121 59 | |

| 51 | 邻二甲苯 O-xylene | C8H10 | 106.2 | 1 153.2 | 184.909 | 1.050 52 | |

| 52 | 苯甲醚 Anisole | C7H8O | 108.1 | 902.9 | 87.555 | 1.044 01 |

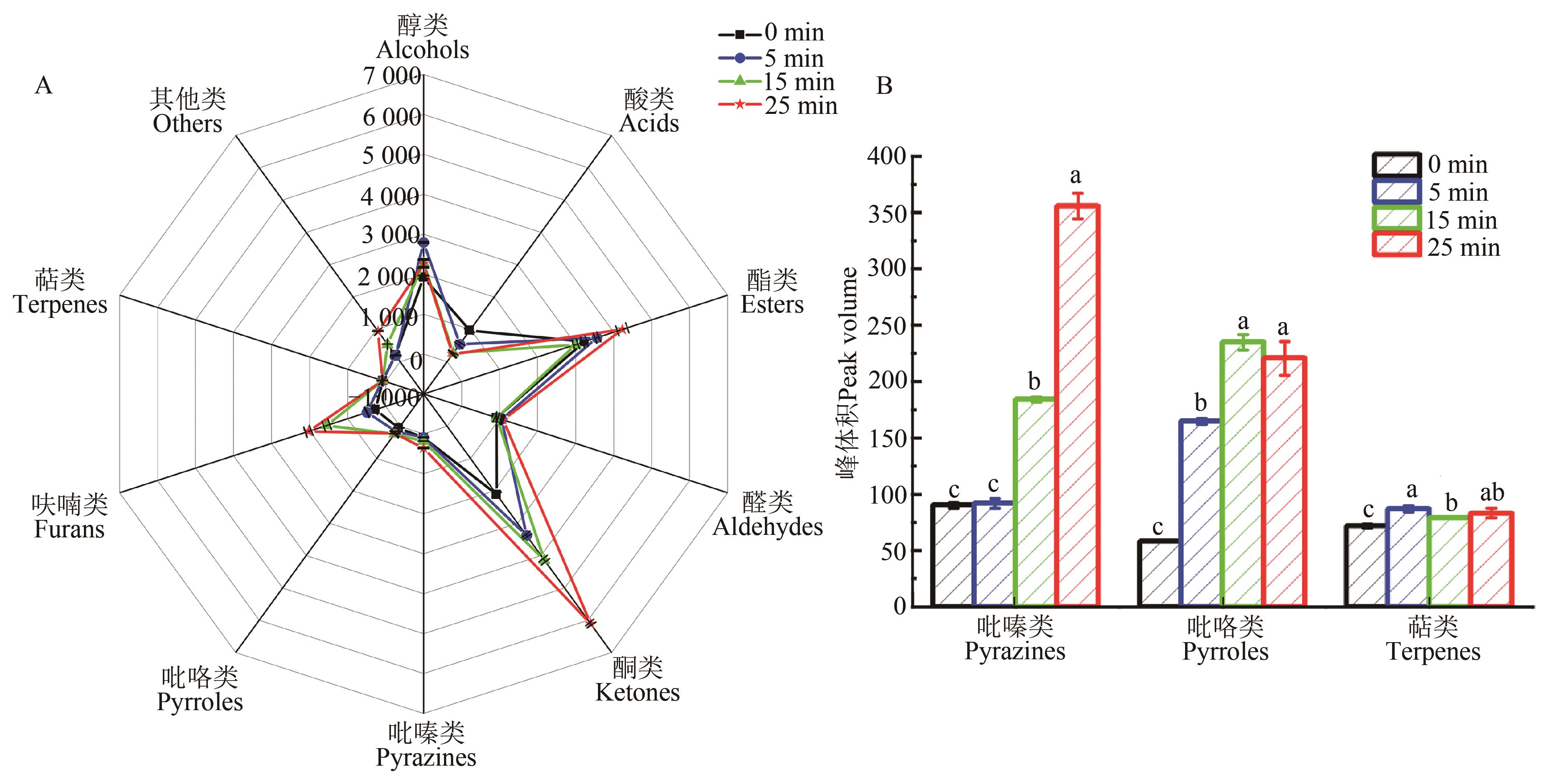

图2 不同焙炒程度黑芝麻各类风味物质峰体积A:雷达图;B:柱状图;不同小写字母表示不同焙炒程度间在P<0.05水平差异显著。

Fig. 2 Peak volume of various flavor substances of black sesame at different roasting levelsA: Radar chart; B: Histogram; different lowercase letters indicate significant differences between different roasting levels at P<0.05 level.

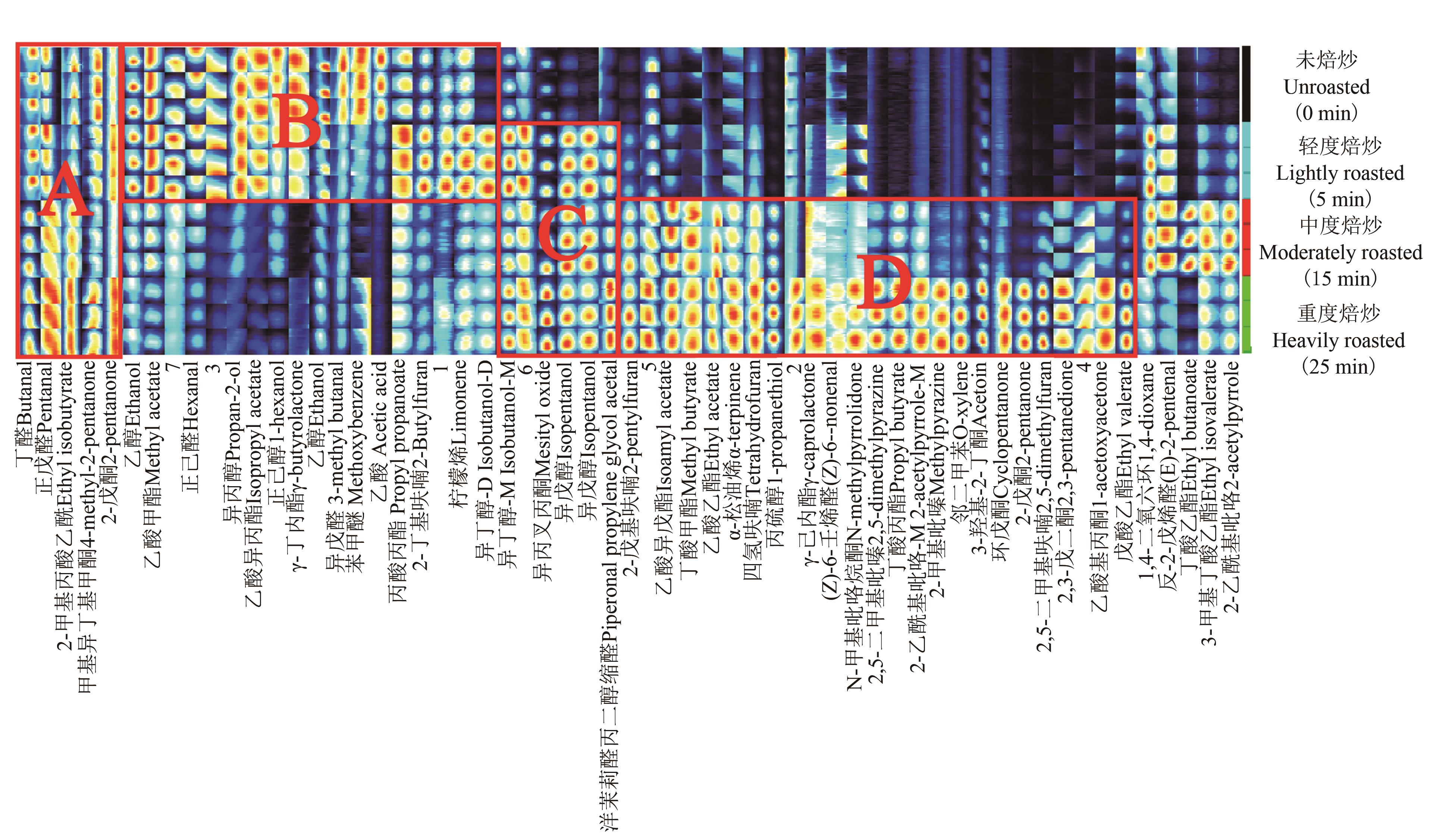

图3 不同焙炒程度黑芝麻风味物质指纹谱图注:1~7表示无法定性的化合物;A—4种焙炒处理下含量均较高的化合物;B—未焙炒和轻度焙炒处理下含量较高的化合物;C—焙炒后含量显著增加的化合物;D—中度焙炒和重度焙炒处理下含量较高的化合物。

Fig. 3 Fingerprints of black sesame flavor substances at different roasting levelsNote:1~7 indicate compounds that cannot be identified; A—Compounds with higher contents under 4 roasting treatments; B—Compounds with higher contents under unroasted and lightly roasted treatments; C—Compounds whose content increases significantly after roasting; D—Compounds with higher contents under moderately and heavily roasted treatments.

图4 不同焙炒程度黑芝麻挥发性香气的多元统计分析A:PCA得分图;B:PCA载荷图;C:OPLS-DA得分图;D:OPLS-DA模型验证

Fig. 4 Multivariate statistical analysis of volatile aroma of black sesame with different roasting degreesA: PCA score plot; B: PCA loading plot; C: OPLS-DA score plot; D: OPLS-DA model validation

图5 不同焙炒程度黑芝麻挥发性风味物质VIP值和聚类热图A:VIP值;B:聚类热图;1、2、3分别表示3次重复。

Fig. 5 VIP values and clustering heat map of volatile flavor substances of black sesame at different roasting levelsA: VIP value; B: Clustering heat map;1, 2, 3 indicate 3 repetitions.

| 1 | 赵宇航,尹文婷,汪学德,等.微波预处理对芝麻油风味、营养和安全品质的影响[J].食品科学,2023,44(9):47-57. |

| ZHAO Y H, YIN W T, WANG X D, et al.. Effect of microwave pretreatment of sesame seeds on the flavor, nutrition and safety of sesame oil [J]. Food Sci., 2023, 44(9):47-57. | |

| 2 | 刘怡真,马传国,陈小威,等.凝胶剂对芝麻酱稳定性及感官特性的影响[J].食品科学,2021,42(22):61-69. |

| LIU Y Z, MA C G, CHEN X W, et al.. Effects of organogelators on stability and sensory characteristics of sesame paste [J]. Food Sci., 2021, 42(22):61-69. | |

| 3 | 赵赛茹,张丽霞,黄纪念,等.焙炒时间对芝麻油风味及芝麻氨基酸含量的影响[J].中国粮油学报,2016,31(8):30-38. |

| ZHAO S R, ZHANG L X, HUANG J N, et al.. Effect of roasting time on flavor of sesame oil and the content of amino acids in sesame seeds [J]. J. Chin. Cereals Oils Association, 2016, 31(8):30-38. | |

| 4 | 许仕文,张国治,李志建,等.焙炒方式对芝麻酱品质的影响[J].中国油脂,2022,47(2):136-142. |

| XU S W, ZHANG G Z, LI Z J, et al.. Effect of roasting method on quality of sesame paste [J]. China Oils Fats, 2022, 47(2):136-142. | |

| 5 | 朱珠,蔡敏,焦珺玥.黑芝麻酸价变化规律的探究[J].现代食品,2022, 28(20):194-197. |

| ZHU Z, CAI M, JIAO J Y. Research on the change rule of black sesame acid value [J]. Mod. Food, 2022, 28(20):194-197. | |

| 6 | 张国治,张富重,黄纪念.芝麻加工的研究进展及展望[J].粮食加工,2020,45(1):43-46. |

| ZHANG G Z, ZHANG F Z, HUANG J N. Research progress and prospects of sesame processing [J]. Grain Proc., 2020, 45(1):43-46. | |

| 7 | GU S, ZHANG J, WANG J, et al.. Recent development of HS-GC-IMS technology in rapid and non-destructive detection of quality and contamination in agri-food products [J/OL]. Trends Anal. Chem., 2021, 144:116435 [2023-08-20]. . |

| 8 | 李娟,任芳,甄大卫,等.气相色谱-离子迁移谱分析乳制品挥发性风味化合物[J].食品科学,2021,42(10):235-240. |

| LI J, REN F, ZHEN D W, et al.. Analysis of volatile flavor compounds dairy products by gas chromatography-ion mobility spectrometry [J]. Food Sci., 2021, 42(10):235-240. | |

| 9 | 郭雅红,佟立涛,王丽丽,等.基于GC-IMS分析炒制温度对青稞糌粑粉挥发性风味物质的影响[J].食品工业科技,2023,44(14):326-335. |

| GUO Y H, TONG L T, WANG L L, et al.. GC-IMS-based analysis of the effect of frying temperature on volatile flavor substances in highland barley tsampa flour [J]. Sci. Technol. Food Ind., 2023, 44(14):326-335. | |

| 10 | 卞景阳,孙兴荣,刘琳帅,等.基于气相色谱-离子迁移谱的不同品种香稻米挥发性有机物指纹图谱分析[J].中国粮油学报,2023,38(6):133-140. |

| BIAN J Y, SUN X R, LIU L S, et al.. Analysis of volatile organic compounds fingerprint in different varieties of fragrant rice based on gas chromatography ion-mobility spectrometry (GC-IMS) [J]. J. Chin. Cereals Oils Association, 2023, 38(6):133-140. | |

| 11 | 王子妍,窦博鑫,贾健辉,等.GC-IMS结合PCA分析不同焙炒程度留胚米挥发性化合物指纹差异[J].食品科学,2023, 44(8):212-218. |

| WANG Z Y, DOU B X, JIA J H, et al.. Differential fingerprint analysis of volatile compounds in rice with remained germ roasted to different degrees by gas chromatography-ion mobility spectrometry and principal component analysis [J]. Food Sci., 2023, 44(8):212-218. | |

| 12 | 马雪停,尹文婷,李诗佳,等.炒籽温度对芝麻油香气活性组分和感官品质的影响[J].中国油脂,2021,46(8):6-11. |

| MA X T, YIN W T, LI S J, et al.. Effect of seed roasting temperature on the aroma-active composition and sensory quality of sesame oil [J]. China Oils Fats, 2021, 46(8):6-11. | |

| 13 | HE F, DUAN J W, ZHAO J W, et al.. Different distillation stages Baijiu classification by temperature-programmed headspace-gas chromatography-ion mobility spectrometry and gas chromatography-olfactometry-mass spectrometry combined with chemometric strategies [J/OL]. Food Chem., 2021, 365:130430 [2023-08-20]. . |

| 14 | XI L J, ZHANG J, WU R X, et al.. Characterization of the volatile compounds of Zhenba Bacon at different process stages using GC-MS and GC-IMS [J/OL]. Foods, 2021, 10:2869 [2023-08-20]. |

| 15 | 李宏强,王宏博,席斌,等.牦牛乳贮藏期间品质变化及挥发性物质的GC-IMS鉴定[J].食品与发酵工业,2023,49(12):269-277. |

| LI H Q, WANG H B, XI B, et al.. Change in quality indices and GC-IMS identification of volatile substances in yak milk during storage [J]. Food Ferm. Ind., 2023, 49(12):269-277. | |

| 16 | 周瑞宝.芝麻香油风味成分[J].中国粮油学报,2006,21(3):310-315. |

| ZHOU R B. The flavoring composition of seasame aroma oil [J]. J. Chin. Cereals Oils Association, 2006, 21(3):310-315. | |

| 17 | KIRALAN M. Volatile compounds of black cumin seeds (Nigella sativa L.) from microwave-heating and conventional roasting [J]. J. Food Sci., 2012, 77(4):481-484. |

| 18 | FANG G Z, LU J P, PAN M F, et al.. Substitution of antibody with molecularly imprinted film in enzyme-linked immunosorbent assay for determination of trace ractopamine in urine and pork samples [J]. Food Anal. Method., 2011, 4(4):590-597. |

| 19 | WORLEY B, POWERS R. Multivariate analysis in metabolomics [J]. Curr. Metabolomics, 2013, 1(1):92-107. |

| 20 | 黄浩,余鹏辉,赵熙,等.不同季节保靖黄金茶1号工夫红茶挥发性成分的HS-SPME-GC-MS分析[J].食品科学,2020,41(12):188-196. |

| HUANG H, YU P H, ZHAO X, et al.. HS-SPME-GC-MS analysis of volatile components of congou black tea processed from Baojing Huangjincha 1 from different harvesting seasons [J]. Food Sci., 2020, 41(12):188-196. | |

| 21 | 张谦益,熊巍林,李敏丽,等.浓香菜籽油制取精制工艺实践[J].农产品加工,2011(1):80-81. |

| ZHANG Q Y, XIONG W L, LI M L, et al.. Preparation and refining process of fragrant rapeseed oil [J]. Agric. Prod. Proc., 2011(1):80-81. | |

| 22 | 董国鑫,王淑珍,雷风,等.焙炒处理对不同植物油品质特性的影响[J].中国油脂,2022,47(9):19-25. |

| DONG G X, WANG S Z, LEI F, et al.. Effect of roasting pretreatment on quality characteristic of different vegetable oils [J]. China Oils Fats, 2022, 47(9):19-25. | |

| 23 | ZHANG Y, LI X, LU X, et al.. Effect of oilseed roasting on the quality, flavor and safety of oil: a comprehensive review [J/OL]. Food Res. Int., 2021, 150(Pt A):110791 [2023-08-20]. . |

| 24 | 严群.焙炒芝麻香气成分研究[J].食品工业,2014,35(3):245-247. |

| YAN Q. Studies on volatile components of roasted sesame [J]. Food Ind., 2014, 35(3):245-247. | |

| 25 | 陈丽兰,陈祖明,袁灿.气相色谱-离子迁移谱结合化学计量法分析不同炒制时间对郫县豆瓣酱挥发性化合物的影响[J].食品科学,2023,44(14):283-290. |

| CHEN L L, CHEN Z M, YUAN C. Effect of cooking time on volatile compounds of Pixian bean paste determined by gas chromatography-ion mobility spectrometry combined with chemometrics [J]. Food Sci., 2023, 44(14):283-290. | |

| 26 | 刘杰梅,李雪玲,孙玥,等.核桃仁炒制工艺优化及其风味成分分析[J].中国粮油学报,2024,39(2):172-180. |

| LIU J M, LI X L, SUN Y, et al.. Optimization of roasting process and analysis of flavor components of walnut [J]. J. Chin. Cereals Oils Association, 2024, 39(2):172-180. |

| [1] | 王如月, 虎海防, 罗莎莎, 甄紫怡, 徐业勇, 胡晓静. 杏李不同采收成熟度果实品质分析[J]. 中国农业科技导报, 2025, 27(2): 158-169. |

| [2] | 史亚兴, 董会, 徐丽, 樊艳丽, 刘辉, 史亚民, 俞嫒年, 高宁, 赵久然, 卢柏山, 王荣焕. 基于电子鼻和GC-IMS技术分析不同类型鲜食玉米的风味差异[J]. 中国农业科技导报, 2024, 26(11): 143-156. |

| [3] | 纪蕾, 李红艳, 王颖, 姜晓东, 刘天红, 李晓, 孙元芹, 刘洪军. 番茄味膨化虾片加工工艺优化及香气组分分析[J]. 中国农业科技导报, 2024, 26(1): 140-153. |

| [4] | 孟祥勇1,2,3,4§,冯东阳1,2§,毛健1,2,3,4*,刘双平1,2,3,4, 周志磊1,2,3,4,姬中伟1,2,3,4. 循环超声波辅助黄酒后发酵风味物质的变化分析[J]. 中国农业科技导报, 2015, 17(5): 142-150. |

| [5] | 秦晓|王锡昌|陶宁萍*. 水产品风味主要影响因素研究进展[J]. , 2013, 15(6): 27-34. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号