中国农业科技导报 ›› 2024, Vol. 26 ›› Issue (11): 97-106.DOI: 10.13304/j.nykjdb.2023.0799

黄椿1( ), 李粤1,2(

), 李粤1,2( ), 位士全1, 高阳1, 吴紫晗1, 黄麒润1, 魏晨辉1

), 位士全1, 高阳1, 吴紫晗1, 黄麒润1, 魏晨辉1

收稿日期:2023-11-01

接受日期:2024-02-06

出版日期:2024-11-15

发布日期:2024-11-19

通讯作者:

李粤

作者简介:黄椿 E-mail:18808955631@163.com;

基金资助:

Chun HUANG1( ), Yue LI1,2(

), Yue LI1,2( ), Shiquan WEI1, Yang GAO1, Zihan WU1, Qirun HUANG1, Chenhui WEI1

), Shiquan WEI1, Yang GAO1, Zihan WU1, Qirun HUANG1, Chenhui WEI1

Received:2023-11-01

Accepted:2024-02-06

Online:2024-11-15

Published:2024-11-19

Contact:

Yue LI

摘要:

针对现有机具作业时存在的秸秆粉碎还田效果差、秸秆抛洒不均匀等问题,设计一种异向双轴香蕉秸秆粉碎还田机,该机具主要由粉碎装置、传动装置、三点悬挂装置组成。以机具前进速度、粉碎刀轴转速和刀片厚度为试验因素,以香蕉秸秆粉碎合格率和抛撒不均匀度作为评价指标,开展三因素三水平田间试验,分析各个试验因素对评价指标的影响。方差分析结果表明,对香蕉秸秆粉碎合格率来说,机具前进速度和粉碎刀轴转速影响极显著,刀片厚度影响显著;对抛撒不均匀度来说,粉碎刀轴转速影响显著。确定了最优工作参数组合为机具前进速度1.4 m·s-1、粉碎刀轴转速1 600 r·min-1、刀片厚度10 mm,在此参数下的香蕉秸秆粉碎合格率为96.76%,抛撒不均匀度为8.96%,满足香蕉秸秆粉碎还田要求,达到了预期设计目标要求,为后续的机具升级换代提供了技术支持。

中图分类号:

黄椿, 李粤, 位士全, 高阳, 吴紫晗, 黄麒润, 魏晨辉. 异向双轴香蕉秸秆粉碎还田机设计与试验[J]. 中国农业科技导报, 2024, 26(11): 97-106.

Chun HUANG, Yue LI, Shiquan WEI, Yang GAO, Zihan WU, Qirun HUANG, Chenhui WEI. Design and Experiment of Double Shafts Banana Straw Crushing and Returning Machine with Different Rotational Directions[J]. Journal of Agricultural Science and Technology, 2024, 26(11): 97-106.

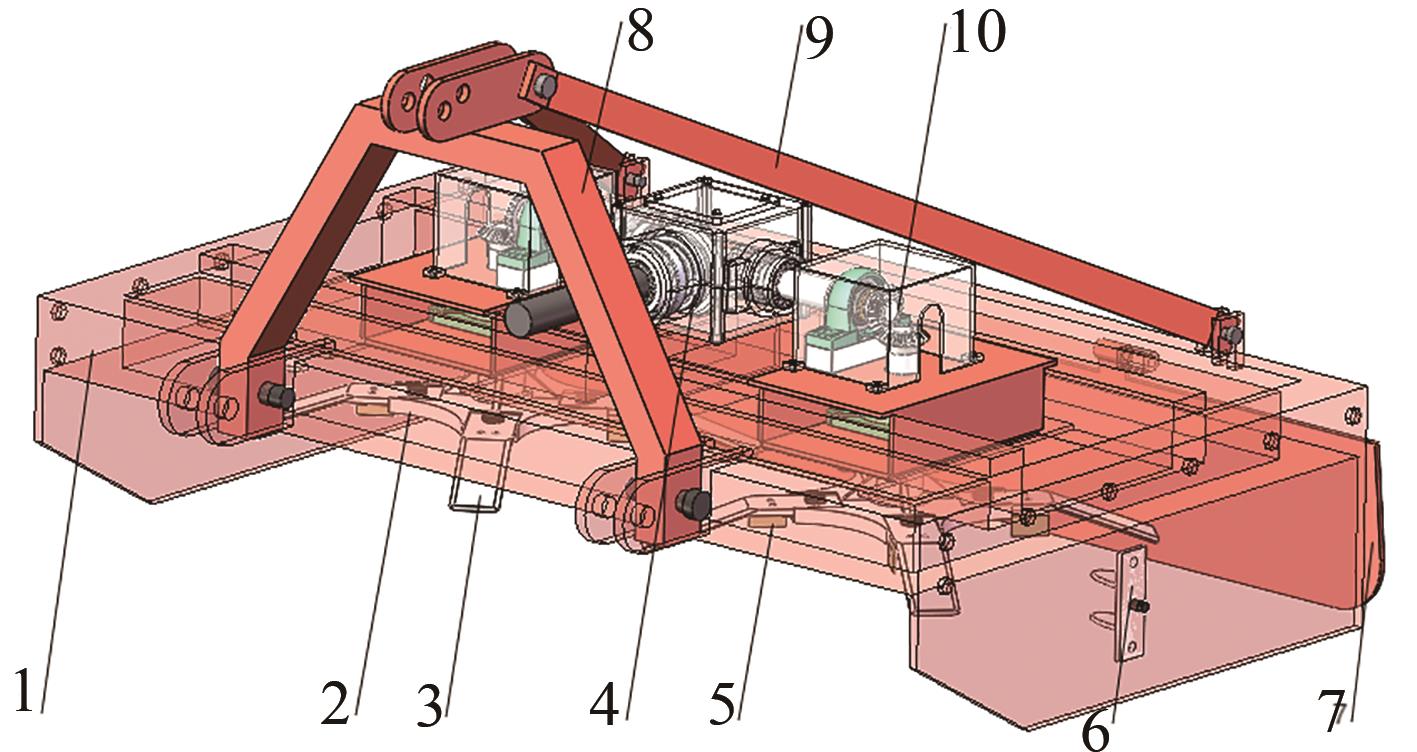

图1 整机结构注:1—机架;2—粉碎刀盘;3—粉碎刀片;4—变速箱;5—扇叶;6—定刀;7—安全防护板;8—三点悬挂装置;9—悬挂带;10—从传动箱。

Fig. 1 Structure of the machineNote:1—Framework;2—Crushing disc;3—Crushing knife;4—Transmission case;5—Fan blade;6—Fixed blade;7—Safety protection plates;8—Three-point linkage;9—Suspension belt;10—Driven box.

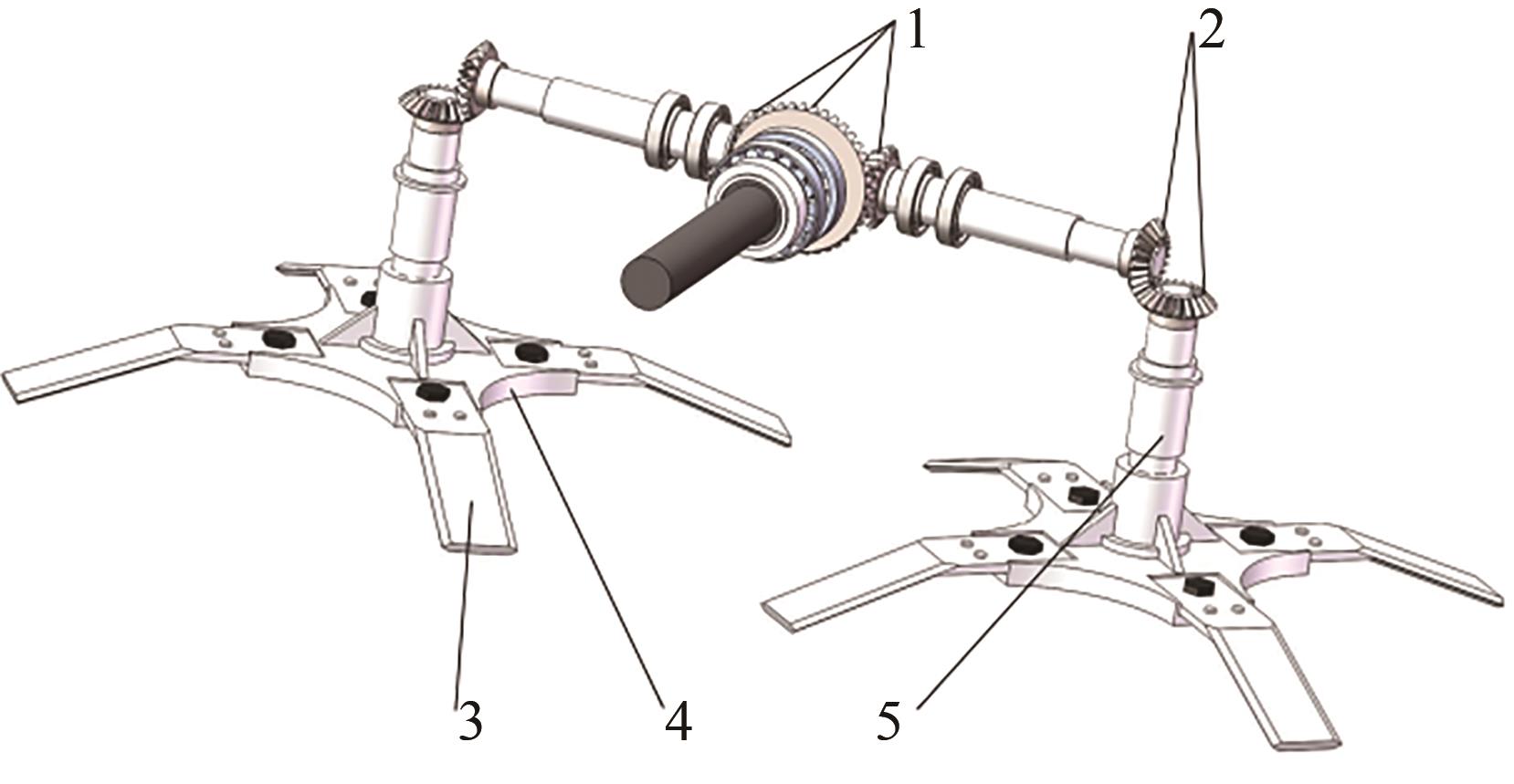

图2 传动系统注:1—变速箱锥齿轮组;2—从传动箱锥齿轮组;3—粉碎刀片;4—粉碎刀盘;5—粉碎刀轴。

Fig. 2 Transmission systemNote: 1—Transmission bevel gear set;2—Driven bevel gear set;3—Crushing knife;4—Crushing disc;5—Knife shaft.

技术参数 Technical parameter | 取值 Value |

|---|---|

整体尺寸(长×宽×高) Overall size (L×W×H)/mm×mm×mm | 1 850×1 100×400 |

总质量 Total mass/kg | 550 |

配套动力 Auxiliary power/kW | 59 |

机具行驶速度 Machine travel speed/(m·s-1) | 0.8~3.0 |

刀轴转速 Knife shaft speed/(r·min-1) | 1 200~2 000 |

粉碎刀片数量 Number of crushing knife | 8 |

防缠定刀数量 Number of anti-tangle fixed blade | 2 |

工作幅宽 Working width/mm | 1 500 |

刀轴数量 Number of knife shaft | 2 |

表1 香蕉秸秆粉碎还田机主要技术参数

Table 1 Main technical parameters of banana straw crushing and returning machine

技术参数 Technical parameter | 取值 Value |

|---|---|

整体尺寸(长×宽×高) Overall size (L×W×H)/mm×mm×mm | 1 850×1 100×400 |

总质量 Total mass/kg | 550 |

配套动力 Auxiliary power/kW | 59 |

机具行驶速度 Machine travel speed/(m·s-1) | 0.8~3.0 |

刀轴转速 Knife shaft speed/(r·min-1) | 1 200~2 000 |

粉碎刀片数量 Number of crushing knife | 8 |

防缠定刀数量 Number of anti-tangle fixed blade | 2 |

工作幅宽 Working width/mm | 1 500 |

刀轴数量 Number of knife shaft | 2 |

编码 Code | A:机具前进速度 Forwardspeed of implement/(m·s-1) | B:粉碎刀轴转速 Knife shaft speed/(r·min-1) | C:刀片厚度 Blade thickness/mm |

|---|---|---|---|

| 1 | 1.0 | 1 200 | 8 |

| 2 | 1.4 | 1 400 | 10 |

| 3 | 1.8 | 1 600 | 12 |

表2 试验因素编码

Table 2 Code of experimental factors and levels

编码 Code | A:机具前进速度 Forwardspeed of implement/(m·s-1) | B:粉碎刀轴转速 Knife shaft speed/(r·min-1) | C:刀片厚度 Blade thickness/mm |

|---|---|---|---|

| 1 | 1.0 | 1 200 | 8 |

| 2 | 1.4 | 1 400 | 10 |

| 3 | 1.8 | 1 600 | 12 |

试验序号 No. | A:机具前进速度 Forwardspeed of implement /(m·s-1) | B:粉碎刀轴转速 Knife shaft speed/(r·min-1) | C:刀片厚度 blade thickness /mm | Crushing qualification rate/% | Fb :抛撒不均匀度 Uneven degree of scattering/% |

|---|---|---|---|---|---|

| 1 | 1.0 | 1 200 | 8 | 87.59 | 16.91 |

| 2 | 1.0 | 1 400 | 10 | 91.21 | 15.64 |

| 3 | 1.0 | 1 600 | 12 | 93.06 | 10.82 |

| 4 | 1.4 | 1 200 | 8 | 89.23 | 15.12 |

| 5 | 1.4 | 1 400 | 12 | 91.18 | 13.56 |

| 6 | 1.4 | 1 600 | 10 | 96.76 | 8.96 |

| 7 | 1.8 | 1 200 | 12 | 85.92 | 14.04 |

| 8 | 1.8 | 1 400 | 8 | 88.78 | 16.35 |

| 9 | 1.8 | 1 600 | 10 | 93.28 | 11.50 |

表3 正交试验结果

Table 3 Orthogonal experimental results

试验序号 No. | A:机具前进速度 Forwardspeed of implement /(m·s-1) | B:粉碎刀轴转速 Knife shaft speed/(r·min-1) | C:刀片厚度 blade thickness /mm | Crushing qualification rate/% | Fb :抛撒不均匀度 Uneven degree of scattering/% |

|---|---|---|---|---|---|

| 1 | 1.0 | 1 200 | 8 | 87.59 | 16.91 |

| 2 | 1.0 | 1 400 | 10 | 91.21 | 15.64 |

| 3 | 1.0 | 1 600 | 12 | 93.06 | 10.82 |

| 4 | 1.4 | 1 200 | 8 | 89.23 | 15.12 |

| 5 | 1.4 | 1 400 | 12 | 91.18 | 13.56 |

| 6 | 1.4 | 1 600 | 10 | 96.76 | 8.96 |

| 7 | 1.8 | 1 200 | 12 | 85.92 | 14.04 |

| 8 | 1.8 | 1 400 | 8 | 88.78 | 16.35 |

| 9 | 1.8 | 1 600 | 10 | 93.28 | 11.50 |

指标 Index | 方差来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| A | 14.190 | 2 | 7.095 | 108.531 | 0.009** | |

| B | 30.242 | 2 | 15.121 | 231.311 | 0.004** | |

| C | 3.663 | 2 | 1.831 | 28.015 | 0.034* | |

误差 Pure error | 0.131 | 2 | 0.065 | |||

| Fb | A | 5.898 | 2 | 2.949 | 6.099 | 0.141 |

| B | 23.585 | 2 | 11.792 | 24.387 | 0.039 | |

| C | 5.000 | 2 | 2.500 | 5.170 | 0.162 | |

误差 Pure error | 0.967 | 2 | 0.484 |

表 4 方差分析

Table 4 Variance analysis

指标 Index | 方差来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| A | 14.190 | 2 | 7.095 | 108.531 | 0.009** | |

| B | 30.242 | 2 | 15.121 | 231.311 | 0.004** | |

| C | 3.663 | 2 | 1.831 | 28.015 | 0.034* | |

误差 Pure error | 0.131 | 2 | 0.065 | |||

| Fb | A | 5.898 | 2 | 2.949 | 6.099 | 0.141 |

| B | 23.585 | 2 | 11.792 | 24.387 | 0.039 | |

| C | 5.000 | 2 | 2.500 | 5.170 | 0.162 | |

误差 Pure error | 0.967 | 2 | 0.484 |

| 1 | 邹冬梅,范琼.世界香蕉生产、贸易现状与产业展望[J].广东农业科学,2022,49(7):131-140. |

| ZOU D M, FAN Q. Present situation of globle banana production and trade and prospect for banana industry [J]. Guangdong Agric. Sci., 2022,49(7):131-140. | |

| 2 | 国家统计局.中国统计年鉴2022[M].北京:中国统计出版社,2022. |

| 3 | 孔德杰,朱金霞,任成杰,等.麦豆长期轮作下秸秆还田对土壤碳氮组分及作物产量的影响[J].干旱地区农业研究,2022,40(5):190-200. |

| KONG D J, ZHU J X, REN C J, et al.. Effects of straw return on soil carbon and nitrogen components and crop yield under long-term wheat-soybean rotation [J]. Agric. Res. Arid Areas, 2022, 40(5): 190-200. | |

| 4 | 刘世杰,冯秋苹,王呈玉,等.不同秸秆还田方式对土壤水分特性的影响[J/OL].吉林农业大学学报,2022:1-11 [2024-05-30].. |

| LIU S J, FENG Q P, WANG C Y, et al.. Effects of different straw returning methods on soil moisture characteristics [J/OL]. J.Jilin Agric. Univ., 2022:1-11[2024-05-30].. | |

| 5 | 吴学尚,李粤,张喜瑞,等.甩刀式立式香蕉秸秆粉碎机的设计[J].农机化研究,2014(4):83-86. |

| WU X S, LI Y, ZHANG X R, et al.. The design of the vertical flail banana stalk crushing machine [J]. J. Agric. Mech. Res., 2014(4):83-86. | |

| 6 | 吴思浩,李粤,张喜瑞,等.基于模态分析的立式香蕉秸秆粉碎还田机机架优化[J].农机化研究,2017, 39(05):46-51. |

| WU S H, LI Y, ZHANG X R, et al.. Optimal design for rack of vertical flail banana stalk crushing machine based on modal analysis [J]. J. Agric. Mech. Res., 2017, 39(5):46-51. | |

| 7 | 贺宁波,李粤,郭超凡,等.香蕉秸秆粉碎还田机刀片优化设计与试验[J].农机化研究,2021,43(12):85-91. |

| HE N B, LI Y, GUO C F, et al.. Optimization design and test of blade of banana straw returning machine [J]. J. Agric. Mech. Res., 2021, 43(12):85-91. | |

| 8 | 魏思林.基于耦合仿生机理立式香蕉秸秆粉碎还田机的优化设计[D].海口:海南大学,2019. |

| WEI S L. Optimum design of banana straw crushing and returning combined machine with vertical type based on coupling bionics mechanism [D]. Haikou: Hainan University, 2019. | |

| 9 | 柴向阳,杨兆文,潘一兵,等. 保护性耕作机械 秸秆粉碎还田机: [S].北京:中国标准出版社, 2010. |

| 10 | 郝文录,刘恒新,朱良,等. 农业机械试验条件 测定方法的一般规定: [S].北京:中国标准出版社,2009. |

| 11 | 李粤,郭超凡,姚德宇,等.定甩刀防缠式香蕉秸秆粉碎还田机设计与试验[J].农业工程学报,2021,37(18): 11-19. |

| LI Y, GUO C F, YAO D Y, et al.. Design and experiment of banana straw crushing and returning machine with anti- wrapping device supported by flailing blade [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(18):11-19. | |

| 12 | YU C Y, LIU J, ZHANG J, et al.. Design and optimization and experimental verification of a segmented double-helix blade roller for straw returning cultivators [J]. J. Chin. Inst. Eng., 2021, 44(4):379-387. |

| 13 | 刘鹏,何进,章志强,等.基于CFD-DEM的秸秆还田机碎秆运动特性分析与试验[J].农业机械学报,2020, 51(S1): 244-253. |

| LIU P, HE J, ZHANG Z Q, et al.. Kinematic characteristic analysis and field test of chopped stalk in straw retention machine based on CFD-DEM coupling simulation method [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(S1):244-253. | |

| 14 | 郭超凡,李粤,姚德宇,等.仿生香蕉秸秆粉碎装置关键部件作业参数优化与试验[J].中国农机化学报,2022,43(1):93-100. |

| GUO C F, LI Y, YAO D Y, et al.. Optimization and experiment of operating parameters of key components of bionic banana straw crushing devices [J]. J. Chin. Agric. Mechan., 2022, 43(1):93-100. | |

| 15 | 王传贵,江泽慧,费本华,等. 木材顺纹抗剪强度试验方法: [S].北京:中国标准出版社,2009. |

| 16 | 江京辉,骆秀琴,殷亚方,等. 木材顺纹抗压强度试验方法: [S].北京:中国标准出版社,2009. |

| 17 | 李志强,李粤,贺宁波,等.纵向双辊式香蕉秸秆粉碎还田机的设计与试验[J].中国农机化学报,2020, 41(3):180-184. |

| LI Z Q, LI Y, HE N B, et al.. Design and experiment of the banana stalk crushing and returning machine with lengthways double rollers type [J]. J. Chin. Agric. Mechan., 2020, 41(3):180-184. | |

| 18 | VISVANATHAN R, SREENARAYANAN V V, SWAMINATHAN K R. Effect of knife angle and velocity on the energy required to cut cassava tubers [J]. J. Agric. Eng. Res., 1996, 64(2):99-102. |

| 19 | 吴思浩.立式香蕉秸秆粉碎还田机关键部件优化研究[D]. 海口:海南大学,2019. |

| WU S H. Optimization design and research of key parts of vertical-shaft banana stalks chopper [D]. Haikou: Hainan University, 2019. | |

| 20 | 牛国梁.机采棉立式秸秆粉碎还田机关键部件优化设计与试验[D].石河子:石河子大学,2021. |

| NIU G L. Optimal design and test of key components of the vertical straw crushing and returning machine [D]. Shihezi:Shihezi University, 2021. | |

| 21 | 贾洪雷,姜鑫铭,郭明卓,等.V-L型秸秆粉碎还田刀片设计与试验[J].农业工程学报,2015(1):28-33. |

| JIA H L, JIANG X M, GUO M Z, et al.. Design and experiment of V-L shaped smashed straw blade [J]. Trans. Chin. Soc. Agric. Eng., 2015(1): 28-33. | |

| 22 | 刘鹏,何进,李艳洁,等.异速对辊式玉米秸秆粉碎还田装置设计与试验[J].农业工程学报,2020,36(14): 69-79. |

| LIU P, HE J, LI Y J, et al.. Design and experiment of double rollers maize stalk chopping device with different rotation speeds [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(14):69-79. | |

| 23 | CHANDRU B T, SURESH P M, SATHYA J, et al.. Modal analysis of car hood with viscoelastic damper [J]. Material Today: Proceedings, 2018, 5(10):22293-22302. |

| 24 | ER P V, TAN K K. Machine vibration analysis based on experimental modal analysis with radial basis functions [J]. Measurement, 2018, 128:45-54. |

| 25 | 张喜瑞,王自强,李粤,等.滑切防缠式香蕉秸秆还田机设计与试验[J].农业工程学报,2018,34(3):26-34. |

| ZHANG X R, WANG Z Q, LI Y, et al.. Design and experiment of sliding-cutting and anti-twining returning device for banana straw [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(3):26-34. | |

| 26 | 吴紫晗,李粤,郭超凡,等.自走式香蕉秸秆粉碎还田机设计与仿真分析[J].中国农机化学报,2022, 43(9):40-46. |

| WU Z H, LI Y, GUO C F, et al.. Design and simulation analysis of self-propelled banana straw crushing and returning machine [J]. J. Chin. Agric. Mechanization, 2022, 43(9):40-46. |

| [1] | 高阳, 李粤, 位士全, 黄椿, 吴紫晗, 魏晨辉, 黄麒润. 具有腐熟剂喷施装置的香蕉秸秆粉碎还田机的设计与试验[J]. 中国农业科技导报, 2024, 26(9): 93-104. |

| [2] | 潘梦诗, 郭文阳, 周留柱, 邓丽, 苗建利, 徐宏光, 张宗源, 亓兰达. 贝莱斯芽孢杆菌菌剂对花生白绢病的田间防效及作用机理研究[J]. 中国农业科技导报, 2022, 24(11): 130-136. |

| [3] | 骆丽莎, 廖桂平, 刘凡, 官春云. 基于冠层光谱特征参数的油菜品种识别[J]. 中国农业科技导报, 2021, 23(7): 93-106. |

| [4] | 张久权1,李彩斌2,凌爱芬3,董建新1. 运用SAS广义线性混合模型分析裂区试验数据[J]. 中国农业科技导报, 2021, 23(2): 89-95. |

| [5] | 刘东,肖宏儒*,金月,杨光. 基于ANSYS的鸡毛菜茎秆切割的有限元分析及验证试验[J]. 中国农业科技导报, 2018, 20(11): 85-93. |

| [6] | 李晓栋,方宪法,韩增德*,张子瑞,刘贵明,崔俊伟, 乔晓东,韩科立. 基于ANSYS/LS-DYNA的滚刀式甜高粱切割器动力学仿真[J]. , 2015, 17(3): 70-76. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号