中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (7): 204-216.DOI: 10.13304/j.nykjdb.2024.0050

• 生物制造 资源生态 • 上一篇

收稿日期:2024-01-18

接受日期:2024-03-11

出版日期:2025-07-15

发布日期:2025-07-11

通讯作者:

闫明

作者简介:丁献华E-mail: dingxianhua2007@163.com;

基金资助:

Xianhua DING1( ), Shuangdui YAN2, Ming YAN3(

), Shuangdui YAN2, Ming YAN3( )

)

Received:2024-01-18

Accepted:2024-03-11

Online:2025-07-15

Published:2025-07-11

Contact:

Ming YAN

摘要:

为利用农林废弃物以低成本制备高品质生物焦燃料,以雪松木屑(cedar sawdust, CS)为原料,采用微型高压反应釜进行加压烘焙试验,研究烘焙半焦燃料品质的提高和物化结构、热解动力学特性变化以及气体产物组分分布。结果表明,与同温度下(230 ℃)常压烘焙相比,加压烘焙半焦的固定碳含量均有所提高,压力促进了生物质中挥发性物质向固定碳的转化。CS-290-1.5半焦的挥发分从CS原样的84.09%降至45.74%,热值增加到28.15 MJ·kg-1,燃料品质显著增加,且氧碳比、氢碳比降低至0.24和0.85,基本达到烟煤的燃料性能范围。温度对挥发分的脱除以及脱氧增碳效果起着重要的作用。傅里叶变换红外光谱结果显示,烘焙半焦中含氧基团减少,C=C增加,生物质组分间的脱氧及芳构化反应加强。拉曼试验结果表明,加压下温度的提高使烘焙半焦中小芳香环向大芳香环的缩聚程度提高,石墨化程度增加。随温度升高,固体半焦比表面积与总孔体积呈逐渐增加趋势,CS-290-1.5比表面积高达40.02 m2·g-1,温度的提高促进了挥发分脱除与小分子气体的生成,导致孔隙数量增加,燃烧反应性增强。热解动力学计算表明,加压烘焙半焦在热解反应后期的活化能显著增加,烘焙半焦中交联反应增强,生成更多热稳定性高的物质。气体组分测定结果表明,相比常压加压烘焙更有利于生物质中纤维素和半纤维素组分的深度分解,促进了含氧基团的大量脱除,更多的以H2O、CO、CO2等形式释放。综上表明,借助气体压力增强松木木屑脱氧提质,为芳香类植物废弃物高值能源化利用提供了理论依据。

中图分类号:

丁献华, 闫双堆, 闫明. 松木木屑加压烘焙制备高品质生物焦燃料及其特性研究[J]. 中国农业科技导报, 2025, 27(7): 204-216.

Xianhua DING, Shuangdui YAN, Ming YAN. Preparation and Characteristics of High-quality Biochar Fuel by Pressurized Torrefaction of Pine Sawdust[J]. Journal of Agricultural Science and Technology, 2025, 27(7): 204-216.

样品 Sample | 工业成分Proximate composition/% | 元素分析 Ultimate analysis/% | 高位发热量HHV/(MJ·kg-1) | |||||

|---|---|---|---|---|---|---|---|---|

挥发分 Vdaf | 固定碳 FCdaf | 碳C | 氢H | 氮N | 氧O△ | 硫S | ||

| CS | 84.09±2.06 a | 15.91±0.81 c | 46.71±0.96 c | 5.38±0.53 b | 0.25±0.01 c | 47.51±1.85 a | 0.15±0.01 b | 14.99±0.75 c |

| CS-230-AP | 76.35±2.00 b | 22.65±1.57 b | 54.84±1.42 b | 5.47±0.14 b | 0.76±0.03 a | 38.80±0.96 b | 0.13±0.00 b | 19.44±0.26 b |

| CS-230-0.5 | 70.70±1.70 b | 27.30±2.30 b | 57.94±2.55 b | 4.98±1.11 c | 0.50±0.04 b | 36.48±0.64 b | 0.10±0.00 b | 20.20±1.20 b |

| CS-230-1.0 | 66.02±2.11 b | 33.98±2.11 a | 63.32±0.95 a | 5.05±0.31 c | 0.59±0.02 b | 30.92±2.02 b | 0.12±0.01 b | 23.12±1.62 a |

| CS-230-1.5 | 63.85±3.14 c | 36.15±1.72 a | 65.97±3.09 a | 5.70±0.28 a | 0.48±0.07 b | 27.65±1.72 c | 0.20±0.01 a | 25.54±1.14 a |

| CS-230-2.0 | 63.01±2.36 c | 36.99±2.85 a | 67.00±0.52 a | 5.35±0.32 b | 0.45±0.07 b | 27.06±1.39 c | 0.14±0.01 b | 25.49±0.81 a |

表1 CS原样及不同压力下加压烘焙半焦工业成分和元素分析

Table 1 Proximate composition and ultimate analysis of CS samples and pressurized torrefied semi-char

样品 Sample | 工业成分Proximate composition/% | 元素分析 Ultimate analysis/% | 高位发热量HHV/(MJ·kg-1) | |||||

|---|---|---|---|---|---|---|---|---|

挥发分 Vdaf | 固定碳 FCdaf | 碳C | 氢H | 氮N | 氧O△ | 硫S | ||

| CS | 84.09±2.06 a | 15.91±0.81 c | 46.71±0.96 c | 5.38±0.53 b | 0.25±0.01 c | 47.51±1.85 a | 0.15±0.01 b | 14.99±0.75 c |

| CS-230-AP | 76.35±2.00 b | 22.65±1.57 b | 54.84±1.42 b | 5.47±0.14 b | 0.76±0.03 a | 38.80±0.96 b | 0.13±0.00 b | 19.44±0.26 b |

| CS-230-0.5 | 70.70±1.70 b | 27.30±2.30 b | 57.94±2.55 b | 4.98±1.11 c | 0.50±0.04 b | 36.48±0.64 b | 0.10±0.00 b | 20.20±1.20 b |

| CS-230-1.0 | 66.02±2.11 b | 33.98±2.11 a | 63.32±0.95 a | 5.05±0.31 c | 0.59±0.02 b | 30.92±2.02 b | 0.12±0.01 b | 23.12±1.62 a |

| CS-230-1.5 | 63.85±3.14 c | 36.15±1.72 a | 65.97±3.09 a | 5.70±0.28 a | 0.48±0.07 b | 27.65±1.72 c | 0.20±0.01 a | 25.54±1.14 a |

| CS-230-2.0 | 63.01±2.36 c | 36.99±2.85 a | 67.00±0.52 a | 5.35±0.32 b | 0.45±0.07 b | 27.06±1.39 c | 0.14±0.01 b | 25.49±0.81 a |

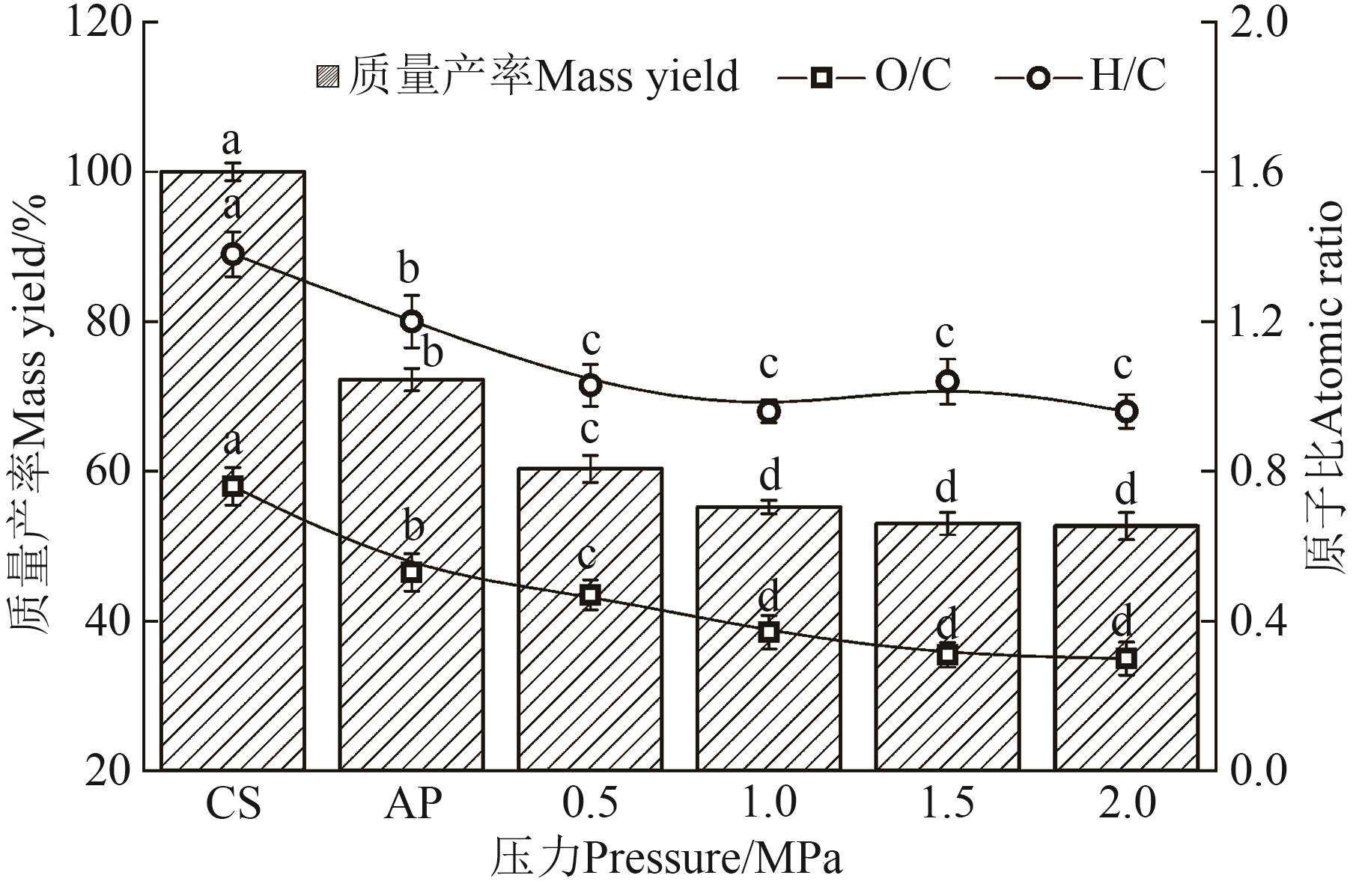

图2 CS原样及230 ℃、不同压力下的烘焙半焦质量产率、氧碳比和氢碳比注:不同小写字母表示不同处理间在P<0.05水平差异显著。Note:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

Fig. 2 Mass yield, O/C and H/C of torrefied semi-char under different pressures at 230 ℃ and CS samples

样品 Sample | 工业成分Proximate composition/% | 元素分析Ultimate analysis/% | 高位发热量HHV/(MJ·kg-1) | |||||

|---|---|---|---|---|---|---|---|---|

挥发分 Vdaf | 固定碳 FCdaf | 碳C | 氢H | 氮N | 氧O△ | 硫S | ||

| CS | 84.09±2.06 a | 15.91±0.81 e | 46.71±0.96 c | 5.38±0.53 a | 0.25±0.01 c | 47.51±1.85 a | 0.15±0.01 a | 14.99±0.75 c |

| CS-200-1.5 | 75.83±2.92 b | 24.17±0.97 d | 54.20±0.96 b | 4.85±0.32 b | 0.38±0.02 b | 40.49±1.24 a | 0.08±0.01 b | 18.02±0.52 b |

| CS-230-1.5 | 63.85±2.46 c | 36.15±2.07 c | 65.97±2.42 a | 5.70±0.24 a | 0.48±0.02 b | 27.65±0.66 b | 0.20±0.00 a | 25.54±1.26 a |

| CS-260-1.5 | 53.40±1.90 d | 46.60±1.30 b | 68.78±1.55 a | 5.39±0.75 a | 0.49±0.02 b | 25.25±0.40 b | 0.09±0.00 b | 26.48±1.03 a |

| CS-290-1.5 | 45.74±1.83 e | 54.26±2.55 a | 71.71±3.01 a | 5.63±1.04 a | 0.66±0.01 a | 22.39±1.63 b | 0.15±0.01 a | 28.15±1.33 a |

表2 CS原样及不同温度下加压烘焙半焦工业成分和元素分析

Table 2 Proximate composition and ultimate analysis of CS samples and pressurized torrefied semi-char

样品 Sample | 工业成分Proximate composition/% | 元素分析Ultimate analysis/% | 高位发热量HHV/(MJ·kg-1) | |||||

|---|---|---|---|---|---|---|---|---|

挥发分 Vdaf | 固定碳 FCdaf | 碳C | 氢H | 氮N | 氧O△ | 硫S | ||

| CS | 84.09±2.06 a | 15.91±0.81 e | 46.71±0.96 c | 5.38±0.53 a | 0.25±0.01 c | 47.51±1.85 a | 0.15±0.01 a | 14.99±0.75 c |

| CS-200-1.5 | 75.83±2.92 b | 24.17±0.97 d | 54.20±0.96 b | 4.85±0.32 b | 0.38±0.02 b | 40.49±1.24 a | 0.08±0.01 b | 18.02±0.52 b |

| CS-230-1.5 | 63.85±2.46 c | 36.15±2.07 c | 65.97±2.42 a | 5.70±0.24 a | 0.48±0.02 b | 27.65±0.66 b | 0.20±0.00 a | 25.54±1.26 a |

| CS-260-1.5 | 53.40±1.90 d | 46.60±1.30 b | 68.78±1.55 a | 5.39±0.75 a | 0.49±0.02 b | 25.25±0.40 b | 0.09±0.00 b | 26.48±1.03 a |

| CS-290-1.5 | 45.74±1.83 e | 54.26±2.55 a | 71.71±3.01 a | 5.63±1.04 a | 0.66±0.01 a | 22.39±1.63 b | 0.15±0.01 a | 28.15±1.33 a |

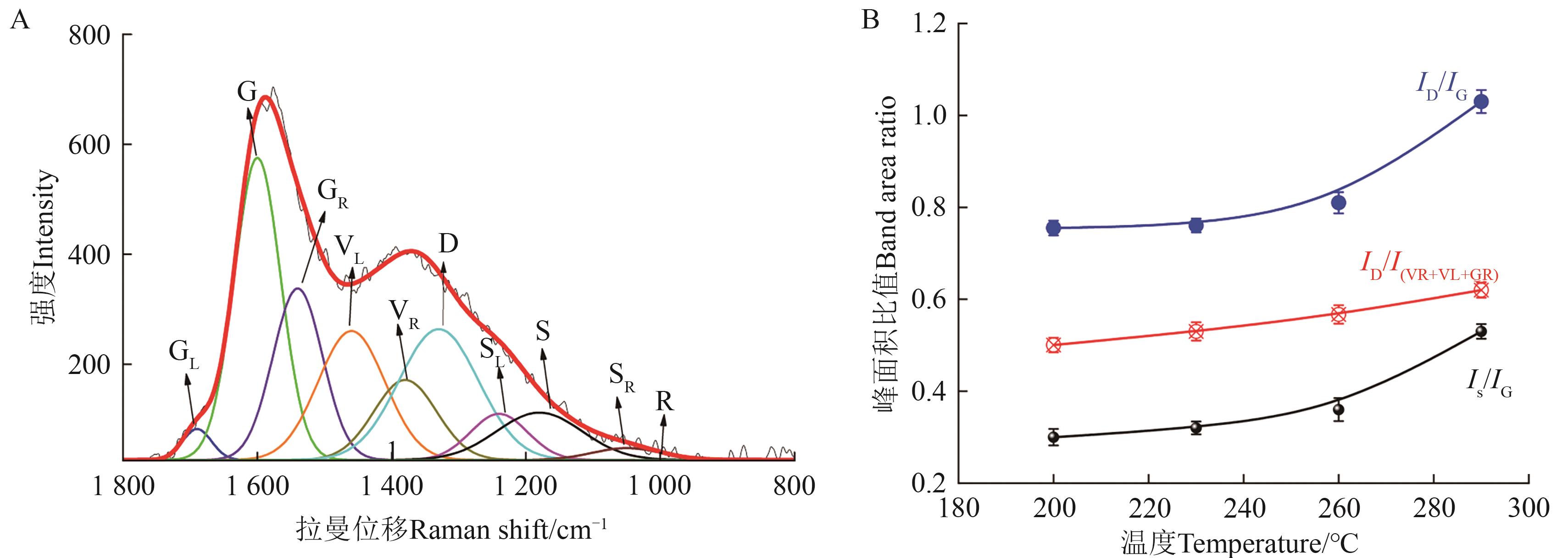

图5 不同温度下CS加压烘焙半焦的拉曼分峰结果A:CS-230-1.5的拉曼分峰;B:各样品分峰面积计算结果

Fig. 5 Raman peak splitting results of CS pressurized torrefied semi-char at different temperaturesA:Raman splitting of CS-230-1.5;B:Peak area results of each sample

样品 Sample | 比表面积 Specific surface area/(m2·g-1) | 总孔体积 Total pore volume/(cm3·g-1) | 平均孔径 Average pore size/nm |

|---|---|---|---|

| CS | 27.47 | 0.042 9 | 3.23 |

| CS-230-AP | 25.03 | 0.047 3 | 5.12 |

| CS-200-1.5 | 24.25 | 0.043 9 | 4.78 |

| CS-230-1.5 | 37.69 | 0.056 8 | 4.38 |

| CS-260-1.5 | 38.92 | 0.068 3 | 3.99 |

| CS-290-1.5 | 40.02 | 0.070 4 | 3.52 |

表3 CS原样及各温度下固体半焦的BET测试结果

Table 3 BET test results of solid semi-char at different temperatures and CS sample

样品 Sample | 比表面积 Specific surface area/(m2·g-1) | 总孔体积 Total pore volume/(cm3·g-1) | 平均孔径 Average pore size/nm |

|---|---|---|---|

| CS | 27.47 | 0.042 9 | 3.23 |

| CS-230-AP | 25.03 | 0.047 3 | 5.12 |

| CS-200-1.5 | 24.25 | 0.043 9 | 4.78 |

| CS-230-1.5 | 37.69 | 0.056 8 | 4.38 |

| CS-260-1.5 | 38.92 | 0.068 3 | 3.99 |

| CS-290-1.5 | 40.02 | 0.070 4 | 3.52 |

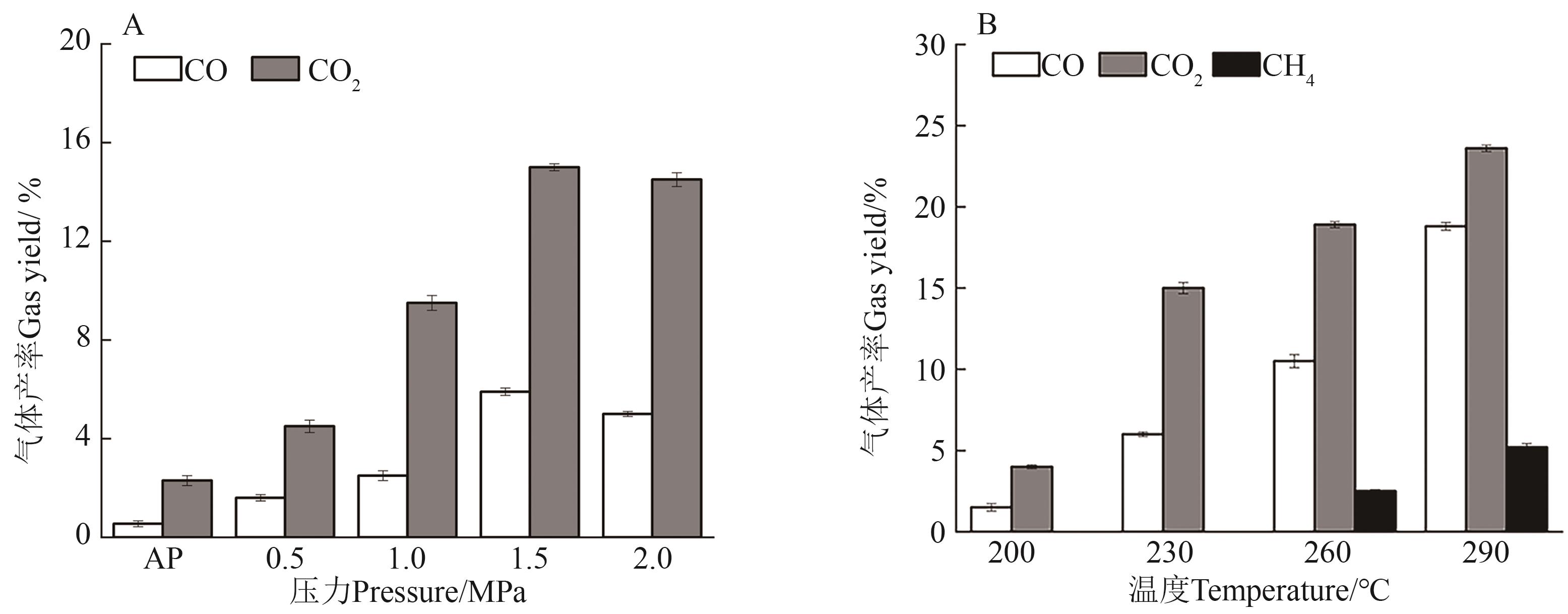

图10 不同压力及温度下烘焙气体产物组成A:230 ℃、不同压力下气体分布;B:1.5 MPa、不同温度下气体分布

Fig. 10 Compositions of torrefied gas products under different pressures and temperaturesA:Gas distribution at 230 ℃ and different pressures;B:Gas distribution at 1.5 MPa and different temperatures

| [1] | FIELD C B, CAMPBELL J E, LOBELL D B.Biomass energy:the scale of the potential resource [J]. Trends Ecol. Evol., 2008,23(2):65-72. |

| [2] | LONG H L, LI X B, WANG H, et al.. Biomass resources and their bioenergy potential estimation:a review [J]. Renew.Sustain. Energy Rev., 2013, 26: 344-352. |

| [3] | QUADER M A, AHMED S, GHAZILLA R A R, et al.. A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing [J]. Renew. Sustain. Energy Rev., 2015,50:594-614. |

| [4] | 严云,何强,沙建雄,等.污泥-杏壳基生物质炭的制备工艺优化及对亚甲基蓝吸附研究[J].化工新型材料,2022,50(11):278-282. |

| YAN Y, HE Q, SHA J X, et al.. Optimization of the preparation process of sludge-apricot shell-based biomass carbon and its adsorption towards methylene blue [J]. New Chem. Mater.,2022,50(11):278-282. | |

| [5] | BACH Q V, SKREIBERG Ø. Upgrading biomass fuels via wet torrefaction:a review and comparison with dry torrefaction [J].Renew. Sustain. Energy Rev., 2016,54: 665-677. |

| [6] | 孙启祥,彭镇华,张齐生.自然状态下杉木木材挥发物成分及其对人体身心健康的影响[J].安徽农业大学学报,2004,31(2):158-163. |

| SUN Q X, PENG Z H, ZHANG Q S. Volatiles of wood of Chinese fir in nature and its effect on human health [J]. J.Anhui Agric. Univ., 2004,31(2):158-163. | |

| [7] | 金紫霖,张启翔,潘会堂,等.芳香植物的特性及对人体健康的作用[J].湖北农业科学,2009,48(5):1245-1247. |

| JIN Z L, ZHANG Q X, PAN H T, et al.. The aromatic characteristics and healthy effects of the aromatic plants [J].Hubei Agric. Sci., 2009, 48(5):1245-1247. | |

| [8] | DING Y M, HUANG B Q, LI K Y, et al.. Thermal interaction analysis of isolated hemicellulose and cellulose by kinetic parameters during biomass pyrolysis [J/OL]. Energy, 2020, 195:117010 [2023-12-18]. . |

| [9] | STRANDBERG M, OLOFSSON I, POMMER L, et al.. Effects of temperature and residence time on continuous torrefaction of spruce wood [J]. Fuel Process. Technol., 2015,134:387-398. |

| [10] | TOOR S S, ROSENDAHL L, RUDOLF A. Hydrothermal liquefaction of biomass:a review of subcritical water technologies [J]. Energy, 2011, 36(5):2328-2342. |

| [11] | TONG S, SUN Y M, LI X, et al.. Gas-pressurized torrefaction of biomass wastes:Roles of pressure and secondary reactions [J/OL].Bioresour. Technol., 2020, 313:123640 [2023-12-18]. . |

| [12] | MATALI S, RAHMAN N A, IDRIS S S, et al.. Lignocellulosic biomass solid fuel properties enhancement via torrefaction [J].Procedia Eng., 2016,148:671-678. |

| [13] | NHUCHHEN D R, BASU P. Experimental investigation of mildly pressurized torrefaction in air and nitrogen [J]. Energy Fuels, 2014, 28(5):3110-3121. |

| [14] | 丁亮,张永奇,黄戒介,等.热解压力对生物质焦结构及气化反应性能的影响[J].燃料化学学报,2014,42(11):1309-1315. |

| DING L, ZHANG Y Q, HUANG J J, et al.. Effects of pyrolysis pressure on the properties and gasification reactivities of biomass chars [J]. J. Fuel Chem. Technol., 2014, 42(11):1309-1315. | |

| [15] | WANNAPEERA J, WORASUWANNARAK N. Upgrading of woody biomass by torrefaction under pressure [J]. J. Anal. Appl. Pyrolysis, 2012, 96:173-180. |

| [16] | AGAR D, DEMARTINI N, HUPA M. Influence of elevated pressure on the torrefaction of wood [J]. Energy Fuels, 2016, 30(3):2127-2136. |

| [17] | 张传佳,李安心,涂德浴.水稻秸秆成型燃料热解特性试验研究[J].中国农业科技导报,2017,19(7):95-100. |

| ZHANG C J, LI A X, TU D Y. The experimental study on pyrolysis characteristics of rice straw briquette fuel [J]. J. Agric.Sci. Technol., 2017, 19(7):95-100. | |

| [18] | 肖军,沈来宏,王泽明,等.生物质加压热重分析研究[J].燃烧科学与技术,2005,11(5):415-420. |

| XIAO J, SHEN L H, WANG Z M, et al.. Pressurized thermogravimetric analysis of pyrolysis of biomass [J].J.Combust. Sci. Technol., 2005, 11(5): 415-420. | |

| [19] | SONOBE T, WORASUWANNARAK N.Kinetic analyses of biomass pyrolysis using the distributed activation energy model [J]. Fuel, 2008, 87(3):414-421. |

| [20] | DE CAPRARIIS B, SANTARELLI M L, SCARSELLA M, et al..Kinetic analysis of biomass pyrolysis using a double distributed activation energy model [J]. J. Therm. Anal.Calorim., 2015, 121(3): 1403-1410. |

| [21] | 严云,刘洪,曹芮,等.农林废弃生物质的热解特性及动力学研究[J].化工新型材料,2020,48(1):148-151, 156. |

| YAN Y, LIU H, CAO R, et al.. Study on pyrolysis characteristics and kinetics of waste biomass in agriculture and forestry [J]. New Chem. Mater., 2020, 48(1):148-151, 156. | |

| [22] | LIU X G, LI B Q, MIURA K. Analysis of pyrolysis and gasification reactions of hydrothermally and supercritically upgraded low-rank coal by using a new distributed activation energy model [J]. Fuel Process. Technol., 2001, 69(1):1-12. |

| [23] | SATTASATHUCHANA S, PARNTHONG J, YOUNGIAN S,et al..Energy efficiency of bio-coal derived from hydrothermal carbonized biomass:Assessment as sustainable solid fuel for municipal biopower plant [J/OL]. Appl. Therm. Eng., 2023, 221:119789 [2024-12-30]. . |

| [24] | 陈勇,陈登宇,孙琰,等.烘焙脱氧预处理对生物质秸秆燃料品质的影响[J].科学技术与工程,2015,15(11):205-209. |

| CHEN Y, CHEN D Y, SUN Y, et al.. Effect of torrefaction on the fuel properties of biomass straw [J]. Sci. Technol. Eng., 2015, 15(11):205-209. | |

| [25] | XIN S Z, YANG H P, CHEN Y Q, et al.. Chemical structure evolution of char during the pyrolysis of cellulose [J]. J. Anal.Appl. Pyrolysis, 2015, 116:263-271. |

| [26] | 周亚运,肖军,吕潇,等.预处理生物质的热解实验研究[J].东南大学学报(自然科学版),2016,46(2):317-325. |

| ZHOU Y Y, XIAO J, LYU X, et al.. Experimental study on pyrolysis of pretreated biomass [J]. J. Southeast Univ.(Nat. Sci.), 2016, 46(2):317-325. | |

| [27] | 宫聚辉,邵婷婷,路平,等.煤和沙柳的O2/CO2混合燃烧特性及相互作用研究[J].中国农业科技导报,2017,19(10):96-106. |

| GONG J H, SHAO T T, LU P, et al.. Combustion characteristic and interaction of coal and Salix Psammophila under O2/CO2 atmosphere [J]. J. Agric. Sci. Technol., 2017, 19(10):96-106. | |

| [28] | 苏允泓,任菊荣,孙云娟,等.烘焙提升生物质燃料品质的研究[J].林产化学与工业,2023,43(2):27-35. |

| SU Y H, REN J R, SUN Y J, et al.. Improving the quality of biofuel by torrefaction [J].Chem.Ind.For.Prod.,2023,43(2):27-35. | |

| [29] | SETKIT N, LI X, YAO H, et al.. Torrefaction under mechanical pressure of 10-70 atMPa 250 ℃ and its effect on pyrolysis behaviours of Leucaena wood [J/OL].Bioresour.Technol., 2021, 338:125503 [2023-12-18]. . |

| [30] | LI X J, HAYASHI J I, LI C Z. FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal [J]. Fuel, 2006, 85(12/13):1700-1707. |

| [1] | 乔慧艳, 石雅丽, 韩昊健. 微生物来源纤维素酶的研究进展[J]. 中国农业科技导报, 2025, 27(5): 21-38. |

| [2] | 马振华, 时倩茹, 宁欣杰, 魏宏杨, 王璨, 张静静, 张彪, 杨素勤. 生物质炭对镉铅污染土壤线虫群落的影响[J]. 中国农业科技导报, 2025, 27(2): 201-210. |

| [3] | 张继东, 张亚雄, 程伟, 蒲莉, 柳路行, 王亚明. 生物质炭和有机肥配施对苹果重茬育苗地土壤理化性质和微生物群落特征的影响[J]. 中国农业科技导报, 2024, 26(8): 213-222. |

| [4] | 陈雨欣, 赵红梅, 杨卫君, 杨梅, 郭颂, 宋世龙, 惠超. 生物质炭对土壤微生物碳源利用及春小麦产量的影响[J]. 中国农业科技导报, 2024, 26(5): 174-183. |

| [5] | 赵秀英, 黄晴雯, 曹浩杰, 王杰, 李瑞姣, 聂冬霞, 韩铮, 赵志辉. 响应面法优化禾谷镰刀菌产脱氧雪腐镰刀菌烯醇及其衍生物的液体培养条件[J]. 中国农业科技导报, 2023, 25(7): 222-233. |

| [6] | 刘师豆1,朱新萍1,2*,赵一1,王博言1,韩耀光1,杨贝贝1,卢智1,贾宏涛1,2. 棉秆炭减缓土壤中镉对水稻生长的胁迫效应[J]. 中国农业科技导报, 2020, 22(4): 139-146. |

| [7] | 王薇,李泳,王伟,边雪,李熙英*. Y-S-Y12发酵液和生物质热解液混配对辣椒炭疽病的防治及作用机理[J]. 中国农业科技导报, 2020, 22(10): 129-138. |

| [8] | 殷全玉1,李阳1,张玉兰1,王生才2,方明2,李宏光2,王新发3,刘国顺1*. 生物质炭与土质互作对土壤硝态氮含量的动态影响[J]. 中国农业科技导报, 2019, 21(6): 143-151. |

| [9] | 陈永对1,朱海滨2,胡占军2,杨义2,吴阔1,董家红1*,张仲凯1*. 五种芳香植物精油对烟草疫霉的抑菌活性分析[J]. 中国农业科技导报, 2019, 21(5): 104-109. |

| [10] | 夏先飞1,肖宏儒1*,肖苏伟1,李波2,李国平2. 基于混合正交试验的生物质旋压成型多目标优化[J]. 中国农业科技导报, 2019, 21(3): 69-75. |

| [11] | 刘宏元1,张爱平1,王永生2,杨世琦1,邢磊1,杨正礼1*. 施用棉花秸秆生物质炭对华北平原农田温室气体排放的影响[J]. 中国农业科技导报, 2019, 21(11): 121-129. |

| [12] | 孙颖材,董泰丽*. 能源玉米不同种植模式下土地甲烷产量的研究[J]. 中国农业科技导报, 2018, 20(7): 91-97. |

| [13] | 黄宇,樊啟洲*,汪烈,范先红. 闷烧热解及间接加热直立移动床生物质炭化设备设计研究[J]. 中国农业科技导报, 2018, 20(11): 69-78. |

| [14] | 白勇,司 慧*,王霄,吴煜. 流化床生物质快速热解气组成及冷凝技术的研究进展 [J]. 中国农业科技导报, 2017, 19(8): 77-83. |

| [15] | 张传佳1,李安心1,涂德浴1,2*. 水稻秸秆成型燃料热解特性试验研究[J]. 中国农业科技导报, 2017, 19(7): 95-100. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号