Journal of Agricultural Science and Technology ›› 2022, Vol. 24 ›› Issue (6): 123-132.DOI: 10.13304/j.nykjdb.2021.0783

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Shisheng SONG( ), Songlin SUN, Qin FANG, Caiwang PENG(

), Songlin SUN, Qin FANG, Caiwang PENG( ), Ting ZHOU, Haiying ZHU

), Ting ZHOU, Haiying ZHU

Received:2021-09-06

Accepted:2022-03-08

Online:2022-06-15

Published:2022-06-21

Contact:

Caiwang PENG

宋世圣( ), 孙松林, 方芹, 彭才望(

), 孙松林, 方芹, 彭才望( ), 周婷, 朱海英

), 周婷, 朱海英

通讯作者:

彭才望

作者简介:宋世圣 E-mail:hunausss@163.com;

基金资助:CLC Number:

Shisheng SONG, Songlin SUN, Qin FANG, Caiwang PENG, Ting ZHOU, Haiying ZHU. Parameters Calibration of Discrete Element for Kitchen Waste Organic Fertilizer Bioconversion by Black Soldier Fly[J]. Journal of Agricultural Science and Technology, 2022, 24(6): 123-132.

宋世圣, 孙松林, 方芹, 彭才望, 周婷, 朱海英. 黑水虻生物转化餐厨垃圾有机肥离散元模型参数标定[J]. 中国农业科技导报, 2022, 24(6): 123-132.

参数符号 Parameter symbol | 参数 Parameter | 低水平 Low level(-1) | 高水平 High level(1) | 文献 Reference |

|---|---|---|---|---|

| A | 泊松比 Poisson’s ratio | 0.10 | 0.30 | [ |

| B | 剪切模量 Shear modulus/MPa | 4.00 | 10.00 | [ |

| C | 颗粒密度 Particle density/(kg·m-3) | 1 500 | 2 500 | [ |

| D | 有机肥-有机肥碰撞恢复系数 Organic fertilizer-organic fertilizer restitution coefficient | 0.10 | 0.70 | [ |

| E | 有机肥-有机肥静摩擦系数 Organic fertilizer-organic fertilizer static friction coefficient | 0.75 | 0.85 | 测定Measure |

| F | 有机肥-有机肥滚动摩擦系数 Organic fertilizer-organic fertilizer rolling friction coefficient | 0.10 | 0.20 | 测定Measure |

| G | 有机肥-钢碰撞恢复系数 Organic fertilizer-steel restitution coefficient | 0.30 | 0.90 | [ |

| H | 有机肥-钢静摩擦系数 Organic fertilizer-steel static friction coefficient | 0.60 | 0.70 | 测定Measure |

| J | 有机肥钢滚动摩擦系数 Organic fertilizer-steel rolling friction coefficient | 0.01 | 0.11 | 测定Measure |

| K | JKR表面能 JKR surface energy/(J·m-2) | 0.05 | 0.15 | [ |

Table 1 Factors of Plackett-Burman Design

参数符号 Parameter symbol | 参数 Parameter | 低水平 Low level(-1) | 高水平 High level(1) | 文献 Reference |

|---|---|---|---|---|

| A | 泊松比 Poisson’s ratio | 0.10 | 0.30 | [ |

| B | 剪切模量 Shear modulus/MPa | 4.00 | 10.00 | [ |

| C | 颗粒密度 Particle density/(kg·m-3) | 1 500 | 2 500 | [ |

| D | 有机肥-有机肥碰撞恢复系数 Organic fertilizer-organic fertilizer restitution coefficient | 0.10 | 0.70 | [ |

| E | 有机肥-有机肥静摩擦系数 Organic fertilizer-organic fertilizer static friction coefficient | 0.75 | 0.85 | 测定Measure |

| F | 有机肥-有机肥滚动摩擦系数 Organic fertilizer-organic fertilizer rolling friction coefficient | 0.10 | 0.20 | 测定Measure |

| G | 有机肥-钢碰撞恢复系数 Organic fertilizer-steel restitution coefficient | 0.30 | 0.90 | [ |

| H | 有机肥-钢静摩擦系数 Organic fertilizer-steel static friction coefficient | 0.60 | 0.70 | 测定Measure |

| J | 有机肥钢滚动摩擦系数 Organic fertilizer-steel rolling friction coefficient | 0.01 | 0.11 | 测定Measure |

| K | JKR表面能 JKR surface energy/(J·m-2) | 0.05 | 0.15 | [ |

试验序号 No. | A | B | C | D | E | F | G | H | J | K | L | 堆积角 Repose angle/(°) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 30.2 |

| 2 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 62.85 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 40.28 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 33.25 |

| 5 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 31.58 |

| 6 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 32.13 |

| 7 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 51.05 |

| 8 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 55.35 |

| 9 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 30.95 |

| 10 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 53.58 |

| 11 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 51.18 |

| 12 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 52.08 |

Table 2 Design and results of Plackett-Burman Design

试验序号 No. | A | B | C | D | E | F | G | H | J | K | L | 堆积角 Repose angle/(°) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 30.2 |

| 2 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 62.85 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 40.28 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 33.25 |

| 5 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 31.58 |

| 6 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 32.13 |

| 7 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 51.05 |

| 8 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 55.35 |

| 9 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 30.95 |

| 10 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 53.58 |

| 11 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 51.18 |

| 12 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 52.08 |

方差来源 Soruce of variation | 标准化效应 Stdized effects | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value | 排序 Ranking |

|---|---|---|---|---|---|---|

| 模型Model | — | 1 526.53 | 10 | 772.40 | 0.028 0 | — |

| A | 2.58 | 19.92 | 1 | 100.78 | 0.063 2 | 5 |

| B | -2.73 | 22.30 | 1 | 112.86 | 0.059 8 | 4 |

| C | -0.87 | 2.25 | 1 | 11.40 | 0.183 3 | 8 |

| D | -21.28 | 1 358.94 | 1 | 6 876.07 | 0.007 7** | 1 |

| E | 1.37 | 5.60 | 1 | 28.35 | 0.118 2 | 9 |

| F | -0.090 | 0.024 | 1 | 0.12 | 0.785 3 | 10 |

| G | 3.83 | 44.01 | 1 | 222.67 | 0.042 6* | 3 |

| H | 2.53 | 19.25 | 1 | 97.42 | 0.064 3 | 6 |

| J | -4.05 | 49.21 | 1 | 248.98 | 0.040 3* | 2 |

| K | -1.29 | 5.02 | 1 | 25.39 | 0.124 7 | 7 |

Table 3 Significance analysis of Plackett-Burman test results

方差来源 Soruce of variation | 标准化效应 Stdized effects | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value | 排序 Ranking |

|---|---|---|---|---|---|---|

| 模型Model | — | 1 526.53 | 10 | 772.40 | 0.028 0 | — |

| A | 2.58 | 19.92 | 1 | 100.78 | 0.063 2 | 5 |

| B | -2.73 | 22.30 | 1 | 112.86 | 0.059 8 | 4 |

| C | -0.87 | 2.25 | 1 | 11.40 | 0.183 3 | 8 |

| D | -21.28 | 1 358.94 | 1 | 6 876.07 | 0.007 7** | 1 |

| E | 1.37 | 5.60 | 1 | 28.35 | 0.118 2 | 9 |

| F | -0.090 | 0.024 | 1 | 0.12 | 0.785 3 | 10 |

| G | 3.83 | 44.01 | 1 | 222.67 | 0.042 6* | 3 |

| H | 2.53 | 19.25 | 1 | 97.42 | 0.064 3 | 6 |

| J | -4.05 | 49.21 | 1 | 248.98 | 0.040 3* | 2 |

| K | -1.29 | 5.02 | 1 | 25.39 | 0.124 7 | 7 |

试验编号 Code | D | G | J | 堆积角 Repose angle/(°) | 相对误差 Relative errors/% |

|---|---|---|---|---|---|

| 1 | 0.70 | 0.30 | 0.11 | 36.58 | 11.51 |

| 2 | 0.58 | 0.42 | 0.09 | 39.38 | 4.74 |

| 3 | 0.46 | 0.54 | 0.07 | 47.65 | 15.26 |

| 4 | 0.34 | 0.66 | 0.05 | 56.23 | 36.02 |

| 5 | 0.22 | 0.78 | 0.03 | 59.34 | 43.54 |

| 6 | 0.10 | 0.90 | 0.01 | 61.25 | 48.16 |

Table 4 Design and results of steepest ascent test

试验编号 Code | D | G | J | 堆积角 Repose angle/(°) | 相对误差 Relative errors/% |

|---|---|---|---|---|---|

| 1 | 0.70 | 0.30 | 0.11 | 36.58 | 11.51 |

| 2 | 0.58 | 0.42 | 0.09 | 39.38 | 4.74 |

| 3 | 0.46 | 0.54 | 0.07 | 47.65 | 15.26 |

| 4 | 0.34 | 0.66 | 0.05 | 56.23 | 36.02 |

| 5 | 0.22 | 0.78 | 0.03 | 59.34 | 43.54 |

| 6 | 0.10 | 0.90 | 0.01 | 61.25 | 48.16 |

试验编号 Code | 水平 Level | 堆积角 Repose angle/(°) | ||

|---|---|---|---|---|

| D | G | J | ||

| 1 | 0 | -1 | 1 | 43.25 |

| 2 | 0 | 1 | 1 | 48.35 |

| 3 | -1 | 0 | -1 | 34.15 |

| 4 | 1 | 0 | 1 | 50.85 |

| 5 | 0 | 0 | 0 | 47.30 |

| 6 | 0 | 0 | 0 | 45.73 |

| 7 | -1 | 0 | 1 | 45.50 |

| 8 | 0 | 0 | 0 | 46.80 |

| 9 | 1 | -1 | 0 | 42.50 |

| 10 | 1 | 0 | -1 | 41.65 |

| 11 | 0 | 0 | 0 | 47.85 |

| 12 | -1 | 1 | 0 | 40.80 |

| 13 | 0 | -1 | -1 | 38.23 |

| 14 | 0 | 1 | -1 | 39.28 |

| 15 | 1 | 1 | 0 | 43.15 |

| 16 | 0 | 0 | 0 | 48.23 |

| 17 | -1 | -1 | 0 | 36.19 |

Table 5 Design and results of Box-Behnken Design

试验编号 Code | 水平 Level | 堆积角 Repose angle/(°) | ||

|---|---|---|---|---|

| D | G | J | ||

| 1 | 0 | -1 | 1 | 43.25 |

| 2 | 0 | 1 | 1 | 48.35 |

| 3 | -1 | 0 | -1 | 34.15 |

| 4 | 1 | 0 | 1 | 50.85 |

| 5 | 0 | 0 | 0 | 47.30 |

| 6 | 0 | 0 | 0 | 45.73 |

| 7 | -1 | 0 | 1 | 45.50 |

| 8 | 0 | 0 | 0 | 46.80 |

| 9 | 1 | -1 | 0 | 42.50 |

| 10 | 1 | 0 | -1 | 41.65 |

| 11 | 0 | 0 | 0 | 47.85 |

| 12 | -1 | 1 | 0 | 40.80 |

| 13 | 0 | -1 | -1 | 38.23 |

| 14 | 0 | 1 | -1 | 39.28 |

| 15 | 1 | 1 | 0 | 43.15 |

| 16 | 0 | 0 | 0 | 48.23 |

| 17 | -1 | -1 | 0 | 36.19 |

方差来源 Soruce of variation | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|

| 模型Model | 340.15 | 9 | 23.37 | 0.000 2** |

| D | 57.84 | 1 | 35.76 | 0.000 6** |

| G | 16.27 | 1 | 10.06 | 0.015 7* |

| J | 149.99 | 1 | 92.73 | <0.000 1** |

| DG | 3.92 | 1 | 2.42 | 0.163 5 |

| DJ | 1.16 | 1 | 0.71 | 0.425 9 |

| GJ | 4.10 | 1 | 2.54 | 0.155 4 |

| D2 | 34.95 | 1 | 21.61 | 0.002 3** |

| G2 | 55.82 | 1 | 34.51 | 0.000 6** |

| J2 | 6.72 | 1 | 4.16 | 0.080 9 |

| 残差Residual | 11.32 | 7 | ||

| 失拟项Lack of fit | 7.51 | 3 | 2.63 | 0.187 0 |

| 纯误差Pure error | 3.81 | 4 | ||

| 总和Sum | 351.48 | 16 |

Table 6 ANOVA of regression model of Box Behnken Design

方差来源 Soruce of variation | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|

| 模型Model | 340.15 | 9 | 23.37 | 0.000 2** |

| D | 57.84 | 1 | 35.76 | 0.000 6** |

| G | 16.27 | 1 | 10.06 | 0.015 7* |

| J | 149.99 | 1 | 92.73 | <0.000 1** |

| DG | 3.92 | 1 | 2.42 | 0.163 5 |

| DJ | 1.16 | 1 | 0.71 | 0.425 9 |

| GJ | 4.10 | 1 | 2.54 | 0.155 4 |

| D2 | 34.95 | 1 | 21.61 | 0.002 3** |

| G2 | 55.82 | 1 | 34.51 | 0.000 6** |

| J2 | 6.72 | 1 | 4.16 | 0.080 9 |

| 残差Residual | 11.32 | 7 | ||

| 失拟项Lack of fit | 7.51 | 3 | 2.63 | 0.187 0 |

| 纯误差Pure error | 3.81 | 4 | ||

| 总和Sum | 351.48 | 16 |

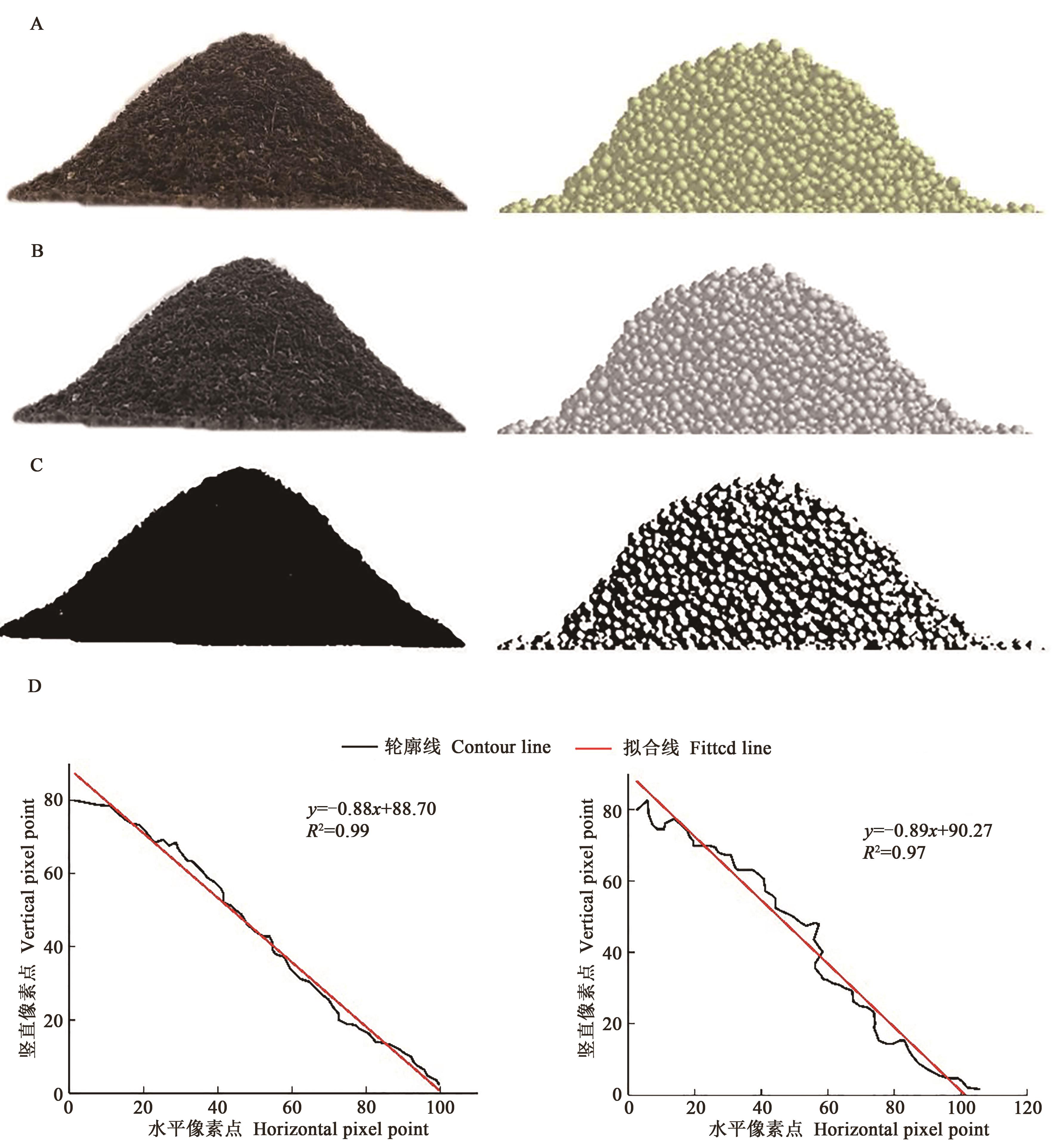

Fig. 5 Comparison of physical test and simulation testA: Physical test and simulation image; B: Grayscale processing; C: Binarization processing; D:Comparison of boundary contou. The left shows physical test and the right shows simulation test

| 1 | RAHMAN M A, SHAHAZI R, NOVA S N B, et al.. Biogas production from anaerobic co-digestion using kitchen waste and poultry manure as substrate—part 1: substrate ratio and effect of temperature [J/OL]. Biomass Convers. Bioresour., 2021 [2021-10-27]. . |

| 2 | ISHA A, D' SILVA T C, SUBBARAO P M V, et al.. Stabilization of anaerobic digestion of kitchen wastes using protein-rich additives: Study of process performance, kinetic modelling and energy balance [J/OL]. Bioresour. Technol., 2021, 337:125331[2021-03-05]. . |

| 3 | 谷士艳, 闫屹嵩, 张文一,等. 高盐高油对餐厨垃圾厌氧发酵酶活性及产VFAs的影响 [J]. 农业工程学报,2021,37(6):228-234. |

| GU S Y, YAN Y S, ZHANG W Y, et al.. Effects of high salt and high oil content on anaerobic fermentation enzyme activity and production of VFAs in food waste [J]. Trans. CSAE, 2021,37(6):228-234. | |

| 4 | 黄晶晶, 戴思慧, 张良,等.生活垃圾有机肥制造设备的设计与试验 [J]. 湖南农业大学学报(自然科学版),2019,45(3):332-336. |

| HUANG J J, DAI S H, ZHANG L, et al.. Design and experimental research on the organic fertilizer manufacturing equipment for domestic garbage [J]. J. Hunan Agric. Univ. (Nat. Sci.), 2019, 45(3):332-336. | |

| 5 | 张晓林, 段永改, 贺永惠. 餐厨垃圾与鸡粪饲养黑水虻幼虫条件优化 [J]. 浙江农业科学,2021,62(06):1200-1203, 1258. |

| ZHANG X L, DUAN Y G, HE Y H. Optimization of feeding conditions of black soldier fly larvae by food waste and chicken manure [J]. J. Zhejiang Agric. Sci., 2021,62(6):1200-1203, 1258. | |

| 6 | LU Y, ZHANG S Y, SUN S B, et al.. Effects of different nitrogen sources and ratios to carbon on larval development and bioconversion efficiency in food waste treatment by black soldier fly larvae (Hermetia illucens) [J/OL]. Insects, 2021, 12(6):507[2021-03-05]. . |

| 7 | 尹靖凯,龚小燕,孙丽娜,等.黑水虻对餐厨垃圾养分转化研究[J].中国农业科技导报,2021,23(6):154-159. |

| YIN J K, GONG X Y, SUN L N, et al.. Study on the transformation of nutrients in kitchen waste by black soldier fly [J]. J. Agric. Sci. Tech. China, 2021,23(6):154-159. | |

| 8 | 张志剑,王先哲,许绍伟,等.虻粪二次堆肥生化特性的动态变化趋势及其微生物演替规律[J].微生物学报,2020,60(12):2664-2674. |

| ZHANG Z J, WANG X Z, XV S W, et al.. Dynamic features of biochemical property and microbial succession of black soldier fly larvae (Hermetia illucens L) vermicompost during secondary composting [J]. Acta Microbiol. Sin., 2020,60(12):2664-2674. | |

| 9 | 李逵,杨启志,雷朝亮,等.我国利用昆虫转化有机废弃物的发展现状及前景[J].环境昆虫学报,2017,39(2):453-459. |

| LI K, YANG Q Z, LEI C L, et al. Status and prospects of the transformation of organic wastes by insects in China [J]. J. Environ. Entomol., 2017,39(2):453-459. | |

| 10 | 王国强.离散单元法及其在EDEM上的实践[M]. 西安:西北工业大学出版社,2010: 1-155. |

| 11 | 胡国明.颗粒系统的离散元素法分析仿真[M]. 武汉:武汉理工大学出版社,2010: 1-302. |

| 12 | 韩树杰,戚江涛,坎杂,等.新疆果园深施散体厩肥离散元参数标定研究[J].农业机械学报,2021,52(4):101-108. |

| HAN S J, QI J T, KAN Z, et al. Parameters calibration of discrete element for deep application of bulk manure in Xinjiang orchard [J]. Trans. CSAM, 2021,52(4):101-108. | |

| 13 | 王韦韦,蔡丹艳,谢进杰,等.玉米秸秆粉料致密成型离散元模型参数标定[J].农业机械学报,2021,52(3):127-134. |

| WANG W W, CAI D Y, XIE J J, et al. Parameters calibration of eiscrete element model for corn stalk powder compression simulation [J]. Trans. CSAM, 2021,52(3):127-134. | |

| 14 | 石辰风,杨茂蕊,唐正馨,等.中药浸膏粉离散元模拟参数标定方法研究[J].中草药,2020,51(24):6205-6212. |

| SHI C F, YANG M R, TANG Z X, et al.. Calibration of discrete element simulation parameters of Chinese medicine extract powders [J]. China Tradit Herb Drugs, 2020,51(24):6205-6212. | |

| 15 | 彭才望,许道军,贺喜,等.黑水虻处理的猪粪有机肥离散元仿真模型参数标定[J].农业工程学报,2020,36(17):212-218. |

| PENG C W, XV D J, HE X, et al.. Parameter calibration of discrete element simulation model for pig manure organic fertilizer treated with Hermetia illucen [J]. Trans. CSAE, 2020,36(17):212-218. | |

| 16 | 邢洁洁,张锐,吴鹏,等.海南热区砖红壤颗粒离散元仿真模型参数标定[J].农业工程学报,2020,36(5):158-166. |

| XING J J, ZHANG R, WU P, et al.. Parameter calibration of discrete element simulation model for latosol particles in hot areas of Hainan Province [J]. Trans. CSAE, 2020,36(5):158-166. | |

| 17 | 刘家平,刘胜芳.利用物理方法对餐厨垃圾分类处理研究[J].食品安全导刊,2017(18):117-118. |

| 18 | 任立斌.黑水虻生物转化餐厨垃圾试验的研究[D]. 兰州:兰州交通大学, 2020. |

| REN L B. The experimental Study on the biological transformation of food waste from black solider fly larva [D]. Lanzhou: Lanzhou Jiaotong University, 2020. | |

| 19 | 余参参,段宏兵,蔡兴奎,等.基于离散元仿真参数的微型薯物料测定[J].华中农业大学学报,2021,40(1):210-217. |

| YU C C, DUAN H B, CAI X K, et al.. Discrete element simulation parameters-based measurement of materials for potato minituber [J]. J. Huazhong Agric. Univ., 2021,40(1):210-217. | |

| 20 | 张晓明.有机肥颗粒热风干燥工艺及装备研究[D].北京:中国农业大学, 2017. |

| ZHANG X M. Study on the Drying Process and Equipment for Organic Feretilizer Pellets [D]. Beijing: China Agricultural University, 2017. | |

| 21 | 武涛,黄伟凤,陈学深,等.考虑颗粒间黏结力的黏性土壤离散元模型参数标定[J].华南农业大学学报(自然科学版),2017,38(3):93-98. |

| WU T, HUANG W F, CHEN X S, et al.. Calibration of discrete element model parameters for cohesive soil considering the cohesion between particles [J]. J. South China Agric. Univ. (Nat. Sci.), 2017,38(3):93-98. | |

| 22 | 林嘉聪,罗帅,袁巧霞,等.不同含水率蚯蚓粪颗粒物料流动性研究[J].农业工程学报,2019,35(9):221-227. |

| LIN J C, LUO S, YUAN Q X, et al.. Flow properties of vermicompost particle with different moisture contents [J]. Trans. CSAE, 2019,35(9):221-227. | |

| 23 | 罗帅,袁巧霞, GOUDA S, 等. 基于JKR粘结模型的蚯蚓粪基质离散元法参数标定[J].农业机械学报,2018,49(4):343-350. |

| LUO S, YUAN Q X, GOUDA S, et al.. Parameters calibration of vermicomposting nursery substrate with discrete element method based on JKR contact model [J]. Trans. CSAM, 2018,49(4):343-350. | |

| 24 | 温翔宇,袁洪方,王刚,等.颗粒肥料离散元仿真摩擦因数标定方法研究[J].农业机械学报,2020,51(2):115-122, 142. |

| WEN X Y, YUAN H F, WANG G, et al.. Calibration method of friction coefficient of granular fertilizer by discrete element simulation [J]. Trans. CSAM, 2020,51(2):115-122, 142. | |

| 25 | 马彦华,宋春东,宣传忠,等.苜蓿秸秆压缩仿真离散元模型参数标定[J].农业工程学报,2020,36(11):22-30. |

| MA Y H, SONG C D, XUAN C Z, et al.. Parameters calibration of discrete element model for alfalfa straw compression simulation [J]. Trans. CSAE, 2020,36(11):22-30. | |

| 26 | 葛宜元.试验设计方法与Design-Expert软件应用[M].哈尔滨:哈尔滨工业大学出版社,2015:1-207. |

| 27 | 李俊伟,佟金,胡斌,等.不同含水率黏重黑土与触土部件互作的离散元仿真参数标定[J].农业工程学报,2019,35(6):130-140. |

| LI J W, TONG J, HU B, et al.. Calibration of parameters of interaction between clayey black soil with different moisture content and soil-engaging component in northeast China [J]. Trans. CSAE, 2019,35(6):130-140. | |

| 28 | 郝建军,魏文波,黄鹏程,等.油葵籽粒离散元参数标定与试验验证 [J].农业工程学报,2021,37(12):36-44. |

| HAO J J, WEI W B, HUANG P C, et al.. Calibration and experimental verification of discrete element parameters of oil sunflower seeds [J]. Trans. CSAE, 2021,37(12):36-44. | |

| 29 | 张杰,温逸婷,高正辉,等.黑水虻的资源化利用研究现状[J].应用昆虫学报,2019,56(5):997-1006. |

| ZHANG J, WEN Y T, GAO Z H, et al.. Progress in research on, and the utilization of, Hermetia illucens [J]. China J. Appl. Entomol., 2019,56(5):997-1006. | |

| 30 | 彭才望,贺喜,孙松林,等.斗式黑水虻处理猪粪有机肥取料机设计与试验[J]. 农业机械学报,2021,52(2):145-156. |

| PENG C W, HE X, SUN S L, et al.. Design and experiment on shoveling eevice of pig manure organic rertilizer by Hermetia illucen transforming based on bucket-wheel mechanism [J]. Trans. CSAM, 2021,52(2):145-156. | |

| 31 | 彭才望,宋世圣,谢烨林,等.黑水虻虫沙双向集料装置参数优化与试验[J].河南农业大学学报,2021,55(4):689-697, 714. |

| PENG C W, SONG S S, XIE Y L, et al.. Parameter optimization and experiment for Hermetia illucens sand bidirectional aggregating device [J]. J. Henan Agric.Univ., 2021,55(4):689-697, 714. | |

| 32 | 蔡静.基于DEM的蛆粪混合物动力学与多维振动筛的优化设计[D]. 江苏镇江:江苏大学, 2018. |

| CAI J. Dynamics of maggots and manure based on DEM and optimal design of the multi-dimensional sieving machine [D]. Jiangsu Zhenjiang: Jiangsu University, 2018. |

| [1] | Jianwei YAN, Song WEI, Dongjun HU, Qihe LIU, Fuigui ZHANG. Parameter Calibration of Radish Seeds with Different Filling Particle Radius by DEM [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 119-128. |

| [2] | Qin FANG, Shisheng SONG, Ting ZHOU, Caiwang PENG, Songlin SUN, Haiying ZHU. Design and Experiment of a Two-Stage Segmented Drum Screening Device for Black Soldier Fly Insect Sand [J]. Journal of Agricultural Science and Technology, 2022, 24(3): 130-139. |

| [3] | YIN Jingkai, GONG Xiaoyan, SUN Lina, HAN Mengqi, YANG Yuan, XU Xiaoyan, WANG Xiaobo. Study on the Transformation of Nutrients in Kitchen Waste by Black Soldier Fly [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 154-159. |

| [4] | QUAN Wei, WU Mingliang, GUAN Chunyun, LUO Haifeng. Experimental Study on the Shape Optimization of Soil Opener for Rapeseed Pot Seedling Transplanter [J]. Journal of Agricultural Science and Technology, 2021, 23(10): 97-106. |

| [5] | XIANG Wei1,2, WU Mingliang1*, LYU Jiangnan2, MA Lan2, QUAN Wei1, LIU Jiajie2, XIAO Le3. Simulation and Experiment on Hole-forming Performance of Hole-forming Mechanism for Rape Seedling Transplanting Based on EDEM [J]. Journal of Agricultural Science and Technology, 2019, 21(7): 70-81. |

| [6] | LIU Yuping, ZHANG Tuo, LIU Yu*. Calibration and Experiment of Contact Parameters of Rice Grain Based on Discrete Element Method [J]. Journal of Agricultural Science and Technology, 2019, 21(11): 70-76. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号