Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (9): 172-180.DOI: 10.13304/j.nykjdb.2024.0187

• BIO-MANUFACTURING & RESOURCE AND ECOLOGY • Previous Articles

Jiang WU1,2( ), Hongsheng CHENG2,3, Jingtao DING2,3, Yujun SHEN1,2, Haibin ZHOU2,3, Wenxiu GUO1,2, Ying ZHANG2,3

), Hongsheng CHENG2,3, Jingtao DING2,3, Yujun SHEN1,2, Haibin ZHOU2,3, Wenxiu GUO1,2, Ying ZHANG2,3

Received:2024-03-12

Accepted:2024-04-07

Online:2025-09-15

Published:2025-09-24

Contact:

Yujun SHEN

吴疆1,2( ), 程红胜2,3, 丁京涛2,3, 沈玉君1,2, 周海宾2,3, 郭文袖1,2, 张迎2,3

), 程红胜2,3, 丁京涛2,3, 沈玉君1,2, 周海宾2,3, 郭文袖1,2, 张迎2,3

通讯作者:

沈玉君

作者简介:吴疆 E-mail:1667469373@qq.com;

基金资助:CLC Number:

Jiang WU, Hongsheng CHENG, Jingtao DING, Yujun SHEN, Haibin ZHOU, Wenxiu GUO, Ying ZHANG. Effects of Different Filling Rate and Aeration Technology on Composting Effect of Roller[J]. Journal of Agricultural Science and Technology, 2025, 27(9): 172-180.

吴疆, 程红胜, 丁京涛, 沈玉君, 周海宾, 郭文袖, 张迎. 不同填充率与曝气工艺对滚筒堆肥效果的影响[J]. 中国农业科技导报, 2025, 27(9): 172-180.

材料 Material | 碳含量 Carbon content/% | 氮含量 Nitrogen content/% | 含水率 Moisture content/% |

|---|---|---|---|

| 秸秆Straw | 42.36 | 0.79 | 8.50 |

| 猪粪Pig manures | 11.38 | 0.68 | 67.50 |

| 混合后物料Mixed material | 15.28 | 0.73 | 57.42 |

Table 1 Basic physical and chemical properties of test materials

材料 Material | 碳含量 Carbon content/% | 氮含量 Nitrogen content/% | 含水率 Moisture content/% |

|---|---|---|---|

| 秸秆Straw | 42.36 | 0.79 | 8.50 |

| 猪粪Pig manures | 11.38 | 0.68 | 67.50 |

| 混合后物料Mixed material | 15.28 | 0.73 | 57.42 |

处理 Treatment | 通风方式 Ventilation mode | 填充率 Filling rate | 通风速率 Ventilation rate/(L·min‒1·kg‒1 TS) |

|---|---|---|---|

| T1 | 持续通12 min、停18 min Keep on 12 min, stop 18 min | 0.60 | 8.5 |

| T2 | 升温期通5 min、停25 min;高温期通12 min停18 min;降温期通8 min停22 min Heating period on 5, stop 25;high temperature period on 12 min, stop 18 min;cooling period on 8 min, stop 22 min | 0.60 | 8.5 |

| T3 | 持续通12 min停18 min Keep on 12 min, stop 18 min | 0.75 | 8.5 |

Table 2 Experimental scheme

处理 Treatment | 通风方式 Ventilation mode | 填充率 Filling rate | 通风速率 Ventilation rate/(L·min‒1·kg‒1 TS) |

|---|---|---|---|

| T1 | 持续通12 min、停18 min Keep on 12 min, stop 18 min | 0.60 | 8.5 |

| T2 | 升温期通5 min、停25 min;高温期通12 min停18 min;降温期通8 min停22 min Heating period on 5, stop 25;high temperature period on 12 min, stop 18 min;cooling period on 8 min, stop 22 min | 0.60 | 8.5 |

| T3 | 持续通12 min停18 min Keep on 12 min, stop 18 min | 0.75 | 8.5 |

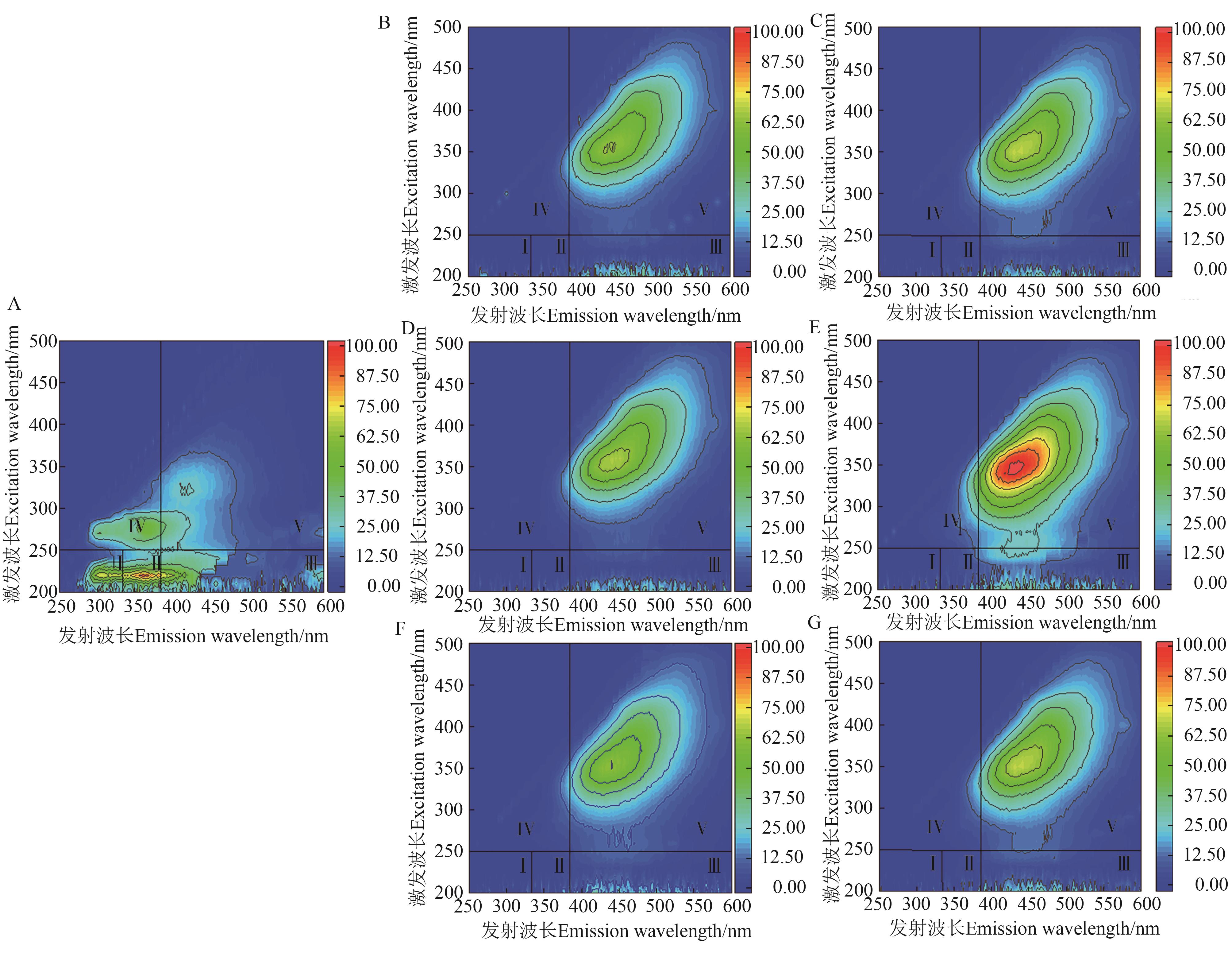

Fig. 6 3D fluorescence spectral change of DOM during compostingA: Initial DOM state of the material; A and B, C and D, E and F are the DOM states of T1, T2, T3 treatments for the 15th and 21th day, respectively. Ⅰ—Tyrosine-like;Ⅱ—Tryptophan-like;Ⅲ—Fulvic acid-like;Ⅳ—Soluble microbial byproduct;Ⅴ—Humic acid-like components; the bar in the right of each figure is fluorescence intensity

处理 Treatment | 物料干质量Dry material quality/kg | 产肥率 Fertilizer production rate/% | |

|---|---|---|---|

| 初始Initial | 堆肥后After composting | ||

| T1 | 14.90±0.22 b | 11.32±0.34 b | 76.00±3.41 b |

| T2 | 14.90±0.22 b | 11.02±0.28 b | 74.00±2.97 b |

| T3 | 18.74±0.42 a | 15.06±0.49 a | 80.00±0.81 a |

Table 3 Fertilizer yield under different treatments

处理 Treatment | 物料干质量Dry material quality/kg | 产肥率 Fertilizer production rate/% | |

|---|---|---|---|

| 初始Initial | 堆肥后After composting | ||

| T1 | 14.90±0.22 b | 11.32±0.34 b | 76.00±3.41 b |

| T2 | 14.90±0.22 b | 11.02±0.28 b | 74.00±2.97 b |

| T3 | 18.74±0.42 a | 15.06±0.49 a | 80.00±0.81 a |

| [1] | BARI Q H, KOENIG A. Effect of air recirculation and reuse on composting of organic solid waste [J]. Resour. Conserv. Recycl., 2001,33(2):93-111. |

| [2] | 张锐,韩鲁佳.好氧堆肥反应器系统在废弃物处理中的应用[J].农机化研究,2006,28(10):173-175, 178. |

| ZHANG R, HAN L J. Large-scale aerobic composting reactor systems and its application in residues treatment [J]. J. Agric. Mech. Res., 2006, 28(10):173-175, 178. | |

| [3] | 冯明谦,蒋培志.卧式发酵滚筒的设计与研究[J].环境卫生工程,2000(3):97-100. |

| FENG M Q, JIANG P Z. Design and study of horizontal composting cylinder [J]. Environ. Sanitation Eng., 2000(3):97-100. | |

| [4] | 马蔷,王奎升,李秀金,等.用于城市生活垃圾好氧堆肥的滚筒式生物反应器研制[J].环境工程,2013,31(3):110-112, 138. |

| MA Q, WANG K S, LI X J, et al.. Design of the rotary drum biological reactor used in municipal solid waste composting [J]. Environ. Eng., 2013,31(3):110-112, 138. | |

| [5] | 周艳文.动态滚筒式污泥堆肥一体化设备的研制和应用[J].污染防治技术,2016,29(2):49-52. |

| [6] | 于海涵,肖爱平.滚筒发酵实验设备设计及实验研究[J].林业机械与木工设备,2020,48(1):13-17. |

| YU H H, XIAO A P. Design and experimental study of drum fermentation experimental equipment [J]. For. Mach. Woodwork. Equip., 2020,48(1):13-17. | |

| [7] | 程红胜,隋斌,孟海波,等.滚筒式沼渣好氧发酵反应器中试装置设计与性能试验[J].农业工程学报,2018,34(24):224-231. |

| CHENG H S, SUI B, MENG H B, et al.. Design and performance test of aerobic fermentation rotary reactorpilot plant for biogas residue [J]. Trans. Chin. Soc. Agric. Eng., 2018,34(24):224-231. | |

| [8] | 施亮.滚筒式智能型好氧堆肥反应器的设计及试验研究[D].合肥:安徽农业大学,2023. |

| SHI L. Design and experimental study of a drum type intelligent aerobic composting reactor [D]. Hefei: Anhui Agricultural University, 2023. | |

| [9] | 邹亚东,程红胜,沈玉君,等.不同抗粘抄板对滚筒式堆肥反应器堆肥效果影响[C]//中国环境科学学会2021年科学技术年会,2021:6. |

| ZOU Y D, CHENG H S, SHEN Y J, et al.. Effect of different anti flights on composting effect of drum composting reactor [C]// Chinese Society for Environmental Science 2021 Annual Scientific and Technical Conference, 2021:6. | |

| [10] | 王盼柳,曹哲,李浩,等.利用牛粪生产垫料的滚筒结构优化[J].中国农业大学学报,2021,26(9):189-196. |

| WANG P L, CAO Z, LI H, et al.. Structure optimization of a drum recycling solid cow manure as bedding [J]. J. China Agric. Univ., 2021,26(9):189-196. | |

| [11] | 张远澄.污泥与绿化废物滚筒反应器好氧堆肥过程控制研究[D].北京:清华大学,2014. |

| ZHANG Y C. The composting process control of sewage sludge and greening waste in a rotary drum reactor [D]. Beijing: Tsinghua University, 2014. | |

| [12] | 刘幸福,盛金良.大型滚筒式好氧发酵反应器筒体及支撑件结构分析[J].机械设计与制造,2016(3):1-4, 9. |

| LIU X F, SHENG J L. The structural analysis of shell and support parts of large-scale aerobic fermentation rotary reactor [J]. Mach. Des. Manuf., 2016(3):1-4, 9. | |

| [13] | REN X N, WANG Q, LI R H, et al.. Effect of clay on greenhouse gas emissions and humification during pig manure composting as supported by spectroscopic evidence [J/OL]. Sci. Total Environ., 2020,737:139712 [2024-02-10]. . |

| [14] | 徐鹏翔,王越,杨军香,等.好氧堆肥中通风工艺与参数研究进展[J].农业环境科学学报,2018,37(11):2403-2408. |

| XU P X, WANG Y, YANG J X, et al..Advances in ventilation systems and parameter choices during aerobic composting [J]. J. Agro-Environ. Sci., 2018, 37(11):2403-2408. | |

| [15] | 周飞梅,曹志勇,汤治,等.采用离子色谱法检测电除尘飞灰中的氨含量[J].浙江电力,2014,33(6):43-47. |

| ZHOU F M, CAO Z Y, TANG Z, et al..Application of ion-chromatography method in detecting ammonia content in electrostatic precipitator fly ash [J].Zhejiang Electr. Power, 2014, 33(6):43-47. | |

| [16] | 郭嘉,陈玉柱.亚甲基蓝分光光度法测定水中硫化物不确定度的评定研究[J].黑龙江科学,2023,14(18):52-55. |

| GUO J, CHEN Y Z. Uncertainty evaluation of methylene blue spectrophotometry for determination of sulfide in water [J]. Heilongjiang Sci., 2023, 14(18):52-55. | |

| [17] | 李季,彭生平.堆肥工程实用手册[M]. 第2版.北京:化学工业出版社,2011:1-216. |

| [18] | 田有国,李季,沈其荣,等. 有机肥料: [S].北京:中国标准出版社,2021. |

| [19] | 李季,杨军香,李国学,等. 畜禽粪便堆肥技术规范: [S].北京:中国农业出版社,2019. |

| [20] | COOK K L, RITCHEY E L, LOUGHRIN J H,et al.. Effect of turning frequency and season on composting materials from swine high-rise facilities [J]. Waste Manage., 2015, 39:86-95. |

| [21] | ZENG J F, SHEN X L, YIN H J, et al..Oxygen dynamics, organic matter degradation and main gas emissions during pig manure composting: effect of intermittent aeration [J/OL]. Bioresour. Technol., 2022,361:127697 [2024-02-10].. |

| [22] | GABHANE J, WILLIAM S P, BIDYADHAR R, et al.. Additives aided composting of green waste: Effects on organic matter degradation, compost maturity, and quality of the finished compost [J]. Bioresour. Technol., 2012, 114:382-388. |

| [23] | 赵世淏,程琼仪,孟海波.不同通风工艺对猪粪好氧堆肥腐熟效果的影响[J].环境工程,2023,41():1242-1246. |

| ZHAO S H, CHENG Q Y, MENG H B. Effects of different ventilation techniqes on the decomposition effect of aerobic composting of pig manure [J]. Environ. Eng., 2023, 41(S2):1242-1246. | |

| [24] | YU Z P, HUANG Q, XIE X H, et al.. Experimental study and failure criterion analysis of plain concrete under combined compression-shear stress [J]. Constr. Build. Mater., 2018,179:198-206. |

| [25] | XIN L Q, QIN Y, LOU T R, et al.. Rapid start-up and humification of kitchen waste composting by an innovative biodrying-enhanced process [J/OL]. Chem. Eng. J., 2023,452:139459 [2024-02-10]. . |

| [26] | 张玉冬,张红玉,顾军,等.翻堆频率对厨余垃圾堆肥过程中H2S和NH3排放的影响[J].环境工程,2016,34(4):127-131. |

| ZHANG Y D, ZHANG H Y, GU J, et al.. Effect of turning frequency on emission of H2S and NH3 in kitchen waste composting [J]. Environ.Eng., 2016, 34(4):127-131. | |

| [27] | 沈玉君,孟海波,张朋月,等.猪粪堆肥挥发性有机物的产生规律与影响因素[J].农业工程学报,2017,33(5):211-216. |

| SHEN Y J, MENG H B, ZHANG P Y, et al.. Generation law and influencing factors of volatile organic compounds during pig manure composting [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(5):211-216. | |

| [28] | 衣淑娟,邵浩宸,沈玉君,等.牛粪和玉米秸秆混合好氧堆肥过程分层规律[J].农业工程学报,2023,39(3):180-189. |

| YI S J, SHAO H C, SHEN Y J, et al.. Stratification law of the mixed aerobic composting process of cow manure and maize stovers [J]. Trans. Chin. Soc. Agric. Eng., 2023, 39(3):180-189. | |

| [29] | 沈玉君,张朋月,孟海波,等.通风方式对猪粪堆肥主要臭气物质控制的影响研究[J].农业工程学报,2019,35(7):203-209. |

| SHEN Y J, ZHANG P Y, MENG H B, et al.. Effects of ventilation modes on control of main odor substances in pig manure composting [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(7):203-209. | |

| [30] | 张玉冬,张红玉,顾军,等.通风量对厨余垃圾堆肥过程中H2S和NH3排放的影响[J].农业环境科学学报,2015,34(7):1371-1377. |

| ZHANG Y D, ZHANG H Y, GU J, et al.. Influence of ventilation on H2S and NH3 emissions during kitchen waste compositing [J]. J. Agro-Environ. Sci., 2015, 34(7):1371-1377. | |

| [31] | 路一鸣,李军,代雨,等.翻堆对好氧堆肥腐殖质电子转移能力的影响[J].中国环境科学,2022,42(12):5748-5757. |

| LU Y M, LI J, DAI Y, et al.. Effects of turning on the electron transfer capacity of humic substances in aerobic composting [J]. China Environ. Sci., 2022, 42(12):5748-5757. | |

| [32] | 曹玉博,张陆,王选,等.畜禽废弃物堆肥氨气与温室气体协同减排研究[J].农业环境科学学报,2020,39(4):923-932. |

| CAO Y B, ZHANG L, WANG X, et al.. Synergistic mitigation of ammonia and greenhouse gas emissions during livestock waste composting [J]. J. Agro-Environ. Sci., 2020, 39(4):923-932. |

| [1] | Li LIU, Zhongping DU, Yi LI, Laisheng CHEN, Rui HAN. Effect of NaOH Pretreatment on Anaerobic Fermentation Characteristics of Hulless Barley Straw [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 192-200. |

| [2] | JIAO Jing, ZHENG Yong, LI Zunxiang, HUANG Xiaohong, DU Jihua, ZHENG Jin. JIAO Jing1,2, ZHENG Yong3*, LI Zunxiang1, HUANG Xiaohong1, DU Jihua1, ZHENG Jin1 [J]. Journal of Agricultural Science and Technology, 2021, 23(9): 87-95. |

| [3] | XIAO Shengling1, JING Yong1,2, FENG Jing2, SHEN Ruixia2*, ZHAO Lixin2, WANG Quanliang1, ZHANG Ying2. Effect of Wood Biochar on the Methane Production Performance of Anaerobic Fermentation [J]. Journal of Agricultural Science and Technology, 2021, 23(1): 128-135. |

| [4] | FENG Kang1,2, MENG Haibo1,2*, ZHOU Haibin1, SHEN Yujun1,2, WANG Liming2. Research Status and Prospect of Integrated Aerobic Fermentation Equipment [J]. Journal of Agricultural Science and Technology, 2018, 20(6): 63-69. |

| [5] | ZHANG Jianglin, HOU Wenfeng, LU Jianwei, REN Tao, CONG Rihuan, LI Xiaokun*. Effects of Nitrogen Application Rates and Planting Density on Rice Yield and Grain-Filling Properties [J]. Journal of Agricultural Science and Technology, 2017, 19(2): 75-85. |

| [6] | YU Xiao-xia, LIU Xiao-qing, TIAN Jian, WU Ning-feng*. Gene Cloning, Expression and Characterization of cotA, a Laccase from Bacillus subtilis [J]. , 2015, 17(1): 102-108. |

| [7] | SHEN Yu\|jun, ZHAO Li\|xin*, MENG Hai\|bo. Present Status of Harmless Disposal of Dead Livestock and Poultry in China and Counter\|measures [J]. , 2013, 15(6): 167-173. |

| [8] | XU Fuxian, GUO Xiaoyi, ZHANG Lin, XIONG Hong, ZHU Yongchuan, LIU Mao, ZHOU Xi. Effects of Sinksource Structures on Filling of Superior and Inferior Spikelets of Midseason Hybrid Rice [J]. , 2013, 15(1): 96-101. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号