中国农业科技导报 ›› 2024, Vol. 26 ›› Issue (6): 72-81.DOI: 10.13304/j.nykjdb.2023.0828

柳亚峰1( ), 方志超1,2(

), 方志超1,2( ), 夏海峰1, 曲永波1, 吴明亮1,2

), 夏海峰1, 曲永波1, 吴明亮1,2

收稿日期:2023-11-10

接受日期:2024-01-19

出版日期:2024-06-15

发布日期:2024-06-12

通讯作者:

方志超

作者简介:柳亚峰 E-mail:liuyafeng1222@163.com;

基金资助:

Yafeng LIU1( ), Zhichao FANG1,2(

), Zhichao FANG1,2( ), Haifeng XIA1, Yongbo QU1, Mingliang WU1,2

), Haifeng XIA1, Yongbo QU1, Mingliang WU1,2

Received:2023-11-10

Accepted:2024-01-19

Online:2024-06-15

Published:2024-06-12

Contact:

Zhichao FANG

摘要:

针对藠头机械收获时根土分离效果差、损伤率高等问题,设计了一种对辊拨刷式藠头收获机,主要由挖掘铲、摆动筛、拨送辊、碎土辊、缓冲低铺栅等组成。提出了“对辊差速碎土+拨刷式输送分离”的藠头收获技术方案,即碎土辊与拨送辊配合,以较高的速度对土壤进行破碎,拨送辊不断向后拨送,完成对藠头根茎与土壤的分离;并对碎土辊旋转碎土与拨送辊低损拨送的作业机理进行分析,确定了影响藠头收获效果的主要因素及其取值范围。以机具前进速度、对辊转速差、碎土辊旋转半径为试验因素,以根土分离率、根茎损伤率为评价指标进行二次旋转正交组合试验,建立试验因素与评价指标的回归模型,分析试验因素对评价指标的影响。采用Design-Expert13.0软件进行优化分析,得出最佳的参数组合:在机具前进速度为0.38 m·s-1,转速差为46.02 r·min-1,碎土辊旋转半径为48.72 mm时,根土分离率为89.30%,根茎损伤率为1.73%,在相同条件下进行田间验证试验,根土分离率为88.5%,根茎损伤率为1.78%,机具满足藠头收获要求。该研究可为藠头机械化收获根土分离技术及装备研究提供参考。

中图分类号:

柳亚峰, 方志超, 夏海峰, 曲永波, 吴明亮. 对辊拨刷式藠头收获机设计与试验[J]. 中国农业科技导报, 2024, 26(6): 72-81.

Yafeng LIU, Zhichao FANG, Haifeng XIA, Yongbo QU, Mingliang WU. Design and Experiment of a Opposite Roller Extrusion Type Allium chinense Harvester[J]. Journal of Agricultural Science and Technology, 2024, 26(6): 72-81.

| 参数 Parameter | 数值 Value |

|---|---|

| 外形尺寸(长×宽×高) Shape size(length×width×high)/m | 2.0×1.9×1.5 |

| 作业幅宽 Operating width/m | 1.6 |

| 前进速度 Forward speed/(m·s-1) | 0.2~0.6 |

| 最大挖掘深度 Digging depth/m | 0.3 |

| 生产率 Productivity/(hm2·h-1) | 1.152~3.456 |

| 整机质量 Total weight/kg | 450 |

| 配套动力 Mating power/kW | 50~70 |

表1 对辊拨刷式藠头收获机主要参数

Table 1 Technical parameters of double roller extrusion type Allium chinense harvester

| 参数 Parameter | 数值 Value |

|---|---|

| 外形尺寸(长×宽×高) Shape size(length×width×high)/m | 2.0×1.9×1.5 |

| 作业幅宽 Operating width/m | 1.6 |

| 前进速度 Forward speed/(m·s-1) | 0.2~0.6 |

| 最大挖掘深度 Digging depth/m | 0.3 |

| 生产率 Productivity/(hm2·h-1) | 1.152~3.456 |

| 整机质量 Total weight/kg | 450 |

| 配套动力 Mating power/kW | 50~70 |

图1 藠头收获机结构注:1—挖掘铲;2—摆动筛;3—摆动摇杆;4—可调连杆;5—三点悬挂架;6—机架;7—传动轴;8—限深调节轮;9—拨送辊;10—碎土辊;11—限深轮;12—集料栅。

Fig. 1 Structure of Allium chinense harvesterNote:1—Excavation shovel; 2—Swinging sieve; 3—Adjustable connecting rod; 4—Connecting rod; 5—Suspension bracket; 6—Body frame; 7—Transmission shaft; 8—Depth adjustment handwheel; 9—Feeding roller; 10—Crushing roller; 11—Depth wheel; 12—Laying grid.

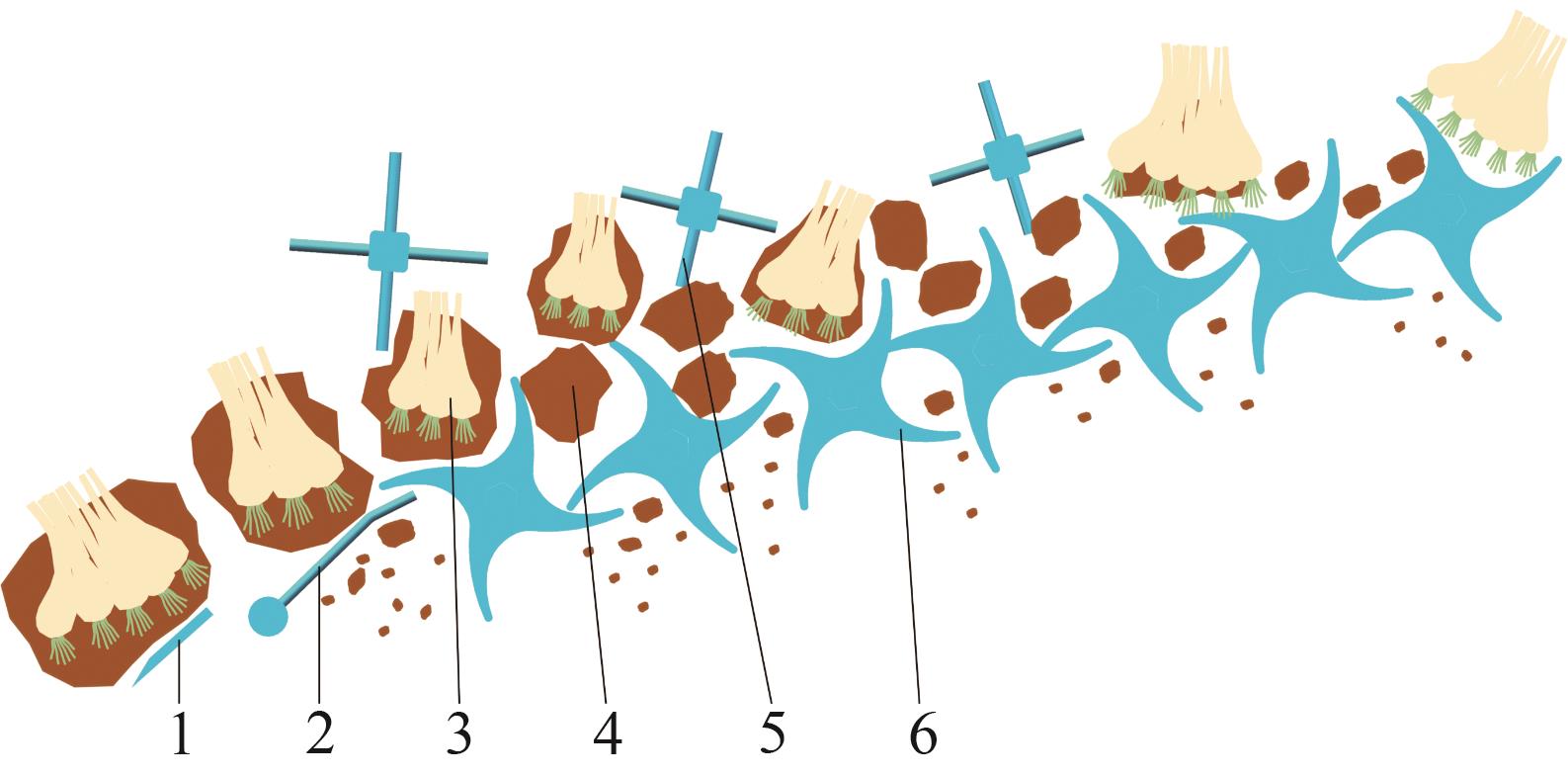

图2 对辊拨刷分离示意图注:1—挖掘铲;2—摆动筛;3—藠头;4—土壤;5—碎土辊;6—拨送辊。

Fig. 2 Schematic diagram of opposite roller extrusion separationNote:1—Excavation shovel; 2—Swinging sieve; 3—Allium chinense; 4—Soil; 5—Crushing roller; 6—Feeding roller.

水平 Level | 因素 Factor | ||

|---|---|---|---|

X1:前进速度 Forward speed/(m·s-1) | X2:转速差 Rotation difference/(r·min-1) | X3:旋转半径 Rotation radius/mm | |

| -1 | 0.2 | 40 | 40 |

| 0 | 0.4 | 60 | 50 |

| 1 | 0.6 | 80 | 60 |

表2 试验因素及水平

Table 2 Experimental factors and levels

水平 Level | 因素 Factor | ||

|---|---|---|---|

X1:前进速度 Forward speed/(m·s-1) | X2:转速差 Rotation difference/(r·min-1) | X3:旋转半径 Rotation radius/mm | |

| -1 | 0.2 | 40 | 40 |

| 0 | 0.4 | 60 | 50 |

| 1 | 0.6 | 80 | 60 |

试验号 Test number | X1 | X2 | X3 | Y1/% | Y2/% |

|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 88.0 | 2.90 |

| 2 | 0 | 1 | -1 | 86.0 | 2.16 |

| 3 | 0 | -1 | -1 | 85.9 | 1.58 |

| 4 | 0 | 0 | 0 | 90.2 | 1.99 |

| 5 | 0 | 0 | 0 | 89.5 | 1.89 |

| 6 | 1 | 1 | 0 | 90.6 | 2.47 |

| 7 | 0 | 0 | 0 | 89.9 | 1.84 |

| 8 | 0 | 0 | 0 | 90.0 | 2.05 |

| 9 | -1 | 1 | 0 | 89.1 | 2.43 |

| 10 | 0 | -1 | 1 | 86.2 | 2.36 |

| 11 | 1 | 0 | -1 | 86.2 | 2.29 |

| 12 | 0 | 1 | 1 | 89.1 | 2.63 |

| 13 | 0 | 0 | 0 | 90.5 | 2.10 |

| 14 | -1 | -1 | 0 | 88.1 | 1.61 |

| 15 | -1 | 0 | -1 | 85.7 | 1.91 |

| 16 | -1 | 0 | 1 | 86.1 | 2.52 |

| 17 | 1 | -1 | 0 | 89.3 | 2.19 |

表3 试验方案与结果

Table 3 Test scheme and results

试验号 Test number | X1 | X2 | X3 | Y1/% | Y2/% |

|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 88.0 | 2.90 |

| 2 | 0 | 1 | -1 | 86.0 | 2.16 |

| 3 | 0 | -1 | -1 | 85.9 | 1.58 |

| 4 | 0 | 0 | 0 | 90.2 | 1.99 |

| 5 | 0 | 0 | 0 | 89.5 | 1.89 |

| 6 | 1 | 1 | 0 | 90.6 | 2.47 |

| 7 | 0 | 0 | 0 | 89.9 | 1.84 |

| 8 | 0 | 0 | 0 | 90.0 | 2.05 |

| 9 | -1 | 1 | 0 | 89.1 | 2.43 |

| 10 | 0 | -1 | 1 | 86.2 | 2.36 |

| 11 | 1 | 0 | -1 | 86.2 | 2.29 |

| 12 | 0 | 1 | 1 | 89.1 | 2.63 |

| 13 | 0 | 0 | 0 | 90.5 | 2.10 |

| 14 | -1 | -1 | 0 | 88.1 | 1.61 |

| 15 | -1 | 0 | -1 | 85.7 | 1.91 |

| 16 | -1 | 0 | 1 | 86.1 | 2.52 |

| 17 | 1 | -1 | 0 | 89.3 | 2.19 |

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 53.68 | 9 | 5.96 | 52.16 | <0.000 1** |

| 3.25 | 1 | 3.25 | 28.43 | 0.001 1** | |

| 3.51 | 1 | 3.51 | 30.70 | 0.000 9** | |

| 3.92 | 1 | 3.92 | 34.28 | 0.000 6** | |

| 0.02 | 1 | 0.02 | 0.19 | 0.670 7 | |

| 0.49 | 1 | 0.49 | 4.28 | 0.077 2 | |

| 1.96 | 1 | 1.96 | 17.14 | 0.004 3** | |

| 1.15 | 1 | 1.15 | 10.05 | 0.015 7* | |

| 0.21 | 1 | 0.20 | 1.82 | 0.219 0 | |

| 37.83 | 1 | 37.83 | 330.80 | <0.000 1** | |

| 残差 Residual | 0.800 5 | 7 | 0.114 4 | ||

| 失拟 Lack of fit | 0.252 5 | 3 | 0.084 2 | 0.614 4 | 0.640 9 |

| 误差 Error | 0.548 | 4 | 0.137 | ||

| 总和 Sum | 54.48 | 16 |

表4 根土分离率方差分析及显著性检验

Table 4 Variance analysis for root-soil separation rate

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 53.68 | 9 | 5.96 | 52.16 | <0.000 1** |

| 3.25 | 1 | 3.25 | 28.43 | 0.001 1** | |

| 3.51 | 1 | 3.51 | 30.70 | 0.000 9** | |

| 3.92 | 1 | 3.92 | 34.28 | 0.000 6** | |

| 0.02 | 1 | 0.02 | 0.19 | 0.670 7 | |

| 0.49 | 1 | 0.49 | 4.28 | 0.077 2 | |

| 1.96 | 1 | 1.96 | 17.14 | 0.004 3** | |

| 1.15 | 1 | 1.15 | 10.05 | 0.015 7* | |

| 0.21 | 1 | 0.20 | 1.82 | 0.219 0 | |

| 37.83 | 1 | 37.83 | 330.80 | <0.000 1** | |

| 残差 Residual | 0.800 5 | 7 | 0.114 4 | ||

| 失拟 Lack of fit | 0.252 5 | 3 | 0.084 2 | 0.614 4 | 0.640 9 |

| 误差 Error | 0.548 | 4 | 0.137 | ||

| 总和 Sum | 54.48 | 16 |

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 1.990 0 | 9 | 0.220 7 | 97.00 | 0.000 1** |

| 0.238 0 | 1 | 0.238 0 | 29.08 | 0.001** | |

| 0.475 3 | 1 | 0.475 3 | 58.07 | 0.000 1** | |

| 0.762 6 | 1 | 0.762 6 | 93.17 | <0.000 1** | |

| 0.072 9 | 1 | 0.072 9 | 8.91 | 0.020 4* | |

| 0 | 1 | 0 | 0 | 1.000 0 | |

| 0.024 0 | 1 | 0.024 0 | 2.94 | 0.130 4 | |

| 0.188 8 | 1 | 0.188 8 | 23.07 | 0.002 0** | |

| 0.000 5 | 1 | 0.000 5 | 0.06 | 0.814 4 | |

| 0.202 4 | 1 | 0.202 4 | 24.73 | 0.001 6** | |

| 残差Residual | 0.057 3 | 7 | 0.008 2 | ||

| 失拟Lack of fit | 0.010 4 | 3 | 0.003 5 | 0.294 8 | 0.828 3 |

| 误差Error | 0.046 9 | 4 | 0.011 7 | ||

| 总和Sum | 2.040 0 | 16 |

表5 根茎损伤率方差分析

Table 5 Variance analysis for damage rate of rhizome

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型 Model | 1.990 0 | 9 | 0.220 7 | 97.00 | 0.000 1** |

| 0.238 0 | 1 | 0.238 0 | 29.08 | 0.001** | |

| 0.475 3 | 1 | 0.475 3 | 58.07 | 0.000 1** | |

| 0.762 6 | 1 | 0.762 6 | 93.17 | <0.000 1** | |

| 0.072 9 | 1 | 0.072 9 | 8.91 | 0.020 4* | |

| 0 | 1 | 0 | 0 | 1.000 0 | |

| 0.024 0 | 1 | 0.024 0 | 2.94 | 0.130 4 | |

| 0.188 8 | 1 | 0.188 8 | 23.07 | 0.002 0** | |

| 0.000 5 | 1 | 0.000 5 | 0.06 | 0.814 4 | |

| 0.202 4 | 1 | 0.202 4 | 24.73 | 0.001 6** | |

| 残差Residual | 0.057 3 | 7 | 0.008 2 | ||

| 失拟Lack of fit | 0.010 4 | 3 | 0.003 5 | 0.294 8 | 0.828 3 |

| 误差Error | 0.046 9 | 4 | 0.011 7 | ||

| 总和Sum | 2.040 0 | 16 |

试验号 Test number | Y1:根土分离率 Rhizome soil separation rate/% | Y2:根茎损伤率 Rhizome damage rate/% |

|---|---|---|

| 1 | 88.9 | 1.81 |

| 2 | 87.9 | 1.73 |

| 3 | 89.6 | 1.87 |

| 4 | 88.5 | 1.78 |

| 5 | 87.7 | 1.71 |

| 平均值 Average value | 88.5 | 1.78 |

| 预测值 Prediction value | 89.3 | 1.73 |

| 相对误差 Relative error | 0.89 | 2.89 |

表6 模型预测值与验证试验结果对比

Table.6 Comparison of model prediction and validation test results

试验号 Test number | Y1:根土分离率 Rhizome soil separation rate/% | Y2:根茎损伤率 Rhizome damage rate/% |

|---|---|---|

| 1 | 88.9 | 1.81 |

| 2 | 87.9 | 1.73 |

| 3 | 89.6 | 1.87 |

| 4 | 88.5 | 1.78 |

| 5 | 87.7 | 1.71 |

| 平均值 Average value | 88.5 | 1.78 |

| 预测值 Prediction value | 89.3 | 1.73 |

| 相对误差 Relative error | 0.89 | 2.89 |

| 1 | 袁祖华,彭莹.长江流域藠头高产栽培技术[J].长江蔬菜,2015(13):39-41. |

| 2 | 陈学军,程和生,万新建,等.绿色食品藠头栽培技术规程[J].江西农业学报,2009,21(8):97-98. |

| CHEN X J, CHENG H S, WAN X J, et al.. Cultivation technology regulation of green food crop Allium chinensis [J]. Acta Agric. Jiangxi, 2009, 21(8): 97-98. | |

| 3 | 王龙,刘浩,胡海波.中药薤白基源植物的历史变迁[J].中华中医药杂志,2017,32(6):2422-2424. |

| WANG L, LIU H, HU H B. History of origin plants of Chinese herbal medicine Bulbus Allii macrostemi [J]. China J. Trad. Chin. Med. Pharm., 2017, 32(6): 2422-2424. | |

| 4 | 张兆国,李彦彬,王海翼,等.马铃薯机械化收获关键技术与装备研究进展[J].云南农业大学学报(自然科学),2021,36(6):1092-1103. |

| ZHANG Z G, LI Y B, WANG H Y, et al.. Research progress on key technology and equipment of potato mechanized harvest [J]. J. Yunnan Agric. Univ. (Nat. Sci.), 2021, 36(6): 1092-1103. | |

| 5 | 陈中玉,高连兴, CHEN Charles,等.中美花生收获机械化技术现状与发展分析[J].农业机械学报,2017,48(4):1-21. |

| CHEN Z Y, GAO L X, CHEN C, et al.. Development course of peanut harvest mechanization technology of the united states and enlightenment to China [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(4): 1-21. | |

| 6 | 王申莹,胡志超, CHEN Charles,等.牵引式甜菜联合收获机自动对行系统设计与台架试验[J].农业机械学报,2020,51(4): 103-112, 163. |

| WANG S Y, HU Z C, CHEN C, et al.. Bench test and analysis on performance of autofollow row for traction sugar beet combine harvester [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(4): 103-112, 163. | |

| 7 | 李涛,周进,徐文艺,等. 4UGS2 型双行甘薯收获机的研制[J]. 农业工程学报,2018,34(11):26-33. |

| LI T, ZHOU J, XU W Y, et al.. Development of 4UGS2 type double-row sweet potato harvester [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(11): 26-33. | |

| 8 | 侯加林,陈彦宇,李玉华,等.铲筛组合式大葱挖掘抖土疏整装置设计与试验[J].农业工程学报,2021,37(18):29-39. |

| HOU J L, CHEN Y Y, LI Y H, et al.. Design and experiment of shovel-screen combined green onion digging, shaking, and soil tillage device [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(18): 29-39. | |

| 9 | 宋江,邱胜蓝,王新忠. 4B-1200型平贝母药材收获机的设计与试验[J].农业工程学报,2015,31(8):34-41. |

| SONG J, QIU S L, WANG X Z. Design and test on 4B-1200 type bulbus Fritillariae ussuriensis medicinal material harvester [J]. Trans. Chin. Soc. Agric. Eng., 2015, 31(8): 34-41. | |

| 10 | 张兆国,王法安,张永成,等.自走式三七收获机设计与试验[J]. 农业机械学报,2016,47(S1):234-240. |

| ZHANG Z G, WANG F A, ZHANG Y C, et al.. Design and experiment of self-propelled Panax notoginseng harvester [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(S1): 234-240. | |

| 11 | 陈学深,马旭,武涛,等.虎杖根系脱土装置设计与试验[J].农业机械学报, 2015,46(7):59-65. |

| CHEN X S, MA X, WU T, et al.. Design and experiment of Roots-Soil separating device of knotweeds [J]. Trans. Chin. Soc. Agric. Mach., 2015, 46(7): 59-65. | |

| 12 | 杨发展,杨云鹏,李维华,等.悬挂式山药收获机振动挖掘碎土装置设计与试验[J].农业机械学报,,2020,,51(6):104-111. |

| YANG F Z, YANG Y P, LI W H, et al.. Structural design and experiment on vibrating soil breaking device of mounted yam harvester [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(6): 104-111. | |

| 13 | 吕金庆,杨晓涵,吕伊宁,等.马铃薯挖掘机升运分离过程块茎损伤机理分析与试验[J].农业机械学报,2020,51(1):103-113. |

| LYU J Q, YANG X H, LYU Y N, et al.. Analysis and experiment of potato damage in process of lifting and separating potato excavator [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(1): 103-113. | |

| 14 | 魏忠彩,苏国粱,李学强,等.基于离散元的马铃薯收获机波浪形筛面参数优化与试验[J].农业机械学报,2020,51(10):109-122. |

| WEI Z C, SU G L, LI X Q, et al.. Parameter optimization and test of potato harvester wavy sieve based on EDEM [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(10): 109-122. | |

| 15 | 万里鹏程,李永磊,赵虎,等.根茎类作物单摆铲栅收获装置渐变抛掷特性[J].农业工程学报,2021,37(24):9-21. |

| WAN L P C, LI Y L, ZHAO H, et al.. Gradient throwing characteristics of oscillating slat shovel for rhizome crop harvesters [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(24): 9-21. | |

| 16 | 张兆国,薛浩田,王一驰,等.基于离散元法的三七仿生挖掘铲设计与试验[J].农业机械学报,2022,53(5):100-111. |

| ZHANG Z G, XUE H T, WANG Y C, et al.. Design and experiment of Panax notoginseng bionic excavating shovel based on EDEM [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(5): 100-111. | |

| 17 | 曲永波,方志超,吴明亮,等.振动和拨辊推送式藠头收获机研制[J]. 农业工程学报,2022,38(19):51-59. |

| QU Y B, FANG Z C, WU M L, et al.. Development of vibrating and roller pushing type Allium chinense harvester [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(19): 51-59. | |

| 18 | 康建明,李树君,杨学军,等.正弦指数曲线型开沟刀片结构参数优化[J].农业机械学报,2016,47(11):91-99, 17. |

| KANG J M, LI S J, YANG X J, et al.. Structure parameters optimization of sine exponential curve type ditching blade [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(11): 91-99, 17. | |

| 19 | 吴建民,李辉,孙伟,等.拨指轮式马铃薯挖掘机试验[J].农业工程学报,2011,27(7):173-177. |

| WU J M, LI H, SUN W, et al.. Experiment on poke finger wheel type potato digger [J]. Trans. Chin. Soc. Agric. Eng., 2011, 27(7): 173-177. | |

| 20 | 代振维,吴明亮,方志超,等.抛送辊式百合收获机的设计与试验[J].农业工程学报,2023,39(12):20-29. |

| DAI Z W, WU M L, FANG Z C, et al.. Design and test of a throwing roller type lily bulb harvester [J]. Trans. Chin. Soc. Agric. Eng., 2023, 39(12): 20-29. | |

| 21 | 管春松,崔志超,高庆生,等.双轴旋耕碎土试验台设计与分层耕作试验[J].农业工程学报,2021,37(10):28-37. |

| GUAN C S, CUI Z C, GAO Q S, et al.. Design of biaxial rotary tillage soil test bench and layered tillage test [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(10): 28-37. | |

| 22 | 陈桂斌,王庆杰,李问盈,等.对辊差速式块状有机肥破碎施肥装置设计与试验[J].农业机械学报,2021,52(12):65-76. |

| CHEN G B, WANG Q J, Li W Y, et al.. Design and experiment of double roller differential speed crushing fertilizer device for block organic fertilizer [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(12): 65-76. | |

| 23 | 杨然兵,杨红光,尚书旗,等.拨辊推送式马铃薯收获机设计与试验[J].农业机械学报,2016,47(7):119-126. |

| YANG R B, YANG H G, SHANG S Q, et al.. Design and experiment of vertical circular separating and conveying device for potato combine harvester [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(7): 119-126. | |

| 24 | 吕金庆,孙贺,兑瀚,等.粘重土壤下马铃薯挖掘机分离输送装置改进设计与试验[J].农业机械学报,2017,48(11):146-155. |

| LV J Q, SUN H, DUI H, et al.. Design and experiment on conveyor separation device of potato digger under heavy soil condition [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(11): 146-155. |

| [1] | 何冯光, 陈自宏, 邓干然, 李腾辉, 周思理, 李国杰, 崔振德, 郑爽, 李玲, 覃双眉, 王翔, 杨少应, 周德强. 甘蔗收获机切割器入土切割深度监控系统设计与试验[J]. 中国农业科技导报, 2024, 26(5): 101-109. |

| [2] | 何冯光, 邓干然, 崔振德, 郑爽, 李国杰, 李玲, 覃双眉. 自走式木薯茎叶青贮饲料收获机作业性能研究[J]. 中国农业科技导报, 2022, 24(8): 109-115. |

| [3] | 魏天路1§,杜爽2§,葛宜元2*,姜永成2,王俊发2,刘东旭2. 青饲料收获机切碎辊刀具的优化设计及试验[J]. 中国农业科技导报, 2020, 22(12): 77-87. |

| [4] | 杨安明1,吴明亮1,2*,吕江南3,向伟3. 饲用苎麻收获机切碎系统设计与试验[J]. 中国农业科技导报, 2020, 22(10): 110-118. |

| [5] | 金月,肖宏儒*,肖苏伟,许萌,丁文芹,刘东. 叶类蔬菜收获技术与装备研究现状及发展趋势[J]. 中国农业科技导报, 2018, 20(9): 72-78. |

| [6] | 杨红光1,2,杨然兵1,2*,尚书旗1,2,刘志深1,倪志伟1. 振动挖掘式马铃薯收获机设计与试验[J]. 中国农业科技导报, 2017, 19(8): 55-62. |

| [7] | 薛忠1,2,宋德庆1*,刘恩平3,郭向明1,黄正明1,王刚1,黄小红1,张劲1,王槊1. 国内外芦笋种植收获机械化研究进展[J]. , 2014, 16(2): 79-84. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号