中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (5): 90-102.DOI: 10.13304/j.nykjdb.2024.0813

雷朝旭1( ), 金诚谦1,2(

), 金诚谦1,2( ), 李盼盼1, 杨萧瑜1, 赵紫皓1, 吕璐璐1

), 李盼盼1, 杨萧瑜1, 赵紫皓1, 吕璐璐1

收稿日期:2024-10-07

接受日期:2025-02-10

出版日期:2025-05-15

发布日期:2025-05-20

通讯作者:

金诚谦

作者简介:雷朝旭 E-mail:525720863@qq.com;

基金资助:

Chaoxu LEI1( ), Chengqian JIN1,2(

), Chengqian JIN1,2( ), Panpan LI1, Xiaoyu YANG1, Zihao ZHAO1, Lulu LYU1

), Panpan LI1, Xiaoyu YANG1, Zihao ZHAO1, Lulu LYU1

Received:2024-10-07

Accepted:2025-02-10

Online:2025-05-15

Published:2025-05-20

Contact:

Chengqian JIN

摘要:

脱粒装置作为谷物联合收获机的核心工作部件之一,其性能的优劣直接影响机具作业质量。为解决我国谷物联合收获机脱粒装置损失较大而导致机收质量较低的问题,从谷物力学特性、谷物收获理论、脱粒装置零部件、脱粒装置结构参数与运动参数、谷物收获脱粒技术研究、脱粒装置的损失监测以及控制方法等方面进行综述,旨在改进设计出具有更高性能的脱粒装置。在试验研究过程中,需对现有装置进行详细的理论分析与计算,包括效率、功耗等,并通过计算模拟优化设计;分析不同类型装置的优缺点,根据作物特性选择合适的脱粒装置和元部件组合;设计并进行台架试验和小规模田间试验,验证改进设计的有效性;结合物联网、大数据和人工智能技术,开发智能化的脱粒装置,实时监测和自动控制,从而实现精准农业目标,为农业生产带来更高效益。

中图分类号:

雷朝旭, 金诚谦, 李盼盼, 杨萧瑜, 赵紫皓, 吕璐璐. 谷物联合收获机脱粒技术与装置发展现状[J]. 中国农业科技导报, 2025, 27(5): 90-102.

Chaoxu LEI, Chengqian JIN, Panpan LI, Xiaoyu YANG, Zihao ZHAO, Lulu LYU. Development Status of Threshing Technology and Equipment of Grain Combine Harvester[J]. Journal of Agricultural Science and Technology, 2025, 27(5): 90-102.

图2 YT-5型压电陶瓷压电元件[34]注:1—敏感板;2—绝缘层;3—电极+;4—压电陶瓷;5—电极;6—保护层;7—信号线。

Fig. 2 YT-5 piezoelectric ceramic piezoelectric element[34]Note:1—Sensitive plate; 2—Insulation; 3—Electrode+; 4—Piezoelectric ceramics; 5—Electrode; 6—Protective layer; 7—Signal lines.

图3 全喂入式与半喂入式脱粒装置的类型样式[9,21]A:轴流滚筒式;B:切流滚筒式;C:钉齿滚筒式;D:纹杆滚筒式;E:双滚筒式;F:弓齿滚筒式

Fig. 3 Types of full feeding and half feeding threshing devices[9,21]A: Axial-flow drum type; B: Tangential-flow drum type; C: Spike-tooth drum type; D: Rasp-bar drum type; E: Double-drum type; F: Arc-tooth drum type

图4 几种纵轴流式脱粒滚筒[7,18,43]A:纹杆-杆齿组合式脱粒滚筒;B:闭式弓齿式脱粒滚筒;C:开式杆齿脱粒滚筒

Fig. 4 Several kinds of longitudinal axial flow threshing[7,18,43]A: Rasp-bar and spike-tooth combined threshing drum; B: Closed-type arc-tooth threshing drum; C: Open-type spike-tooth threshing drum

图5 几种筛体类型[1,7,9,14]A:栅格筛;B:编织筛;C:圆形冲孔筛;D:矩形冲孔筛;E:方形冲孔筛;F:组合式凹板筛

Fig. 5 Several sieve body types[1,7,9,14]A: Grid sieve; B: Woven sieve; C: Circular perforated sieve; D: Rectangular perforated sieve; E: Square perforated sieve; F: Combined concave sieve

图7 不同联合收获机滚筒装置A:科乐收LEXION 8700-7600系列;B:爱科旗下梅西弗格森的MF IDEAL系列;C:约翰迪尔的X9系列;D:约翰迪尔C230;E:久保田WRH1200

Fig. 7 Different combine harvester drum devicesA: CLAAS LEXION 8700-7600 series; B: AGCO’s Massey Ferguson MF IDEAL series; C: John Deere X9 series; D: John Deere C230; E: Kubota WRH1200

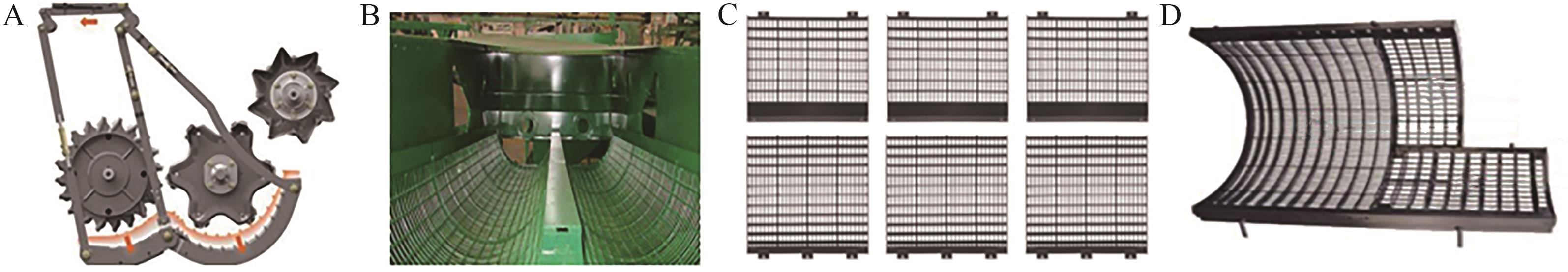

图8 不同联合收获机凹板筛装置A:科乐收LEXION 8700-7600系列;B:约翰迪尔 R2 300系列;C:久保田WRH1200;D:洋马AG600A

Fig. 8 Different combine harvester concave plate screen devicesA: CLAAS LEXION 8700-7600 series; B: John Deere R2 300 series; C: Kubota WRH1200; D: Yanmar AG600A

| 1 | 郝俊发.玉米种子脱粒机清选装置的研究[D].北京:中国农业机械化科学研究院,2016. |

| HAO J F. Research on cleaning device for seeds thresher [D]. Beijing: Chinese Academy of Agricultural Mechanization Sciences, 2016. | |

| 2 | DOSHI J S, PATEL V B, PATEL J B, et al.. Quantification of quality improvement in wheat seed processing [J]. J. Agric. Eng., 2013, 50(4): 83-86. |

| 3 | UNAKITAN G, AYDIN B. A comparison of energy use efficiency and economic analysis of wheat and sunflower production in Turkey: a case study in Thrace region [J]. Energy, 2018, 149: 279-285. |

| 4 | ZHU M, SHABALA S, SHABALA L, et al.. Evaluating predictive values of various physiological indices for salinity stress tolerance in wheat [J]. J. Agron. Crop Sci., 2016, 202(2): 115-124. |

| 5 | 胡铁欢,孙永媛,时荣荣,等.2017年度河北省大豆生产调研报告[J].河北农业科学,2018,22(4):85-88. |

| HU T H, SUN Y Y, SHI R R, et al.. Research report on soybean production of Hebei province in 2017 [J]. J. Hebei Agric. Sci., 2018, 22(4): 85-88. | |

| 6 | 吕凤妍.大豆籽粒物理力学性质测试分析及建模方法研究[D].长春:吉林大学,2017. |

| LYU F Y. Investigation of physical and mechanical properties and modeling method for soybean grains [D]. Changchun: Jilin University, 2017. | |

| 7 | 刘基.大豆收获机低损伤脱粒机构设计与试验[D].北京:中国农业科学院,2017. |

| LIU J. The design and experiment of low damage threshing mechanism of soybean harvester [D]. Beijing: Chinese Academy of Agricultural Sciences, 2017. | |

| 8 | 高鹏.玉米籽粒力学特性及其与仓储中籽粒降破碎的关系研究[D].郑州:河南工业大学,2024. |

| GAO P. Study on the mechanical properties of corn kernels and its relationship with the reduction of kernel breakage in storage [D]. Zhengzhou: Henan University of Technology, 2024. | |

| 9 | 倪有亮.大豆机收破碎机理与低损收获技术研究[D].北京:中国农业科学院,2023. |

| NI Y L. Study on soybean harvesting crushing mechanism and low damage harvesting technology [D]. Beijing: Chinese Academy of Agricultural Sciences, 2023. | |

| 10 | 薛浩田.三七联合收获机整机设计及关键部件的仿真试验[D].昆明:昆明理工大学,2022. |

| XUE H T. The whole machine design and simulation test of key components of Panax notoginseng combined harvester [D]. Kunming: Kunming University of Science and Technology, 2022. | |

| 11 | 金诚谦,郭飞扬,徐金山,等.大豆联合收获机作业参数优化[J].农业工程学报,2019,35(13):10-22. |

| JIN C Q, GUO F Y, XU J S, et al.. Optimization of working parameters of soybean combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(13): 10-22. | |

| 12 | TANG Z, LI Y, LI X, et al.. Structural damage modes for rice stalks undergoing threshing [J]. Biosyst. Eng., 2019, 186: 323-336. |

| 13 | 钱震杰,金诚谦,袁文胜,等.柔性脱粒齿杆与谷物含摩擦打击动力学模型[J].吉林大学学报(工学版),2021,51(3):1121-1130. |

| QIAN Z J, JIN C Q, YUAN W S, et al.. Frictional impact dynamics model of threshing process between flexible teeth and grains [J]. J. Jilin Univ. (Eng. Technol.), 2021, 51(3): 1121-1130. | |

| 14 | 王嘉伟.内外滚筒旋转式荞麦脱粒装置设计与研究[D].太谷:山西农业大学,2020. |

| WANG J W. Design and research of inner and outer roller rotary buckwheat threshing device [D]. Taigu: Shanxi Agricultural University, 2020. | |

| 15 | PUŽAUSKAS E, STEPONAVIČIUS D, JOTAUTIENĖ E, et al.. Substantiation of concave crossbar shape for corn ear threshing [J]. Mechanics, 2016, 22(6): 553-561. |

| 16 | LOVCHIKOV A P, OGNEV I I. Theoretical background for the development of stationary process of grain mass threshing with a combine harvester [J]. E3S Web Conf., 2020, 193: 1004-1013. |

| 17 | 高连兴,李晓峰,接鑫,等.大豆机械脱粒损伤特征及损伤率研究[J].沈阳农业大学学报,2010,41(1):55-58. |

| GAO L X, LI X F, JIE X, et al.. Investigation on characteristics and ratio of soybean kernel mechanical damage [J]. J. Shenyang Agric. Univ., 2010, 41(1): 55-58. | |

| 18 | 倪有亮,金诚谦,王廷恩,等.4LZ-1.5型大豆联合收获机设计与试验[J].农业工程学报,2022,38(22):1-11. |

| NI Y L, JIN C Q, WANG T E, et al.. Design and experiments of the 4LZ-1.5 soybean combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(22): 1-11. | |

| 19 | 滕悦江,金诚谦,陈艳普,等.稻麦联合收获机分段式脱粒装置设计与优化[J].农业工程学报,2020,36(12):1-12. |

| TENG Y J, JIN C Q, CHEN Y P, et al.. Design and optimization of segmented threshing device of combine harvester for rice and wheat [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(12): 1-12. | |

| 20 | 樊晨龙,崔涛,张东兴,等.低损伤组合式玉米脱粒分离装置设计与试验[J].农业机械学报,2019,50(4):113-123. |

| FAN C L, CUI T, ZHANG D X, et al.. Design and test of low-damage combined corn threshing and separating device [J]. Trans. Chin. Soc. Agric. Mach., 2019, 50(4): 113-123. | |

| 21 | 何珂,王骞,耿端阳,等.玉米柔性脱粒滚筒仿真分析[J].中国农机化学报,2018,39(7):53-58. |

| HE K, WANG Q, GENG D Y, et al.. Simulation and analysis of flexible threshing cylinder of corn [J]. J. Chin. Agric. Mech., 2018, 39(7): 53-58. | |

| 22 | 屈哲,张东兴,杨丽,等.纵轴流玉米脱粒分离装置喂入量与滚筒转速试验[J].农业机械学报,2018,49(2):58-65. |

| QU Z, ZHANG D X, YANG L, et al.. Experiment on feed rate and cylinder speed of longitudinal axial flow threshing and separating device for maize [J]. Trans. Chin. Soc. Agric. Mach., 2018, 49(2): 58-65. | |

| 23 | 苏航.脱粒与清选装置参数匹配技术与方法研究[D].哈尔滨: 东北农业大学, 2019. |

| SU H. Research on parameter matching technology and method of threshing and cleaning device [D]. Harbin: Northeast Agricultural University, 2019. | |

| 24 | 刘巍.油葵联合收获机割脱减损关键技术与装置研究[D].武汉:华中农业大学,2023. |

| LIU W. Research on key technologies and equipment for reducing losses in cutting and threshing of oil sunflower combine harvester [D]. Wuhan: Huazhong Agricultural University, 2023. | |

| 25 | 李玲.机械脱粒损伤对谷物储藏品质性状的影响研究[D].南京:南京农业大学,2020. |

| LI L. Effects of mechanical threshing damage on grain storage quality traits [D]. Nanjing: Nanjing Agricultural University, 2020. | |

| 26 | GOVINDARAJ M, MASILAMANI P, ASOKAN D, et al.. Effect of different harvesting and threshing methods on seed quality of rice varieties [J]. Int. J. Curr. Microbiol. Appl. Sci., 2017, 6: 2375-2383. |

| 27 | 杨德旭,姜德龙,沈永哲,等.切轴流式双滚筒大豆种子脱粒机设计与试验[J].农业机械学报,2017,48(9):102-110. |

| YANG D X, JIANG D L, SHEN Y Z, et al.. Design and test on soybean seed thresher with tangential-axial flow double-roller [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(9): 102-110. | |

| 28 | 杨立权.切流横轴流玉米脱粒系统设计及试验研究[D].郑州:河南农业大学, 2018. |

| YANG L Q. Design and experiment research based on tangential flow transverse axial flow corn threshing system [D]. Zhengzhou: Henan Agricultural University, 2018. | |

| 29 | 谭云峰,陈霖,胡森,等.纵轴流柔性弯齿式大豆脱粒装置的设计与试验[J].浙江农业学报,2023,35(12):2954-2965. |

| TAN Y F, CHEN L, HU S, et al.. Design and experiment of longitudinal-axial flow flexible bent-tooth soybean thresher [J]. Acta Agric. Zhejiangensis, 2023, 35(12): 2954-2965. | |

| 30 | LIU Y, LI Y M, ZHANG T M, et al.. Effect of concentric and non-concentric threshing gaps on damage of rice straw during threshing for combine harvester [J]. Biosyst. Eng., 2022, 219: 1-10. |

| 31 | LIU Y, LI Y M, DONG Y H, et al.. Development of a variable-diameter threshing drum for rice combine harvester using MBD-DEM coupling simulation [J/OL]. Comput. Electron. Agric., 2022, 196: 106859 [2024-09-20]. . |

| 32 | SU Z, LI Y M, DONG Y H, et al.. Simulation of rice threshing performance with concentric and non-concentric threshing gaps [J]. Biosyst. Eng., 2020, 197: 42-51. |

| 33 | 王博.玉米脱粒损伤机理及籽粒收获脱粒装置研究[D].杭州:浙江大学,2019. |

| WANG B. Studies on mechanism of corn threshing damage and threshing device for corn grain harvest [D]. Hangzhou: Zhejiang University, 2019. | |

| 34 | 王振玉.玉米籽粒收获机脱粒分离装置设计及夹带损失自动调控系统[D].镇江: 江苏大学, 2021. |

| WANG Z Y. Design of threshing and separating device for corn grain harvester and automatic control system of entrainment loss [D]. Zhenjiang: Jiangsu University, 2021. | |

| 35 | 杜岳峰,傅生辉,毛恩荣,等.农业机械智能化设计技术发展现状与展望[J].农业机械学报,2019,50(9):1-17. |

| DU Y F, FU S H, MAO E R, et al.. Development situation and prospects of intelligent design for agricultural machinery [J]. Trans. Chin. Soc. Agric. Mach., 2019, 50(9): 1-17. | |

| 36 | 王修善,谢方平,刘大为,等.基于深度学习的稻谷内部损伤无损检测装置[J].实验技术与管理,2022,39(12):112-117. |

| WANG X S, XIE F P, LIU D W, et al.. Nondestructive testing device for internal damage of rice based on deep learning [J]. Exp. Technol. Manage., 2022, 39(12): 112-117. | |

| 37 | 陈经纬,郝帅华,王成,等.联合收割机脱粒状态监测及故障诊断系统设计[J].农机化研究,2024,46(7):115-120. |

| CHEN J W, HAO S H, WANG C, et al.. Design of state monitoring and fault diagnosis system for combine harvester [J]. J. Agric. Mech. Res., 2024, 46(7): 115-120. | |

| 38 | MAHIRAH J, YAMAMOTO K, MIYAMOTO M, et al.. Monitoring harvested paddy during combine harvesting using a machine vision-Double lighting system [J]. Eng. Agric. Environ. Food, 2017, 10(2): 140-149. |

| 39 | 陈满,倪有亮,金诚谦,等.基于机器视觉的大豆机械化收获质量在线监测方法[J].农业机械学报,2021,52(1):91-98. |

| CHEN M, NI Y L, JIN C Q, et al.. Online monitoring method of mechanized soybean harvest quality based on machine vision [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(1): 91-98. | |

| 40 | LI Y, XU L Z, LI Y, et al.. Study on modeling method of a multi-parameter control system for threshing and cleaning devices in the grain combine harvester [J]. Agriculture, 2022, 12(9): 1483-1483. |

| 41 | 张亚伟.联合收割机脱粒分离质量影响机理及控制策略研究[D].北京:中国农业大学,2019. |

| ZHANG Y W. Mechanisms and control strategies research on threshing and separating quality of combine harvester [D]. Beijing: China Agricultural University, 2019. | |

| 42 | 刘青山.联合收割机作业状态自适应调控系统设计[D].镇江: 江苏大学, 2021. |

| LIU Q S. Design of adaptive control system for the operation status of the combine harvester [D]. Zhenjiang: Jiangsu University, 2021. | |

| 43 | 金诚谦,康艳,郭红星,等.脱粒滚筒结构形式对大豆机收质量影响的试验研究[J].农业工程学报,2021,37(4):49-58. |

| JIN C Q, KANG Y, GUO H X, et al.. Experimental research on the influence of threshing roller structures on the quality of mechanically-harvested soybeans [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(4): 49-58. | |

| 44 | 邸志峰,崔中凯,张华,等.纹杆块与钉齿组合式轴流玉米脱粒滚筒的设计与试验[J].农业工程学报,2018,34(1):28-34. |

| DI Z F, CUI Z K, ZHANG H, et al.. Design and experiment of rasp bar and nail tooth combined axial flow corn threshing cylinder [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(1): 28-34. | |

| 45 | 刘婉茹,周勇,徐红梅,等.水稻鼓形纵轴流脱粒滚筒杆齿优化与试验[J].农业工程学报,2023,39(15):34-45. |

| LIU W R, ZHOU Y, XU H M, et al.. Optimization and experiments of the drum longitudinal axial threshing cylinder with rod tooth for rice [J]. Trans. Chin. Soc. Agric. Eng., 2023, 39(15): 34-45. | |

| 46 | SU Z, DING Z, TIAN L Q, et al.. Design and performance test of variable diameter threshing drum of combine harvester [J]. Food Sci. Nutr., 2021, 9(8): 4322-4334. |

| 47 | 王勋威,谢方平,李旭,等.可调间隙脱粒分离装置的设计与试验[J].湖南农业大学学报(自然科学版),2019,45(2):205-211. |

| WANG X W, XIE F P, LI X, et al.. Design and experiment on threshing and separation device with adjustable concave clearance [J]. J. Hunan Agric. Univ. (Nat. Sci.), 2019, 45(2): 205-211. | |

| 48 | 李耀明,王建鹏,徐立章,等.联合收获机脱粒滚筒凹板间隙调节装置设计与试验[J].农业机械学报,2018,49(8):68-75. |

| LI Y M, WANG J P, XU L Z, et al.. Design and experiment on adjusting mechanism of concave clearance of combine harvester cylinder [J]. Trans. Chin. Soc. Agric. Mach., 2018, 49(8): 68-75. |

| [1] | 张秀全, 冯晚平, 王嘉伟, 宋海燕, 郑德聪. 揉搓式高粱脱粒装置的设计与性能试验[J]. 中国农业科技导报, 2024, 26(8): 112-121. |

| [2] | 赵晖, 金辰华, 宣卫红, 徐海生. 亚麻纤维水泥基复合材料研究现状及发展展望[J]. 中国农业科技导报, 2024, 26(4): 153-163. |

| [3] | 段益平, 吴明亮, 吕江南, 向伟, 颜波, 马兰, 刘佳杰. 免耕播种防堵技术研究现状及发展建议[J]. 中国农业科技导报, 2022, 24(2): 124-135. |

| [4] | 金月,肖宏儒*,肖苏伟,许萌,丁文芹,刘东. 叶类蔬菜收获技术与装备研究现状及发展趋势[J]. 中国农业科技导报, 2018, 20(9): 72-78. |

| [5] | 欧佳顺1,2,刘大为1,2,3,李旭1,2,谢方平1,2,3*,王修善1,2,谢 超1,2. 小型水稻联合收割机高自净脱粒装置设计与分析[J]. 中国农业科技导报, 2017, 19(9): 63-69. |

| [6] | 林嘉聪,刘志刚,袁巧霞*,曹红亮,易宝军. 蚯蚓分离方法与设备的研究现状[J]. 中国农业科技导报, 2017, 19(2): 103-109. |

| [7] | 傅峰. 我国近期林基复合材料的研究现状与趋势[J]. , 2003, 5(2): 10-13. |

| [8] | 段乃雄 姜慧芳. 油料作物种质资源的研究现状与发展对策[J]. , 2002, 4(3): 14-17. |

| [9] | 陈旭升 狄佳春 等. 棉花杂种优势应用研究现状及发展趋势[J]. , 2002, 4(3): 43-46. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号