中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (6): 144-153.DOI: 10.13304/j.nykjdb.2022.0209

• 食品质量 加工储运 • 上一篇

张冬梦1( ), 姚栋萍2, 吴俊2, 罗秋红1, 庄文2, 刘雄伦1, 邓启云2, 柏斌2(

), 姚栋萍2, 吴俊2, 罗秋红1, 庄文2, 刘雄伦1, 邓启云2, 柏斌2( )

)

收稿日期:2022-03-20

接受日期:2022-05-07

出版日期:2023-06-01

发布日期:2023-07-28

通讯作者:

柏斌

作者简介:张冬梦 E-mail:2468171415@qq.com;

基金资助:

Dongmeng ZHANG1( ), Dongping YAO2, Jun WU2, Qiuhong LUO1, Wen ZHUANG2, Xionglun LIU1, Qiyun DENG2, Bin BAI2(

), Dongping YAO2, Jun WU2, Qiuhong LUO1, Wen ZHUANG2, Xionglun LIU1, Qiyun DENG2, Bin BAI2( )

)

Received:2022-03-20

Accepted:2022-05-07

Online:2023-06-01

Published:2023-07-28

Contact:

Bin BAI

摘要:

为研究灌浆期田间自然低温对不同水稻品种淀粉理化指标和稻米蒸煮食味品质的影响,选取7个高产优质水稻品种,分别加工成精米和米粉,测定在常温和低温下淀粉相关理化指标和米饭黏度、硬度及食味值。结果表明,水稻灌浆期遭遇低温会使稻米直链淀粉含量、消减值、峰值时间、糊化温度和米饭硬度显著升高,直链淀粉含量最大变幅达到47.4%;胶稠度、峰值黏度、崩解值和米饭黏度显著降低,其中胶稠度均降至30~50 mm,最终导致稻米的蒸煮食味品质变差。利用食味值和淀粉理化指标对7个水稻品种进行低温耐受程度的综合评价,发现‘Y两优911’的稻米品质耐低温能力最强,‘Y两优1928’的稻米品质耐低温能力最弱。研究结果显示,在水稻灌浆期需采取适当的栽培措施应对低温对稻米品质造成的影响,为筛选培育耐低温优质稻提供了新思路。

中图分类号:

张冬梦, 姚栋萍, 吴俊, 罗秋红, 庄文, 刘雄伦, 邓启云, 柏斌. 灌浆期田间自然低温对稻米蒸煮食味品质的影响[J]. 中国农业科技导报, 2023, 25(6): 144-153.

Dongmeng ZHANG, Dongping YAO, Jun WU, Qiuhong LUO, Wen ZHUANG, Xionglun LIU, Qiyun DENG, Bin BAI. Effect of Natural Low Temperature on Cooking and Eating Quality of Rice During Grain Filling Stage[J]. Journal of Agricultural Science and Technology, 2023, 25(6): 144-153.

品种 Variety | 处理 Treatment | 直链淀粉含量 Apparent amylose content/% | 增幅 Rate of increase/% |

|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 14.30±0.28 b | 12.6 |

| LT | 16.10±0.14 a | ||

Y两优900 Y liangyou 900 | CT | 13.05±0.07 b | 28.4 |

| LT | 16.75±0.21 a | ||

Y两优1928 Y liangyou1928 | CT | 13.10±0.14 b | 32.8 |

| LT | 17.40±0.00 a | ||

黄华占 Huanghuazhan | CT | 14.55±0.07 b | 11.7 |

| LT | 16.25±0.21 a | ||

Y两优911 Y liangyou 911 | CT | 10.55±0.07 b | 47.4 |

| LT | 15.55±0.07 a | ||

野香优油丝 Yexiangyouyousi | CT | 13.50±0.14 b | 29.6 |

| LT | 17.50±0.00 a | ||

桃优香占 Taoyouxiangzhan | CT | 13.65±0.07 b | 24.5 |

| LT | 17.00±0.00 a |

表1 灌浆期自然低温对稻米直链淀粉含量的影响

Table 1 Effect on amylose content of natural low temperature during grain filling stage of rice

品种 Variety | 处理 Treatment | 直链淀粉含量 Apparent amylose content/% | 增幅 Rate of increase/% |

|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 14.30±0.28 b | 12.6 |

| LT | 16.10±0.14 a | ||

Y两优900 Y liangyou 900 | CT | 13.05±0.07 b | 28.4 |

| LT | 16.75±0.21 a | ||

Y两优1928 Y liangyou1928 | CT | 13.10±0.14 b | 32.8 |

| LT | 17.40±0.00 a | ||

黄华占 Huanghuazhan | CT | 14.55±0.07 b | 11.7 |

| LT | 16.25±0.21 a | ||

Y两优911 Y liangyou 911 | CT | 10.55±0.07 b | 47.4 |

| LT | 15.55±0.07 a | ||

野香优油丝 Yexiangyouyousi | CT | 13.50±0.14 b | 29.6 |

| LT | 17.50±0.00 a | ||

桃优香占 Taoyouxiangzhan | CT | 13.65±0.07 b | 24.5 |

| LT | 17.00±0.00 a |

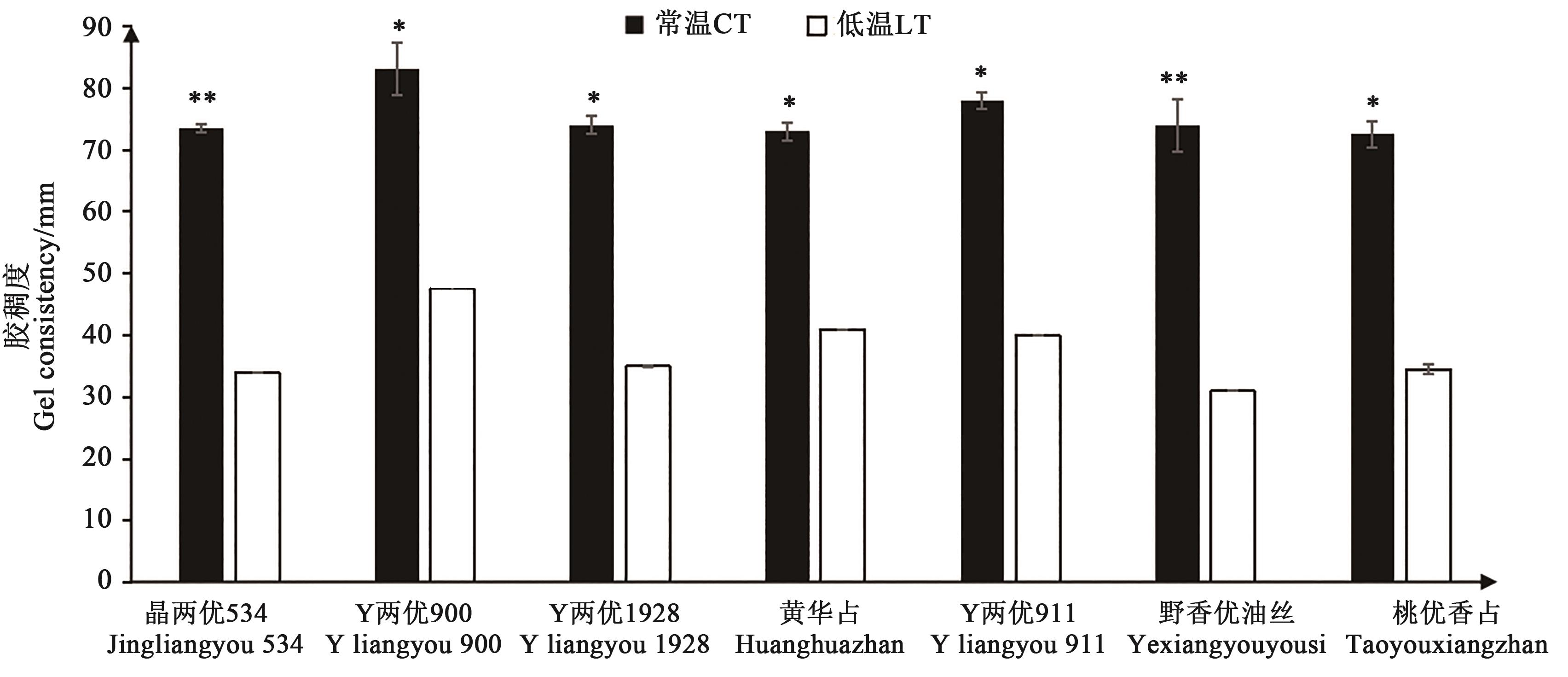

图2 灌浆期自然低温对胶稠度的影响注:*和**分别表示同一品种不同处理间在P<0.05和 P<0.01水平差异显著。

Fig. 2 Effect on gel consistency of natural low temperature during grain filling stage of riceNote: * and ** indicate significant differences between different treatments of same variety at P<0.05 and P<0.01 levels, respectively.

品种 Variety | 处理 Treatment | 峰值黏度 PV/cP | 谷值黏度 TV/cP | 崩解值 BD/cP | 最终黏度 CPV/cP | 消减值 SB/cP | 峰值时间 PT/min | 糊化温度 GT/℃ |

|---|---|---|---|---|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 2 985±3 a | 1 719±38 a | 1 266±35 a | 2 652±46 a | 933±8 b | 5.97±0.05 b | 79.68±0.11 b |

| LT | 1 493±10 b | 1 123±23 b | 371±13 b | 2 471±42 b | 1 349±19 a | 6.04±0.05 a | 93.10±0.07 a | |

Y两优900 Y liangyou 900 | CT | 3 080±21 a | 1 621±18 a | 1 460±4 a | 2 389±11 a | 769±6 b | 5.68±0.014 b | 84.73±0.60 b |

| LT | 1 812±5 b | 1 321±28 b | 491±33 b | 2 422±25 a | 1 101±4 a | 6.17±0.05 a | 91.90±0.57 a | |

Y两优1928 Y liangyou 1928 | CT | 3 177±7 a | 2 007±8 a | 1 171±1 a | 2 749±7 a | 743±1 b | 6.08±0.01 b | 78.73±0.04 b |

| LT | 1 410±7 b | 1 210±4 b | 200±11 b | 2 368±32 b | 1 158±36 a | 6.34±0.09 a | 98.83±0.04 a | |

黄华占 Huanghuazhan | CT | 2 690±15 a | 1 394±10 a | 1 296±5 a | 2 264±9 a | 870±1 b | 5.74±0.01 b | 78.69±0.08 b |

| LT | 1 628±3 b | 1 201±15 b | 428±12 b | 2 456±16 a | 1 256±1 a | 6.07±0.09 a | 93.08±0.11 a | |

Y两优911 Y liangyou 911 | CT | 2 559±43 a | 1 346±16 a | 1 213±28 a | 2 039±31 b | 693±16 b | 5.57±0.05 b | 84.75±0.64 b |

| LT | 1 998±4 b | 1 348±4 a | 650±8 b | 2 699±24 a | 1 351±20 a | 6.09±0.02 a | 91.90±0.49 a | |

野香优油丝 Yexiangyouyousi | CT | 1 217±13 a | 637±27 b | 580±13 a | 1 193±47 b | 556±21 b | 5.60±0.10 b | 87.48±1.17 b |

| LT | 1 160±24 b | 953±9 a | 208±15 b | 2 149±61 a | 1 197±52 a | 6.04±0.05 a | 93.20±0.07 a | |

桃优香占 Taoyouxiangzhan | CT | 1 435±45 a | 723±14 b | 712±31 a | 1 252±11 b | 529±3 b | 5.57±0.06 b | 79.13±0.67 b |

| LT | 1 406±21 a | 1 140±7 a | 266±13 b | 2 379±52 a | 1 239±45 a | 6.17±0.05 a | 93.88±0.04 a |

表2 灌浆期自然低温对稻米RVA谱特征参数的影响

Table 2 Effect on characteristic parameters of rice RVA spectrum of natural low temperature during grain filling stage of rice

品种 Variety | 处理 Treatment | 峰值黏度 PV/cP | 谷值黏度 TV/cP | 崩解值 BD/cP | 最终黏度 CPV/cP | 消减值 SB/cP | 峰值时间 PT/min | 糊化温度 GT/℃ |

|---|---|---|---|---|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 2 985±3 a | 1 719±38 a | 1 266±35 a | 2 652±46 a | 933±8 b | 5.97±0.05 b | 79.68±0.11 b |

| LT | 1 493±10 b | 1 123±23 b | 371±13 b | 2 471±42 b | 1 349±19 a | 6.04±0.05 a | 93.10±0.07 a | |

Y两优900 Y liangyou 900 | CT | 3 080±21 a | 1 621±18 a | 1 460±4 a | 2 389±11 a | 769±6 b | 5.68±0.014 b | 84.73±0.60 b |

| LT | 1 812±5 b | 1 321±28 b | 491±33 b | 2 422±25 a | 1 101±4 a | 6.17±0.05 a | 91.90±0.57 a | |

Y两优1928 Y liangyou 1928 | CT | 3 177±7 a | 2 007±8 a | 1 171±1 a | 2 749±7 a | 743±1 b | 6.08±0.01 b | 78.73±0.04 b |

| LT | 1 410±7 b | 1 210±4 b | 200±11 b | 2 368±32 b | 1 158±36 a | 6.34±0.09 a | 98.83±0.04 a | |

黄华占 Huanghuazhan | CT | 2 690±15 a | 1 394±10 a | 1 296±5 a | 2 264±9 a | 870±1 b | 5.74±0.01 b | 78.69±0.08 b |

| LT | 1 628±3 b | 1 201±15 b | 428±12 b | 2 456±16 a | 1 256±1 a | 6.07±0.09 a | 93.08±0.11 a | |

Y两优911 Y liangyou 911 | CT | 2 559±43 a | 1 346±16 a | 1 213±28 a | 2 039±31 b | 693±16 b | 5.57±0.05 b | 84.75±0.64 b |

| LT | 1 998±4 b | 1 348±4 a | 650±8 b | 2 699±24 a | 1 351±20 a | 6.09±0.02 a | 91.90±0.49 a | |

野香优油丝 Yexiangyouyousi | CT | 1 217±13 a | 637±27 b | 580±13 a | 1 193±47 b | 556±21 b | 5.60±0.10 b | 87.48±1.17 b |

| LT | 1 160±24 b | 953±9 a | 208±15 b | 2 149±61 a | 1 197±52 a | 6.04±0.05 a | 93.20±0.07 a | |

桃优香占 Taoyouxiangzhan | CT | 1 435±45 a | 723±14 b | 712±31 a | 1 252±11 b | 529±3 b | 5.57±0.06 b | 79.13±0.67 b |

| LT | 1 406±21 a | 1 140±7 a | 266±13 b | 2 379±52 a | 1 239±45 a | 6.17±0.05 a | 93.88±0.04 a |

品种 Variety | 处理 Treatment | 硬度 Hardness/kgf | 黏度 Viscosity/kgf | 食味值 Taste value |

|---|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 2.85±0.27 a | 0.36±0.02 a | 67.85±1.06 a |

| LT | 2.99±0.62 a | 0.11±0.03 b | 55.30±4.10 b | |

| 变幅Amplitude/% | 4.91 | 69.44 | 18.50 | |

Y两优900 Y liangyou 900 | CT | 2.40±0.13 b | 0.30±0.01 a | 69.15±0.49 a |

| LT | 3.04±0.07 a | 0.12±0.03 b | 53.15±0.78 b | |

| 变幅Amplitude/% | 26.67 | 60.00 | 23.14 | |

Y两优1928 Y liangyou 1928 | CT | 2.68±0.19 b | 0.25±0.03 a | 70.20±1.70 a |

| LT | 4.04±0.04 a | 0.03±0.01 b | 51.05±1.20 b | |

| 变幅Amplitude/% | 50.75 | 88.00 | 27.28 | |

黄华占 Huanghuazhan | CT | 2.86±0.03 b | 0.30±0.02 a | 63.05±2.47 a |

| LT | 3.34±0.13 a | 0.06±0.00 b | 53.60±1.41 b | |

| 变幅Amplitude/% | 16.78 | 80.00 | 14.99 | |

Y两优911 Y liangyou 911 | CT | 2.90±0.05 a | 0.21±0.04 a | 62.40±1.13 a |

| LT | 3.06±0.05 a | 0.06±0.01 b | 56.70±0.99 b | |

| 变幅Amplitude/% | 5.52 | 71.43 | 9.13 | |

野香优油丝 Yexiangyouyousi | CT | 3.23±0.25 b | 0.13±0.00 a | 58.00±0.57 a |

| LT | 3.98±0.01 a | 0.03±0.01 b | 48.11±0.28 b | |

| 变幅Amplitude/% | 23.22 | 76.92 | 17.05 | |

桃优香占 Taoyouxiangzhan | CT | 2.91±0.25 b | 0.17±0.03 a | 64.25±0.21 a |

| LT | 3.93±0.11 a | 0.04±0.01 b | 51.55±0.64 b | |

| 变幅Amplitude/% | 35.05 | 76.47 | 19.77 |

表3 灌浆期自然低温对硬度、黏度和食味值的影响

Table 3 Effect on hardness, viscosity and taste value of natural low temperature during grain filling stage of rice

品种 Variety | 处理 Treatment | 硬度 Hardness/kgf | 黏度 Viscosity/kgf | 食味值 Taste value |

|---|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 2.85±0.27 a | 0.36±0.02 a | 67.85±1.06 a |

| LT | 2.99±0.62 a | 0.11±0.03 b | 55.30±4.10 b | |

| 变幅Amplitude/% | 4.91 | 69.44 | 18.50 | |

Y两优900 Y liangyou 900 | CT | 2.40±0.13 b | 0.30±0.01 a | 69.15±0.49 a |

| LT | 3.04±0.07 a | 0.12±0.03 b | 53.15±0.78 b | |

| 变幅Amplitude/% | 26.67 | 60.00 | 23.14 | |

Y两优1928 Y liangyou 1928 | CT | 2.68±0.19 b | 0.25±0.03 a | 70.20±1.70 a |

| LT | 4.04±0.04 a | 0.03±0.01 b | 51.05±1.20 b | |

| 变幅Amplitude/% | 50.75 | 88.00 | 27.28 | |

黄华占 Huanghuazhan | CT | 2.86±0.03 b | 0.30±0.02 a | 63.05±2.47 a |

| LT | 3.34±0.13 a | 0.06±0.00 b | 53.60±1.41 b | |

| 变幅Amplitude/% | 16.78 | 80.00 | 14.99 | |

Y两优911 Y liangyou 911 | CT | 2.90±0.05 a | 0.21±0.04 a | 62.40±1.13 a |

| LT | 3.06±0.05 a | 0.06±0.01 b | 56.70±0.99 b | |

| 变幅Amplitude/% | 5.52 | 71.43 | 9.13 | |

野香优油丝 Yexiangyouyousi | CT | 3.23±0.25 b | 0.13±0.00 a | 58.00±0.57 a |

| LT | 3.98±0.01 a | 0.03±0.01 b | 48.11±0.28 b | |

| 变幅Amplitude/% | 23.22 | 76.92 | 17.05 | |

桃优香占 Taoyouxiangzhan | CT | 2.91±0.25 b | 0.17±0.03 a | 64.25±0.21 a |

| LT | 3.93±0.11 a | 0.04±0.01 b | 51.55±0.64 b | |

| 变幅Amplitude/% | 35.05 | 76.47 | 19.77 |

指标 Index | 食味值 Taste value | 日均温ADT | 崩解值 BD | 消减值SB | 糊化温度GT | 峰值黏度PV | 谷值黏度TV | 最终黏度CPV | 峰值时间PT | 直链淀粉含量AAC | 胶稠度GC | 硬度 Hardness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 日均温ADT | 0.874** | |||||||||||

| 崩解值BD | 0.918** | 0.863** | ||||||||||

| 消减值SB | -0.685** | -0.910** | -0.598* | |||||||||

| 糊化温度GT | -0.889** | -0.900** | 0.835** | 0.751** | ||||||||

| 峰值温度PV | 0.843** | 0.626* | 0.922** | -0.344 | -0.688** | |||||||

| 谷值黏度TV | 0.569* | 0.233 | 0.627* | 0.042 | -0.358 | 0.879** | ||||||

| 最终黏度CPV | 0.021 | -0.374 | 0.119 | 0.640* | 0.181 | 0.467 | 0.795** | |||||

| 峰值时间PT | -0.551* | -0.789** | -0.576* | 0.801** | 0.651* | -0.227 | 0.251 | 0.680** | ||||

直链淀粉含量 AAC | -0.805** | -0.923** | -0.800** | 0.801** | 0.742** | -0.614** | -0.251 | 0.294 | 0.800** | |||

| 胶稠度GC | 0.890** | 0.974** | 0.879** | 0.684** | -0.871** | 0.684** | 0.296 | -0.317 | -0.779** | -0.893** | ||

| 硬度Hardness | -0.857** | -0.674** | -0.833** | -0.746** | 0.742** | -0.746** | -0.478 | -0.061 | 0.556* | 0.730** | -0.763** | |

| 黏度Viscosity | 0.905** | 0.841** | 0.938** | -0.598* | -0.869** | 0.861** | 0.579* | 0.082 | -0.520 | -0.688** | 0.858** | -0.796** |

表4 食味值、始穗后40 d平均日均温及理化指标间的相关性分析

Table 4 Correlation analysis of food taste value, average daily temperature and physical and chemical indexes in 40 d after the beginning of ear

指标 Index | 食味值 Taste value | 日均温ADT | 崩解值 BD | 消减值SB | 糊化温度GT | 峰值黏度PV | 谷值黏度TV | 最终黏度CPV | 峰值时间PT | 直链淀粉含量AAC | 胶稠度GC | 硬度 Hardness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 日均温ADT | 0.874** | |||||||||||

| 崩解值BD | 0.918** | 0.863** | ||||||||||

| 消减值SB | -0.685** | -0.910** | -0.598* | |||||||||

| 糊化温度GT | -0.889** | -0.900** | 0.835** | 0.751** | ||||||||

| 峰值温度PV | 0.843** | 0.626* | 0.922** | -0.344 | -0.688** | |||||||

| 谷值黏度TV | 0.569* | 0.233 | 0.627* | 0.042 | -0.358 | 0.879** | ||||||

| 最终黏度CPV | 0.021 | -0.374 | 0.119 | 0.640* | 0.181 | 0.467 | 0.795** | |||||

| 峰值时间PT | -0.551* | -0.789** | -0.576* | 0.801** | 0.651* | -0.227 | 0.251 | 0.680** | ||||

直链淀粉含量 AAC | -0.805** | -0.923** | -0.800** | 0.801** | 0.742** | -0.614** | -0.251 | 0.294 | 0.800** | |||

| 胶稠度GC | 0.890** | 0.974** | 0.879** | 0.684** | -0.871** | 0.684** | 0.296 | -0.317 | -0.779** | -0.893** | ||

| 硬度Hardness | -0.857** | -0.674** | -0.833** | -0.746** | 0.742** | -0.746** | -0.478 | -0.061 | 0.556* | 0.730** | -0.763** | |

| 黏度Viscosity | 0.905** | 0.841** | 0.938** | -0.598* | -0.869** | 0.861** | 0.579* | 0.082 | -0.520 | -0.688** | 0.858** | -0.796** |

品种名称 Variety | 直链淀粉含量 AAC | 胶稠度 GC | 谷值黏度 PV | 崩解值 BD | 消减值 SB | 糊化温度 GT | 峰值时间 PT |

|---|---|---|---|---|---|---|---|

晶两优534 Jingliangyou 534 | 1.27 | -0.66 | -0.90 | -0.48 | 0.86 | -0.30 | 1.68 |

Y两优900 Y liangyou 900 | -0.61 | 1.36 | -0.48 | -0.03 | 0.94 | 0.86 | -0.54 |

Y两优1928 Y liangyou 1928 | -1.12 | -0.47 | -1.18 | -1.57 | 0.44 | -1.47 | 0.73 |

黄华占 Huanghuazhan | 1.44 | 1.18 | -0.39 | -0.12 | 0.86 | -0.50 | 0.41 |

Y两优911 Y liangyou 911 | 0.07 | 0.26 | 0.41 | 1.79 | -0.67 | 0.86 | -0.86 |

野香优油丝 Yexiangyouyousi | -0.78 | -1.39 | 1.20 | 0.16 | -1.09 | 1.25 | -0.23 |

桃优香占 Taoyouxiangzhan | -0.27 | -0.29 | 1.34 | 0.25 | -1.34 | -0.69 | -1.18 |

表5 不同水稻品种灌浆期自然低温淀粉理化指标经SPSS处理标准值

Table 5 Physical and chemical indexes of natural low temperature starch of different rice varieties at filling stage were treated by SPSS

品种名称 Variety | 直链淀粉含量 AAC | 胶稠度 GC | 谷值黏度 PV | 崩解值 BD | 消减值 SB | 糊化温度 GT | 峰值时间 PT |

|---|---|---|---|---|---|---|---|

晶两优534 Jingliangyou 534 | 1.27 | -0.66 | -0.90 | -0.48 | 0.86 | -0.30 | 1.68 |

Y两优900 Y liangyou 900 | -0.61 | 1.36 | -0.48 | -0.03 | 0.94 | 0.86 | -0.54 |

Y两优1928 Y liangyou 1928 | -1.12 | -0.47 | -1.18 | -1.57 | 0.44 | -1.47 | 0.73 |

黄华占 Huanghuazhan | 1.44 | 1.18 | -0.39 | -0.12 | 0.86 | -0.50 | 0.41 |

Y两优911 Y liangyou 911 | 0.07 | 0.26 | 0.41 | 1.79 | -0.67 | 0.86 | -0.86 |

野香优油丝 Yexiangyouyousi | -0.78 | -1.39 | 1.20 | 0.16 | -1.09 | 1.25 | -0.23 |

桃优香占 Taoyouxiangzhan | -0.27 | -0.29 | 1.34 | 0.25 | -1.34 | -0.69 | -1.18 |

品种 Variety | 主成分值Principal component value | 隶属函数Ux | 综合评价值D value | ||

|---|---|---|---|---|---|

| F1 | F2 | U1 | U2 | ||

晶两优534 Jingliangyou 534 | -2.00 | 1.22 | 0.10 | 0.81 | 0.29 |

Y两优900 Y liangyou 900 | 0.25 | 1.12 | 0.59 | 0.79 | 0.50 |

Y两优1928 Y liangyou 1928 | -2.45 | -0.24 | 0.00 | 0.46 | 0.14 |

黄华占 Huanghuazhan | -0.86 | 1.98 | 0.35 | 1.00 | 0.45 |

Y两优911 Y liangyou 911 | 2.14 | -0.24 | 1.00 | 0.46 | 0.58 |

野香优油丝 Yexiangyouyousi | 1.49 | -2.15 | 0.86 | 0.00 | 0.38 |

桃优香占 Taoyouxiangzhan | 1.43 | -1.70 | 0.85 | 0.11 | 0.40 |

| 权重WX | 0.44 | 0.30 | |||

表6 不同水稻品种灌浆期自然低温主成分、隶属函数、权重和综合评价

Table 6 Principal component value, membership function value, weight value and comprehensive evaluation value of natural low temperature in different rice varieties at filling stage

品种 Variety | 主成分值Principal component value | 隶属函数Ux | 综合评价值D value | ||

|---|---|---|---|---|---|

| F1 | F2 | U1 | U2 | ||

晶两优534 Jingliangyou 534 | -2.00 | 1.22 | 0.10 | 0.81 | 0.29 |

Y两优900 Y liangyou 900 | 0.25 | 1.12 | 0.59 | 0.79 | 0.50 |

Y两优1928 Y liangyou 1928 | -2.45 | -0.24 | 0.00 | 0.46 | 0.14 |

黄华占 Huanghuazhan | -0.86 | 1.98 | 0.35 | 1.00 | 0.45 |

Y两优911 Y liangyou 911 | 2.14 | -0.24 | 1.00 | 0.46 | 0.58 |

野香优油丝 Yexiangyouyousi | 1.49 | -2.15 | 0.86 | 0.00 | 0.38 |

桃优香占 Taoyouxiangzhan | 1.43 | -1.70 | 0.85 | 0.11 | 0.40 |

| 权重WX | 0.44 | 0.30 | |||

| 1 | 旷娜,周蔚,张相,等. 再生季稻米蒸煮食味品质与糊化特性、淀粉晶体结构研究[J]. 中国粮油学报, 2021, 36(1): 21-26. |

| KUANG N, ZHOU W, ZHANG X, et al.. The research of ratoon rice on cooking and eating quality and the paste property and starch crystal structure [J]. J. Chin. Cereals Oils Association, 2021, 36(1): 21-26. | |

| 2 | CALINGACION M, LABORTE A, NELSON A, et al.. Diversity of global rice markets and the science required for consumer-targeted rice breeding [J/OL]. PLoS ONE, 2014, 9(1), e85106 [2022-02-20]. . |

| 3 | TIAN Z X, QIAN Q, LIU Q Q, et al.. Allelic diversities in rice starch biosynthesis lead to a diverse array of rice eating and cooking qualities [J]. Proc. Nat. Acad. Sci. USA, 2009, 106(51): 21760-21765. |

| 4 | ZENG D L, TIAN Z X, RAO Y C, et al.. Rational design of high-yield and superior-quality rice [J/OL]. Nat. Plants, 2017, 3:17031 [2022-02-20]. . |

| 5 | 赵春芳,岳红亮,黄双杰,等. 南粳系列水稻品种的食味品质与稻米理化特性[J]. 中国农业科学, 2019, 52(5): 909-920. |

| ZHAO C F, YUE H L, HUANG S J, et al.. Eating quality and physicochemical properties in Nanjing rice varieties [J]. Sci. Agric. Sin., 2019, 52(5): 909-920. | |

| 6 | 吴殿星, 舒庆尧, 夏英武. 低表观直链淀粉含量早籼稻的胚乳外观快速识别及其品质改良应用分析[J]. 作物学报, 2000,26(6): 763-768. |

| WU D X, SHU Q Y, XIA Y W. Rapid identification of early indica rice with low AAC and analysis of its application in quality improvement [J]. Acta Agron. Sin., 2000,26(6):763-768. | |

| 7 | JENKINS P J, DONALD A M. The influence of amylose on starch granule structure [J]. Int. J. Biol. Macromol., 1995, 17(6):315-321. |

| 8 | 吴殿星, 舒庆尧, 夏英武. 胚乳外观标记与RVA谱理化指标相结合辅助改良早籼稻食用品质[J]. 中国水稻科学, 2002, 16(1): 80-82. |

| WU D X, SHU Q Y, XIA Y W. Endosperm appearance marker and physical /chemical indicato r of RVA profile combined- assisted selection for the improvement of eating quality of early Indica rice [J]. Chin. J. Rice Sci., 2002, 16(1):80-82. | |

| 9 | HORI K, SUZUKI K, IIJIMA K, et al.. Variation in cooking and eating quality traits in Japanese rice germplasm accessions [J]. Breed. Sci., 2016, 66(2): 309-318. |

| 10 | 符冠富, 王丹英, 李华, 等. 水稻不同生育期温光条件对籽粒充实和米质的影响[J].中国农业气象, 2009, 30(3): 375-382, 387. |

| FU G F, WANG D Y, LI H, et al.. Influence of temperature and sunlight conditions on rice grain filling and quality in different growth stages [J]. Chin. J. Agrometeorol., 2009, 30(3):375-382, 387. | |

| 11 | 莫惠栋. 我国稻米品质的改良[J].中国农业科学, 1993, 26(4):8-14. |

| MO H D. Improvement of rice quality in China [J]. Sci. Agric. Sin., 1993, 26(4):8-14. | |

| 12 | 林洪鑫, 胡启锋, 肖宇龙, 等.寒露风对双季晚稻品种产量构成和品质的影响[J].江西农业学报, 2016, 28(5):20-23. |

| LIN H X, HU Q F, XIAO Y L, et al.. Effect of cold dew wind on quality,yield and yield components of double cropping late rice varieties [J]. Acta Agric. Jiangxi, 2016, 28(5):20-23. | |

| 13 | 蒋李健.结实期温度胁迫对水稻产量和品质的影响[D].扬州: 扬州大学, 2009. |

| JIANG L J. Effects of temperature stress during grain filling stage on rice grain productivity and quality [D]. Yangzhou:Yangzhou University, 2009. | |

| 14 | 王士强, 宋晓慧, 赵海红, 等. 孕穗期低温胁迫对寒地水稻产量和品质的影响[J]. 农业现代化研究, 2016, 37(3):579-586. |

| WANG S Q, SONG X H, ZHAO H H, et al.. Effect of cold stress at booting stage on rice yield and quality in the cold region [J]. Res. Agric. Mod., 2016, 37(3):579-586. | |

| 15 | 段彬伍,孙成效,朱智伟,等. 稻米直链淀粉的测定 分光光度法: [S].北京:中国标准出版社,2014. |

| 16 | 段彬伍,朱智伟,方长云,等. 米质测定方法: [S].北京:中国标准出版社,2017. |

| 17 | 雷玲,孙辉,姜薇莉. 大米及米粉糊化特性测定 快速粘度仪法: [S].北京:中国标准出版社,2010. |

| 18 | YAO D P, WU J, LUO Q H, et al.. Comprehensive evaluation of high temperature tolerance of six rice varieties during grain-filling period based on key starch physicochemical indexes [J/OL]. LWT-Food Sci. Technol., 2021, 148:111804[2022-02-20]. . |

| 19 | YANO K, MORINAKA Y, WANG F, et al.. GWAS with principal component analysis identifies a gene comprehensively controlling rice architecture [J]. Proc. Natl. Acad. Sci. USA, 2019, 116(42): 21262-21267. |

| 20 | 姜丽娜, 马建辉, 樊婷婷, 等. 孕穗期低温对小麦生理抗寒性的影响[J]. 麦类作物学报, 2014, 34(10): 1373-1382. |

| JIANG L N, MA J H, FAN T T, et al.. Effects of low temperature at booting stage on physiological cold resistance of wheat [J]. J. Triticeae Crops, 2014, 34(10): 1373-1382. | |

| 21 | 张玉华. 稻米直链淀粉含量及其影响因素研究[J]. 黑龙江农业科学, 2002(3):34-37. |

| ZHANG Y H. Content of amylose in rice and its influential factors [J]. Heilongjiang Agric. Sci., 2002(3):34-37. | |

| 22 | 金正勋, 秋太权, 孙艳丽, 等. 稻米蒸煮食味品质特性间的相关性研究[J].东北农业大学学报, 2001, 32(1): 1-7. |

| JIN Z X, QIU T Q, SUN Y L, et al.. Study on the correlation of the cooking and eating quality properties of rice grain [J]. J. Northeast Agric. Univ., 2001, 32(1):1-7. | |

| 23 | BAO J S, YING Y N, ZHOU X, et al.. Relationships among starch biosynthesizing protein content, fine structure and functionality in rice [J/OL]. Carbohyd. Polym., 2020, 237: 116118 [2022-02-20].. |

| 24 | YAO D P, WU J, LUO Q H, et al.. Influence of high natural field temperature during grain filling stage on the morphological structure and physicochemical properties of rice (Oryza sativa L.) starch [J/OL]. Food Chem., 2020,310(3):125817[2022-02-20]. . |

| 25 | 宋广树, 孙忠富, 王夏, 等. 不同生育时期低温处理对水稻品质的影响[J]. 中国农学通报, 2011, 27(18): 174-179. |

| SONG G S, SUN Z F, WANG X, et al.. Effect of low temperature on rice quality in different growth period [J]. Chin. Agric. Sci. Bull., 2011, 27(18):174-179. | |

| 26 | 程方民, 丁元树, 朱碧岩. 稻米直链淀粉含量的形成及其与灌浆结实期温度的关系[J]. 生态学报, 2000,20(4):646-652. |

| CHENG F M, DING Y S, ZHU B Y. The formation of amylose content in rice grain and its relation with field temperature [J]. Acta Ecolo. Sin., 2000,20(4):646-652. | |

| 27 | ZHONG L J, CHENG F M, WEN X, et al.. The deterioration of eating and cooking quality caused by high temperature during grain filling in early-season indica rice cultivars [J]. J. Agron. Crop Sci., 2005, 191(3): 218-225. |

| [1] | 肖芬芳, 张从合, 王慧, 叶亚峰, 张道林, 汪和廷, 李波, 吴跃进, 刘斌美. 杂交水稻花粉收集装置气力输送系统仿真优化[J]. 中国农业科技导报, 2023, 25(4): 110-122. |

| [2] | 尹林江, 李威, 赵卫权, 赵祖伦, 吕思思, 孙小琼. 水稻多时相植被指数特征及覆盖度提取研究[J]. 中国农业科技导报, 2023, 25(2): 83-98. |

| [3] | 曲宗普尺, 毛光锋, 吴敏, 吴洪恺. 水稻种子浸泡液电导率与种子活力的关系[J]. 中国农业科技导报, 2023, 25(1): 35-41. |

| [4] | 王巍, 谢莉娟, 肖东芽, 陈根生, 谢靓, 吴自明, 石绪根, 李辉婕. 江西省双季稻病虫害绿色防控技术模式探究[J]. 中国农业科技导报, 2022, 24(9): 129-138. |

| [5] | 金辉, 王伟, 颜尘栋, 王薇, 李熙英. 水稻纹枯病生防木霉菌分离鉴定及适应性研究[J]. 中国农业科技导报, 2022, 24(9): 139-148. |

| [6] | 文双雅, 石楠, 陈崇怡, 胡海燕, 高志强. 基于涡度相关法的水稻光能利用率研究[J]. 中国农业科技导报, 2022, 24(7): 159-166. |

| [7] | 李琼华, 张琳, 韩昕儒, 宋莉莉. 我国双季稻全要素生产率的时空分析及对策建议[J]. 中国农业科技导报, 2022, 24(5): 15-23. |

| [8] | 唐楠锐, 周勇, 张国忠, 梁方, 柯烩彬. 搅种型孔式水稻穴播排种器的性能模拟与试验[J]. 中国农业科技导报, 2022, 24(4): 107-115. |

| [9] | 杨涛, 马小倩, 张全, 张洪亮. 组蛋白修饰在水稻中的研究进展[J]. 中国农业科技导报, 2022, 24(4): 11-20. |

| [10] | 何振嘉, 范王涛, 杜宜春, 王启龙. 基于土体有机重构的水肥耦合对土壤理化性质和水稻产量的影响[J]. 中国农业科技导报, 2022, 24(3): 176-185. |

| [11] | 徐君, 李婷, 胡敏骏, 蒋玉根, 闫慧莉, 许文秀, 虞轶俊, 何振艳. 水稻籽粒镉积累KASP分子标记LCd-38的开发与利用[J]. 中国农业科技导报, 2022, 24(3): 40-47. |

| [12] | 马小倩, 杨涛, 张全, 张洪亮. 水稻新型育种技术研究现状与展望[J]. 中国农业科技导报, 2022, 24(1): 24-30. |

| [13] | 习敏, 许有尊, 孙雪原, 吴文革, 周永进. 氮素穗肥对水稻垩白籽粒灌浆影响及与加工品质的关系[J]. 中国农业科技导报, 2021, 23(9): 144-151. |

| [14] | 吴子帅, 李虎, 黄秋要, 陈传华, 罗群昌, 周新明, 吴佳桔, 刘广林. 施氮量和栽插密度对桂育11号产量和稻米品质的影响[J]. 中国农业科技导报, 2021, 23(8): 154-162. |

| [15] | 罗友谊, 王慰亲, 郑华斌, 刘功义, 巢英, 徐彩, 郑志刚, 李雪倩, 韦银兰, 唐启源. 不同机械有序种植方式对水稻生长特性及产量的影响[J]. 中国农业科技导报, 2021, 23(7): 162-171. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号