中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (4): 110-122.DOI: 10.13304/j.nykjdb.2022.0048

• 智慧农业 农机装备 • 上一篇

肖芬芳1,2( ), 张从合3, 王慧3, 叶亚峰1, 张道林3, 汪和廷3, 李波1, 吴跃进1, 刘斌美1(

), 张从合3, 王慧3, 叶亚峰1, 张道林3, 汪和廷3, 李波1, 吴跃进1, 刘斌美1( )

)

收稿日期:2022-01-18

接受日期:2022-05-06

出版日期:2023-04-01

发布日期:2023-06-26

通讯作者:

刘斌美

作者简介:肖芬芳 E-mail:xiaofenfang@mail.ustc.edu.cn;

基金资助:

Fenfang XIAO1,2( ), Conghe ZHANG3, Hui WANG3, Yafeng YE1, Daolin ZHANG3, Heting WANG3, Bo LI1, Yuejin WU1, Binmei LIU1(

), Conghe ZHANG3, Hui WANG3, Yafeng YE1, Daolin ZHANG3, Heting WANG3, Bo LI1, Yuejin WU1, Binmei LIU1( )

)

Received:2022-01-18

Accepted:2022-05-06

Online:2023-04-01

Published:2023-06-26

Contact:

Binmei LIU

摘要:

为解决杂交水稻父、母本分田种植下父本花粉机械化高效收集的问题,对杂交水稻花粉收集装置的关键部件气力输送系统进行了仿真优化研究。首先对系统建立了流体力学模型,进一步利用CFD-DPM(computational fluid dynamics-discrete phase model)结合响应面法以进粉管内径、吸粉口长度、吸粉口宽度为因素,系统内气流均匀性及全压差为指标,优化系统结构参数并加以验证。结果表明,进粉管内径、吸粉口长度、吸粉口宽度及内径和长度的交互作用、长度与宽度的交互作用对气力输送系统内气流均匀性及全压差影响显著;两指标均随内径的增加而增加,吸粉均匀性随长度和宽度的增加先增加后减小,全压差随长度和宽度的增加而增加。气力输送系统较优的参数组合为内径200.00 mm、长度564.40 mm、宽度192.48 mm,对优化后结构进行仿真,得到气流速度变异速度和全压差分别为16.03%、238.37 Pa,与预测结果的相对误差分别为4.91%、3.39%,较初始结构下两指标分别减少了56.29%、31.57%,说明优化效果明显。研究结果提供了杂交水稻花粉收集装置气力输送系统快速优化设计的方法,可为装置气力输送系统的优化设计提供参考。

中图分类号:

肖芬芳, 张从合, 王慧, 叶亚峰, 张道林, 汪和廷, 李波, 吴跃进, 刘斌美. 杂交水稻花粉收集装置气力输送系统仿真优化[J]. 中国农业科技导报, 2023, 25(4): 110-122.

Fenfang XIAO, Conghe ZHANG, Hui WANG, Yafeng YE, Daolin ZHANG, Heting WANG, Bo LI, Yuejin WU, Binmei LIU. Simulation and Optimization of Pneumatic Conveying System for Hybrid Rice Pollen Collection Device[J]. Journal of Agricultural Science and Technology, 2023, 25(4): 110-122.

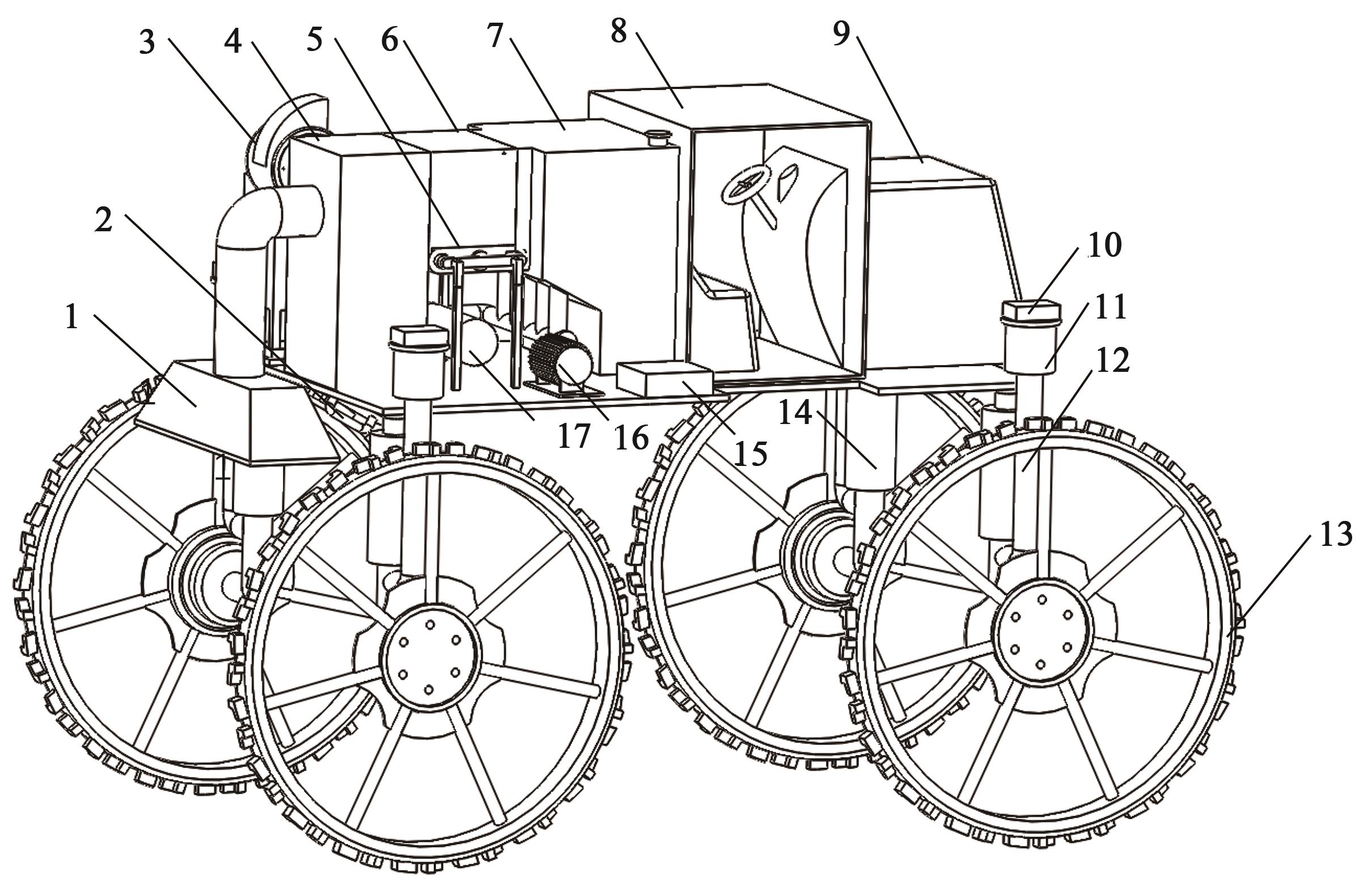

图1 气吸式杂交水稻花粉收集装置结构注:1—气力输送系统;2—排杂门;3—负压风机组件;4—过滤分离室;5—传送带;6—送粉通道;7—冷却干燥室;8—驾驶室;9—柴油发动机;10—转向启动机;11—转向轴套;12—转向轴;13—自走轮;14—液压升降系统;15—蓄电池;16—电机;17—冷却气罐。

Fig. 1 Structure of air-suction pollen collection deviceNote:1—Pneumatic conveying system; 2—Complicated door; 3—Negative pressure fan assembly; 4—Filtration separation chamber; 5—Conveyor belt; 6—Feeding channel; 7—Condensing kiln; 8—Cab; 9—Diesel; 10—Steering starter; 11—Steering column jacket; 12—Stub axle; 13—Wheels; 14—Hydraulic lift system; 15—Storage battery; 16—Electrical machinery; 17—Cooling tank.

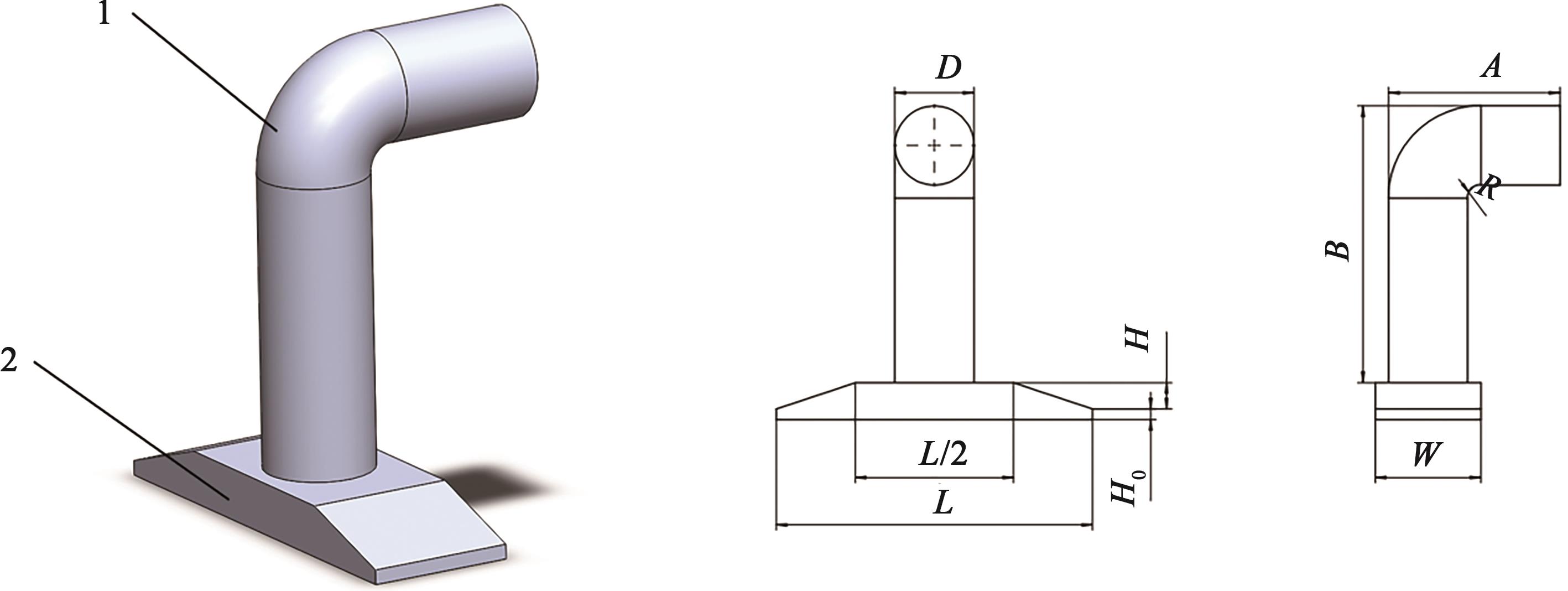

图2 杂交水稻花粉收集装置气力输送系统结构注:1—进粉管;2—吸粉口。

Fig. 2 Structure of pneumatic conveying system of hybrid rice pollen collectionNote:1—Pollen intake pipe; 2— Pollen suction mouth.

指标 Index | 具体参数 Specific psrameter | DPM边界条件 Boundary conditions of DPM |

|---|---|---|

| 流体相Fluid phase | 空气密度Density of air /(kg· 空气粘度Viscosity of air/(kg· | |

| 离散相Dispersed phase | 花粉密度Density of pollen/(kg· 花粉平均直径Average diameter of pollen / 花粉流量Flow of pollen/(kg· 花粉入射速度Injection velocity of pollen/(m· | |

| 压力入口Pressure inlet | 表压Gauge pressure/(Pa):-1 000 | 逃离Escape |

| 压力出口Pressure outlet | 表压Gauge pressure/(Pa):0 | 捕捉Trap |

| 固体壁面边界Wall | 铝密度Density of aluminum/(kg· | 反射Reflect |

表1 Fluent仿真参数设置

Table 1 Fluent simulation parameter settings

指标 Index | 具体参数 Specific psrameter | DPM边界条件 Boundary conditions of DPM |

|---|---|---|

| 流体相Fluid phase | 空气密度Density of air /(kg· 空气粘度Viscosity of air/(kg· | |

| 离散相Dispersed phase | 花粉密度Density of pollen/(kg· 花粉平均直径Average diameter of pollen / 花粉流量Flow of pollen/(kg· 花粉入射速度Injection velocity of pollen/(m· | |

| 压力入口Pressure inlet | 表压Gauge pressure/(Pa):-1 000 | 逃离Escape |

| 压力出口Pressure outlet | 表压Gauge pressure/(Pa):0 | 捕捉Trap |

| 固体壁面边界Wall | 铝密度Density of aluminum/(kg· | 反射Reflect |

| 结构参数Structure parameter | 变化范围Range of variation |

|---|---|

| 进粉管内径 D/mm | [100:25:200] |

| 吸粉口长度 L/mm | [400:100:800] |

| 吸粉口宽度 W/mm | [100:50:300] |

表2 主要因素变化范围及水平

Table 2 Variation range and level of main factors

| 结构参数Structure parameter | 变化范围Range of variation |

|---|---|

| 进粉管内径 D/mm | [100:25:200] |

| 吸粉口长度 L/mm | [400:100:800] |

| 吸粉口宽度 W/mm | [100:50:300] |

| 水平Level | 进粉管内径 D/mm | 吸粉口长度 L/mm | 吸粉口宽度 W/mm |

|---|---|---|---|

| -1 | 150 | 500 | 150 |

| 0 | 175 | 600 | 200 |

| 1 | 200 | 700 | 250 |

表3 试验因素水平及编码

Table 3 Levels and codes of experimental factors

| 水平Level | 进粉管内径 D/mm | 吸粉口长度 L/mm | 吸粉口宽度 W/mm |

|---|---|---|---|

| -1 | 150 | 500 | 150 |

| 0 | 175 | 600 | 200 |

| 1 | 200 | 700 | 250 |

试验编号 Test number | 进粉管内径 Diameter of the tube D/mm | 吸粉口长度 Length of the inlet L/mm | 吸粉口宽度 Width of the inlet W/mm | 流速变异系数 Velocity variation coefficient CV/% | 全压差 Differential pressure |

|---|---|---|---|---|---|

| 1 | 175 | 600 | 200 | 17.51 | 268.44 |

| 2 | 200 | 600 | 250 | 21.47 | 245.85 |

| 3 | 200 | 500 | 200 | 19.32 | 216.38 |

| 4 | 175 | 600 | 200 | 16.38 | 269.58 |

| 5 | 150 | 600 | 250 | 30.56 | 325.44 |

| 6 | 175 | 500 | 250 | 28.71 | 226.65 |

| 7 | 200 | 600 | 150 | 23.36 | 211.93 |

| 8 | 175 | 700 | 150 | 37.44 | 247.29 |

| 9 | 175 | 500 | 150 | 30.48 | 218.46 |

| 10 | 150 | 500 | 200 | 28.58 | 275.07 |

| 11 | 175 | 600 | 200 | 18.45 | 270.93 |

| 12 | 175 | 600 | 200 | 19.01 | 271.23 |

| 13 | 200 | 700 | 200 | 20.63 | 243.52 |

| 14 | 150 | 700 | 200 | 36.67 | 348.36 |

| 15 | 175 | 600 | 200 | 17.95 | 269.94 |

| 16 | 175 | 700 | 250 | 29.42 | 309.47 |

| 17 | 150 | 600 | 150 | 35.34 | 297.24 |

表4 试验方案与结果

Table 4 Experiment plan and results

试验编号 Test number | 进粉管内径 Diameter of the tube D/mm | 吸粉口长度 Length of the inlet L/mm | 吸粉口宽度 Width of the inlet W/mm | 流速变异系数 Velocity variation coefficient CV/% | 全压差 Differential pressure |

|---|---|---|---|---|---|

| 1 | 175 | 600 | 200 | 17.51 | 268.44 |

| 2 | 200 | 600 | 250 | 21.47 | 245.85 |

| 3 | 200 | 500 | 200 | 19.32 | 216.38 |

| 4 | 175 | 600 | 200 | 16.38 | 269.58 |

| 5 | 150 | 600 | 250 | 30.56 | 325.44 |

| 6 | 175 | 500 | 250 | 28.71 | 226.65 |

| 7 | 200 | 600 | 150 | 23.36 | 211.93 |

| 8 | 175 | 700 | 150 | 37.44 | 247.29 |

| 9 | 175 | 500 | 150 | 30.48 | 218.46 |

| 10 | 150 | 500 | 200 | 28.58 | 275.07 |

| 11 | 175 | 600 | 200 | 18.45 | 270.93 |

| 12 | 175 | 600 | 200 | 19.01 | 271.23 |

| 13 | 200 | 700 | 200 | 20.63 | 243.52 |

| 14 | 150 | 700 | 200 | 36.67 | 348.36 |

| 15 | 175 | 600 | 200 | 17.95 | 269.94 |

| 16 | 175 | 700 | 250 | 29.42 | 309.47 |

| 17 | 150 | 600 | 150 | 35.34 | 297.24 |

变量 Variate | 数值 Value | y:速度平均值 Average of velocity/(m·s-1) | 标准差 Standard deviation | 流速变异系数 Velocity variation coefficient CV/% | 全压差 Differential pressure |

|---|---|---|---|---|---|

D:进粉管内径 Diameter of the tube/mm | 100 | 28.59 | 11.23 | 39.27 | 421.66 |

| 125 | 27.40 | 8.39 | 30.64 | 395.83 | |

| 150 | 26.69 | 6.03 | 22.59 | 357.24 | |

| 175 | 28.70 | 5.13 | 17.86 | 269.71 | |

| 200 | 25.17 | 3.85 | 15.31 | 244.59 | |

L:吸粉口长度 Length of the inlet/mm | 400 | 19.15 | 6.35 | 33.21 | 236.12 |

| 500 | 23.96 | 6.84 | 28.58 | 279.07 | |

| 600 | 26.69 | 7.55 | 28.32 | 314.58 | |

| 700 | 24.21 | 8.88 | 36.67 | 348.36 | |

| 800 | 22.88 | 9.33 | 40.79 | 367.54 | |

W:吸粉口宽度 Width of the inlet/mm | 100 | 21.48 | 8.92 | 41.53 | 265.89 |

| 150 | 23.72 | 8.38 | 35.34 | 327.24 | |

| 200 | 26.69 | 7.33 | 27.47 | 368.62 | |

| 250 | 24.32 | 7.43 | 30.56 | 394.44 | |

| 300 | 22.98 | 7.65 | 33.29 | 423.97 |

表5 不同变量下系统速度变异系数与全压差

Table 5 Variation coefficient and total pressure difference under different variables

变量 Variate | 数值 Value | y:速度平均值 Average of velocity/(m·s-1) | 标准差 Standard deviation | 流速变异系数 Velocity variation coefficient CV/% | 全压差 Differential pressure |

|---|---|---|---|---|---|

D:进粉管内径 Diameter of the tube/mm | 100 | 28.59 | 11.23 | 39.27 | 421.66 |

| 125 | 27.40 | 8.39 | 30.64 | 395.83 | |

| 150 | 26.69 | 6.03 | 22.59 | 357.24 | |

| 175 | 28.70 | 5.13 | 17.86 | 269.71 | |

| 200 | 25.17 | 3.85 | 15.31 | 244.59 | |

L:吸粉口长度 Length of the inlet/mm | 400 | 19.15 | 6.35 | 33.21 | 236.12 |

| 500 | 23.96 | 6.84 | 28.58 | 279.07 | |

| 600 | 26.69 | 7.55 | 28.32 | 314.58 | |

| 700 | 24.21 | 8.88 | 36.67 | 348.36 | |

| 800 | 22.88 | 9.33 | 40.79 | 367.54 | |

W:吸粉口宽度 Width of the inlet/mm | 100 | 21.48 | 8.92 | 41.53 | 265.89 |

| 150 | 23.72 | 8.38 | 35.34 | 327.24 | |

| 200 | 26.69 | 7.33 | 27.47 | 368.62 | |

| 250 | 24.32 | 7.43 | 30.56 | 394.44 | |

| 300 | 22.98 | 7.65 | 33.29 | 423.97 |

响应 Response | 来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | 显著性Significance |

|---|---|---|---|---|---|---|---|

流速变异系数 Velocity variation coefficient/% | 模型Model | 820.18 | 9 | 91.13 | 81.58 | <0.000 1 | ** |

| D | 268.77 | 1 | 268.77 | 240.62 | <0.000 1 | ** | |

| L | 36.42 | 1 | 36.42 | 32.61 | 0.000 7 | ** | |

| W | 33.87 | 1 | 33.87 | 30.32 | 0.000 9 | ** | |

| DL | 11.49 | 1 | 11.49 | 10.29 | 0.014 9 | * | |

| DW | 2.09 | 1 | 2.09 | 1.87 | 0.213 8 | ||

| LW | 9.77 | 1 | 9.77 | 8.74 | 0.021 2 | * | |

| 22.37 | 1 | 22.37 | 20.03 | 0.002 9 | ** | ||

| 158.48 | 1 | 158.48 | 141.87 | <0.000 1 | ** | ||

| 237.95 | 1 | 237.95 | 213.02 | <0.000 1 | ** | ||

| 残差Residual | 7.82 | 7 | 1.12 | ||||

| 失拟Lack of fit | 3.83 | 3 | 1.28 | 1.28 | 0.395 3 | ||

| 误差Error | 3.99 | 4 | 1.00 | ||||

| 总和Summation | 828.00 | 16 | |||||

全压差 Differential pressure | 模型Model | 23 773.96 | 9 | 2 641.55 | 627.51 | <0.000 1 | ** |

| D | 13 483.28 | 1 | 13 483.28 | 3 203.01 | <0.000 1 | ** | |

| L | 5 622.24 | 1 | 5 622.24 | 1 335.59 | <0.000 1 | ** | |

| W | 2 194.20 | 1 | 2 194.20 | 521.24 | <0.000 1 | ** | |

| DL | 532.46 | 1 | 532.46 | 126.49 | <0.000 1 | ** | |

| DW | 8.18 | 1 | 8.18 | 1.94 | 0.206 0 | ||

| LW | 728.73 | 1 | 728.73 | 173.11 | <0.000 1 | ** | |

| 440.47 | 1 | 440.47 | 104.64 | <0.000 1 | ** | ||

| 373.59 | 1 | 373.59 | 88.75 | <0.000 1 | ** | ||

| 432.67 | 1 | 432.67 | 102.78 | <0.000 1 | ** | ||

| 残差Residual | 29.47 | 1 | 4.21 | <0.000 1 | ** | ||

| 失拟Lack of fit | 24.48 | 1 | 8.16 | 6.54 | 0.050 6 | ||

| 误差Erro | 4.99 | 4 | 1.25 | ||||

| 总和Summation | 23 803.42 | 16 |

表6 响应面方差分析结果

Table 6 Results of response surface analysis of variance

响应 Response | 来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | 显著性Significance |

|---|---|---|---|---|---|---|---|

流速变异系数 Velocity variation coefficient/% | 模型Model | 820.18 | 9 | 91.13 | 81.58 | <0.000 1 | ** |

| D | 268.77 | 1 | 268.77 | 240.62 | <0.000 1 | ** | |

| L | 36.42 | 1 | 36.42 | 32.61 | 0.000 7 | ** | |

| W | 33.87 | 1 | 33.87 | 30.32 | 0.000 9 | ** | |

| DL | 11.49 | 1 | 11.49 | 10.29 | 0.014 9 | * | |

| DW | 2.09 | 1 | 2.09 | 1.87 | 0.213 8 | ||

| LW | 9.77 | 1 | 9.77 | 8.74 | 0.021 2 | * | |

| 22.37 | 1 | 22.37 | 20.03 | 0.002 9 | ** | ||

| 158.48 | 1 | 158.48 | 141.87 | <0.000 1 | ** | ||

| 237.95 | 1 | 237.95 | 213.02 | <0.000 1 | ** | ||

| 残差Residual | 7.82 | 7 | 1.12 | ||||

| 失拟Lack of fit | 3.83 | 3 | 1.28 | 1.28 | 0.395 3 | ||

| 误差Error | 3.99 | 4 | 1.00 | ||||

| 总和Summation | 828.00 | 16 | |||||

全压差 Differential pressure | 模型Model | 23 773.96 | 9 | 2 641.55 | 627.51 | <0.000 1 | ** |

| D | 13 483.28 | 1 | 13 483.28 | 3 203.01 | <0.000 1 | ** | |

| L | 5 622.24 | 1 | 5 622.24 | 1 335.59 | <0.000 1 | ** | |

| W | 2 194.20 | 1 | 2 194.20 | 521.24 | <0.000 1 | ** | |

| DL | 532.46 | 1 | 532.46 | 126.49 | <0.000 1 | ** | |

| DW | 8.18 | 1 | 8.18 | 1.94 | 0.206 0 | ||

| LW | 728.73 | 1 | 728.73 | 173.11 | <0.000 1 | ** | |

| 440.47 | 1 | 440.47 | 104.64 | <0.000 1 | ** | ||

| 373.59 | 1 | 373.59 | 88.75 | <0.000 1 | ** | ||

| 432.67 | 1 | 432.67 | 102.78 | <0.000 1 | ** | ||

| 残差Residual | 29.47 | 1 | 4.21 | <0.000 1 | ** | ||

| 失拟Lack of fit | 24.48 | 1 | 8.16 | 6.54 | 0.050 6 | ||

| 误差Erro | 4.99 | 4 | 1.25 | ||||

| 总和Summation | 23 803.42 | 16 |

试验组别 Test group | 1 | 2 | 3 | 仿真平均值 Simulated average | 预测值 Predicted average | 相对误差 Relative error/% |

|---|---|---|---|---|---|---|

流速变异系数 Velocity variation coefficient/% | 16.32 | 15.99 | 15.78 | 16.03 | 15.28 | 4.91 |

全压差 Differential pressure/Pa | 241.46 | 239.47 | 234.19 | 238.37 | 230.46 | 3.39 |

表7 仿真验证结果

Table 7 Simulation verification results

试验组别 Test group | 1 | 2 | 3 | 仿真平均值 Simulated average | 预测值 Predicted average | 相对误差 Relative error/% |

|---|---|---|---|---|---|---|

流速变异系数 Velocity variation coefficient/% | 16.32 | 15.99 | 15.78 | 16.03 | 15.28 | 4.91 |

全压差 Differential pressure/Pa | 241.46 | 239.47 | 234.19 | 238.37 | 230.46 | 3.39 |

| 1 | 吴辉,熊朝,刘爱民,等. 杂交水稻机械化制种辅助授粉技术研究现状与设想[J].作物研究,2014,28(3):321-323, 327. |

| WU H, XIONG C, LIU A M, et al.. Research status and prospects of assisted pollination techniques for mechanized seed production of hybrid rice [J]. Crop Res., 2014, 28(3):321-323, 327. | |

| 2 | 彭少兵. 转型时期杂交水稻的困境与出路[J].作物学报,2016,42(3):313-319. |

| PENG S B. Difficulties and solutions of hybrid rice in transition period [J]. Acta Agron. Sin., 2016, 42(3):313-319. | |

| 3 | 袁珅. 常规稻和杂交稻在节本栽培条件下的农学表现及能量与经济分析[D]. 武汉:华中农业大学,2020. |

| YUAN S. Agronomic performance, energy and economic analysis of conventional rice and hybrid rice under cost-saving cultivation conditions [D]. Wuhan:Huazhong Agricultural University, 2020. | |

| 4 | 王跃星,葛露方,朱旭东. 杂交水稻机械化制种技术研究的现状与展望[J].杂交水稻,2011,26(4):5-7, 47. |

| WANG Y X, GE L F, ZHU X D. Research status and prospect of mechanized hybrid rice seed production [J]. Hybrid Rice, 2011, 26 (4) : 5-7, 47. | |

| 5 | 徐庆国,黄丰. 杂交水稻机械化种子生产技术的研究进展[J].农业工程学报,2010,26():37-41. |

| XU Q G, HUANG F. Research progress in mechanized seed production technology of hybrid rice [J]. Trans. Chin. Soc. Agric. Eng., 2010, 26(S1):37-41. | |

| 6 | 黄崇德,季申清,黄河清,等. 杂交水稻机械采授粉制种实用新技术(EB/OL). (2006-01-01)[2021-12-17].. |

| 7 | 舒焜. 一种适于机械化采授粉的籼型杂交水稻制种技术:CN1169237A[P]. 1998-01-07. |

| 8 | KATHERINE E S, FEDERICO V, JASON C,et al.. Pollen preservation method:EP3648595[P]. 2020-05-13. |

| 9 | 张从合,王慧,冯冲,等. 一种保持禾本科作物离体花粉高活力的装置及方法: CN111328703A[P]. 2020-06-26. |

| 10 | 蒋宗谨. 双流式喷雾参数优化与猕猴桃授粉装置研制[D]. 咸阳:西北农林科技大学, 2020. |

| JIANG Z J. Optimization of double-flow spray parameters and development of Kiwifruit pollination device [D]. Xianyang:Northwest A&F University, 2020. | |

| 11 | 王建伟. 无人机风场下的水稻花粉运动规律的研究[D]. 广州:华南农业大学, 2016. |

| WANG J W. Study on rice pollen movement rule under uav wind field [D]. Guangzhou:South China Agricultural University,2016. | |

| 12 | 肖芬芳,张从合,刘斌美,等. 一种气吸式高活力花粉收集冷却装置及其方法:CN113875576A[P]. 2022-01-04. |

| 13 | 刘正怀,郑一平,王志明,等. 微型稻麦联合收获机气流式清选装置研究[J].农业机械学报,2015,46(7):102-108. |

| LIU Z H, ZHENG Y P, WANG Z M, et al.. Design on air-flowing cleaning unit of micro rice-wheat combine harvester [J].Trans. Chin. Soc. Agric. Mach., 2015,46(7):102-108. | |

| 14 | 马秋成,雷林韬,卢安舸,等. 基于CFD-DEM耦合法的莲子壳仁分离装置优化与试验分析[J].食品与机械,2016,32(12):87-91. |

| MA Q C, LEI L T, LU A G, et al.. Optimization and experimental analysis of separation device of lotus seed kernel based on CFD-DEM coupling method [J]. Food Mach., 2016, 32 (12) : 87-91. | |

| 15 | 张凤奎,张宏,兰海鹏,等. 基于CFD-EDM耦合的气吸式红枣捡拾机气力输送装置仿真分析[J].中国农业科技导报,2021,23(7):107-116. |

| ZHANG F K, ZHANG H, LAN H P, et al.. Simulation and analysis of pneumatic conveying device based on CFD-EDM coupling [J]. J. Agric. Sci. Technol., 2021,23(7):107-116. | |

| 16 | 杨红杰. 统收式采棉机气力输送系统的设计及其动力学研究[D]. 石河子: 石河子大学, 2014. |

| YANG H J. Design and dynamics study of pneumatic conveying system of integrated cotton picker [D]. Shihezi: Shihezi University, 2014. | |

| 17 | 彭宇源. 电动清扫车的新型清扫装置设计与流场仿真[D]. 镇江: 江苏大学, 2017. |

| PENG Y Y. New cleaning device design and flow field simulation of electric sweeper [D]. Zhenjiang: Jiangsu University, 2017. | |

| 18 | 彭丽,柳冠青,董方,等. 基于CFD-DPM的旋风分离器结构设计优化[J].中国粉体技术,2021,27(2):63-73. |

| PENG L, LIU G Q, DONG F, et al.. Based on CFD-DPM cyclone separator structure design optimization [J]. J. Powder Technol. China, 2021, 27 (2) : 63-73. | |

| 19 | 敬志臣,韩正晟,高爱民,等. 基于Fluent软件的旋风分离清选系统仿真研究[J].机械研究与应用,2014,27(6):25-27, 30. |

| JING Z C, HAN Z S, GAO A M, et al.. Simulation research on cyclone separation and cleaning system based on fluent software [J]. Mech. Res. Appl., 2014,27(6):25-27, 30. | |

| 20 | 姬长英,张纯,顾宝兴,等. 梳割气吸一体式贡菊采摘机设计与试验[J].农业机械学报,2017,48(11):137-145. |

| JI C Y, ZHANG C, GU B X, et al.. Design and experiment of shear-sucting mountain chrysanthemum picking machine [J].Trans. Chin. Soc. Agric. Mach., 2017, 48(11):137-145. | |

| 21 | 李赛飞,尤佳,韩长杰,等. 自走气吸式红枣捡拾机研制[J].中国农机化学报,2020,41(6):126-130. |

| LI S F, YOU J, HAN C J, et al.. Development of self-propelled jujube suction pick-up machine [J]. J. Chin. Agric. Mech., 2020,41(6):126-130. | |

| 22 | 方明超,周磊.风机的选型[J].建材世界,2020,41(5):45-50. |

| FANG M C, ZHOU L. Selection of fan [J]. Build. Materials World, 2020,41(5):45-50. | |

| 23 | TARPAGKOU R, PANTOKRATORAS A. CFD methodology for sedimentation tanks: the effect of secondary phase on fluid phase using DPM coupled calculations [J]. Appl. Math. Model., 2013,37(5): 3478-3494. |

| 24 | GARY J B, DAVID F F, JEREMY W L, et al.. Investigation of turbulence model selection on the predicted flow behaviour in an industrial crystalliser-RANS and URANS approaches [J]. Chem. Eng. Res. Design, 2018,140: 205-220. |

| 25 | 薛博茹,李永锋,胡艺萱,等. 基于CFD的进水管布设位置对沉降式固体颗粒排污影响的数值模拟[J].大连海洋大学学报,2021,36(4):620-628. |

| XUE B R, LI Y F, HU Y X, et al.. Numerical simulation of the effect of water inlet pipe layout position on settling solid particle discharge based on CFD [J]. J. Dalian Ocean Univ., 2021, 36 (4) : 620-628. | |

| 26 | ZHAO B, SU Y, ZHANG J. Simulation of gas flow pattern and separation efficiency in cyclone with conventional single and spiral double inlet configuration [J]. Chem. Eng. Res. Design, 2006,84(12): 1158-1165. |

| 27 | 李炽. 道路清扫车的气力输送系统的节能研究[D]. 武汉:武汉理工大学, 2019. |

| LI C. Research on energy saving of pneumatic conveying system of road sweeper [D]. Wuhan: Wuhan University of Technology, 2019. | |

| 28 | 姚福强,王永维,郝一枫,等.气力式杂交水稻制种授粉机授粉管结构参数优化[J].农业工程学报,2020,36(18):18-25. |

| YAO F Q, WANG Y W, HAO Y F, et al.. Optimization of pollination tube structure parameters of pneumatic hybrid rice seed pollinator [J]. Trans. Chin. Soc. Agric. Eng., 2020,36(18):18-25. | |

| 29 | 段建,陈树人,张体强.黄花苜蓿收获机设计与试验[J].中国农机化学报,2021,42(8):10-17. |

| DUAN J, CHEN S R, ZHANG T Q. Design and experiment of Medicago Falcata L. harvester [J]. J. Chin. Agric. Mechan., 2021,42(8):10-17. | |

| 30 | 葛宜元. 试验设计方法与 Design-Expert 软件应用[M]. 哈尔滨:哈尔滨工业大学出版社,2015:1-214. |

| 31 | 黄震. 杂交水稻制种碰撞式授粉机理研究[D]. 长沙:湖南农业大学,2013. |

| HUANG Z. Mechanism of collision pollination in hybrid rice seed production [D]. Changsha:Hunan Agricultural University, 2013. | |

| 32 | 陈军. 杂交水稻制种机械化授粉机研制[D]. 杭州:浙江大学,2017. |

| CHEN J. Development of mechanized pollinator for hybrid rice seed production [D]. Hangzhou: Zhejiang University, 2017. | |

| 33 | 李中秋. 杂交水稻制种气力碰撞组合式授粉参数与特性研究[D]. 长沙:湖南农业大学,2015. |

| LI Z Q. Parameters and characteristics of hybrid rice combined pollination by pneumatic impact in seed production [D]. Changsha: Hunan Agricultural University, 2015. | |

| 34 | 王永维,何焯亮,陈军,等. 碰撞气吹式杂交水稻授粉机结构与参数优化[J].浙江大学学报(农业与生命科学版),2018,44(1):98-106. |

| WANG Y W, HE C L, CHEN J, et al.. Structure and parameter optimization of impact air-blown hybrid rice pollinator [J]. J. Zhejiang Univ. (Agric. life Sci.), 2018,44(1):98-106. | |

| 35 | 肖育军. PCF型湿式脱硫除尘器结构的CFD优化研究[D]. 长沙:湖南大学, 2014. |

| XIAO Y J. CFD optimization of THE STRUCTURE of PCF wet desulfurization precipitator [D]. Changsha:Hunan University, 2014. | |

| 36 | 徐云,李欣峰,肖田元,等.计算流体力学在清扫车仿真分析中的应用研究[J].系统仿真学报, 2004,16(2):270-273. |

| XU Y, LI X F, XIAO T Y, et al.. Application of computational fluid dynamics in simulation analysis of sweeper [J]. J. Syst. Simulation, 2004,16(2):270-273. | |

| 37 | 杨春朝,章易程,欧阳智江,等. 基于流场模拟的真空清扫车吸尘口的参数设计[J].中南大学学报(自然科学版),2012,43(9):3704-3709. |

| YANG C C, ZHANG Y C, OUYANG Z J, et al.. Parametric design of dust collection port of vacuum sweeper based on flow simulation [J]. J. Central South Univ. (Sci. Technol.), 2012,43(9):3704-3709. |

| [1] | 张豫丹, 王卫民, 倪博, 马晓寒, 李俊领, 许自成, 贾玮, 史久长. 烟草秸秆绿原酸提取工艺优化及其抑菌效果研究[J]. 中国农业科技导报, 2023, 25(1): 119-127. |

| [2] | 王洁1,2,赵阳1*,王磊2*. 一个新的玉米胞质雄性不育系的获得及鉴定[J]. 中国农业科技导报, 2019, 21(3): 28-33. |

| [3] | 代邹,王春雨,李娜,蒋明金,严奉君,徐徽,孙永健,马均*. 硒、硅配施对镉胁迫下杂交稻中镉及矿质元素的影响[J]. 中国农业科技导报, 2017, 19(1): 108-117. |

| [4] | 熊夏宇,曾新安*,王满生,张智宏. 响应面法优化脉冲电场辅助提取油菜花粉中黄酮类物质工艺研究[J]. 中国农业科技导报, 2015, 17(5): 88-93. |

| [5] | 李云爽1,靳芳1,杨喜霞1,张丰收2,张涛2,苏颖2,连慕兰1,周云龙1. 电子束辐照对金花葵花粉萌发率的影响[J]. , 2011, 13(3): 97-101. |

| [6] | 胡培松. 杂交水稻产业发展与技术创新[J]. , 2010, 12(2): 17-23. |

| [7] | 吕泽林,邓贤康,杨航. 香型优质高产杂交水稻宜香101的选育与应用[J]. , 2009, 11(S2): 82-84. |

| [8] | 岳兵,薛晓锋,吴黎明,李熠,赵静. 高效液相色谱法测定蜂花粉中的腺苷[J]. , 2009, 11(S1): 72-74. |

| [9] | 张红林,刘海平,刘跃清,张瑞祥,钟晓英. e型杂交水稻研究现状与前景[J]. , 2009, 11(4): 10-15. |

| [10] | 王秀君,郎志宏,陆伟,林敏,单安山,黄大昉. 利用花粉管通道法将耐草甘膦基因mG2-epsps 导入玉米自交系的研究初报[J]. , 2008, 10(4): 56-62. |

| [11] | 罗玉水. 三明市超级稻发展现状与对策[J]. , 2006, 8(2): 19-21. |

| [12] | 邹应斌 周上游 唐起源. 中国超级杂交水稻超高产栽培研究的现状与展望[J]. , 2003, 5(1): 31-35. |

| [13] | 袁隆平. 依靠科技创新发展杂交水稻|确保我国粮食安全[J]. , 2001, 3(2): 54-56. |

| [14] | 倪万潮[1] 郭三堆[2] 贾士荣[2]. 花粉管通道法介导的棉花遗传转化[J]. , 2000, 2(2): 27-32. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号