Journal of Agricultural Science and Technology ›› 2022, Vol. 24 ›› Issue (9): 188-196.DOI: 10.13304/j.nykjdb.2021.1105

• BIO-MANUFACTURING & RESOURCE AND ECOLOGY • Previous Articles

Yan MENG1( ), Wei WANG1(

), Wei WANG1( ), Quancai XI2, Yi LI1, Laisheng CHEN1, Zhongping DU1, Rui HAN1(

), Quancai XI2, Yi LI1, Laisheng CHEN1, Zhongping DU1, Rui HAN1( )

)

Received:2021-12-29

Accepted:2022-03-09

Online:2022-09-15

Published:2022-10-11

Contact:

Rui HAN

孟艳1( ), 汪微1(

), 汪微1( ), 葸全财2, 李屹1, 陈来生1, 杜中平1, 韩睿1(

), 葸全财2, 李屹1, 陈来生1, 杜中平1, 韩睿1( )

)

通讯作者:

韩睿

作者简介:孟艳 E-mail:1991218370@qq.com基金资助:CLC Number:

Yan MENG, Wei WANG, Quancai XI, Yi LI, Laisheng CHEN, Zhongping DU, Rui HAN. Effect of Biogas Slurry Pretreatment on Anaerobic Digestion of Vegetable Straws[J]. Journal of Agricultural Science and Technology, 2022, 24(9): 188-196.

孟艳, 汪微, 葸全财, 李屹, 陈来生, 杜中平, 韩睿. 沼液预处理对蔬菜秸秆厌氧消化性能的影响[J]. 中国农业科技导报, 2022, 24(9): 188-196.

参数 Paremeter | 黄瓜秸秆 Cucumber straw | 番茄秸秆 Tomato straw | 茄子秸秆 Eggplant straw | 辣椒秸秆 Pepper straw | 接种物 Inoculum | 猪粪沼液 Pig manure biogas slurry |

|---|---|---|---|---|---|---|

| pH | — | — | — | — | 7.56±0.05 | 7.11±0.03 |

| 总固体TS/% | 94.88±0.03 | 95.12±0.30 | 94.60±0.20 | 94.59±0.06 | 3.87±0.04 | 1.64±0.06 |

| 挥发性固体VS/% | 83.20±0.02 | 87.91±0.70 | 84.73±0.13 | 85.28±0.71 | 2.49±0.08 | 1.39±0.11 |

Table 1 Characteristics of raw materials and inoculum

参数 Paremeter | 黄瓜秸秆 Cucumber straw | 番茄秸秆 Tomato straw | 茄子秸秆 Eggplant straw | 辣椒秸秆 Pepper straw | 接种物 Inoculum | 猪粪沼液 Pig manure biogas slurry |

|---|---|---|---|---|---|---|

| pH | — | — | — | — | 7.56±0.05 | 7.11±0.03 |

| 总固体TS/% | 94.88±0.03 | 95.12±0.30 | 94.60±0.20 | 94.59±0.06 | 3.87±0.04 | 1.64±0.06 |

| 挥发性固体VS/% | 83.20±0.02 | 87.91±0.70 | 84.73±0.13 | 85.28±0.71 | 2.49±0.08 | 1.39±0.11 |

处理 Treatment | 半纤维素 Hemicellulose/% | 纤维素 Cellulose/% | 木质素 Lignin/% |

|---|---|---|---|

| H0 | 9.49±0.65 a | 32.68±0.09 a | 7.69±0.06 d |

| H3 | 9.29±0.43 a | 29.65±0.16 b | 8.69±0.27 c |

| H5 | 4.83±0.72 b | 29.05±0.53 b | 9.67±0.14 b |

| H7 | 4.62±0.26 b | 25.67±0.73 c | 11.15±0.53 a |

| H9 | 4.51±0.53 b | 25.47±0.22 c | 11.23±0.36 a |

| F0 | 8.28±0.25 a | 31.93±0.16 a | 8.39±0.13 c |

| F3 | 7.28±0.31 b | 30.81±0.34 b | 8.89±0.42 c |

| F5 | 5.26±0.62 c | 27.91±0.47 c | 11.53±0.27 b |

| F7 | 5.11±0.74 c | 27.31±0.71 d | 12.28±1.01 ab |

| F9 | 5.02±0.18 c | 27.12±0.15 d | 12.54±0.15 a |

| Q0 | 7.16±0.56 a | 33.27±0.13 a | 7.34±0.22 c |

| Q3 | 6.33±0.22 a | 32.76±0.27 a | 12.85±0.34 b |

| Q5 | 5.77±1.03 b | 28.91±0.66 b | 12.03±0.19 a |

| Q7 | 5.70±0.55 c | 27.40±0.73 c | 13.08±0.63 a |

| Q9 | 5.29±0.41 d | 27.17±0.82 c | 13.19±0.25 a |

| L0 | 6.59±0.44 a | 35.79±0.11 a | 11.21±0.17 c |

| L3 | 6.05±0.19 ab | 29.92±0.24 b | 15.40±0.26 b |

| L5 | 5.51±0.36 b | 28.25±0.36 c | 17.57±0.49 a |

| L7 | 5.46±0.71 b | 27.93±0.52 c | 17.52±0.15 a |

| L9 | 5.42±0.35 b | 27.03±0.13 d | 17.33±0.38 a |

Table 2 Lignocellulose content of vegetable straw after pretreatment of biogas slurry

处理 Treatment | 半纤维素 Hemicellulose/% | 纤维素 Cellulose/% | 木质素 Lignin/% |

|---|---|---|---|

| H0 | 9.49±0.65 a | 32.68±0.09 a | 7.69±0.06 d |

| H3 | 9.29±0.43 a | 29.65±0.16 b | 8.69±0.27 c |

| H5 | 4.83±0.72 b | 29.05±0.53 b | 9.67±0.14 b |

| H7 | 4.62±0.26 b | 25.67±0.73 c | 11.15±0.53 a |

| H9 | 4.51±0.53 b | 25.47±0.22 c | 11.23±0.36 a |

| F0 | 8.28±0.25 a | 31.93±0.16 a | 8.39±0.13 c |

| F3 | 7.28±0.31 b | 30.81±0.34 b | 8.89±0.42 c |

| F5 | 5.26±0.62 c | 27.91±0.47 c | 11.53±0.27 b |

| F7 | 5.11±0.74 c | 27.31±0.71 d | 12.28±1.01 ab |

| F9 | 5.02±0.18 c | 27.12±0.15 d | 12.54±0.15 a |

| Q0 | 7.16±0.56 a | 33.27±0.13 a | 7.34±0.22 c |

| Q3 | 6.33±0.22 a | 32.76±0.27 a | 12.85±0.34 b |

| Q5 | 5.77±1.03 b | 28.91±0.66 b | 12.03±0.19 a |

| Q7 | 5.70±0.55 c | 27.40±0.73 c | 13.08±0.63 a |

| Q9 | 5.29±0.41 d | 27.17±0.82 c | 13.19±0.25 a |

| L0 | 6.59±0.44 a | 35.79±0.11 a | 11.21±0.17 c |

| L3 | 6.05±0.19 ab | 29.92±0.24 b | 15.40±0.26 b |

| L5 | 5.51±0.36 b | 28.25±0.36 c | 17.57±0.49 a |

| L7 | 5.46±0.71 b | 27.93±0.52 c | 17.52±0.15 a |

| L9 | 5.42±0.35 b | 27.03±0.13 d | 17.33±0.38 a |

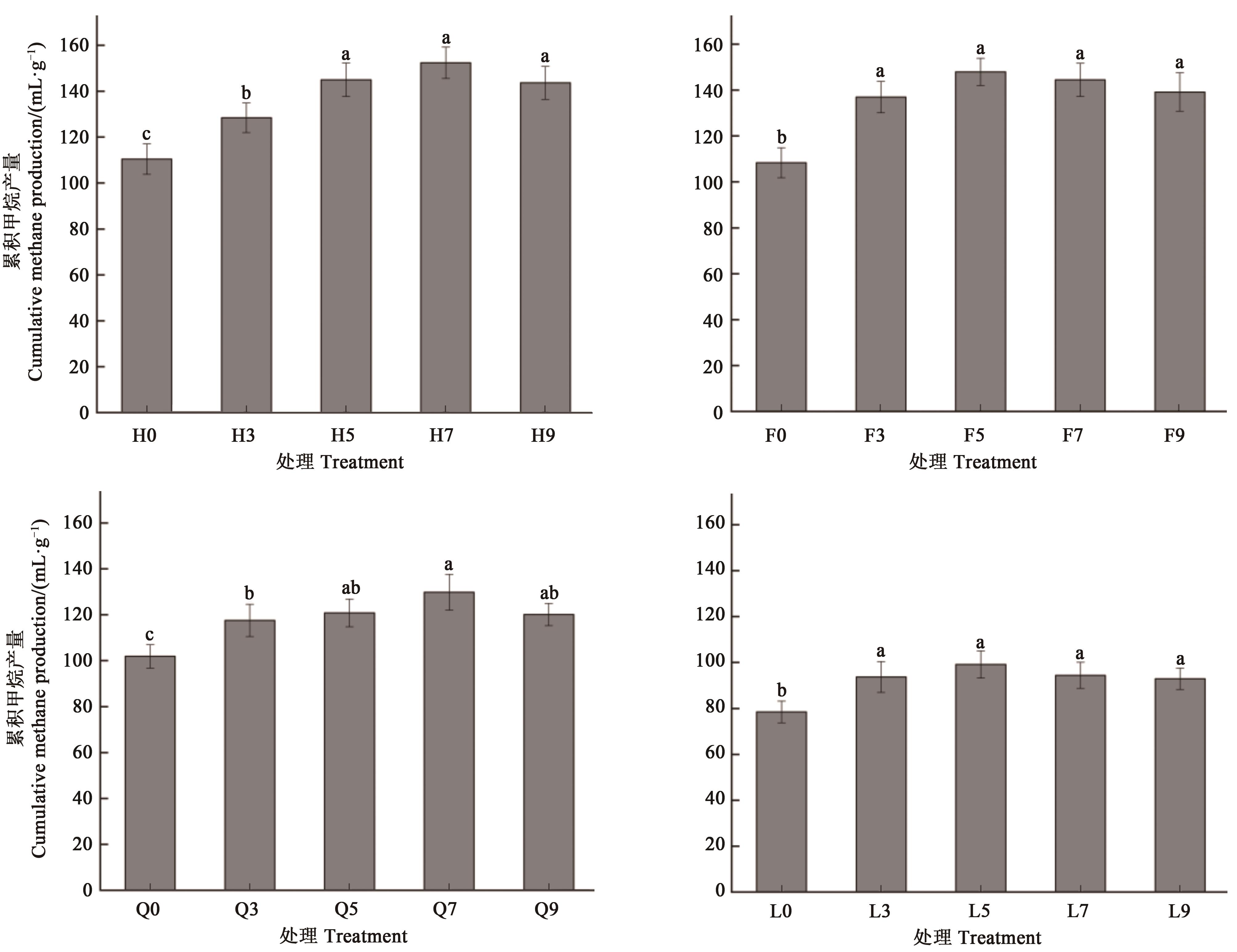

Fig. 2 Cumulative methane production of 4 vegetable straws after pretreatment of biogas slurryNote:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

处理 Treatment | 消化时间T90 Digestion time T90/d | 实际甲烷产量 Actual methane production/(mL·g-1) | 产甲烷潜力 Methane production potential/(mL·g-1) | 最大甲烷日产率 Maximum methane daily production rate/(mL·g-1·d-1) | R2 | 延滞期 Lag phase/d |

|---|---|---|---|---|---|---|

| H0 | 17 | 110.45 | 105.20 | 10.80 | 0.981 | 0.65 |

| H3 | 10 | 128.46 | 125.50 | 19.34 | 0.996 | 0.63 |

| H5 | 12 | 145.02 | 140.46 | 20.23 | 0.989 | 0.23 |

| H7 | 9 | 152.42 | 148.69 | 23.12 | 0.995 | 0.24 |

| H9 | 11 | 143.65 | 139.80 | 18.12 | 0.993 | 0.01 |

| F0 | 16 | 108.37 | 103.36 | 12.19 | 0.970 | -0.35 |

| F3 | 13 | 136.98 | 133.96 | 14.85 | 0.987 | -0.76 |

| F5 | 11 | 147.95 | 145.41 | 15.59 | 0.997 | -0.47 |

| F7 | 12 | 144.48 | 142.01 | 15.14 | 0.994 | -0.79 |

| F9 | 11 | 139.17 | 136.73 | 16.21 | 0.994 | -0.87 |

| Q0 | 17 | 101.90 | 96.55 | 11.68 | 0.979 | 0.13 |

| Q3 | 14 | 117.59 | 113.03 | 13.66 | 0.989 | 0.00 |

| Q5 | 13 | 120.85 | 116.63 | 14.41 | 0.989 | -0.11 |

| Q7 | 14 | 129.84 | 124.79 | 15.18 | 0.987 | 0.00 |

| Q9 | 13 | 120.14 | 116.26 | 14.58 | 0.987 | -0.13 |

| L0 | 18 | 78.50 | 73.88 | 8.75 | 0.966 | -0.15 |

| L3 | 13 | 93.70 | 90.48 | 11.75 | 0.973 | -0.80 |

| L5 | 14 | 99.17 | 95.35 | 10.85 | 0.972 | -1.06 |

| L7 | 12 | 94.45 | 91.22 | 12.25 | 0.981 | -0.53 |

| L9 | 12 | 92.90 | 89.32 | 12.54 | 0.977 | -0.56 |

Table 3 Fitting model parameters of methane production of 4 vegetable straws after pretreatment of biogas slurry and digestion time T90

处理 Treatment | 消化时间T90 Digestion time T90/d | 实际甲烷产量 Actual methane production/(mL·g-1) | 产甲烷潜力 Methane production potential/(mL·g-1) | 最大甲烷日产率 Maximum methane daily production rate/(mL·g-1·d-1) | R2 | 延滞期 Lag phase/d |

|---|---|---|---|---|---|---|

| H0 | 17 | 110.45 | 105.20 | 10.80 | 0.981 | 0.65 |

| H3 | 10 | 128.46 | 125.50 | 19.34 | 0.996 | 0.63 |

| H5 | 12 | 145.02 | 140.46 | 20.23 | 0.989 | 0.23 |

| H7 | 9 | 152.42 | 148.69 | 23.12 | 0.995 | 0.24 |

| H9 | 11 | 143.65 | 139.80 | 18.12 | 0.993 | 0.01 |

| F0 | 16 | 108.37 | 103.36 | 12.19 | 0.970 | -0.35 |

| F3 | 13 | 136.98 | 133.96 | 14.85 | 0.987 | -0.76 |

| F5 | 11 | 147.95 | 145.41 | 15.59 | 0.997 | -0.47 |

| F7 | 12 | 144.48 | 142.01 | 15.14 | 0.994 | -0.79 |

| F9 | 11 | 139.17 | 136.73 | 16.21 | 0.994 | -0.87 |

| Q0 | 17 | 101.90 | 96.55 | 11.68 | 0.979 | 0.13 |

| Q3 | 14 | 117.59 | 113.03 | 13.66 | 0.989 | 0.00 |

| Q5 | 13 | 120.85 | 116.63 | 14.41 | 0.989 | -0.11 |

| Q7 | 14 | 129.84 | 124.79 | 15.18 | 0.987 | 0.00 |

| Q9 | 13 | 120.14 | 116.26 | 14.58 | 0.987 | -0.13 |

| L0 | 18 | 78.50 | 73.88 | 8.75 | 0.966 | -0.15 |

| L3 | 13 | 93.70 | 90.48 | 11.75 | 0.973 | -0.80 |

| L5 | 14 | 99.17 | 95.35 | 10.85 | 0.972 | -1.06 |

| L7 | 12 | 94.45 | 91.22 | 12.25 | 0.981 | -0.53 |

| L9 | 12 | 92.90 | 89.32 | 12.54 | 0.977 | -0.56 |

处理 Treatment | pH | 挥发性脂肪酸含量 VFAs content/(mg·L-1) | 总碱度 TA/(mg CaCO3·L-1) | 氨氮含量 AN content/(mg·L-1) | 挥发性脂肪酸/总碱度 VFAs/TA |

|---|---|---|---|---|---|

| H0 | 7.81±0.02 | 935.89±46.79 | 5 624.37±139.24 | 626.37±21.32 | 0.17 |

| H3 | 7.98±0.14 | 563.45±28.17 | 4 373.12±0.00 | 734.72±56.74 | 0.13 |

| H5 | 7.67±0.06 | 1 062.26±53.11 | 4 373.12±0.00 | 864.34±73.22 | 0.24 |

| H7 | 7.94±0.08 | 656.56±32.83 | 9 359.35±231.79 | 658.32±42.92 | 0.07 |

| H9 | 7.87±0.05 | 982.45±49.12 | 5 624.37±137.48 | 652.84±32.64 | 0.17 |

| F0 | 7.94±0.05 | 524.02±13.22 | 6 869.36±110.86 | 633.86±40.61 | 0.08 |

| F3 | 7.88±0.12 | 707.38±35.46 | 6 869.36±102.83 | 673.46±53.67 | 0.10 |

| F5 | 7.75±0.07 | 955.84±47.23 | 7 494.99±148.22 | 669.20±83.46 | 0.13 |

| F7 | 7.66±0.09 | 761.07±40.25 | 4 998.74±88.19 | 770.18±38.51 | 0.15 |

| F9 | 7.74±0.04 | 752.99±27.83 | 6 869.36±0.00 | 812.15±71.69 | 0.11 |

| Q0 | 7.94±0.13 | 650.86±31.28 | 4 373.12±123.27 | 653.72±32.69 | 0.15 |

| Q3 | 7.72±0.12 | 1 007.86±75.36 | 5 624.37±182.47 | 737.09±46.85 | 0.18 |

| Q5 | 7.51±0.04 | 889.33±44.47 | 6 243.74±130.42 | 686.17±64.31 | 0.14 |

| Q7 | 7.47±0.07 | 1 035.65±51.78 | 4 998.74±0.00 | 671.58±85.58 | 0.21 |

| Q9 | 7.31±0.03 | 1 073.18±55.08 | 4 998.74±76.45 | 785.06±59.25 | 0.21 |

| L0 | 7.41±0.05 | 1 059.40±51.43 | 9 359.35±260.78 | 604.42±40.72 | 0.11 |

| L3 | 7.52±0.13 | 1 214.99±62.01 | 6 869.36±0.00 | 636.92±51.85 | 0.18 |

| L5 | 7.39±0.07 | 1 062.26±53.11 | 7 494.99±170.83 | 762.60±38.13 | 0.14 |

| L7 | 7.38±0.09 | 1 167.95±59.33 | 6 869.36±0.00 | 714.49±70.22 | 0.17 |

| L9 | 7.64±0.06 | 574.53±30.18 | 6 869.36±123.78 | 706.30±30.31 | 0.08 |

Table 4 pH, VFAs content, alkalinity and ammonia nitrogen content of biogas slurry after anaerobic digestion

处理 Treatment | pH | 挥发性脂肪酸含量 VFAs content/(mg·L-1) | 总碱度 TA/(mg CaCO3·L-1) | 氨氮含量 AN content/(mg·L-1) | 挥发性脂肪酸/总碱度 VFAs/TA |

|---|---|---|---|---|---|

| H0 | 7.81±0.02 | 935.89±46.79 | 5 624.37±139.24 | 626.37±21.32 | 0.17 |

| H3 | 7.98±0.14 | 563.45±28.17 | 4 373.12±0.00 | 734.72±56.74 | 0.13 |

| H5 | 7.67±0.06 | 1 062.26±53.11 | 4 373.12±0.00 | 864.34±73.22 | 0.24 |

| H7 | 7.94±0.08 | 656.56±32.83 | 9 359.35±231.79 | 658.32±42.92 | 0.07 |

| H9 | 7.87±0.05 | 982.45±49.12 | 5 624.37±137.48 | 652.84±32.64 | 0.17 |

| F0 | 7.94±0.05 | 524.02±13.22 | 6 869.36±110.86 | 633.86±40.61 | 0.08 |

| F3 | 7.88±0.12 | 707.38±35.46 | 6 869.36±102.83 | 673.46±53.67 | 0.10 |

| F5 | 7.75±0.07 | 955.84±47.23 | 7 494.99±148.22 | 669.20±83.46 | 0.13 |

| F7 | 7.66±0.09 | 761.07±40.25 | 4 998.74±88.19 | 770.18±38.51 | 0.15 |

| F9 | 7.74±0.04 | 752.99±27.83 | 6 869.36±0.00 | 812.15±71.69 | 0.11 |

| Q0 | 7.94±0.13 | 650.86±31.28 | 4 373.12±123.27 | 653.72±32.69 | 0.15 |

| Q3 | 7.72±0.12 | 1 007.86±75.36 | 5 624.37±182.47 | 737.09±46.85 | 0.18 |

| Q5 | 7.51±0.04 | 889.33±44.47 | 6 243.74±130.42 | 686.17±64.31 | 0.14 |

| Q7 | 7.47±0.07 | 1 035.65±51.78 | 4 998.74±0.00 | 671.58±85.58 | 0.21 |

| Q9 | 7.31±0.03 | 1 073.18±55.08 | 4 998.74±76.45 | 785.06±59.25 | 0.21 |

| L0 | 7.41±0.05 | 1 059.40±51.43 | 9 359.35±260.78 | 604.42±40.72 | 0.11 |

| L3 | 7.52±0.13 | 1 214.99±62.01 | 6 869.36±0.00 | 636.92±51.85 | 0.18 |

| L5 | 7.39±0.07 | 1 062.26±53.11 | 7 494.99±170.83 | 762.60±38.13 | 0.14 |

| L7 | 7.38±0.09 | 1 167.95±59.33 | 6 869.36±0.00 | 714.49±70.22 | 0.17 |

| L9 | 7.64±0.06 | 574.53±30.18 | 6 869.36±123.78 | 706.30±30.31 | 0.08 |

| 1 | MA S S, WANG H L, LI L R, et al.. Enhanced biomethane production from corn straw by a novel anaerobic digestion strategy with mechano chemical pretreatment [J/OL]. Renew. Sust. Energ. Rev., 2021, 146:111099 [2021-11-15]. . |

| 2 | KANG X H, ZHANG Y, LIN R C, et al.. Optimization of liquid hot waterpretreatment on Hybrid Pennisetum anaerobic digestion and its effect on energy efficiency [J/OL]. Energy Convers. Manag., 2020, 1: 112718 [2021-11-15]. . |

| 3 | YUAN H R, SONG X C, GUANR L, et al.. Effect of low severity hydrothermal pretreatment on anaerobic digestion performance of corn stover [J/OL]. Bioresour. Technol., 2019, 294:122238 [2021-11-15]. . |

| 4 | 中国统计局.中国统计年鉴2016[M/OL].北京.中国统计出版社,2017.. |

| 5 | 蔡凡凡.设施蔬菜废弃物厌氧消化产甲烷性能的研究[D].北京:北京化工大学,2019. |

| CAI F F. Study on the methane production performance of facilities vegetable wastes during anaerobic digestion [D]. Beijing: Beijing University of Chemical Technology, 2019. | |

| 6 | BOUALLAGUI H, TOUHAMI Y, CHEIKH R B, et al.. Bioreactor performance in anaerobic digestion of fruit and vegetable wastes [J]. Process Biochem., 2005, 40(3/4):989-995. |

| 7 | 曹燕篆,张海波,苏婉,等.MC1预处理对豆秸水解特性及产甲烷效率的影响[J].农业环境科学学报,2020,39(9):2074-2080. |

| CAO Y Z, ZHANG H B, SU W, et al.. Effects of MC1 pretreatment on hydrolysis characteristics and methane production efficiency of soybean straw [J]. J. Agro-Environ. Sci., 2020, 39(9):2074-2080. | |

| 8 | CHEN J X, WANG X, ZHANG B Y, et al.. Integrating enzymatic hydrolysis into subcritical water pretreatment optimization for bioethanol production from wheat straw [J/OL]. Sci. Total Environ., 2021:145321 [2021-11-15] . |

| 9 | 王忠江,邹舰洋,曹振,等.尿素预处理玉米秸秆降解木质素动力学研究[J].农业机械学报,2020,51(11):321-328. |

| WANG Z J, ZOU J Y, CAO Z, et al.. Delignification kinetics of corn stover with urea pretreatment [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(11):321-328. | |

| 10 | WANG J, FENG K, LOUY, et al.. The synergistic effect of potassium ferrate and peroxymonosulfate application on biogas production and shaping microbial community during anaerobic co-digestion of a cow manure-cotton straw mixture [J/OL]. Bioresour. Technol., 2021,333:125166 [2021-11-15]. . |

| 11 | ADGHIM M, SARTAJ M, ABDEHAGH N. Enhancing mono- and co-digestion of poultry manure by a novel post-hydrolysis ammonia stripping approach in a two-stage anaerobic digestion process [J]. Waste Biomass Valorization, 2021, 12(11): 6045-6056. |

| 12 | 王英琪,杨宏志,孟海波,等.沼液预处理玉米秸秆产沼气工艺参数优化[J].农业工程学报,2018,34(23):239-245. |

| WANG Y Q, YANG H Z, MENG H B, et al.. Parameter optimization of corn staw anaerobic digestibility pretreated by biogas slurry [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(23):239-245. | |

| 13 | 李建,刘庆玉,郎咸明,等.响应面法优化沼液预处理玉米秸秆条件的研究[J].可再生能源,2016,34(2):292-297. |

| LI J, LIU Q Y, LANG X M, et al.. Process parameters optimization of maize straw pretreated bybiogas slurry using response surface methodology [J]. Renew Energy Resour., 2016, 34(2):292-297. | |

| 14 | 兰艳艳,朱嘉琳,刘春梅,等.猪粪沼液预处理麦秸厌氧消化性能分析[J].可再生能源,2017,35(8):1135-1142. |

| LAN Y Y, ZHU J L, LIU C M, et al.. Evaluation of anaerobic digestion performance of wheat straw using pig manure liquid fraction of digestate pretreatment [J]. Renew Energy Resour., 2017, 35(8):1135-1142. | |

| 15 | 李平,龙翰威,高立洪,等.不同预处理方式下水稻秸秆厌氧消化性能比较[J].农业工程学报,2015,31(12):200-205. |

| LI P, LONG H W, GAO L H, et al.. Comparison of anaerobic digestion capability of rice straw with different pretreatment methods [J]. Trans. Chin. Soc. Agric. Eng., 2015, 31(12):200-205. | |

| 16 | WEI Y, LI X, YU L, et al.. Mesophilic anaerobic co-digestion of cattle manure and corn stover with biological and chemical pretreatment [J]. Bioresour. Technol., 2015, 198:431-436. |

| 17 | HU Y, PANG Y, YUAN H, et al.. Promoting anaerobic biogasification of corn stover through biological pretreatment by liquid fraction of digestate (LFD) [J]. Bioresour. Technol., 2015, 175:167-173. |

| 18 | 杨斌,殷引,张浩博,等.洗涤剂法测定烟草及烟草制品中中性洗涤纤维、酸性洗涤纤维、酸性洗涤木质素的研究[J].中国烟草学报,2012,18(3):10-15. |

| YANG B, YIN Y, ZHANG H B, et al.. Determination of NDF,ADF and ADL in tobacco and tobacco products with detergent method [J]. Acta Tabacaria Sin., 2012, 18(3):10-15. | |

| 19 | 詹晓燕,刘臣辉,范海燕,等.水体中氨氮测定方法的比较——纳氏试剂光度法、靛酚蓝比色法[J].环境科学与管理,2010,35(11):131-134. |

| ZHAN X Y, LIU C H, FAN H Y, et al.. Comparison between two N-ammoniacal measurements in water—napierian reagent colorimetric method and indophenol-blue colorimetric method [J]. Environ. Sci. Manage., 2010, 35(11):131-134. | |

| 20 | 谢海婷.氯离子对厌氧处理废水中蒸馏法测定VFA的影响[D].郑州:郑州大学,2017. |

| XIE H T. Influences of chlorides on VFA distillation determination in anaerobic reaction [D]. Zhengzhou: Zhengzhou University, 2017. | |

| 21 | ZHONG B, AN X, SHEN F, et al.. Anaerobic co-digestion of rice straw and pig manure pretreated with a cellulolytic microflora: methane yield evaluation and kinetics analysis [J/OL]. Front. Bioeng. Biotechnol., 2021, 8:579405 [2021-11-15]. . |

| 22 | 黄弘毅,薛寒光,李超,等.汽爆预处理对废弃烤后烟叶产甲烷潜力的影响[J].农业环境科学学报,2020,39(8):1854-1861. |

| HUANG H Y, XUE H G, LI C, et al.. Assessment of biomethane production from cured tobacco leaves using steam explosion pretreatment [J]. J. Agro-Environ. Sci., 2020, 39(8):1854-1861. | |

| 23 | KAFLE G K, SANG H K, et al.. Anaerobic treatment of apple waste with swine manure for biogas production: batch and continuous operation [J]. Appl. Energy., 2013, 103(3):61-72. |

| 24 | LEE D H, BEEHERA S K, KIM J W, et al.. Methane production potential of leachate generated from Korean food waste recycling facilities: a lab-scale study [J]. Waste Manage., 2009, 29(2):876-882. |

| 25 | YUAN Y Y, HU X Y, CHEN H B, et al.. Advances in enhanced volatile fatty acid production from anaerobic fermentation of waste activated sludge [J/OL]. Sci. Total Environ., 2019, 694: 133741 [2021-11-15]. . |

| 26 | RYUE J, LIN L, KAKAR F L, et al.. A critical review of conventional and emerging methods for improving process stability in thermophilic anaerobic digestion [J]. Energy Sustain. Dev., 2020, 54: 72-84. |

| 27 | YENIGÜN O, DEMIREL B. Ammonia inhibition in anaerobic digestion: a review [J]. Process Biochem., 2013, 48(5/6):901-911. |

| 28 | 郑子乔,刘双,武月,等.鸡粪沼液预处理对玉米秸秆厌氧消化性能的影响[J].黑龙江畜牧兽医,2020(3):66-70. |

| 29 | BI S J, QIAO W, XIONG L P, et al.. Improved high solid anaerobic digestion of chicken manure by moderate in situ ammonia stripping and its relation to metabolic pathway [J]. Renew. Energy, 2020, 146(2):2380-2389. |

| 30 | ZHANG H, KHALID H, LI W, et al.. Employing response surface methodology (RSM) to improve methane production from cotton stalk [J]. Environ. Sci. Pollut. Res. Int., 2018, 25(8):7618-7624. |

| 31 | 黄开明,赵立欣,冯晶,等.复合微生物预处理玉米秸秆提高其厌氧消化产甲烷性能[J].农业工程学报,2018,34(16):184-189. |

| HUANG K M, ZHAO L X, FENG J, et al.. Pretreatment of corn stalk by composite microbial strain improving its methane production performance by anaerobic digestion [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(16):184-189. | |

| 32 | 赵昆炀,高雄辉,祝其丽,等.厌氧消化处理玉米秸秆酶解残渣对木质素的影响研究[J].农业环境科学学报,2020,39(11):2661-2667. |

| ZHAO K Y, GAO X H, ZHU Q L, et al.. Effect of anaerobic digestion on lignin derived from unhydrolyzed solid of corn stover [J]. J. Agro-Environ. Sci., 2020, 39(11):2661-2667. | |

| 33 | LI J, LIU Q Y, LANG X M, et al.. Process parameters optimization of maize straw pretreated by biogas slurry using response surface methodology [J]. Renew. Energy Resour., 2016, 34(2):292-297. |

| 34 | YUAN X, CAO Y, LI J, et al.. Effect of pretreatment by a microbial consortium on methane production of waste paper and cardboard [J]. Bioresour. Technol., 2012, 118:281-288. |

| 35 | 李秋敏,张无敌,尹芳,等.沼液预处理对废弃花卉秸秆厌氧消化产沼气特性的影响[J].中国沼气,2020,38(3):52-56. |

| LI Q M, ZHANG W D, YIN F, et al.. Effect of biogas slurry pretreatment on biogas production characteristics in anaerobic digestion of waste flower straw [J]. China Biogas, 2020, 38(3):52-56. | |

| 36 | 楚莉莉,李轶冰,冯永忠,等.沼液预处理对小麦秸秆厌氧发酵产气特性的影响[J].干旱地区农业研究,2011,29(1):247-251. |

| CHU L L, LI Y B, FENG Y Z, et al.. Effect of biogas slurry pretreatment on biogas production characteristics of anaerobic fermentation of wheat straw [J]. Agric. Res. Arid Areas, 2011, 29(1):247-251. | |

| 37 | 尹燕,王兴田,杨道兰,等.沼液预处理对花椰菜废弃物厌氧消化的影响[J].中国农机化学报,2017,38(2):114-119. |

| YIN Y, WANG X T, YANG D L, et al.. Effect of biogas slurry pretreatment on anaerobic fermentation of broccoli wastes [J]. J. Chin. Agric. Mech., 2017, 38(2):114-119. | |

| 38 | 魏域芳,李秀金,袁海荣.沼液预处理玉米秸秆与牛粪混合厌氧消化产气性能的研究[J].中国沼气,2018,36(1):39-46. |

| WEI Y F, LI X J, YUAN H R. Anaerobic co-digestion of cattle manure and corn stalk pretreated by digestate slurry [J]. China Biogas, 2018, 36(1):39-46. |

| [1] | Li LIU, Zhongping DU, Yi LI, Laisheng CHEN, Rui HAN. Effect of NaOH Pretreatment on Anaerobic Fermentation Characteristics of Hulless Barley Straw [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 192-200. |

| [2] | XIAO Shengling1, JING Yong1,2, FENG Jing2, SHEN Ruixia2*, ZHAO Lixin2, WANG Quanliang1, ZHANG Ying2. Effect of Wood Biochar on the Methane Production Performance of Anaerobic Fermentation [J]. Journal of Agricultural Science and Technology, 2021, 23(1): 128-135. |

| [3] | SUN Yingcai, DONG Taili*. Land Methane Production Analysis of Energy Maize Under Different Cropping Patterns [J]. Journal of Agricultural Science and Technology, 2018, 20(7): 91-97. |

| [4] | WANG Yang. Bibliometrics Evaluation on Anaerobic Digestion Technology of Straw [J]. Journal of Agricultural Science and Technology, 2017, 19(4): 1-9. |

| [5] | YIN Fu-bin1, JI Chao2, DONG Hong-min1*, TAO Xiu-ping1, CHEN Yong-xing1. Research Progress on Effect of Antibiotic on Anaerobic Digestion Treatment in Animal Manure [J]. Journal of Agricultural Science and Technology, 2016, 18(5): 171-177. |

| [6] | LIU Xiao-ning, HU Zheng-yi, ZHU Chun-you, WANG Jin-zhi, SHI Yi-chao, HUANG Li-ju. Studies on Technology for Controlling Pollutants from Decentralized Duck Breeding at Islet of Baiyangdian [J]. , 1, 1(1): 132-137. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号