Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (1): 129-137.DOI: 10.13304/j.nykjdb.2023.0251

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Qijun TANG1,2,3( ), Xiang XU1,2,3, Kai REN1,2,3, Daqing ZHANG1,2, Ping JIANG1

), Xiang XU1,2,3, Kai REN1,2,3, Daqing ZHANG1,2, Ping JIANG1

Received:2023-04-03

Accepted:2023-06-21

Online:2025-01-15

Published:2025-01-21

唐琦军1,2,3( ), 许祥1,2,3, 任凯1,2,3, 张大庆1,2, 蒋蘋1

), 许祥1,2,3, 任凯1,2,3, 张大庆1,2, 蒋蘋1

作者简介:唐琦军 E-mail:tangqijun293@126.com

基金资助:CLC Number:

Qijun TANG, Xiang XU, Kai REN, Daqing ZHANG, Ping JIANG. Study on Power Consumption Evaluation of Plough Agricultural Machinery in Field Pperation[J]. Journal of Agricultural Science and Technology, 2025, 27(1): 129-137.

唐琦军, 许祥, 任凯, 张大庆, 蒋蘋. 铧式犁农机田间作业过程机具功耗测评研究[J]. 中国农业科技导报, 2025, 27(1): 129-137.

| 参数 Parameter | 数值或类型 Value or type |

|---|---|

| 整机质量Curb weight/kg | 4 155 |

| 整车尺寸(长×宽×高) Overall vehicle size(length×width×hight)/mm | 4 530×2 050×2 810 |

| 轮胎规格(前轮/后轮) Tire size (front/rear) | 11.2-24/16.9-34 |

| 档位数(前进+倒退) Number of gears (forward+reverse) | 16+8 |

| 驱动形式 Drive form | 四轮驱动 Four-wheel drive |

| 柴油机额定功率 Diesel engine rated power/kW | 100 |

| 农机具 Agricultural implement | 五铧犁 Five-share plough |

| 挂接形式 Hook-up form | 三点悬挂 Three-point suspension |

Table 1 Specification of the plough agricultural machinery

| 参数 Parameter | 数值或类型 Value or type |

|---|---|

| 整机质量Curb weight/kg | 4 155 |

| 整车尺寸(长×宽×高) Overall vehicle size(length×width×hight)/mm | 4 530×2 050×2 810 |

| 轮胎规格(前轮/后轮) Tire size (front/rear) | 11.2-24/16.9-34 |

| 档位数(前进+倒退) Number of gears (forward+reverse) | 16+8 |

| 驱动形式 Drive form | 四轮驱动 Four-wheel drive |

| 柴油机额定功率 Diesel engine rated power/kW | 100 |

| 农机具 Agricultural implement | 五铧犁 Five-share plough |

| 挂接形式 Hook-up form | 三点悬挂 Three-point suspension |

| 名称Name | 型号Model | 参数说明Parameter description |

|---|---|---|

| 拉力传感器Tensile force sensor | NOS-C902 | 0~50 kN/0.5% FS |

| GPS仪 GPS instrument | Speedbox-RTK | 0.05 km·h-1 |

| CAN总线分析仪CAN bus analyzer | Kvaser | 波特率Baud rate 40~1 000 kb·s-1 |

| 转速传感器Speed sensor | 霍尔传感器Hall sensor | ±0.1% FS |

| 发动机台架Engine bench | 电涡流测功机 Eddy current dynamometer | 扭矩Torque:±0.5% FS 转速Rotational speed:±0.5 r·min-1 |

Table 2 Main equipment and parameters in the test

| 名称Name | 型号Model | 参数说明Parameter description |

|---|---|---|

| 拉力传感器Tensile force sensor | NOS-C902 | 0~50 kN/0.5% FS |

| GPS仪 GPS instrument | Speedbox-RTK | 0.05 km·h-1 |

| CAN总线分析仪CAN bus analyzer | Kvaser | 波特率Baud rate 40~1 000 kb·s-1 |

| 转速传感器Speed sensor | 霍尔传感器Hall sensor | ±0.1% FS |

| 发动机台架Engine bench | 电涡流测功机 Eddy current dynamometer | 扭矩Torque:±0.5% FS 转速Rotational speed:±0.5 r·min-1 |

| 编号 Number | 变速器档位 Transmission gear | 目标耕作速度 Target tillage speed/(km·h-1) | 耕深 Tillage depth/cm |

|---|---|---|---|

| 1 | 高档,慢速,主变速三档 High, slow, gear Ⅲ | 5.7 | 23 |

| 2 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 7.1 | 23 |

| 3 | 低档,快速,主变速二档 Low, fast, gear Ⅱ | 8.9 | 23 |

| 4 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 5.7 | 20 |

| 5 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 5.7 | 26 |

Table 3 Field experimental scheme for the plough agricultural machinery

| 编号 Number | 变速器档位 Transmission gear | 目标耕作速度 Target tillage speed/(km·h-1) | 耕深 Tillage depth/cm |

|---|---|---|---|

| 1 | 高档,慢速,主变速三档 High, slow, gear Ⅲ | 5.7 | 23 |

| 2 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 7.1 | 23 |

| 3 | 低档,快速,主变速二档 Low, fast, gear Ⅱ | 8.9 | 23 |

| 4 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 5.7 | 20 |

| 5 | 低档,快速,主变速一档 Low, fast, gear Ⅰ | 5.7 | 26 |

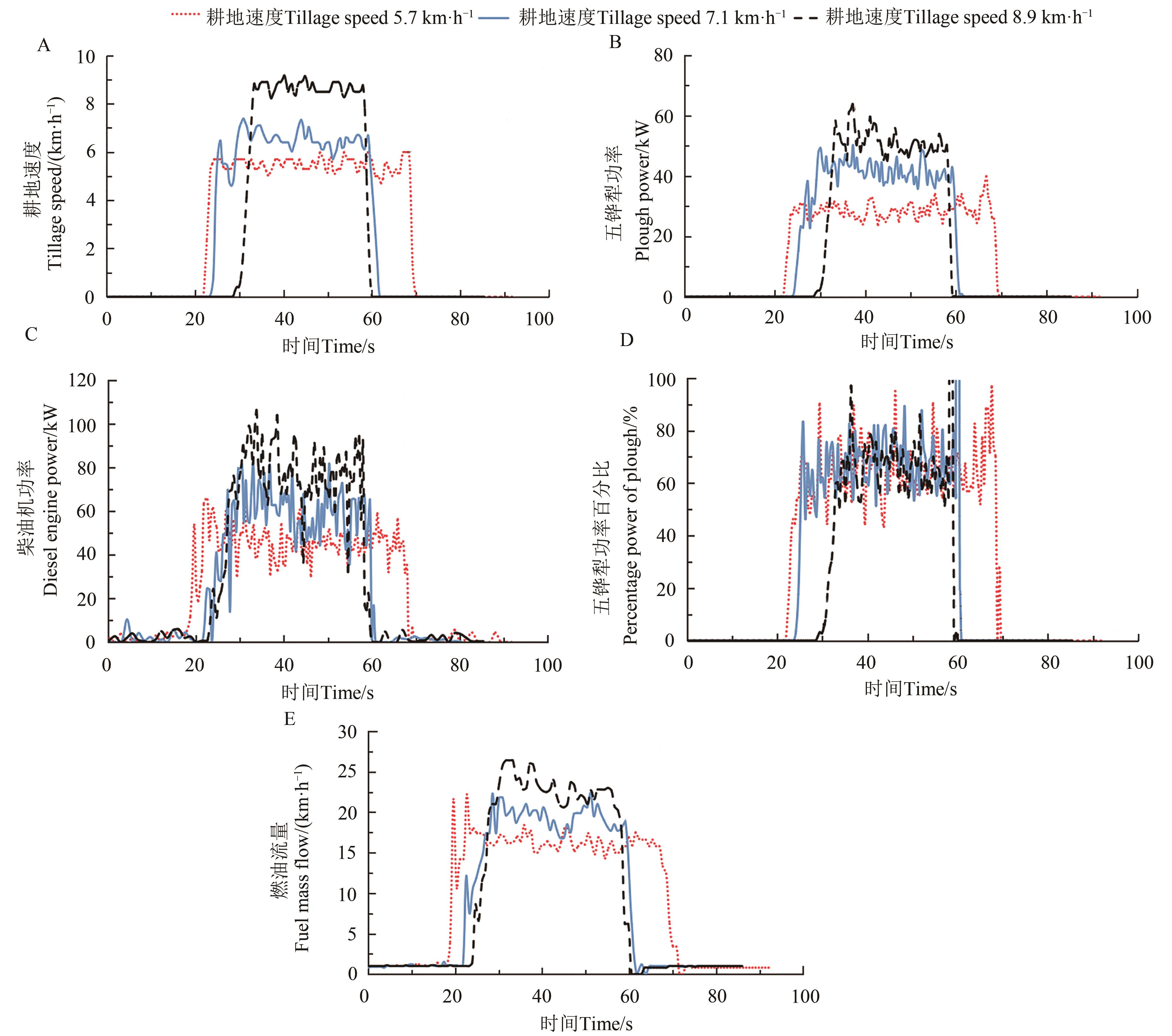

Fig. 3 Test results of different tillage speed of the plough agricultural machineryA:Tillage speed; B:Five-furrow plough power; C:Diesel engine power; D: Five-furrow plough power accounts for the percentage of the diesel engine power; E:Fuel consumption of the plough agricultural machinery

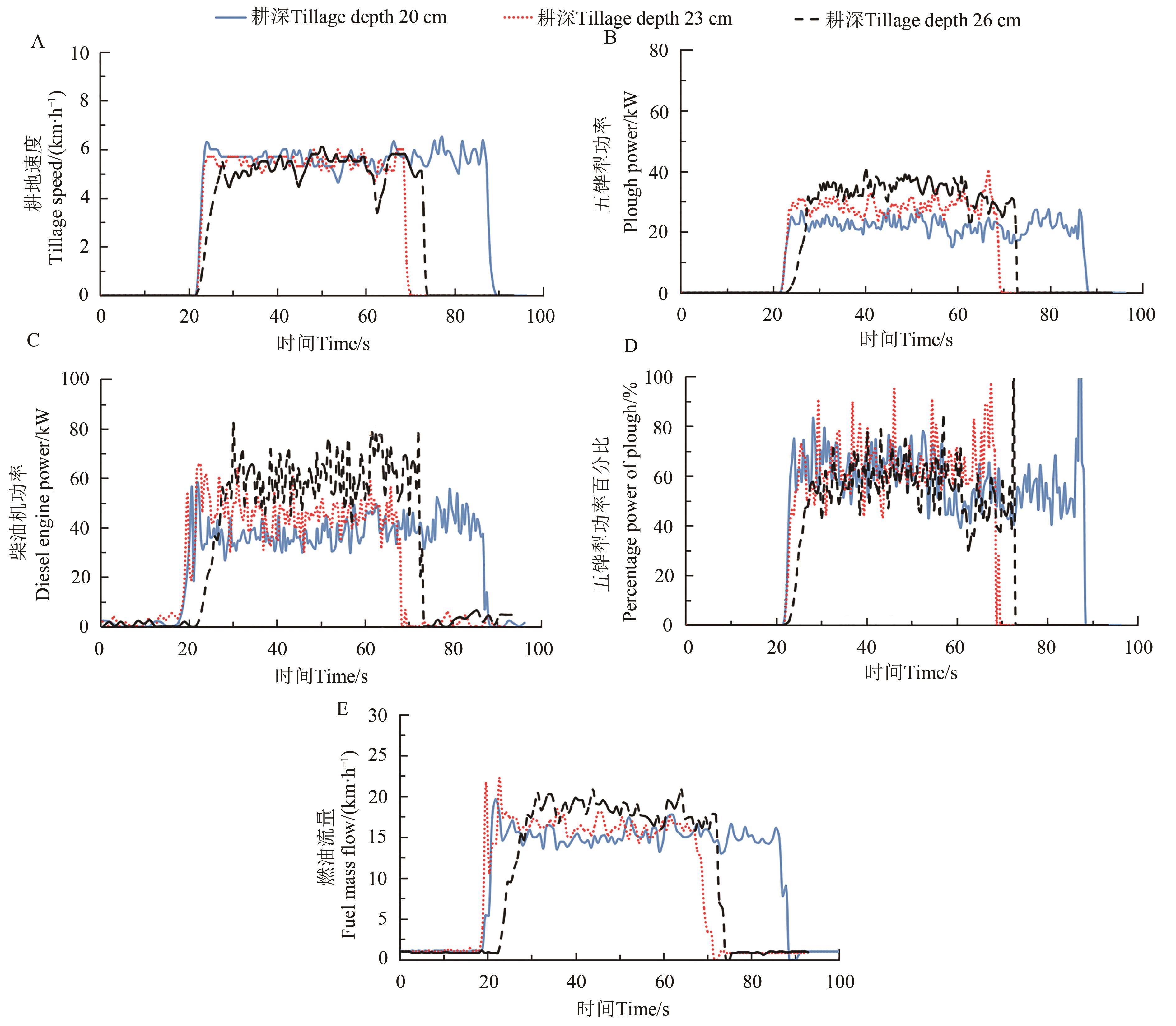

Fig. 4 Test results of different tillage depth of the plough agricultural machineryA:Tillage speed; B:Five-furrow plough power; C:Diesel engine power; D: Five-furrow plough power accounts for the percentage of the diesel engine power; E:Fuel consumption of the plough agricultural machinery

| 编号 Number | 时间 Time/s | 耕地速度 Tillage speed/ (km·h-1) | 铧犁功耗 Plough power/kW | 柴油机功率 Diesel engine power/kW | 铧犁功率比 Plough power ratio/% | 油耗 Fuel mass flow/(kg·h-1) |

|---|---|---|---|---|---|---|

| 1 | 19.61~66.96 | 5.48 | 28.65 | 45.19 | 64.72 | 16.37 |

| 2 | 28.60~59.17 | 6.44 | 40.78 | 59.88 | 67.30 | 19.45 |

| 3 | 31.68~57.43 | 8.69 | 51.44 | 77.52 | 66.10 | 22.97 |

| 4 | 21.03~86.44 | 5.65 | 22.19 | 38.75 | 58.28 | 15.26 |

| 5 | 29.11~71.98 | 5.28 | 33.25 | 60.75 | 56.24 | 18.28 |

Table 4 Average value of the performance parameters of the plough agricultural machinery

| 编号 Number | 时间 Time/s | 耕地速度 Tillage speed/ (km·h-1) | 铧犁功耗 Plough power/kW | 柴油机功率 Diesel engine power/kW | 铧犁功率比 Plough power ratio/% | 油耗 Fuel mass flow/(kg·h-1) |

|---|---|---|---|---|---|---|

| 1 | 19.61~66.96 | 5.48 | 28.65 | 45.19 | 64.72 | 16.37 |

| 2 | 28.60~59.17 | 6.44 | 40.78 | 59.88 | 67.30 | 19.45 |

| 3 | 31.68~57.43 | 8.69 | 51.44 | 77.52 | 66.10 | 22.97 |

| 4 | 21.03~86.44 | 5.65 | 22.19 | 38.75 | 58.28 | 15.26 |

| 5 | 29.11~71.98 | 5.28 | 33.25 | 60.75 | 56.24 | 18.28 |

| 编号 Number | 时间 Time/s | 铧犁功率循环变动率 Coefficient of variation of plough power/% | 柴油机功率循环变动率 Coefficient of variation of diesel engine power/% | 铧犁功率比循环变动率 Coefficient of variation of rate of plough power/% |

|---|---|---|---|---|

| 1 | 19.61~66.96 | 9.57 | 14.18 | 16.47 |

| 2 | 28.60~59.17 | 8.30 | 17.87 | 13.23 |

| 3 | 31.68~57.43 | 8.15 | 17.65 | 13.37 |

| 4 | 21.03~86.44 | 11.59 | 14.04 | 17.16 |

| 5 | 29.11~71.98 | 11.15 | 15.91 | 19.84 |

| 平均值 Average value | 9.75 | 15.93 | 16.01 | |

Table 5 Change rate of the performance parameters of the plough agricultural machinery

| 编号 Number | 时间 Time/s | 铧犁功率循环变动率 Coefficient of variation of plough power/% | 柴油机功率循环变动率 Coefficient of variation of diesel engine power/% | 铧犁功率比循环变动率 Coefficient of variation of rate of plough power/% |

|---|---|---|---|---|

| 1 | 19.61~66.96 | 9.57 | 14.18 | 16.47 |

| 2 | 28.60~59.17 | 8.30 | 17.87 | 13.23 |

| 3 | 31.68~57.43 | 8.15 | 17.65 | 13.37 |

| 4 | 21.03~86.44 | 11.59 | 14.04 | 17.16 |

| 5 | 29.11~71.98 | 11.15 | 15.91 | 19.84 |

| 平均值 Average value | 9.75 | 15.93 | 16.01 | |

| 1 | 邵雪冬, 杨子涵, 宋正河,等. 不同旋耕作业载荷下拖拉机动力输出传动系振动特性分析[J]. 农业机械学报, 2022, 53():332-339. |

| SHAO X D, YANG Z H, SONG Z H, et al.. Analysis of influence of tractor rotary tillage load on power take-off driveline [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(S1):332-339. | |

| 2 | 杨子涵,宋正河,尹宜勇,等.基于POT模型的大功率拖拉机传动轴载荷时域外推方法[J].农业工程学报,2019,35(15):40-47. |

| YANG Z H, SONG Z H, YIN Y Y, et al.. Time domain extrapolation method for load of drive shaft of high-power tractor based on POT model [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(15): 40-47. | |

| 3 | 李淑艳,翟友邦,王小龙,等.基于核密度估计的拖拉机传动轴载荷外推方法[J].中国农业大学学报,2021,26(10):175-184. |

| LI S Y, ZHAI Y B, WANG X L, et al.. An extrapolation method of tractor propeller shaft load based on kernel density estimation [J]. J. China Agric. Univ., 2021,26(10):175-184. | |

| 4 | KIM Y S, KIM W S, BAEK S Y, et al.. Analysis of tillage depth and gear selection for mechanical load and fuel efficiency of an agricultural tractor using an agricultural field measuring system [J/OL]. Sensors, 2020, 20(9): 2450 [2023-03-03]. . |

| 5 | 唐琦军,常宏博,蒋蘋,等.基于转矩模型的柴油机功率在线测试方法研究[J].农业机械学报,2020,51(): 571-578. |

| TANG Q J, CHANG H B, JIANG P, et al.. Online measurement method of diesel engine power based on torque model [J]. Trans. Chin. Soc. Agric. Mach., 2020,51(S2):571-578. | |

| 6 | 陈济勤. 农业机器运用管理学[M]. 第二版. 北京:中国农业出版社, 1997:122-135. |

| 7 | RAJABI-VANDECHALI M, ABBASPOUR-FARD M H, ROHANI A. Development of a prediction model for estimating tractor engine torque based on soft computing and low cost sensors [J]. Measurement, 2018, 121: 83-95. |

| 8 | 刘洪利,王熙. 基于CAN总线的拖拉机机组作业性能分析[J].农业机械学报,2016,47():30-34. |

| LIU H L, WANG X. Analysis of tractor working performace based on CAN bus [J]. Trans. Chin. Soc. Agric. Mach., 2016,47(S1):30-34. | |

| 9 | 翟力欣,姬长英,丁启朔,等.耕作过程中土壤应力场分布的实验研究[J].农机化研究,2014,36(1): 165-169, 173. |

| ZHAI L X, JI C Y, DING Q S, et al.. Stress distribution of soil in the process of soil tillage based on the experiment [J]. J. Agric. Mechan. Res., 2014,36(1):165-169, 173. | |

| 10 | MARI Irshad Ali. 铧式犁作用下的水田土壤三维形变及牵引力研究[D]. 南京: 南京农业大学,2014. |

| MARI I A. Study of three dimensional soil deformation and draught forces on mouldboard plough [D]. Nanjing : Nanjing Agricultural University, 2014. | |

| 11 | SLIMAŘÍK D, SEDLÁK P, DOSTÁL P. Draft sensor loading analysis [J]. Acta Univ. Agric. Et Silviculturae Mendelianae Brunensis, 2014, 62(5): 1103-1108. |

| 12 | KEEN A, GHOLKAR M D, WARD J, et al.. Force measurement between a tractor and a three point linkage mounted cultivation implement [C]// Proceedings of the 10th International Agricultural Engineering Conference. Role of agricultural engineering in advent of changing global landscape. Asian Association for Agricultural Engineering, 2009. |

| 13 | SLIMAŘÍK D, DOSTÁL P, POLCAR A. Static testing of draft sensor for three point hitch dynamometer utilization [J]. Acta Univ. Agric. Et Silviculturae Mendelianae Brunensis, 2015, 63: 835-839. |

| 14 | 王禹,王玲,吕东晓,等.基于FDR阈值自动选取的拖拉机PTO转矩载荷谱外推[J].农业机械学报,2021,52(3):364-372. |

| WANG Y, WANG L, LYU D X, et al.. Extrapolation of tractor PTO torque load spectrum based on automated threshold selection with FDR [J]. Trans. Chin. Soc. Agric. Mach.,2021,52(3):364-372. | |

| 15 | 翟新婷,张晓晨,江柱锦,等.基于混合分布的轮式装载机半轴载荷谱编制[J].农业工程学报,2018,34(8):78-84. |

| ZHAI X T, ZHANG X C, JIANG Z J, et al.. Load spectrum compiling for wheel loader semi-axle based on mixed distribution [J].Trans. Chin. Soc. Agric. Eng., 2018,34(8):78-84. | |

| 16 | 王玲,宗建华,王禹,等.基于最优分布拟合的拖拉机三点悬挂牵引力载荷谱编制与台架试验[J].农业工程学报,2022,38(2):41-49. |

| WANG L, ZONG J H, WANG Y, et al.. Compilation and bench test of traction force load spectrum of tractor three-point hitch based on optimal distribution fitting [J]. Trans. Chin. Soc. Agric. Eng., 2022,38(2):41-49. | |

| 17 | CEROVİĆ V, MILKOVIĆ D, ALEKSANDAR G, et al.. 2D analytical model for evaluation of the forces in the three point hitch mechanism [J]. J. Agric. Sci., 2020, 26(3): 271-281. |

| 18 | CEROVIĆ V, MILKOVIĆ D, GRBOVIĆ A, et al.. Measurement of the stress state in the lower link of the three-point hitch mechanism [M]// Experimental and Numerical Investigations in Materials Science and Engineering. Springer, Cham, 2018: 112-121. |

| 19 | PORTEŠ P, BAUER F, ČUPERA J. Analysis of measured and computed force effects in tractor’s three-point linkage during tillage [C]//18th International Conference Engineering Mechanics 2012, 2012: 1033-1040. |

| 20 | PORTEŠ P, BAUER F, ČUPERA J. Laboratory-experimental verification of calculation of force effects in tractor’s three-point hitch acting on driving wheels [J]. Soil Tillage Res., 2013, 128: 81-90. |

| 21 | JEON H H, JUNG Y J, SIDDIQUE M A A, et al.. Development and validation of simulation model for three point-hitch during agricultural operation [C]//2019 ASABE Annual International Meeting. American Society of Agricultural and Biological Engineers, 2019. |

| 22 | 康云友, 张道林, 鹿秀凤,等. 玉米籽粒机械化直收技术与机具试验研究[J]. 农机化研究, 2019, 41(4):176-181. |

| KANG Y Y, ZHANG D L, LU X F, et al.. Experimental study on mechanized directly harvesting technology and mechinery for corn grain [J]. J. Agric. Mechan. Res., 2019, 41(4):176-181. | |

| 23 | 刘明勇,胡成龙,谢柏林. 基于离散元法的铧式犁仿真优化分析及试验[J]. 浙江农业学报,2022,34(11):2542-2552. |

| LIU M Y, HU C L, XIE B L. Simulation and optimization analysis and experiment of split plough based on discrete ele-ment method [J]. Acta Agric. Zhejiangensis, 2022,34(11):2542-2552. | |

| 24 | 张启森. 拖拉机驱动系统对其性能和油耗的影响及试验研究[J]. 农机化研究,2024,46(2):249-254, 259. |

| ZHANG Q S. Effect of tractor drive system on its performance and fuel consumption and experimental study [J]. J. Agric. Mechan. Res., 2024,46(2):249-254, 259. |

| [1] | Zizhong SHI, Xiangdong HU. Theoretical Logic and Strategic Path of Accelerating the Construction of Livestock Powerhouse [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 1-12. |

| [2] | Wenzhong GAO, Yi ZHANG. Operational Optimization of CCHP Systems on Deep Reinforcement Learning Under Influence of Demand Charge [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 100-109. |

| [3] | Ruiting JIA, Limin YUAN, Zhongju MENG. Effects of Plant Measures on Soil Improvement of Desert Photovoltaic Power Station [J]. Journal of Agricultural Science and Technology, 2023, 25(10): 182-188. |

| [4] | Yu WANG, Ling WANG, Jianhua ZONG, Dongxiao LYU, Shumao WANG. Design and Experiment of Dynamic Loading Bench for Tractor [J]. Journal of Agricultural Science and Technology, 2022, 24(1): 91-97. |

| [5] | LI Siqingaowa, WANG Chunguang, DU Haifeng, JIN Eerdumutu. Research on Cutting Performance of Convex Arc Blade [J]. Journal of Agricultural Science and Technology, 2021, 23(12): 94-100. |

| [6] | LIU Yu, LIU Yuping, ZHANG Tuo. Load Analysis of Rotary Cutter Shaft for Power Tiller Based on DEM and MBD Theory [J]. Journal of Agricultural Science and Technology, 2020, 22(11): 79-86. |

| [7] | ZHOU Zhijiang1,2, CHEN Mingliang2, YANG Peijuan2. Establishment and Optimization of Tissue Culture System for Nandina domestica ‘Fire power’ [J]. Journal of Agricultural Science and Technology, 2019, 21(1): 164-168. |

| [8] | CHEN Xiaodong, CHU Qingquan*. Research on Planning of Ecological Agricultural Park PV-Powered Based on Health-oriented Agriculture [J]. Journal of Agricultural Science and Technology, 2017, 19(10): 45-51. |

| [9] | YANG Yan-tao, QIN Fu*. Estimation of International Market Pricing Power and Countermeasure Research on China's Corn Import [J]. Journal of Agricultural Science and Technology, 2016, 18(3): 195-200. |

| [10] | WEI Xun1, MA Zhong2, JIA Jing-dun1, JIN Shu-qin3. Comparative Studies on Comprehensive Economic Cost of Wood-based Biomass-fired and Coal-fired Cogeneration Plant [J]. , 2012, 14(1): 122-130. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号