Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (9): 131-144.DOI: 10.13304/j.nykjdb.2024.0266

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Xiang DAI1,2( ), Haichao SONG1(

), Haichao SONG1( ), Chuan SU1

), Chuan SU1

Received:2024-04-02

Accepted:2024-07-02

Online:2025-09-15

Published:2025-09-24

Contact:

Haichao SONG

通讯作者:

宋海潮

作者简介:代祥 E-mail: 18852089528@139.com;

基金资助:CLC Number:

Xiang DAI, Haichao SONG, Chuan SU. Design and Experiment of Self-propelled Garlic Vertically-planting and Fertilizing Integrated Machine[J]. Journal of Agricultural Science and Technology, 2025, 27(9): 131-144.

代祥, 宋海潮, 苏川. 自走式大蒜正芽播种施肥机设计与试验[J]. 中国农业科技导报, 2025, 27(9): 131-144.

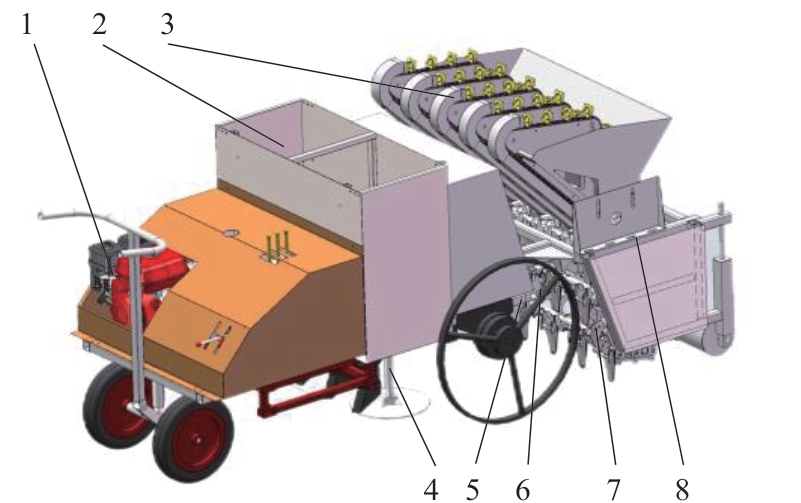

Fig. 1 Overall structure diagram and the virtual prototypeNote: 1—Power system; 2—Automatic fertilization system; 3—Single-seed fetching system; 4—Hydraulic system; 5—Frame; 6—Automatic pesticide spraying system; 7—Vertically-planting system; 8—Tailstock frame.

| 参数 Parameter | 数值 Value |

|---|---|

| 整机尺寸Overall size/mm | 2 360×1 150×1 050 |

| 播种行数Number of seeded rows | 5 |

| 施肥行数Number of fertilization rows | 4 |

| 播种行距Seeding row spacing/mm | 180 |

| 标准株距Standard plant spacing (DP)/mm | 120 |

| 理论播种速度Theoretical seeding rate(Vb) /(m·min-1) | 10~20 |

| 理论播种深度Theoretical seeding depth/cm | <6 |

| 作业生产率Working productivity | 0.08 |

| 施肥深度Fertilization depth/cm | <6 |

| 施药喷头数Number of nozzles | 2 |

Table 1 Technical parameters for the prototype

| 参数 Parameter | 数值 Value |

|---|---|

| 整机尺寸Overall size/mm | 2 360×1 150×1 050 |

| 播种行数Number of seeded rows | 5 |

| 施肥行数Number of fertilization rows | 4 |

| 播种行距Seeding row spacing/mm | 180 |

| 标准株距Standard plant spacing (DP)/mm | 120 |

| 理论播种速度Theoretical seeding rate(Vb) /(m·min-1) | 10~20 |

| 理论播种深度Theoretical seeding depth/cm | <6 |

| 作业生产率Working productivity | 0.08 |

| 施肥深度Fertilization depth/cm | <6 |

| 施药喷头数Number of nozzles | 2 |

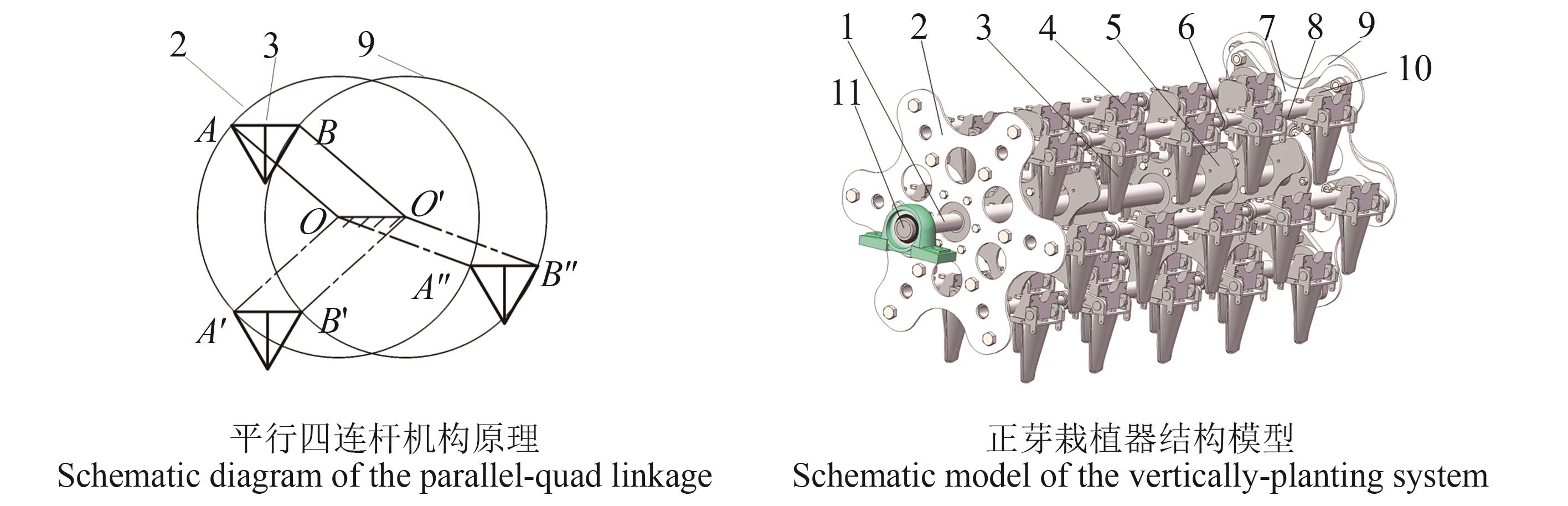

Fig. 3 Vertically-planting systemNote:1—Power shaft of the system; 2, 7—The first planting disc; 3—Insert duck bills; 4—Inoculate duckbill opening disc; 5—Opener disc for duckbill; 6—Duckbill opening disc bearing; 8—Duckbill mounted crankshaft; 9—The second planting disc; 10—Crankshaft slewing bearing; 11—Planter mounted bearings.

Fig. 4 Plant duckbills and the design process of the disc type duckbill openerNote:1—Moving part of duckbill; 2—Static part of duckbill; 3—Duckbill opening bearing; 4—Duckbill opening disc; 5—Crankshaft slewing bearing; 6—Duckbill mounted crankshaft; 7—The first planting disc.

序号 Action phase | 鸭嘴整体位置 Position of duckbill | 鸭嘴打开轴承相对位置 Position of duckbill opening disc bearing | 鸭嘴状态 Status of duckbill | 对应边缘曲线 Corresponding edge curve |

|---|---|---|---|---|

| Ⅰ | 最低端逐步上移 Moving up from the bottom | 从C点运动至D点 From position C to D | 鸭嘴逐步打开 Duckbill opening gradually | d2~d3 |

| Ⅱ | 逐步上移 Moving up | D点 Position D | 鸭嘴完全打开 Duckbill opened completely | d3~d4 |

| Ⅲ | 逐步上移 Moving up | 从D点运动至C点 From position D to C | 鸭嘴逐步关闭 Duckbill closing gradually | d4~d5 |

| Ⅳ | 逐步运动至最低端 Cycle to the very bottom | C点 Position C | 鸭嘴完全关闭 Duckbill closed completely | d5~d6~d7~d1 |

Table 2 Action timing table for duckbill

序号 Action phase | 鸭嘴整体位置 Position of duckbill | 鸭嘴打开轴承相对位置 Position of duckbill opening disc bearing | 鸭嘴状态 Status of duckbill | 对应边缘曲线 Corresponding edge curve |

|---|---|---|---|---|

| Ⅰ | 最低端逐步上移 Moving up from the bottom | 从C点运动至D点 From position C to D | 鸭嘴逐步打开 Duckbill opening gradually | d2~d3 |

| Ⅱ | 逐步上移 Moving up | D点 Position D | 鸭嘴完全打开 Duckbill opened completely | d3~d4 |

| Ⅲ | 逐步上移 Moving up | 从D点运动至C点 From position D to C | 鸭嘴逐步关闭 Duckbill closing gradually | d4~d5 |

| Ⅳ | 逐步运动至最低端 Cycle to the very bottom | C点 Position C | 鸭嘴完全关闭 Duckbill closed completely | d5~d6~d7~d1 |

Fig. 5 Schematic diagram of the garlic storage tank and the single-garlic picking mechanismNote: 1—Garlic seed guard; 2—The third sprocket; 3—Seed chain; 4—Seed spoon; 5—Garlic box; 6—The second sprocket; 7—The first sprocket; 8—Seed groove; 9—Leak-proof cylinder; 10—Mounting bracket.

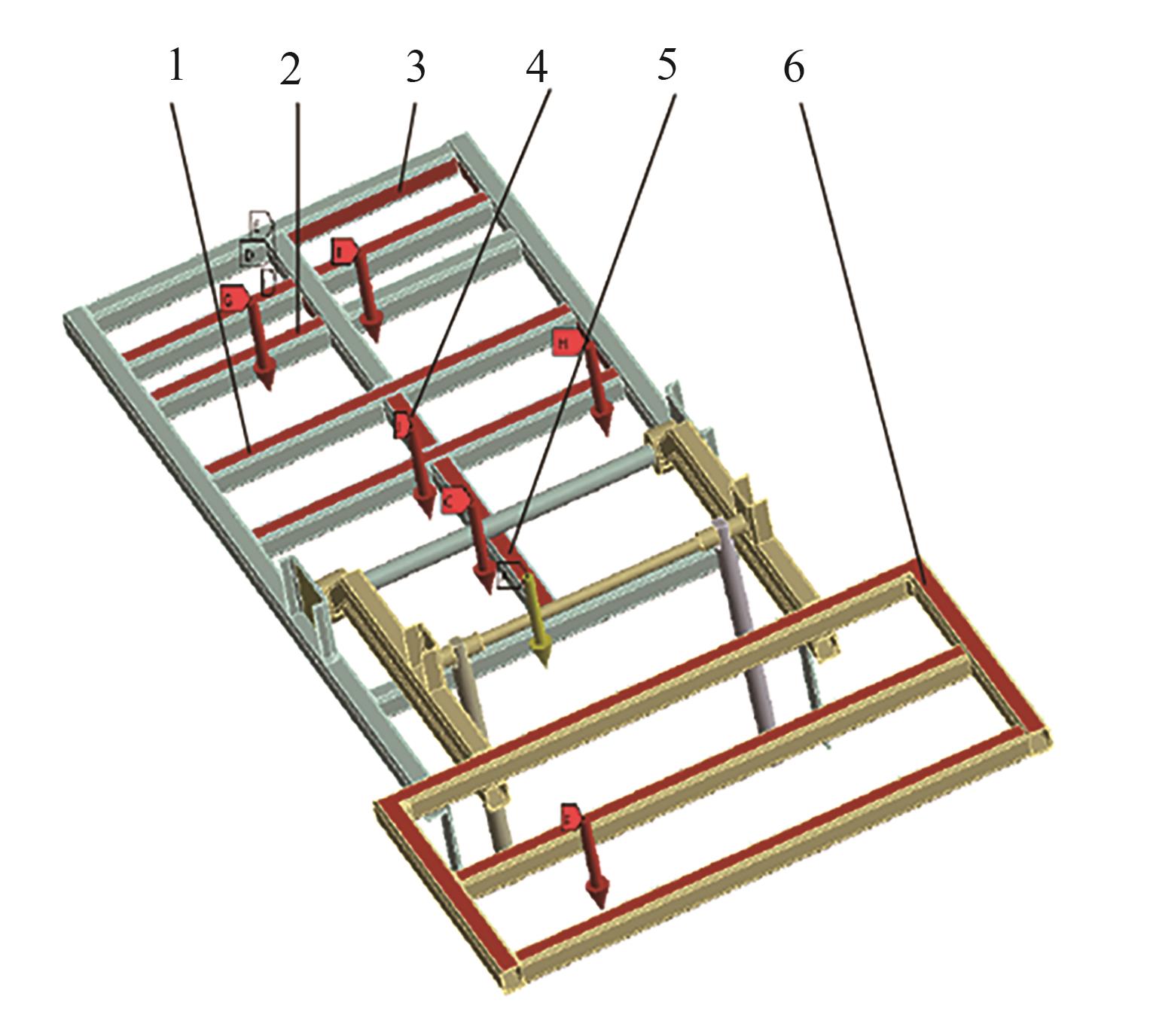

Fig. 7 Loads and constraints of rear tailstock assemblyNote: 1—Bearing position of fertilization system; 2—Bearing position of gearbox and hydraulic source; 3—Bearing position of engine and reducer; 4—Bearing position of main hydraulic cylinder; 5—Bearing position of pesticide application system; 6—Bearing position of storage tank, single-seed fetching and vertically-planting system.

水平 Level | 因素Factor | |

|---|---|---|

| A:播种速度Seeding speed/(m·min-1) | B:播种深度Seeding depth/cm | |

| 1 | 12 | 4 |

| 2 | 15 | 5 |

| 3 | 18 | 6 |

Table 3 Design of multifactor positive bud planting experiment

水平 Level | 因素Factor | |

|---|---|---|

| A:播种速度Seeding speed/(m·min-1) | B:播种深度Seeding depth/cm | |

| 1 | 12 | 4 |

| 2 | 15 | 5 |

| 3 | 18 | 6 |

| 编号NO. | 钢材型号(高×宽×厚)[ Steel type (height×width×thickness)/mm[ | 最大等效应力 Maximum equivalent stress/MPa | 1阶固有频率Natural frequency of the 1st order/Hz | 2阶固有频率Natural frequency of the 2nd order/Hz | 3阶固有频率Natural frequency of the 3rd order/Hz | 4阶固有频率Natural frequency of the 4th order/Hz | 5阶固有频率Natural frequency of the 5th order/Hz | 6阶固有频率Natural frequency of the 6th order/Hz | 机架和后尾架合计质量Total mass of frame and tailstock frame/kg | |

|---|---|---|---|---|---|---|---|---|---|---|

机架 Frame | 后尾架Tailstock frame | |||||||||

| 1 | 40×40×3 | 40×40×3 | 563.10 | 14.36 | 28.55 | 33.52 | 46.46 | 61.00 | 65.14 | 61.44 |

| 2 | 40×40×4 | 40×40×3 | 308.20 | 18.23 | 27.44 | 38.96 | 55.05 | 66.75 | 68.97 | 69.68 |

| 3 | 40×40×4 | 40×40×4 | 281.40 | 13.57 | 17.22 | 36.68 | 58.97 | 60.24 | 86.20 | 75.29 |

| 4 | 50×50×4 | 50×50×3 | 273.50 | 12.52 | 16.58 | 34.53 | 57.68 | 61.23 | 79.65 | 86.15 |

| 5 | 50×50×4 | 50×50×4 | 259.23 | 11.71 | 16.75 | 33.95 | 59.63 | 62.34 | 82.34 | 93.69 |

Table 4 Maximum equivalent stress and natural frequencies caused by the structure of frame and rear tailstock assembly of differing structural sizes

| 编号NO. | 钢材型号(高×宽×厚)[ Steel type (height×width×thickness)/mm[ | 最大等效应力 Maximum equivalent stress/MPa | 1阶固有频率Natural frequency of the 1st order/Hz | 2阶固有频率Natural frequency of the 2nd order/Hz | 3阶固有频率Natural frequency of the 3rd order/Hz | 4阶固有频率Natural frequency of the 4th order/Hz | 5阶固有频率Natural frequency of the 5th order/Hz | 6阶固有频率Natural frequency of the 6th order/Hz | 机架和后尾架合计质量Total mass of frame and tailstock frame/kg | |

|---|---|---|---|---|---|---|---|---|---|---|

机架 Frame | 后尾架Tailstock frame | |||||||||

| 1 | 40×40×3 | 40×40×3 | 563.10 | 14.36 | 28.55 | 33.52 | 46.46 | 61.00 | 65.14 | 61.44 |

| 2 | 40×40×4 | 40×40×3 | 308.20 | 18.23 | 27.44 | 38.96 | 55.05 | 66.75 | 68.97 | 69.68 |

| 3 | 40×40×4 | 40×40×4 | 281.40 | 13.57 | 17.22 | 36.68 | 58.97 | 60.24 | 86.20 | 75.29 |

| 4 | 50×50×4 | 50×50×3 | 273.50 | 12.52 | 16.58 | 34.53 | 57.68 | 61.23 | 79.65 | 86.15 |

| 5 | 50×50×4 | 50×50×4 | 259.23 | 11.71 | 16.75 | 33.95 | 59.63 | 62.34 | 82.34 | 93.69 |

| 机具行进速度Prototype moving speed/(m·min-1) | 取种速度/(株·s-1) Seeds fetching speed/(plant·s-1) | 播种深度 Seeding depth/cm | 重播率PC/% | 漏播率PL/% | 合格率PH/% | 正芽率PZ/% | 播深合格率PS/% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | F | S | F | S | F | S | F | S | F | |||

| 12 | 1.67 | 4 | 5.6 | 3.8 | 6.0 | 7.8 | 88.4 | 88.4 | — | 80.7 | — | 86.6 |

| 12 | 1.67 | 5 | 6.8 | 4.6 | 4.2 | 6.2 | 89.0 | 89.2 | — | 84.5 | — | 92.5 |

| 12 | 1.67 | 6 | 7.2 | 5.3 | 2.2 | 3.5 | 90.6 | 91.2 | — | 86.6 | — | 93.5 |

| 15 | 2.08 | 4 | 4.1 | 2.7 | 5.9 | 8.5 | 90.0 | 88.8 | — | 79.4 | — | 90.6 |

| 15 | 2.08 | 5 | 5.0 | 2.6 | 3.4 | 6.9 | 91.6 | 90.5 | — | 84.3 | — | 91.4 |

| 15 | 2.08 | 6 | 5.2 | 3.0 | 2.5 | 4.0 | 92.3 | 93.0 | — | 85.3 | — | 92.8 |

| 18 | 2.50 | 4 | 2.8 | 2.0 | 9.4 | 10.8 | 87.8 | 87.2 | — | 80.2 | — | 91.3 |

| 18 | 2.50 | 5 | 3.9 | 2.2 | 5.9 | 7.5 | 90.2 | 90.3 | — | 84.0 | — | 92.1 |

| 18 | 2.50 | 6 | 4.3 | 2.5 | 3.1 | 5.1 | 92.6 | 92.4 | — | 84.8 | — | 92.5 |

Table 5 Test results at different drilling rates

| 机具行进速度Prototype moving speed/(m·min-1) | 取种速度/(株·s-1) Seeds fetching speed/(plant·s-1) | 播种深度 Seeding depth/cm | 重播率PC/% | 漏播率PL/% | 合格率PH/% | 正芽率PZ/% | 播深合格率PS/% | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | F | S | F | S | F | S | F | S | F | |||

| 12 | 1.67 | 4 | 5.6 | 3.8 | 6.0 | 7.8 | 88.4 | 88.4 | — | 80.7 | — | 86.6 |

| 12 | 1.67 | 5 | 6.8 | 4.6 | 4.2 | 6.2 | 89.0 | 89.2 | — | 84.5 | — | 92.5 |

| 12 | 1.67 | 6 | 7.2 | 5.3 | 2.2 | 3.5 | 90.6 | 91.2 | — | 86.6 | — | 93.5 |

| 15 | 2.08 | 4 | 4.1 | 2.7 | 5.9 | 8.5 | 90.0 | 88.8 | — | 79.4 | — | 90.6 |

| 15 | 2.08 | 5 | 5.0 | 2.6 | 3.4 | 6.9 | 91.6 | 90.5 | — | 84.3 | — | 91.4 |

| 15 | 2.08 | 6 | 5.2 | 3.0 | 2.5 | 4.0 | 92.3 | 93.0 | — | 85.3 | — | 92.8 |

| 18 | 2.50 | 4 | 2.8 | 2.0 | 9.4 | 10.8 | 87.8 | 87.2 | — | 80.2 | — | 91.3 |

| 18 | 2.50 | 5 | 3.9 | 2.2 | 5.9 | 7.5 | 90.2 | 90.3 | — | 84.0 | — | 92.1 |

| 18 | 2.50 | 6 | 4.3 | 2.5 | 3.1 | 5.1 | 92.6 | 92.4 | — | 84.8 | — | 92.5 |

| [1] | 柳平增, 张艳, 张超, 等. 我国大蒜市场与产业调查分析报告[J]. 农产品市场, 2021(11): 55-56. |

| [2] | 孔素萍, 孙敬强, 吴雄, 等. 大蒜主要农艺性状变异特征及其与产量相关构成分析[J]. 中国农业科学, 2015, 48(6): 1240-1248. |

| KONG S P, SUN J Q, WU X, et al.. Analysis of relationship between variations of main agronomic traits and yield in garlic [J]. Sci. Agric. Sin., 2015, 48(6): 1240-1248. | |

| [3] | 崔荣江, 黄嘉宝, 张振河, 等. 大蒜机械化播种技术研究现状[J]. 农业装备与车辆工程, 2018, 56(6): 54-56. |

| CUI R J, HUANG J B, ZHANG Z H, et al.. Research status of garlic mechanized sowing technology [J]. Agric. Equip. Veh. Eng., 2018, 56(6): 54-56. | |

| [4] | 代祥, 宋海潮, 于林惠, 等. 自走式大蒜播种施肥一体机优化设计与试验[J]. 中国农机化学报, 2023, 44(7): 16-25. |

| DAI X, SONG H C, YU L H, et al.. Optimized design and experiment of the self-propelled garlic drilling and fertilizing integrated machine [J]. J. Chin. Agric. Mech., 2023, 44(7): 16-25. | |

| [5] | 信嘉程. 基于视觉识别的大蒜正芽机构设计与试验研究[D]. 杭州: 浙江理工大学, 2023. |

| XIN J C. Design and experimental study of positive bud garlic mechanism based on visual recognition [D]. Hangzhou: Zhejiang Sci-Tech University, 2023. | |

| [6] | 栗晓宇. 大蒜播种关键技术与装置的研究[D]. 泰安: 山东农业大学, 2019. |

| LI X Y. Research on key technologies and devices of garlic planting [D]. Tai’an: Shandong Agriculture University, 2022. | |

| [7] | 田林. 基于图像识别技术的蒜种定向装置设计与试验[D]. 泰安: 山东农业大学, 2020. |

| TIAN L. Design and experiment of garlic seed orientation device based on image recognition technology [D]. Tai’an: Shandong Agriculture University, 2020. | |

| [8] | 荐世春, 刘云东. 大蒜播种机蒜瓣自动定向控制装置的试验研究[J]. 农业装备与车辆工程, 2009, 47(10): 28-29, 37. |

| JIAN S C, LIU Y D. Experimental research on the garlic clove automatic orientation control device of garlic planting machine [J]. Agric. Equip. Veh. Eng., 2009, 47(10): 28-29, 37. | |

| [9] | 张欣艳. 勺夹式大蒜精量播种装置作用机理与参数试验研究[D]. 大庆: 黑龙江八一农垦大学, 2022. |

| ZHANG X Y. Experimental study on mechanism and parameters of key components of spoon-clip garlic precision seeding device [D]. Daqing: Heilongjiang Bayi Agricultural University, 2022. | |

| [10] | 唐通鸣, 邹帅, 刘勇兰, 等. 振动筛排种器在大蒜播种机中的应用[J]. 农机化研究, 2015, 37(12): 92-96. |

| TANG T M, ZOU S, LIU Y L, et al.. The application of vibration sieve and metering device in the garlic seeder upright screening device [J]. J. Agric. Mech. Res., 2015, 37(12): 92-96. | |

| [11] | 耿爱军, 栗晓宇, 侯加林, 等. 自动定向大蒜播种机的设计与试验[J]. 农业工程学报, 2018, 34(11): 17-25. |

| GENG A J, LI X Y, HOU J L, et al.. Design and experiment of automatic directing garlic planter [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(11): 17-25. | |

| [12] | 李天华, 黄圣海, 牛子孺, 等. 行星轮式大蒜插播机播种直立度优化与试验[J]. 农业工程学报, 2020, 36(3): 37-45. |

| LI T H, HUANG S H, NIU Z R, et al.. Optimization and experiment of planting perpendicularity of planetary wheel garlic planter [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(3): 37-45. | |

| [13] | 栗晓宇, 耿爱军, 侯加林, 等. 全自动蒜种盒提取投放装置设计与试验[J]. 农业工程学报, 2017, 33(23): 32-37. |

| LI X Y, GENG A J, HOU J L, et al.. Design and experiment of full-automatic lifting and releasing device of garlic seed box [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(23): 32-37. | |

| [14] | 崔荣江, 王小瑜, 信嘉程, 等. 弧形鸭嘴式大蒜正芽播种机设计与试验[J]. 农业机械学报, 2022, 53(11): 120-130. |

| CUI R J, WANG X Y, XIN J C, et al.. Design and test of arc duck-billed garlic seed planter [J]. Trans. Chin. Soc. Agric. Mach., 2022, 53(11): 120-130. | |

| [15] | 谢东波. 扰种齿辅助气吸式大蒜排种器设计与试验[D]. 合肥: 安徽农业大学, 2021. |

| XIE D B. Design and test of garlic seed placer with seed disturbing tooth assisted air suction [D]. Hefei: Anhui Agricultural University, 2022. | |

| [16] | DING Y G, LI H, GAO J F, et al.. Parameter optimization of finger clip plate garlic seed-metering device [J/OL]. Agriculture, 2023, 13(11): 2071 [2024-03-03]. . |

| [17] | 崔荣江, 辛丽, 朱月浩, 等. 一种自走式大蒜播种机械设备: CN215073870U[P]. 2021-12-10. |

| [18] | 郭佳皓. 山东大蒜主产区全程机械化生产效率调查研究[D]. 保定: 河北农业大学, 2021. |

| GUO J H. Investigation and study on the whole mechanized operation efficiency in garlic producing areas of Shandong province [D]. Baoding: Hebei Agriculture University, 2020. | |

| [19] | 金文忻, 刘永华, 张东凤, 等. 大蒜直立种植装置设计与试验[J]. 中国农机化学报, 2020, 41(6): 37-42. |

| JIN W X, LIU Y H, ZHANG D F, et al.. Design and test of vertical planting device for garlic [J]. J. Chin. Agric. Mech., 2020, 41(6): 37-42. | |

| [20] | 侯加林, 黄圣海, 牛子孺, 等. 双鸭嘴式大蒜正头装置调头机理分析与试验[J]. 农业机械学报, 2018, 49(11): 87-96. |

| HOU J L, HUANG S H, NIU Z R, et al.. Mechanism analysis and test of adjusting garlics upwards using two duckbill devices [J]. Trans. Chin. Soc. Agric. Mach., 2018, 49(11): 87-96. | |

| [21] | 李天华, 张海阔, 韩相龙, 等. 勺链式大蒜播种机漏取种检测与补种装置设计及试验[J]. 农业工程学报, 2022, 38(4): 24-32. |

| LI T H, ZHANG H K, HAN X L, et al.. Design and experiment of missing seed detection and the reseeding device for spoon chain garlic seeders [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(4): 24-32. | |

| [22] | 刘泽松, 王浩屹, 李骅, 等. 基于有限元的大蒜播种机机架轻量化设计[J]. 中国农机化学报, 2022, 43(1): 27-32. |

| LIU Z S, WANG H Y, LI H, et al.. Lightweight design of a garlic planter frame based on finite element method [J]. J. Chin. Agric. Mech., 2022, 43(1): 27-32. | |

| [23] | 钱伟中, 王大齐, 朱少文, 等. 结构用冷弯空心型钢尺寸、外形、重量及允许偏差: [S]. 北京: 中国标准出版社, 2002. |

| [24] | 杨兆文, 刘星福, 李问盈. 单粒(精密)播种机试验方法: [S]. 北京: 中国标准出版社, 2005. |

| [25] | 栗慧卿, 王永建, 崇峻, 等. 大蒜播种机 通用技术规范: [S]. 北京: 中国标准出版社, 2019. |

| [1] | Huapeng HU, Xukun ZHANG, Jiajun CHEN, Yangyang PAN, Peilin YANG, Zhi LU. Structural Optimization and Moisture Content Simulation of Tea Residue Dual Axis Stirring Dryer [J]. Journal of Agricultural Science and Technology, 2025, 27(4): 120-132. |

| [2] | Zimin CHEN, Jiangting MO, Guangsheng CHEN, Xiaoxuan GUO, Xianwen ZHU. Analysis and Optimization of the Airflow Field in a Head-air Heat Pump Dryer Based on Fluent [J]. Journal of Agricultural Science and Technology, 2024, 26(10): 135-144. |

| [3] | Tingting SHI, Yulan LIAO, Xuyou PENG, Chenyu YUAN. Design and Optimization of Single Row In-line Cassava Planter [J]. Journal of Agricultural Science and Technology, 2022, 24(6): 115-122. |

| [4] | Wenbin GUO, Yao LI, Zhanghua HUANG, Jianqiang DU, Shanzhu QIAN, Zemin HE, Jingjing GAO. Physical Field Analysis and Structure Optimization of Solar Hot Air Dryer Based on COMSOL [J]. Journal of Agricultural Science and Technology, 2022, 24(10): 90-98. |

| [5] | SONG Haichao1,2, XU Youlin2*, ZHENG Jiaqiang2, DAI Xiang2. Simulation Optimization Analysis of Shrinking Tube pitch and Splitter Position of Rotating Jet Mixer [J]. Journal of Agricultural Science and Technology, 2019, 21(9): 84-89. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号