Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (9): 99-109.DOI: 10.13304/j.nykjdb.2024.0147

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Xuelin DU1( ), Ying LIU1, Jiahua ZOU1, Yu TU2(

), Ying LIU1, Jiahua ZOU1, Yu TU2( ), Can ZHOU1, Jinpeng CHENG1

), Can ZHOU1, Jinpeng CHENG1

Received:2024-03-01

Accepted:2024-03-22

Online:2025-09-15

Published:2025-09-24

Contact:

Xuelin DU,Yu TU

杜雪林1( ), 刘颖1, 邹家华1, 涂宇2(

), 刘颖1, 邹家华1, 涂宇2( ), 周灿1, 程晋鹏1

), 周灿1, 程晋鹏1

通讯作者:

杜雪林,涂宇

作者简介:杜雪林 E-mail:du_xuelin@126.com基金资助:CLC Number:

Xuelin DU, Ying LIU, Jiahua ZOU, Yu TU, Can ZHOU, Jinpeng CHENG. Crushing Effect of Double Tooth Roller Crushing Mechanism and Wall Breaker Crushing Mechanism on Kitchen Waste[J]. Journal of Agricultural Science and Technology, 2025, 27(9): 99-109.

杜雪林, 刘颖, 邹家华, 涂宇, 周灿, 程晋鹏. 双齿辊粉碎机构和破壁机粉碎机构对餐厨垃圾的粉碎效果[J]. 中国农业科技导报, 2025, 27(9): 99-109.

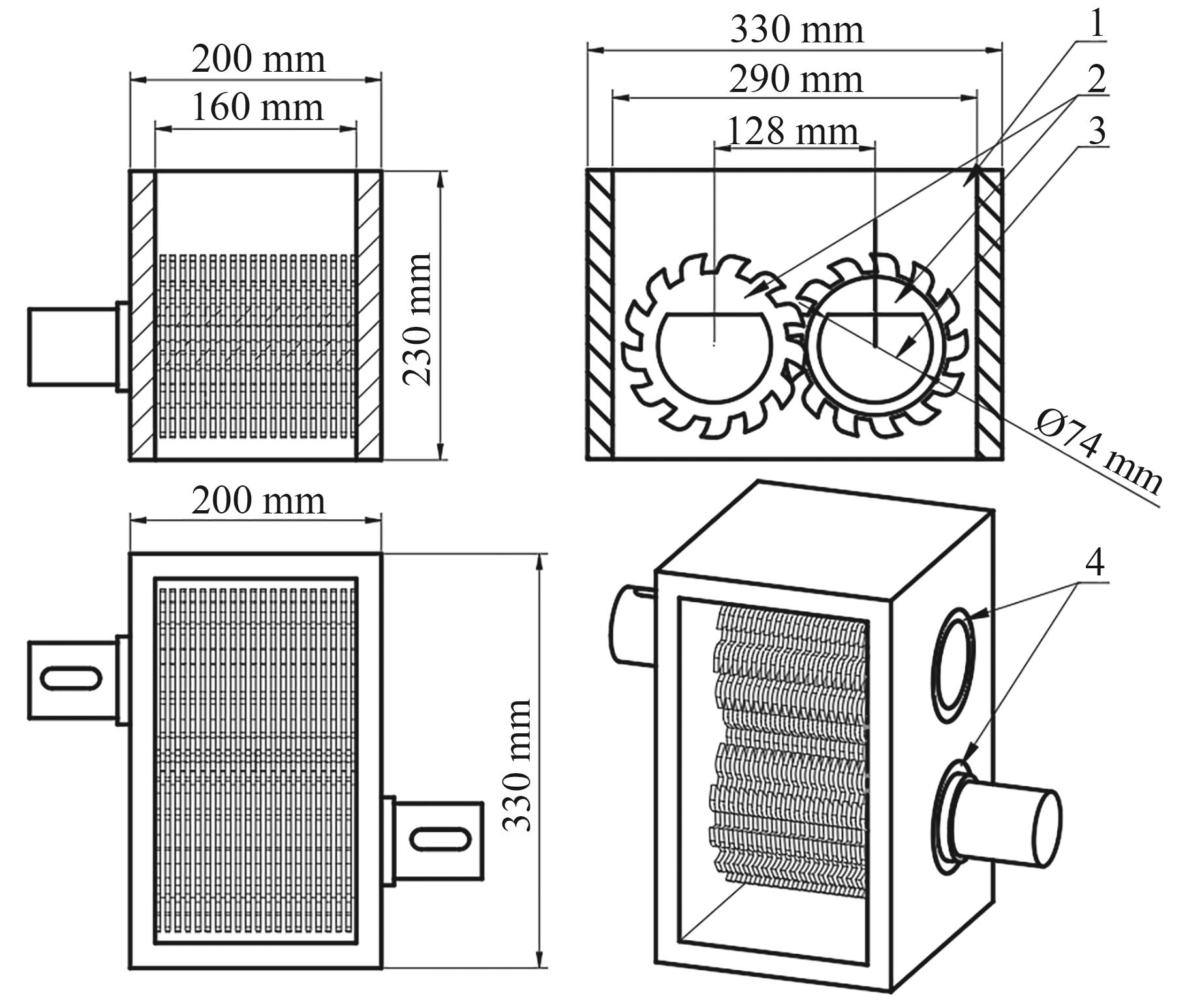

Fig. 3 Overall structure of double-tooth roller mechanismNote: 1—Box part; 2—Crusher teeth and spacer sleeve; 3—Drive shaft; 4—Deep groove ball bearings.

| 因素Factor | 对象1 Object 1 | 对象2 Object 2 |

|---|---|---|

| 单位面积法向刚度Normal stiffness per unit area/(N·m-3) | 12.50×107 | 6.25×108 |

| 单位面积剪切刚度Shear stiffness per unit area/(N·m-3) | 10.00×107 | 4.16×108 |

| 抗拉强度Tensile strength/MPa | 4.40 | 6.42 |

| 抗剪强度Shear strength/MPa | 2.2 | 7.7 |

| 黏合半径Bonding radius/mm | 1.5 | 0.8 |

Table 1 Contact model parameters of crushing objects

| 因素Factor | 对象1 Object 1 | 对象2 Object 2 |

|---|---|---|

| 单位面积法向刚度Normal stiffness per unit area/(N·m-3) | 12.50×107 | 6.25×108 |

| 单位面积剪切刚度Shear stiffness per unit area/(N·m-3) | 10.00×107 | 4.16×108 |

| 抗拉强度Tensile strength/MPa | 4.40 | 6.42 |

| 抗剪强度Shear strength/MPa | 2.2 | 7.7 |

| 黏合半径Bonding radius/mm | 1.5 | 0.8 |

参数 Parameter | 对象1 Object 1 | 对象2 Object 2 | ||

|---|---|---|---|---|

| 物料Material | 钢板Steel plate | 物料Material | 钢板Steel plate | |

| 泊松比Poisson’s ratio | 0.49 | 0.30 | 0.40 | 0.30 |

| 剪切模量Shear modulus/MPa | 1.89 | 70 000.00 | 311.40 | 70 000.00 |

| 密度Density/(kg·m-3) | 1 200 | 7 800 | 1 197 | 7 800 |

物料与物料恢复系数 Recovery coefficient of material and material | 0.900 | 0.284 | ||

物料与钢板恢复系数 Recovery coefficient of material and steel plate | 0.300 | 0.615 | ||

物料与物料静摩擦系数 Static friction coefficient between materials | 0.500 | 0.342 | ||

物料与钢板静摩擦系数 Static friction coefficient between material and steel plate | 0.500 | 0.467 | ||

物料与物料滑动摩擦系数 Sliding friction coefficient between materials | 0.100 0 | 0.054 5 | ||

物料与钢板滑动摩擦系数 Sliding friction coefficient between material and steel plate | 0.010 0 | 0.031 7 | ||

Table 2 Material characteristic parameters for crushing object 1 and object 2[23-24]

参数 Parameter | 对象1 Object 1 | 对象2 Object 2 | ||

|---|---|---|---|---|

| 物料Material | 钢板Steel plate | 物料Material | 钢板Steel plate | |

| 泊松比Poisson’s ratio | 0.49 | 0.30 | 0.40 | 0.30 |

| 剪切模量Shear modulus/MPa | 1.89 | 70 000.00 | 311.40 | 70 000.00 |

| 密度Density/(kg·m-3) | 1 200 | 7 800 | 1 197 | 7 800 |

物料与物料恢复系数 Recovery coefficient of material and material | 0.900 | 0.284 | ||

物料与钢板恢复系数 Recovery coefficient of material and steel plate | 0.300 | 0.615 | ||

物料与物料静摩擦系数 Static friction coefficient between materials | 0.500 | 0.342 | ||

物料与钢板静摩擦系数 Static friction coefficient between material and steel plate | 0.500 | 0.467 | ||

物料与物料滑动摩擦系数 Sliding friction coefficient between materials | 0.100 0 | 0.054 5 | ||

物料与钢板滑动摩擦系数 Sliding friction coefficient between material and steel plate | 0.010 0 | 0.031 7 | ||

粉碎对象 Crushing object | 粉碎机 Crusher | 生成bond键数量 Number of generated bonds | 破碎bond键数量 Number of broken bonds | 破碎键占比 Proportion of broken bonds/% |

|---|---|---|---|---|

对象1 Object 1 | 双齿辊粉碎机 Double-tooth roller crusher | 66 397 | 46 575 | 70.1 |

| 破壁机粉碎机Wall-breaking crusher | 69 899 | 63 135 | 90.3 | |

对象2 Object 2 | 双齿辊粉碎机 Double-tooth roller crusher | 54 040 | 22 804 | 42.2 |

| 破壁机粉碎机Wall-breaking crusher | 53 998 | 32 347 | 59.9 |

Table 3 Number of bond keys before and after crushing

粉碎对象 Crushing object | 粉碎机 Crusher | 生成bond键数量 Number of generated bonds | 破碎bond键数量 Number of broken bonds | 破碎键占比 Proportion of broken bonds/% |

|---|---|---|---|---|

对象1 Object 1 | 双齿辊粉碎机 Double-tooth roller crusher | 66 397 | 46 575 | 70.1 |

| 破壁机粉碎机Wall-breaking crusher | 69 899 | 63 135 | 90.3 | |

对象2 Object 2 | 双齿辊粉碎机 Double-tooth roller crusher | 54 040 | 22 804 | 42.2 |

| 破壁机粉碎机Wall-breaking crusher | 53 998 | 32 347 | 59.9 |

粉碎对象 Crushing object | 颗粒类型 Particle type | 占比Percentage/% | |

|---|---|---|---|

破壁机粉碎机 Wall-breaking crusher | 双齿辊粉碎机 Double-tooth roller crusher | ||

对象1 Object 1 | 大颗粒Large particle | 5.9 | 52.9 |

| 中颗粒Medium particle | 7.7 | 29.7 | |

| 小颗粒Small particle | 86.2 | 17.3 | |

对象2 Object 2 | 大颗粒Large particle | 33.7 | 50.1 |

| 中颗粒Medium particle | 26.4 | 42.8 | |

| 小颗粒Small particle | 39.9 | 7.1 | |

Table 4 Percentage of different sizes of particle after crushing by two types of crushers

粉碎对象 Crushing object | 颗粒类型 Particle type | 占比Percentage/% | |

|---|---|---|---|

破壁机粉碎机 Wall-breaking crusher | 双齿辊粉碎机 Double-tooth roller crusher | ||

对象1 Object 1 | 大颗粒Large particle | 5.9 | 52.9 |

| 中颗粒Medium particle | 7.7 | 29.7 | |

| 小颗粒Small particle | 86.2 | 17.3 | |

对象2 Object 2 | 大颗粒Large particle | 33.7 | 50.1 |

| 中颗粒Medium particle | 26.4 | 42.8 | |

| 小颗粒Small particle | 39.9 | 7.1 | |

Fig. 12 Post processing of materials crushed by two types of crushersA~D: Processing model of double toothed roller crushing mechanism for object 1; E~H: Processing model of wall breaking crushing mechanism for object 1; I~L: Processing moel of double toothed roller crushing mechanism for object 2; M~P: Processing model of wall breaking crushing mechanism for object 2

参数 Parameter | 双齿辊粉碎机Double-tooth roller crusher | 破壁机粉碎机Wall-breaking crusher | ||

|---|---|---|---|---|

| 对象1 Object 1 | 对象2 Object 2 | 对象1 Object 1 | 对象2 Object 2 | |

破碎前表面积 Surface area before crushing/mm² | 1 070.51 | 641.78 | 1 108.46 | 582.47 |

破碎后表面积 Surface area after crushing/mm² | 2 219.90 | 1 106.95 | 2 492.77 | 1 054.12 |

破碎前总质量 Total mass before crushing/g | 23.46 | 7.94 | 23.96 | 7.82 |

破碎后总质量 Total mass after crushing/g | 22.79 | 7.11 | 22.12 | 6.80 |

大颗粒质量 Mass of large particles/g | 11.55 | 3.30 | 2.10 | 2.32 |

中颗粒质量 Mass of medium particles/g | 6.54 | 3.03 | 1.82 | 1.64 |

小颗粒质量 Mass of small particles/g | 4.70 | 0.78 | 18.20 | 2.84 |

大颗粒占比 Percentage of large particles/% | 51.0 | 46.4 | 9.5 | 34.1 |

中颗粒占比 Percentage of Medium particles/% | 28.7 | 42.6 | 8.2 | 24.1 |

小颗粒占比 Percentage of small particles/% | 20.6 | 10.9 | 82.3 | 41.8 |

Table 5 Crushing result of two types of crushers

参数 Parameter | 双齿辊粉碎机Double-tooth roller crusher | 破壁机粉碎机Wall-breaking crusher | ||

|---|---|---|---|---|

| 对象1 Object 1 | 对象2 Object 2 | 对象1 Object 1 | 对象2 Object 2 | |

破碎前表面积 Surface area before crushing/mm² | 1 070.51 | 641.78 | 1 108.46 | 582.47 |

破碎后表面积 Surface area after crushing/mm² | 2 219.90 | 1 106.95 | 2 492.77 | 1 054.12 |

破碎前总质量 Total mass before crushing/g | 23.46 | 7.94 | 23.96 | 7.82 |

破碎后总质量 Total mass after crushing/g | 22.79 | 7.11 | 22.12 | 6.80 |

大颗粒质量 Mass of large particles/g | 11.55 | 3.30 | 2.10 | 2.32 |

中颗粒质量 Mass of medium particles/g | 6.54 | 3.03 | 1.82 | 1.64 |

小颗粒质量 Mass of small particles/g | 4.70 | 0.78 | 18.20 | 2.84 |

大颗粒占比 Percentage of large particles/% | 51.0 | 46.4 | 9.5 | 34.1 |

中颗粒占比 Percentage of Medium particles/% | 28.7 | 42.6 | 8.2 | 24.1 |

小颗粒占比 Percentage of small particles/% | 20.6 | 10.9 | 82.3 | 41.8 |

| [1] | 田维平,邢宇,王周强,等.黑水虻处理城镇污泥和餐厨垃圾的性能评价[J].中国环境科学,2024,44(8):4425-4431. |

| TIAN W P, XING Y, WANG Z Q, et al.. Performance evaluation for the treatment of municipal sludge and kitchen waste via black solider fly larvae [J]. China Environ. Sci., 2024, 44(8): 4425-4431. | |

| [2] | WANG N, LI G, ZHANG H M, et al.. Design and research of home automatic kitchen waste composting device [J/OL]. E3S Web Confer., 2019, 136(7): 04013 [2024-02-10]. . |

| [3] | 王琬,孙远波,孙大禹.一种新型厨余垃圾自动处理系统设计[J].机械科学与技术, 2013, 32(7): 1046-1048. |

| WANG W, SUN Y B, SUN D Y. The design of a new type of automatic processing system for kitchen waste [J]. Mech. Sci. Technol. Aerosp. Eng., 2013, 32(7): 1046-1048. | |

| [4] | FENG Z C, YANG J, CHEN L F, et al.. An intelligent waste-sorting and recycling device based on improved efficient net [J/OL]. Int. J. Environ. Res. Public Health, 2022, 19:15987 [2024-02-10]. . |

| [5] | 蔡传钰.农村生活垃圾分类与资源化处理技术研究[D].杭州: 浙江大学, 2012. |

| CAI C Y. Study on applicable technology for rural solid waste classification and recycling [D]. Hangzhou: Zhejiang University, 2012. | |

| [6] | 张代湘.关于粉碎理论的论述[J].西北轻工业学院学报,1983,1(2):16-19. |

| [7] | SUN K K, MA R D, LI G, et al.. The influence of the structure of double toothed roller crusher on the crushing effect based on EDEM [J/OL]. IOP Conf. Ser. Mater. Sci. Eng., 2018, 423:012152 [2024-02-10]. . |

| [8] | 范国强,王忠宇,王保兴,等.旋筒供料锤式饲草粉碎机设计与试验[J].农业机械学报,2021,52(12):43-53, 76. |

| FAN G Q, WANG Z Y, WANG B X, et al.. Design and experiment of rotary feed tube hammer grinder [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(12): 43-53, 76. | |

| [9] | 丁桐桐,徐建华,李远安,等.基于离散单元法的立轴冲击破碎机成砂率数值计算[J].应用力学学报,2021,38(5):2018-2024. |

| DING T T, XU J H, LI Y A, et al.. Numerical calculation of sand formation rate of vertical shaft impact crusher based on discrete element method [J]. Chin. J. Appl. Mech., 2021, 38(5): 2018-2024. | |

| [10] | 刘进,马立峰,王志霞,等.基于EDEM的旋回破碎机能耗模型研究[J].煤炭工程,2023,55(2):152-157. |

| LIU J, MA L F, WANG Z X, et al.. Energy consumption model of gyratory crusher based on EDEM [J]. Coal Eng., 2023, 55(2): 152-157. | |

| [11] | 毛君,刘歆妍,陈洪月,等.基于EDEM的采煤机滚筒工作性能的仿真研究[J].煤炭学报,2017,42(4):1069-1077. |

| MAO J, LIU X Y, CHEN H Y, et al.. Simulation of shearer drum cutting performance based on EDEM [J]. J. China Coal Soc., 2017, 42(4): 1069-1077. | |

| [12] | 刘煜, 郑群飞.基于离散元素法的双齿辊破碎机影响因素研究[J].矿业科学学报,2018,3(4):364-370. |

| LIU Y, ZHENG Q F. Study on the influence factors of the double-geared roller crusher based on the discrete element method [J]. J. Min. Sci. Technol., 2018, 3(4): 364-370. | |

| [13] | 李强,巩亚东,宋伟刚.基于物料运动特性的旋回破碎机生产率分析[J].中国机械工程,2016,27(15):2034-2039. |

| LI Q, GONG Y D, SONG W G. Gyratory crusher productivity analysis based on kinematic characteristics of materials [J]. China Mech. Eng., 2016, 27(15): 2034-2039. | |

| [14] | FENG F, SHI J, YANG J, et al.. Correlation between the angle of the guide plate and crushing performance in vertical shaft crushers [J/OL]. Shock. Vib., 2022, 2022(1): 9991855 [2024-02-10]. . |

| [15] | XU Y, ZHANG X, WU S, et al.. Numerical simulation of particle motion at cucumber straw grinding process based on EDEM [J/OL]. Int. J. Agric. Biol. Eng., 2020, 13(6):5452 [2024-02-10]. . |

| [16] | 吴硕,李萍萍,张西良,等.基于离散元法的番茄秸秆立式螺旋混合机理[J].排灌机械工程学报, 2018, 36(8): 719-724. |

| WU S, LI P P, ZHANG X L, et al.. Vertical spiral mixing mechanism of tomato straw particles based on discrete element method [J]. J. Drain. Irrig. Mach. Eng., 2018, 36(8): 719-724. | |

| [17] | 张强,张旭,孙绍安.基于EDEM的家用榨油机压榨腔工作性能仿真研究[J].农业工程学报,2018,34(24):283-291. |

| ZHANG Q, ZHANG X, SUN S A. Simulation study on working performance of pressing cavity of household oil press based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(24): 283-291. | |

| [18] | CHENG Q, WANG J X, LIU K. Design of rice straw fiber crusher and evaluation of fiber quality [J]. Agriculture, 2022, 12(5): 1-17. |

| [19] | 袁晓明,王超,阎鹏,等.离散元法在工农业上的应用研究综述[J].机械设计,2016,33(9):1-9. |

| YUAN X M, WANG C, YAN P, et al.. Review of discrete element method in industrial and agricultural applications [J]. J. Mach. Des., 2016, 33(9): 1-9. | |

| [20] | 王浩璇,果霖,王一鸣,等.基于EDEM-Fluent仿真的餐厨垃圾渣液分离机设计与试验[J].食品与机械,2021,37(1):130-136. |

| WANG H X, GUO L, WANG Y M, et al.. Design and test of the separator of kitchen waste residue liquid based on EDEM- Fluent simulation [J]. Food Mach., 2021, 37(1): 130-136. | |

| [21] | POTYONDY D, CUNDALL P. A bonded-particle model for rock [J]. Int. J. Rock Mech. Min. Sci., 2004, 41(8): 1329-1364. |

| [22] | 王国强,郝万军,王继新.离散单元法及其在EDEM上的实践[M].西安:西北工业大学出版社,2010:1-118. |

| [23] | 王美美,王万章,杨立权,等.基于EDEM的玉米子粒建模方法的研究[J].河南农业大学学报,2018,52(1):80-84, 103. |

| WANG M M, WANG W Z, YANG L Q, et al.. Research of discrete element modeling method of maize kernel based on EDEM [J]. J. Henan Agric. Univ., 2018, 52(1): 80-84, 103. | |

| [24] | 李凯锋,杨炳南,杨德秋,等.胡萝卜物理力学特性的试验研究[J].农机化研究,2016,38(5):169-175, 180. |

| LI K F, YANG B N, YANG D Q, et al.. Experimental research on physical and mechanical properties of carrot [J]. J. Agric. Mech. Res., 2016, 38(5): 169-175, 180. |

| [1] | Jingwen QIANG, Wanqing WANG, Manyu TANG, Na ZHANG, Shuang WU, Wei HUA, Hengxuan SHAO, Yanling CHENG. Effects of Anaerobic Digestion of Kitchen Waste on Biogas Microorganisms and Environment [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 159-169. |

| [2] | Lizhen ZHANG, Tan ZHU. Influence of Centrifugal Disc of Centrifugal Feeder on Breaking Rate [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 107-116. |

| [3] | Miao YU, Haibin ZHOU, Jingtao DING, Hongsheng CHENG, Yujun SHEN, Shengyuan FAN, Xi ZHANG, Jian WANG, Pengxiang XU, Qiongyi CHENG. Calibration of Interparticle Contact Parameters of Kitchen Waste Composition Based on EDEM [J]. Journal of Agricultural Science and Technology, 2023, 25(12): 111-120. |

| [4] | Shisheng SONG, Songlin SUN, Qin FANG, Caiwang PENG, Ting ZHOU, Haiying ZHU. Parameters Calibration of Discrete Element for Kitchen Waste Organic Fertilizer Bioconversion by Black Soldier Fly [J]. Journal of Agricultural Science and Technology, 2022, 24(6): 123-132. |

| [5] | Nanrui TANG, Yong ZHOU, Guozhong ZHANG, Fang LIANG, Huibin KE. Performance Simulation and Experiment of Stirred and Bunch Rice Seeding Device [J]. Journal of Agricultural Science and Technology, 2022, 24(4): 107-115. |

| [6] | HU Ting, QUAN Wei, WU Mingliang, LI Lin. Design and Experiment of Seed Channel Opener for Double Ridge Four Row Peanut Seeder [J]. Journal of Agricultural Science and Technology, 2021, 23(9): 129-137. |

| [7] | YIN Jingkai, GONG Xiaoyan, SUN Lina, HAN Mengqi, YANG Yuan, XU Xiaoyan, WANG Xiaobo. Study on the Transformation of Nutrients in Kitchen Waste by Black Soldier Fly [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 154-159. |

| [8] |

DUN Guoqiang1,YU Chunling1,GUO Yanling1*,YANG Yongzhen1,YE Jin1,JI Wenyi2,LIU Yuxuan1.

Design and Simulation Test of Laminatedtype Meshing Arc Gear Fertilizer Device

[J]. Journal of Agricultural Science and Technology, 2020, 22(5): 78-85.

|

| [9] | KANG Jiaxin1, LIU Dawei1, LI Xu1*, XIE Fangping1, HUANG Min2, ZHENG Huabin2. Design and Parameter Optimization of Crank Slide Vibrating Screen of Seedling Mud Treatment Device [J]. Journal of Agricultural Science and Technology, 2020, 22(10): 85-92. |

| [10] | ZHAO Wen-ju, MA Xiao-yi| Ren Hong-yi | ZHAO Xi-an . Studies on Current Software for Optimal Irrigation Water |Distribution Based on COM Component Technology [J]. , 2008, 10(4): 82-88. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号