中国农业科技导报 ›› 2024, Vol. 26 ›› Issue (8): 131-139.DOI: 10.13304/j.nykjdb.2022.1023

• 智慧农业 农机装备 • 上一篇

顿国强1( ), 王雷2(

), 王雷2( ), 纪欣鑫2, 姜新波2, 赵宇3, 郭娜2

), 纪欣鑫2, 姜新波2, 赵宇3, 郭娜2

收稿日期:2022-11-23

接受日期:2023-04-25

出版日期:2024-08-15

发布日期:2024-08-12

通讯作者:

王雷

作者简介:顿国强 E-mail:dunguoqiangpatent@163.com;

基金资助:

Guoqiang DUN1( ), Lei WANG2(

), Lei WANG2( ), Xinxin JI2, Xinbo JIANG2, Yu ZHAO3, Na GUO2

), Xinxin JI2, Xinbo JIANG2, Yu ZHAO3, Na GUO2

Received:2022-11-23

Accepted:2023-04-25

Online:2024-08-15

Published:2024-08-12

Contact:

Lei WANG

摘要:

针对蒜种在播种仿真试验时缺乏参数的问题,以金乡紫皮蒜种为研究目标,测量蒜种的物性参数并对蒜种的离散元仿真参数进行标定。测定了蒜种的密度、含水率、泊松比、剪切模量、静摩擦系数、滚动摩擦系数以及碰撞恢复系数,以多个物性参数为试验因素,以蒜种堆积角为试验指标进行Plackett-Burman试验,筛选出对堆积角影响显著的因素为蒜种间静摩擦系数及滚动摩擦系数。以物理试验结果为最优值,通过CCD响应曲面试验对显著因素进行优化,优化后蒜种间最佳静摩擦系数和滚动摩擦系数分别为0.428和0.287。以转速为试验因素,以多粒率为试验指标,以自制链勺式大蒜排种器装置进行试验验证,结果表明,仿真与测量结果平均相对误差较小,变化折线图趋势相一致,优化标定的蒜种仿真参数具备一定的可靠性,可以为大蒜播种机的仿真试验提供数据支撑。

中图分类号:

顿国强, 王雷, 纪欣鑫, 姜新波, 赵宇, 郭娜. 金乡紫皮蒜种离散元参数标定与试验验证[J]. 中国农业科技导报, 2024, 26(8): 131-139.

Guoqiang DUN, Lei WANG, Xinxin JI, Xinbo JIANG, Yu ZHAO, Na GUO. Calibration and Verification of Discrete Element Parameters of Jinxiang Purple Garlic Seeds[J]. Journal of Agricultural Science and Technology, 2024, 26(8): 131-139.

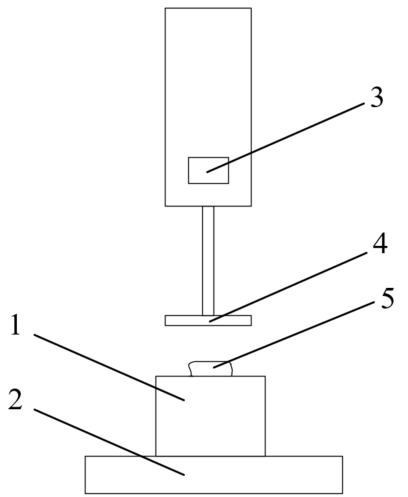

图1 压力试验注:1—不锈钢圆台;2—底座;3—数显屏幕;4—检测探头;5—蒜种。

Fig. 1 Pressure testNote:1—Stainless steel round table;2—Base;3—Digital display screen;4—Detection probe;5—Garlic seeds.

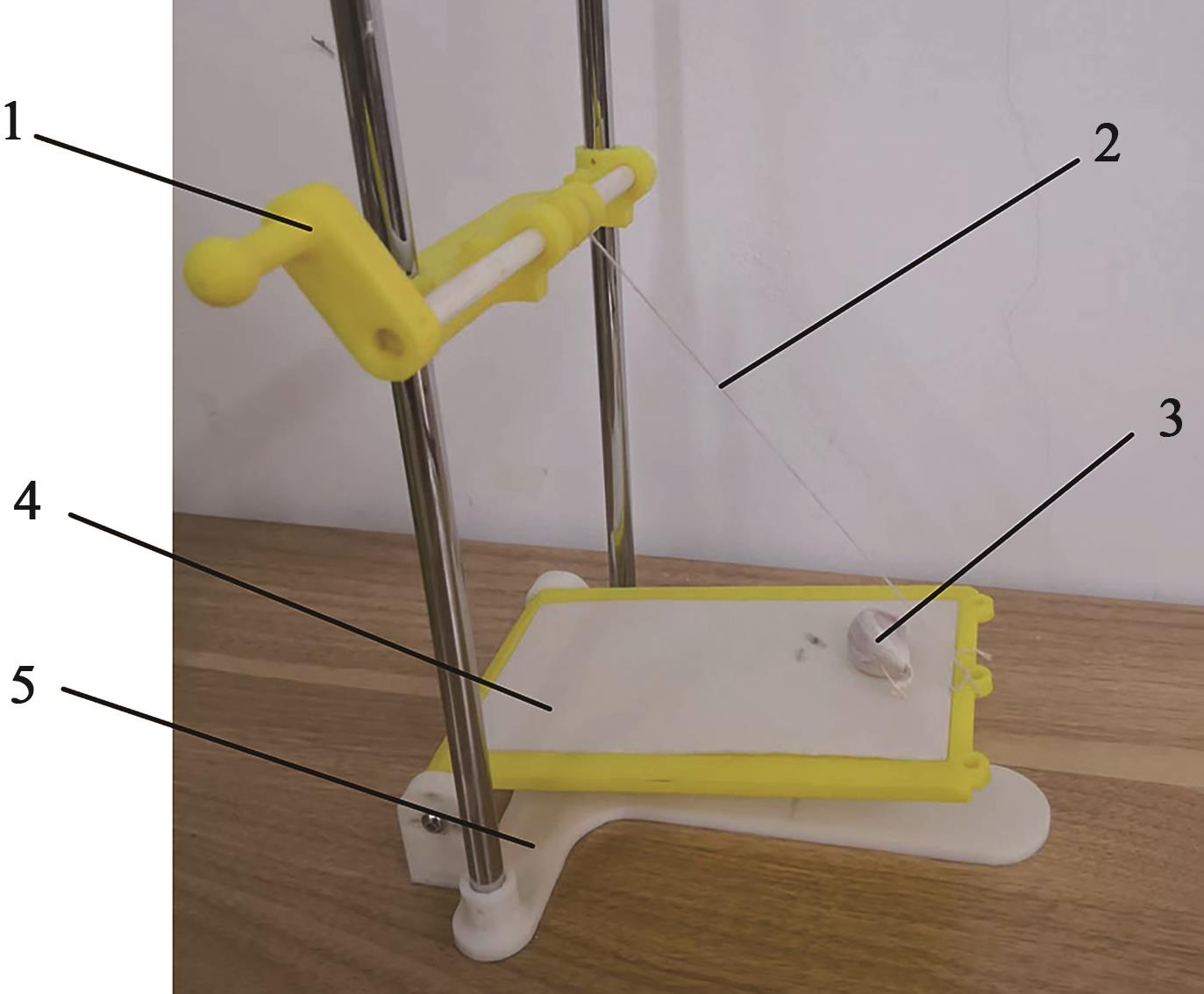

图2 大蒜蒜种的静摩擦角测量注:1—摇柄;2—细线;3—蒜种;4—塑料板;5—机架。

Fig. 2 Measurement of static friction angle of garlic seedsNote:1—Rocker handle;2—Thin lines;3—Garlic seeds;4—Plastic board;5—Rack.

| 序号Number | 试验参数Test parameters | 低水平Low level | 高水平High level |

|---|---|---|---|

| A | 蒜种-PLA塑料板滚动摩擦系数 Rolling friction coefficient of garlic seed PLA plastic plate | 0.207 | 0.294 |

| B | 蒜种-蒜种滚动摩擦系数 Rolling friction coefficient between garlic seeds | 0.236 | 0.314 |

| C | 蒜种-PLA塑料板碰撞恢复系数 Coefficient of restitution of garlic PLA plastic plate collision | 0.537 | 0.675 |

| D | 蒜种-蒜种碰撞恢复系数 Collision coefficient of restitution between garlic seeds | 0.456 | 0.562 |

| E | 蒜种-蒜种静摩擦系数 Coefficient of static friction between garlic seeds | 0.401 | 0.476 |

| F | 蒜种-PLA塑料板静摩擦系数 Static friction coefficient of garlic seed PLA plastic plate | 0.373 | 0.402 |

| G | 泊松比 Poisson ratio | 0.2 | 0.5 |

| H | 剪切模量 Shear modulus | 1e+07 | 3e+08 |

表1 Plackett-Burman验参数

Table 1 Parameters of Plackett-Burman test

| 序号Number | 试验参数Test parameters | 低水平Low level | 高水平High level |

|---|---|---|---|

| A | 蒜种-PLA塑料板滚动摩擦系数 Rolling friction coefficient of garlic seed PLA plastic plate | 0.207 | 0.294 |

| B | 蒜种-蒜种滚动摩擦系数 Rolling friction coefficient between garlic seeds | 0.236 | 0.314 |

| C | 蒜种-PLA塑料板碰撞恢复系数 Coefficient of restitution of garlic PLA plastic plate collision | 0.537 | 0.675 |

| D | 蒜种-蒜种碰撞恢复系数 Collision coefficient of restitution between garlic seeds | 0.456 | 0.562 |

| E | 蒜种-蒜种静摩擦系数 Coefficient of static friction between garlic seeds | 0.401 | 0.476 |

| F | 蒜种-PLA塑料板静摩擦系数 Static friction coefficient of garlic seed PLA plastic plate | 0.373 | 0.402 |

| G | 泊松比 Poisson ratio | 0.2 | 0.5 |

| H | 剪切模量 Shear modulus | 1e+07 | 3e+08 |

水平 Level | B:蒜种间滚动摩擦系数 Rolling friction coefficient between garlic | E:蒜种间静摩擦系数 Static friction coefficient between garlic |

|---|---|---|

| 1.414 | 0.314 | 0.476 |

| 1 | 0.303 | 0.465 |

| 0 | 0.275 | 0.439 |

| -1 | 0.247 | 0.412 |

| -1.414 | 0.236 | 0.401 |

表2 CCD试验因素水平

Table 2 Factor level of CCD test

水平 Level | B:蒜种间滚动摩擦系数 Rolling friction coefficient between garlic | E:蒜种间静摩擦系数 Static friction coefficient between garlic |

|---|---|---|

| 1.414 | 0.314 | 0.476 |

| 1 | 0.303 | 0.465 |

| 0 | 0.275 | 0.439 |

| -1 | 0.247 | 0.412 |

| -1.414 | 0.236 | 0.401 |

序号 Number | A | B | C | D | E | F | G | H | 堆积角 Repose angle/(°) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 28.35 |

| 2 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 30.14 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 24.56 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 29.61 |

| 5 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 25.5 |

| 6 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 23.42 |

| 7 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 27.15 |

| 8 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 27.6 |

| 9 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 28.32 |

| 10 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 27.41 |

| 11 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 26.21 |

| 12 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 24.45 |

表3 Plackett-Burman试验方案和结果

Table 3 Scheme and result of Plackett-Burman test

序号 Number | A | B | C | D | E | F | G | H | 堆积角 Repose angle/(°) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 28.35 |

| 2 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 30.14 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | 24.56 |

| 4 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 29.61 |

| 5 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 25.5 |

| 6 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | -1 | 23.42 |

| 7 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 27.15 |

| 8 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 27.6 |

| 9 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 28.32 |

| 10 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 27.41 |

| 11 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | 26.21 |

| 12 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 24.45 |

方差来源 Variance sources | 堆积角 Repose angle | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型Model | 48.04 | 8.00 | 6.00 | 23.71 | 0.012 4 |

| A | 0.23 | 1.00 | 0.23 | 0.91 | 0.411 2 |

| B | 33.80 | 1.00 | 33.80 | 133.49 | 0.001 4 |

| C | 0.20 | 1.00 | 0.20 | 0.80 | 0.436 8 |

| D | 1.08 | 1.00 | 1.08 | 4.27 | 0.130 8 |

| E | 10.45 | 1.00 | 10.45 | 41.28 | 0.007 6 |

| F | 1.07 | 1.00 | 1.07 | 4.22 | 0.132 3 |

| G | 1.13 | 1.00 | 1.13 | 4.46 | 0.125 2 |

| H | 0.07 | 1.00 | 0.07 | 0.29 | 0.627 2 |

表4 Plackett-Burman结果方差分析

Table 4 Variance analysis of Plackett-Burman test

方差来源 Variance sources | 堆积角 Repose angle | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型Model | 48.04 | 8.00 | 6.00 | 23.71 | 0.012 4 |

| A | 0.23 | 1.00 | 0.23 | 0.91 | 0.411 2 |

| B | 33.80 | 1.00 | 33.80 | 133.49 | 0.001 4 |

| C | 0.20 | 1.00 | 0.20 | 0.80 | 0.436 8 |

| D | 1.08 | 1.00 | 1.08 | 4.27 | 0.130 8 |

| E | 10.45 | 1.00 | 10.45 | 41.28 | 0.007 6 |

| F | 1.07 | 1.00 | 1.07 | 4.22 | 0.132 3 |

| G | 1.13 | 1.00 | 1.13 | 4.46 | 0.125 2 |

| H | 0.07 | 1.00 | 0.07 | 0.29 | 0.627 2 |

| 序号Number | B | E | R |

|---|---|---|---|

| 1 | -1 | -1 | 26.45 |

| 2 | 1 | -1 | 28.73 |

| 3 | -1 | 1 | 26.05 |

| 4 | 1 | 1 | 26.62 |

| 5 | -1.414 | 0 | 26.56 |

| 6 | 1.414 | 0 | 28.48 |

| 7 | 0 | -1.414 | 28.62 |

| 8 | 0 | 1.414 | 26.36 |

| 9 | 0 | 0 | 26.02 |

| 10 | 0 | 0 | 25.23 |

| 11 | 0 | 0 | 26.56 |

| 12 | 0 | 0 | 25.65 |

| 13 | 0 | 0 | 26.46 |

表5 CCD试验方案和结果

Table 5 Scheme and result of CCD test

| 序号Number | B | E | R |

|---|---|---|---|

| 1 | -1 | -1 | 26.45 |

| 2 | 1 | -1 | 28.73 |

| 3 | -1 | 1 | 26.05 |

| 4 | 1 | 1 | 26.62 |

| 5 | -1.414 | 0 | 26.56 |

| 6 | 1.414 | 0 | 28.48 |

| 7 | 0 | -1.414 | 28.62 |

| 8 | 0 | 1.414 | 26.36 |

| 9 | 0 | 0 | 26.02 |

| 10 | 0 | 0 | 25.23 |

| 11 | 0 | 0 | 26.56 |

| 12 | 0 | 0 | 25.65 |

| 13 | 0 | 0 | 26.46 |

方差来源 Variance sources | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

模型 Model | 13.48 | 5 | 2.70 | 9.99 | 0.043 0 |

| B | 3.87 | 1 | 3.87 | 14.34 | 0.006 8 |

| E | 4.07 | 1 | 4.07 | 15.08 | 0.006 0 |

| BE | 0.73 | 1 | 0.73 | 2.71 | 0.143 8 |

| B2 | 2.78 | 1 | 2.78 | 10.31 | 0.014 9 |

| E2 | 2.65 | 1 | 2.65 | 9.82 | 0.016 5 |

残差 Residual | 1.89 | 7 | 0.27 | ||

失拟 Lack of fit | 0.65 | 3 | 0.22 | 0.70 | 0.599 0 |

误差 Error | 1.24 | 4 | 0.31 | ||

| 总和 Sum | 15.37 | 12 |

表6 CCD试验方差分析

Table 6 Sariance analysis of CCD test

方差来源 Variance sources | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

模型 Model | 13.48 | 5 | 2.70 | 9.99 | 0.043 0 |

| B | 3.87 | 1 | 3.87 | 14.34 | 0.006 8 |

| E | 4.07 | 1 | 4.07 | 15.08 | 0.006 0 |

| BE | 0.73 | 1 | 0.73 | 2.71 | 0.143 8 |

| B2 | 2.78 | 1 | 2.78 | 10.31 | 0.014 9 |

| E2 | 2.65 | 1 | 2.65 | 9.82 | 0.016 5 |

残差 Residual | 1.89 | 7 | 0.27 | ||

失拟 Lack of fit | 0.65 | 3 | 0.22 | 0.70 | 0.599 0 |

误差 Error | 1.24 | 4 | 0.31 | ||

| 总和 Sum | 15.37 | 12 |

试验次序 Sequence | 仿真堆积角 Stacking angle of simulation /(°) | 相对误差 Relative error/% |

|---|---|---|

| 1 | 27.122 | 0.98 |

| 2 | 26.554 | 1.14 |

| 3 | 26.682 | 0.66 |

| 4 | 27.234 | 1.40 |

| 5 | 26.386 | 1.76 |

表7 仿真结果分析

Table 7 Analysis of simulation test

试验次序 Sequence | 仿真堆积角 Stacking angle of simulation /(°) | 相对误差 Relative error/% |

|---|---|---|

| 1 | 27.122 | 0.98 |

| 2 | 26.554 | 1.14 |

| 3 | 26.682 | 0.66 |

| 4 | 27.234 | 1.40 |

| 5 | 26.386 | 1.76 |

| 1 | 祝捍敏.我国大蒜出口贸易与国际竞争力评价分析[J].中国瓜菜,2022,35(10):111-116. |

| ZHU H M. Evaluation and analysis on China’s garlic export trade and international competitiveness [J]. China Cucurbits Veg., 2022,35(10):111-116. | |

| 2 | 魏宏玲,王小瑜,陈进熹,等.中国大蒜机械化生产现状与发展思路探讨[J].中国农机化学报,2022,43(4):175-182. |

| WEI H L, WANG X Y, CHEN J X, et al.. Discussion on the present situation and development of mechanized garlic production in China [J]. J. Chin. Agric. Mech., 2022,43(4):175-182. | |

| 3 | 张涛,刘飞,赵满全,等.大豆种子与排种器接触物理参数的测定与离散元仿真标定[J].中国农业大学学报,2017,22(9):86-92. |

| ZHANG T, LIU F, ZHAO M Q, et al.. Measurement of physical parameters of contact between soybean seed and seed metering device and discrete element simulation calibration [J]. J. China Agric. Univ., 2017,22(9):86-92. | |

| 4 | 侯占峰,戴念祖,陈智,等.冰草种子物性参数测定与离散元仿真参数标定[J].农业工程学报,2020,36(24):46-54. |

| HOU Z F, DAI N Z, CHEN Z, et al.. Measurement and calibration of physical property parameters for agropyron seeds in a discrete element simulation [J]. Trans. Chin. Soc. Agric. Eng., 2020,36(24):46-54. | |

| 5 | 张荣芳,焦伟,周纪磊,等.不同填充颗粒半径水稻种子离散元模型参数标定[J].农业机械学报,2020,51(S1):227-235. |

| ZHANG R F, JIAO W, ZHOU J L, et al.. Parameter calibration and experiment of rice seeds discrete element model with different filling particle radius [J]. Trans. Chin. Soc. Agric. Mach., 2020,51(S1):227-235. | |

| 6 | 马文鹏,尤泳,王德成,等.基于RSM和NSGA-Ⅱ的苜蓿种子离散元模型参数标定[J].农业机械学报,2020,51(8):136-144. |

| MA W P, YOU Y, WANG D C, et al.. Parameter calibration of alfalfa seed discrete element model basedon RSM and NSGA-II [J]. Trans. Chin. Soc. Agric. Mach., 2020,51(8):136-144. | |

| 7 | 吴佳胜,曹成茂,谢承健,等.前胡种子物性参数测定及其离散元仿真模型参数标定[J].甘肃农业大学学报,2019,54(4):180-189. |

| WU J S, CAO C M, XIE C J, et al.. Measurement of physical parameters of Radix peucedani seeds and parameter calibration of discrete element simulation model [J]. J. Gansu Agric. Univ., 2019,54(4):180-189. | |

| 8 | 郝建军,魏文波,黄鹏程,等.油葵籽粒离散元参数标定与试验验证[J].农业工程学报, 2021,37(12):36-44. |

| HAO J J, WEI W B, HUANG P C, et al.. Calibration and experimental verification of discrete element parameters of oil sunflower seeds [J]. Trans. Chin. Soc. Agric. Eng., 2021,37(12):36-44. | |

| 9 | 张胜伟,张瑞雨,陈天佑,等.绿豆种子离散元仿真参数标定与排种试验[J].农业机械学报,2022,53(3):71-79. |

| ZHANG S W, ZHANG R Y, GHEN T Y, et al.. Calibration of simulation parameters of mung bean seeds using discrete element method and verification of seed-metering test [J]. Trans. Chin. Soc. Agric. Mach., 2022,53(3):71-79. | |

| 10 | JIA H, DENG J, DENG Y, et al.. Contact parameter analysis and calibration in discrete element simulation of rice straw [J]. Int. J. Agric. Biol. Eng., 2021,14(4):72-81. |

| 11 | LI H, ZHANG G, LI X, et al.. Calibration of the discrete element method parameters in living juvenile manila clam (Ruditapes philippinarum) and seeding verification [J]. AgriEngineering, 2021,3(4):894-906. |

| 12 | 吴孟宸,丛锦玲,闫琴,等.花生种子颗粒离散元仿真参数标定与试验[J].农业工程学报,2020,36(23):30-38. |

| WU M C, CONG J L, YAN Q, et al.. Calibration and experiments for discrete element simulation parameters of peanut seed particles [J]. Trans. Chin. Soc. Agric. Eng., 2020,36(23):30-38. | |

| 13 | 霍星辰,宋卫东,王明友,等.双孢菇麦粒菌种离散元分析参数试验研究及仿真标定[J].江苏农业科学,2019,47(18):271-276. |

| 14 | 顿国强,于春玲,杨永振,等.大豆育种排种盘型孔参数仿真优化与试验[J].农业工程学报,2019,35(19):62-73. |

| DUN G Q, YU C L, YANG Y Z, et al.. Parameter simulation optimization and experiment of seed plate type hole for soybean breeding [J]. Trans. Chin. Soc. Agric. Eng., 2019,35(19):62-73. | |

| 15 | 范旭阳,杨正华,代典,等.磷矿酸浸脱镁提磷过程的响应曲面分析[J].磷肥与复肥,2021,36(8):5-8, 52. |

| FAN X Y, YANG Z H, DAI D, et al.. Analysis of magnesium removal and phosphorus improvement of phosphate rock with hydrochloric acid leaching by response surface methodology [J]. Phosphate Compd. Fert., 2021,36(8):5-8, 52. | |

| 16 | BACHERIKOV I V, NOVIKOV A I, PETRISHCHEV E P. Discrete seed feeder designing for mobile apparatus: early results for Pinus sylvestris Ⅰ. species [J]. Inventions, 2021,6(1):14. |

| 17 | 顿国强,刘文辉,毛宁,等.交替换岗式大豆小区育种排种器优化设计与试验[J].吉林大学学报(工学版),2023,53(1):285-296. |

| DUN G Q, LIU W H, MAO N, et al.. Optimization design and experiment of alternate post changing seed metering device for soybean plot breeding [J]. J. Jilin Univ. (Eng. Technol.), 2023,53(1):285-296. | |

| 18 | GUO H, CAO Y, SONG W, et al.. Design and simulation of a garlic seed metering mechanism [J]. Agriculture, 2021,11(12):12-39. |

| 19 | 顿国强,于春玲,郭艳玲,等,双齿轮式排肥器设计与试验 [J].农业机械学报,2020,51(3):87-96. |

| DUN G Q, YU C L, GUO Y L, et al.. Design and experiment of Double-gear type fertilizer apparatus [J]. Trans. Chin. Soc. Agric. Mach., 2020,51(3):87-96. |

| [1] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [2] | 李明, 董帅, 庞永强, 燕洁华, 叶汪忠. 风沙土混拌刀具的改良设计与试验[J]. 中国农业科技导报, 2024, 26(4): 87-96. |

| [3] | 黄元昊, 全腊珍, 胡广发, 全伟, 石方刚. 多种材料与不同含水率土壤的离散元接触参数标定[J]. 中国农业科技导报, 2024, 26(3): 98-109. |

| [4] | 陈林, 余南辉, 王立宗, 范吉军, 雷港, 刘晓鹏, 周龙, 周劲. 米糠和碎米的接触参数测量与离散元仿真标定[J]. 中国农业科技导报, 2024, 26(2): 127-136. |

| [5] | 王洪波, 樊志鹏, 乌兰图雅, 王春光, 马哲. 揉碎玉米秸秆螺旋输送仿真离散元模型参数标定[J]. 中国农业科技导报, 2023, 25(3): 96-106. |

| [6] | 于淼, 周海宾, 丁京涛, 程红胜, 沈玉君, 范盛远, 张曦, 王健, 徐鹏翔, 程琼仪. 基于EDEM的餐厨垃圾组成颗粒间接触参数标定[J]. 中国农业科技导报, 2023, 25(12): 111-120. |

| [7] | 马紫涛, 赵智豪, 全伟, 石方刚, 高晨, 吴明亮. 基于EDEM的水稻残茬秸秆离散元仿真参数标定[J]. 中国农业科技导报, 2023, 25(11): 103-113. |

| [8] | 单发科, 康朔, 朱建锡, 王永维, 王俊. 基于EDEM的粉垄和旋耕作业混肥效果研究[J]. 中国农业科技导报, 2023, 25(11): 90-102. |

| [9] | 周婷, 孙松林, 朱海英, 彭才望. 含水率对黑水虻生物转化猪粪有机肥黏结流动的影响[J]. 中国农业科技导报, 2023, 25(10): 126-136. |

| [10] | 李飞翔, 王鹏, 王云飞, 葛越锋, 唐凯怿, 李得志. 基于堆积试验的玉米包衣种子离散元参数标定[J]. 中国农业科技导报, 2022, 24(7): 97-107. |

| [11] | 宋世圣, 孙松林, 方芹, 彭才望, 周婷, 朱海英. 黑水虻生物转化餐厨垃圾有机肥离散元模型参数标定[J]. 中国农业科技导报, 2022, 24(6): 123-132. |

| [12] | 闫建伟, 魏松, 胡冬军, 刘启合, 张富贵. 白萝卜种子颗粒模型离散元接触参数标定与试验[J]. 中国农业科技导报, 2022, 24(5): 119-128. |

| [13] | 杨贵川, 张富贵, 郑乐, 王震, 孔曼曼, 章鑫鹏. 半夏块茎物理特性研究及离散元仿真参数标定[J]. 中国农业科技导报, 2022, 24(10): 99-108. |

| [14] | 全伟, 吴明亮, 官春云, 罗海峰. 油菜钵苗移栽机成穴器外形优化试验研究[J]. 中国农业科技导报, 2021, 23(10): 97-106. |

| [15] | 刘妤,刘羽平,张拓. 基于离散元与多体动力学的微耕机旋耕刀轴负荷分析[J]. 中国农业科技导报, 2020, 22(11): 79-86. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号