中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (4): 110-119.DOI: 10.13304/j.nykjdb.2023.0792

• 智慧农业 农机装备 • 上一篇

收稿日期:2023-10-30

接受日期:2024-05-05

出版日期:2025-04-15

发布日期:2025-04-15

通讯作者:

刘一琦

作者简介:豆中中E-mail:Sunshine0082024@163.com

基金资助:

Zhongzhong DOU1,2( ), Yiqi LIU2(

), Yiqi LIU2( )

)

Received:2023-10-30

Accepted:2024-05-05

Online:2025-04-15

Published:2025-04-15

Contact:

Yiqi LIU

摘要:

针对马铃薯排种器在播种过程中出现的单粒播种不稳定问题,以恩施富硒马铃薯薯种为研究对象,测量了马铃薯薯种的三轴尺寸及体积、密度,并根据薯种的参数对排种器的尺寸结构进行了三维建模,利用Recurdyn-EDEM耦合仿真模拟弧爪式马铃薯排种器的播种过程,并通过响应曲面试验对参数进行优化。以有效取种长度(X1)和种勺宽度(X2)为试验因素,以单粒率、多粒率、空粒率为试验指标,配合耦合仿真进行二次通用旋转组合设计试验,结果表明,X22和X22对单粒率、多粒率、空粒率影响极显著, X1和X1X2对多粒率、空粒率影响显著,其余各项对指标影响皆不显著。利用优化模块对参数进行优化,确定有效取种长度和种勺宽度的最佳参数组合为99.74和60.02 mm。以精量播种单粒率为目标值,在最佳参数组合条件下,仿真试验与目标值的误差值小于2%且单粒率大于80%,证明了优化后试验参数的准确性,且精量播种率具备可行性。

中图分类号:

豆中中, 刘一琦. 弧爪式马铃薯精量排种器的仿真分析[J]. 中国农业科技导报, 2025, 27(4): 110-119.

Zhongzhong DOU, Yiqi LIU. Simulation Analysis of Arc-jaw Type Potato Precision Seed Discharger[J]. Journal of Agricultural Science and Technology, 2025, 27(4): 110-119.

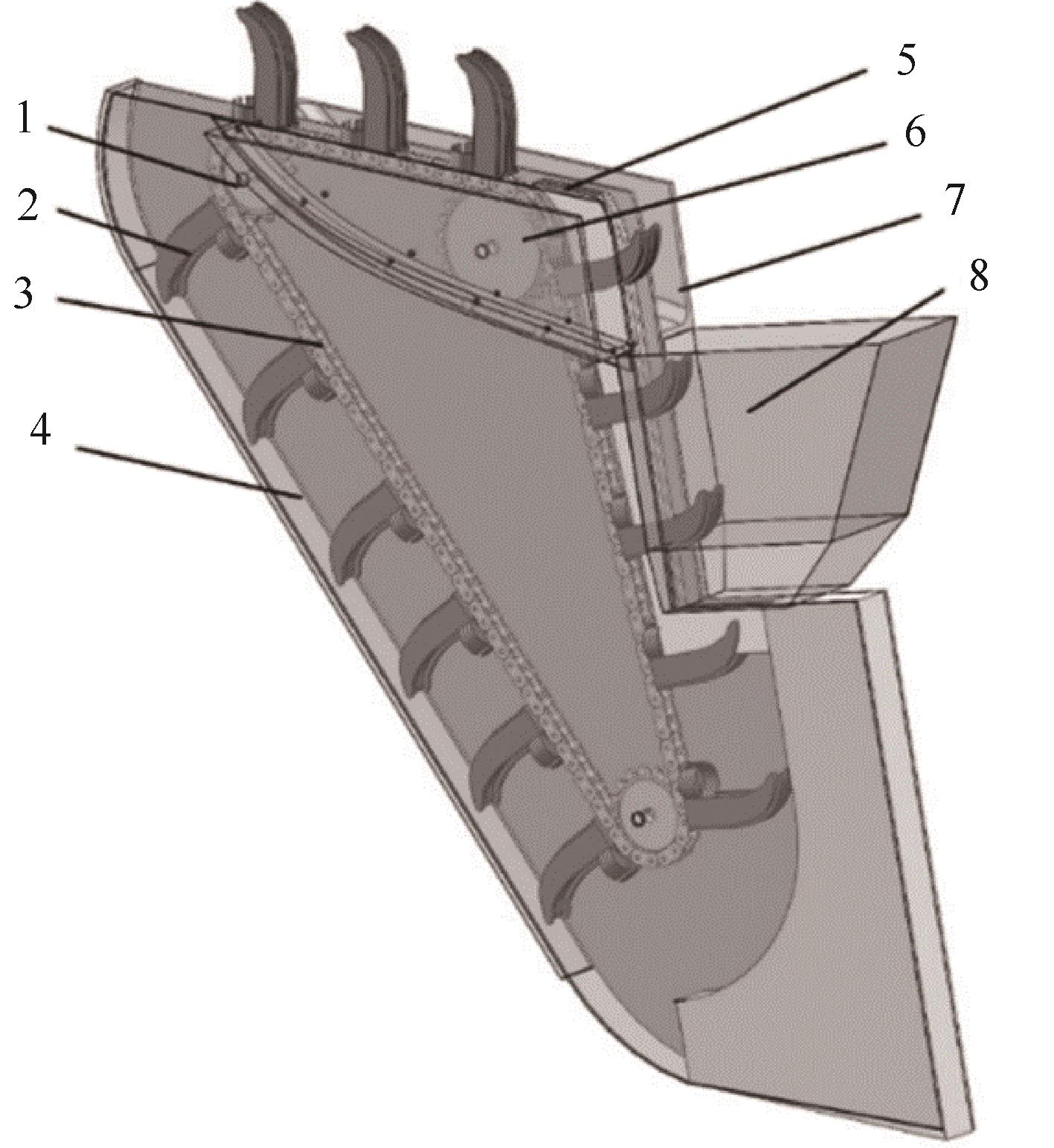

图1 弧爪式马铃薯精量排种器结构注:1—主动链轮;2—弧爪式取种勺;3—滚子链条;4—排种壁;5—清种板;6—从动链轮;7—回种板;8—种箱。

Fig. 1 Structure of levelling type garlic precision seed dischargerNote:1—Active sprocket; 2—Arc claw seed pick-up spoon;3—Roller chain;4—Seed discharge wall;5—Seed clearing plate; 6—Slave sprocket;7—Seed return plate;8—Seed box.

材料 Test material | 参数 Parameter | 值 Value |

|---|---|---|

薯种-薯种 Potato seeds-Potato seeds | 泊松比 Poisson’s ratio | 0.57 |

剪切模量 Shear modulus | 1.34 | |

静摩擦系数 Coefficient of static friction | 0.45 | |

动摩擦系数 Coefficient of kinetic friction | 0.03 | |

碰撞恢复系数 Crash recovery factor | 0.79 | |

薯种-钢板 Potato seed-steel plate | 静摩擦系数 Coefficient of static friction | 0.64 |

| 动摩擦系数 Coefficient of kinetic friction | 0.27 | |

| 碰撞恢复系数 Crash recovery factor | 0.71 |

表1 仿真参数

Table 1 Simulation parameters

材料 Test material | 参数 Parameter | 值 Value |

|---|---|---|

薯种-薯种 Potato seeds-Potato seeds | 泊松比 Poisson’s ratio | 0.57 |

剪切模量 Shear modulus | 1.34 | |

静摩擦系数 Coefficient of static friction | 0.45 | |

动摩擦系数 Coefficient of kinetic friction | 0.03 | |

碰撞恢复系数 Crash recovery factor | 0.79 | |

薯种-钢板 Potato seed-steel plate | 静摩擦系数 Coefficient of static friction | 0.64 |

| 动摩擦系数 Coefficient of kinetic friction | 0.27 | |

| 碰撞恢复系数 Crash recovery factor | 0.71 |

因素水平 Level of factor | 有效取种长度 Effective seed length/mm | 种勺宽度 Width of seed scoop/mm |

|---|---|---|

| +1.414 | 136.18 | 68.09 |

| +1.000 | 129.93 | 64.96 |

| 0 | 114.84 | 57.42 |

| -1.000 | 99.74 | 49.88 |

| -1.414 | 93.49 | 46.75 |

表2 因素编码

Table 2 Factor coding

因素水平 Level of factor | 有效取种长度 Effective seed length/mm | 种勺宽度 Width of seed scoop/mm |

|---|---|---|

| +1.414 | 136.18 | 68.09 |

| +1.000 | 129.93 | 64.96 |

| 0 | 114.84 | 57.42 |

| -1.000 | 99.74 | 49.88 |

| -1.414 | 93.49 | 46.75 |

| 序号 Serial No. | 因素水平 Factor level | 试验指标 Test indictor/% | |||

|---|---|---|---|---|---|

X1:有效取种长度 Effective seeding length | X2:种勺宽度 Width of seed scoop | Y1:单粒率 Single grain rate | Y2:多粒率 Multiple grain rates | Y3:空粒率 Empty grain rates | |

| 1 | -1.000 | -1.000 | 46 | 1 | 53 |

| 2 | 1.000 | -1.000 | 65 | 10 | 25 |

| 3 | -1.000 | 1.000 | 88 | 10 | 2 |

| 4 | 1.000 | 1.000 | 95 | 3 | 2 |

| 5 | -1.414 | 0 | 85 | 2 | 13 |

| 6 | 1.414 | 0 | 87 | 9 | 4 |

| 7 | 0 | -1.414 | 55 | 10 | 35 |

| 8 | 0 | 1.414 | 88 | 10 | 2 |

| 9 | 0 | 0 | 91 | 5 | 4 |

| 10 | 0 | 0 | 91 | 6 | 3 |

| 11 | 0 | 0 | 93 | 2 | 5 |

| 12 | 0 | 0 | 85 | 3 | 12 |

| 13 | 0 | 0 | 85 | 6 | 9 |

表3 试验方案和结果

Table 3 Experimental programme and result

| 序号 Serial No. | 因素水平 Factor level | 试验指标 Test indictor/% | |||

|---|---|---|---|---|---|

X1:有效取种长度 Effective seeding length | X2:种勺宽度 Width of seed scoop | Y1:单粒率 Single grain rate | Y2:多粒率 Multiple grain rates | Y3:空粒率 Empty grain rates | |

| 1 | -1.000 | -1.000 | 46 | 1 | 53 |

| 2 | 1.000 | -1.000 | 65 | 10 | 25 |

| 3 | -1.000 | 1.000 | 88 | 10 | 2 |

| 4 | 1.000 | 1.000 | 95 | 3 | 2 |

| 5 | -1.414 | 0 | 85 | 2 | 13 |

| 6 | 1.414 | 0 | 87 | 9 | 4 |

| 7 | 0 | -1.414 | 55 | 10 | 35 |

| 8 | 0 | 1.414 | 88 | 10 | 2 |

| 9 | 0 | 0 | 91 | 5 | 4 |

| 10 | 0 | 0 | 91 | 6 | 3 |

| 11 | 0 | 0 | 93 | 2 | 5 |

| 12 | 0 | 0 | 85 | 3 | 12 |

| 13 | 0 | 0 | 85 | 6 | 9 |

| 评价指标 Evaluation indicators | 方差来源 Source of variance | 平方和 Square sum | 自由度 Degrees of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| 单粒率 Single grain rate | 模型 Model | 2 620.48 | 5 | 524.10 | 14.2 | 0.001 5 |

| X1 | 103.88 | 1 | 103.88 | 2.81 | 0.137 4 | |

| X2 | 1 760.29 | 1 | 1 760.29 | 47.68 | 0.000 2 | |

| X1X2 | 36.00 | 1 | 36.00 | 0.98 | 0.356 3 | |

| X12 | 55.03 | 1 | 55.03 | 1.49 | 0.261 7 | |

| X22 | 704.38 | 1 | 704.38 | 19.08 | 0.003 3 | |

残差 Residual | 258.45 | 7 | 36.92 | |||

失拟项 Lack of fit | 202.45 | 3 | 67.48 | 4.82 | 0.081 4 | |

纯误差 Pure error | 56.00 | 4 | 14.00 | |||

总变异 Total variation | 2 878.92 | 12 |

表4 方差分析

Table 4 Variance analysis

| 评价指标 Evaluation indicators | 方差来源 Source of variance | 平方和 Square sum | 自由度 Degrees of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| 单粒率 Single grain rate | 模型 Model | 2 620.48 | 5 | 524.10 | 14.2 | 0.001 5 |

| X1 | 103.88 | 1 | 103.88 | 2.81 | 0.137 4 | |

| X2 | 1 760.29 | 1 | 1 760.29 | 47.68 | 0.000 2 | |

| X1X2 | 36.00 | 1 | 36.00 | 0.98 | 0.356 3 | |

| X12 | 55.03 | 1 | 55.03 | 1.49 | 0.261 7 | |

| X22 | 704.38 | 1 | 704.38 | 19.08 | 0.003 3 | |

残差 Residual | 258.45 | 7 | 36.92 | |||

失拟项 Lack of fit | 202.45 | 3 | 67.48 | 4.82 | 0.081 4 | |

纯误差 Pure error | 56.00 | 4 | 14.00 | |||

总变异 Total variation | 2 878.92 | 12 |

| 评价指标 Evaluation indicator | 方差来源 Source of variance | 平方和 Square sum | 自由度 Degrees of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| 多粒率 Multiple grain rates | 模型 Model | 121.30 | 5 | 24.26 | 6.15 | 0.016 9 |

| X1 | 17.70 | 1 | 17.70 | 4.48 | 0.072 0 | |

| X2 | 0.50 | 1 | 0.50 | 0.13 | 0.732 4 | |

| X1X2 | 64.00 | 1 | 64.00 | 16.22 | 0.005 0 | |

| X12 | 0.088 | 1 | 0.09 | 0.02 | 0.885 5 | |

| X22 | 38.83 | 1 | 38.83 | 9.84 | 0.016 5 | |

残差 Residual | 27.63 | 7 | 3.95 | |||

失拟项 Lack of fit | 14.43 | 3 | 4.81 | 1.46 | 0.352 2 | |

纯误差 Pure error | 13.20 | 4 | 3.30 | |||

总变异 Total variation | 148.92 | 12 | ||||

| 空粒率 Empty grain rates | 模型 Model | 2 656.27 | 5 | 531.25 | 13.39 | 0.001 8 |

| X1 | 207.35 | 1 | 207.35 | 5.23 | 0.056 1 | |

| X2 | 1 820.13 | 1 | 1 820.13 | 45.88 | 0.000 3 | |

| X1X2 | 196 | 1 | 196.00 | 4.94 | 0.061 6 | |

| X12 | 50.71 | 1 | 50.71 | 1.28 | 0.295 5 | |

| X22 | 412.45 | 1 | 412.45 | 10.4 | 0.014 6 | |

残差 Residual | 277.73 | 7 | 39.68 | |||

失拟项 Lack of fit | 220.53 | 3 | 73.51 | 5.14 | 0.073 8 | |

纯误差 Pure error | 57.20 | 4 | 14.30 | |||

总变异 Total variation | 2 934.00 | 12 |

表4 方差分析表 (续表Continued)

Table 4 Variance analysis

| 评价指标 Evaluation indicator | 方差来源 Source of variance | 平方和 Square sum | 自由度 Degrees of freedom | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|---|

| 多粒率 Multiple grain rates | 模型 Model | 121.30 | 5 | 24.26 | 6.15 | 0.016 9 |

| X1 | 17.70 | 1 | 17.70 | 4.48 | 0.072 0 | |

| X2 | 0.50 | 1 | 0.50 | 0.13 | 0.732 4 | |

| X1X2 | 64.00 | 1 | 64.00 | 16.22 | 0.005 0 | |

| X12 | 0.088 | 1 | 0.09 | 0.02 | 0.885 5 | |

| X22 | 38.83 | 1 | 38.83 | 9.84 | 0.016 5 | |

残差 Residual | 27.63 | 7 | 3.95 | |||

失拟项 Lack of fit | 14.43 | 3 | 4.81 | 1.46 | 0.352 2 | |

纯误差 Pure error | 13.20 | 4 | 3.30 | |||

总变异 Total variation | 148.92 | 12 | ||||

| 空粒率 Empty grain rates | 模型 Model | 2 656.27 | 5 | 531.25 | 13.39 | 0.001 8 |

| X1 | 207.35 | 1 | 207.35 | 5.23 | 0.056 1 | |

| X2 | 1 820.13 | 1 | 1 820.13 | 45.88 | 0.000 3 | |

| X1X2 | 196 | 1 | 196.00 | 4.94 | 0.061 6 | |

| X12 | 50.71 | 1 | 50.71 | 1.28 | 0.295 5 | |

| X22 | 412.45 | 1 | 412.45 | 10.4 | 0.014 6 | |

残差 Residual | 277.73 | 7 | 39.68 | |||

失拟项 Lack of fit | 220.53 | 3 | 73.51 | 5.14 | 0.073 8 | |

纯误差 Pure error | 57.20 | 4 | 14.30 | |||

总变异 Total variation | 2 934.00 | 12 |

试验次序 Test order | 单粒播种率 Single seeding rate/% | 误差值 Error value/% |

|---|---|---|

| 1 | 81.4 | 0.70 |

| 2 | 82.8 | 0.95 |

| 3 | 83.6 | 1.90 |

| 4 | 82.5 | 0.58 |

| 5 | 81.2 | 1.00 |

表5 试验误差

Table 5 Test error

试验次序 Test order | 单粒播种率 Single seeding rate/% | 误差值 Error value/% |

|---|---|---|

| 1 | 81.4 | 0.70 |

| 2 | 82.8 | 0.95 |

| 3 | 83.6 | 1.90 |

| 4 | 82.5 | 0.58 |

| 5 | 81.2 | 1.00 |

| 1 | KOFFI Y D, KONAN G A, KONÉ B V, et al.. Accelerating the healing of hard-to-heal wounds with food supplements: nutritional analysis in the Côte d’Ivoire [J/OL]. J. Wound Care, 2023,32(10):cci-ccx[2024-04-15]. . |

| 2 | 王丽,邓志峰,汪长钢,等.不同品种马铃薯淀粉功能性质的相关性及主成分分析[J].中国粮油学报,2024,39(1):83-89. |

| WANG L, DENG Z F, WANG C G, et al.. Correlation and principal component analysis of potato starch quality physicochemical properties of different varieties [J]. J. Chin. Cereals Oils Assoc., 2024,39(1):83-89. | |

| 3 | 靳生鹏.马铃薯全程机械化作业技术分析[J].现代农机,2021(5):40-41. |

| 4 | 吕金庆,刘金妮,赵治明,等.马铃薯碎土整地联合作业机设计与试验[J].农业机械学报,2023,54(8):19-29. |

| LYU J Q, LIU J N, ZHAO Z M, et al.. Design and test of key components of potato soil-crushing site preparation machine [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(8):19-29. | |

| 5 | ZHOU B D, LI Y X, ZHANG C, et al.. Potato planter and planting technology: a review of recent developments [J]. Agriculture, 2022,12(10):1600-1600. |

| 6 | 高全德,高爱民,孟养荣.马铃薯种植机研究现状及发展趋势[J].林业机械与木工设备,2023,51(5):11-14. |

| GAO Q D, GAO A M, MENG Y R, et al.. Research status and development trend of potato planter [J]. Forestry Mach. Woodworking Equip., 2023,51(5):11-14. | |

| 7 | 王启增.马铃薯播种机排种装置研究现状及展望[J].现代化农业,2022(8):88-90. |

| 8 | 吕金庆,杨颖,李紫辉,等.舀勺式马铃薯播种机排种器的设计与试验[J].农业工程学报,2016,32(16):17-25. |

| LYU J Q, YANG Y, LI Z H, et al.. Design and experiment of cup-belt type potato seed-metering device [J]. Trans. Chin. Soc. Agric. Eng., 2016,32(16):17-25. | |

| 9 | 高原,黄玉祥,李鹏,等.三爪勺式马铃薯精量排种器设计与试验[J].农机化研究,2023,45(12):191-197. |

| GAO Y, HUANG Y X, LI P, et al.. Design and experiment of three-claw spoon type potato precise metering device [J]. J. Agric. Mech. Res., 2023,45(12):191-197. | |

| 10 | 杨然兵,王婕,尚书旗,等.圆台格盘式马铃薯育种试验播种机设计与试验[J].农业机械学报,2023,54(1):84-93. |

| YANG R B, WANG J, SHANG S Q, et al.. Design and experiment of potato breeding planter with rotary table grid [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(1):84-93 | |

| 11 | 潘思奇,赵胜雪,刘崇林,等.勺带式马铃薯排种器改进设计与试验研究[J].农机化研究,2022,44(8):164-168. |

| PAN S Q, ZHAO S X, LIU C L, et al.. Improved design and experimental research on spoon-belt potato seed meter [J]. J. Agric. Mech. Res., 2022,44(8):164-168. | |

| 12 | 谭本芳,段宏兵,付锦,等.基于RecurDyn-EDEM耦合的三角链杯勺式马铃薯排种器性能仿真[J].甘肃农业大学学报,2023,58(3):218-227. |

| TAN B F, DUAN H B, FU J, et al.. Performance simulation of a triangular chain cup-spoon potato seed feeder based on RecurDyn-EDEM coupling [J]. J. Gansu Agric. Univ., 2023,58(3):218-227. | |

| 13 | 田悦,赵萍,李永奎,等.东北五种早熟马铃薯的物理参数测试与分析[J].沈阳农业大学学报,2017,48(6):737-744. |

| TIAN Y, ZHAO P, LI Y K, et al.. Measurement and analys of physical parameters of five early maturing potato varieties in Northeast China [J]. J. Shenyang Agric. Univ., 2017,48(6):737-744. | |

| 14 | 王希英,唐汉,王金武,等.双列交错勺带式马铃薯精量排种器优化设计与试验[J].农业机械学报,2016,47(11):82-90. |

| WANG X Y, TANG H, WANG J W, et al.. Optimized design and experiment on double-row cross spoon-belt potato precision seed metering device [J]. Trans. Chin. Soc. Agric. Mach., 2016,47(11):82-90. | |

| 15 | 姜伟,张华,崔中凯,等.分拣式马铃薯联合收获机设计与试验[J].山西农业大学学报(自然科学版),2024,44(1):130-140. |

| JIANG W, ZHANG H, CUI Z K, et al.. Design and experimentation of sorting-type potato combined harvester [J]. J. Shanxi Agric. Univ. (Nat. Sci.), 2024,44(1):130-140. | |

| 16 | 李学强,王兴欢,刘洋,等.马铃薯联合收获机环形减损集薯升运装置设计与试验[J].农业机械学报,2023,54(12):109-120. |

| LI X Q, WANG X H, LIU Y, et al.. Design and testing of a ring-type loss-reducing potato collecting and lifting device for potato combine harvesters [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(12):109-120. | |

| 17 | 顿国强,范芯蕊,杨永振,等.基于离散元的插装式大豆排种器改进设计及试验[J].华中农业大学学报,2020,39(3):135-144. |

| DUN G Q, FAN X R, YANG Y Z, et al.. Improved design and experiment of a plug-in soybean seed metering device based on discrete element [J]. J. Huazhong Agric. Univ., 2020,39(3):135-144. | |

| 18 | 黄玉,方梦祥,余鹏,等.基于响应曲面法优化氮掺杂活性炭的制备和CO2吸附性能研究[J]. 煤炭转化,2024,47(1):49-59. |

| HUANG Y, FANG M X, YU P, et al.. Optimization of preparation of nitrogen-doped activated carbon and CO2 adsorption property based on response surface methodology [J]. Coal Conversion, 2024,47(1):49-59. | |

| 19 | 张涛,张万枝,陈志伟,等.基于EDEM的勺带式马铃薯排种器充种性能仿真研究[J].江苏农业科学,2021,49(12):181-185. |

| ZHANG T, ZHANG W Z, CHENG Z W,et al.. Simulation research on filling performance of spoonbelt potato seed meter based on EDEM [J]. Jiangsu Agric. Sci., 2021,49(12):181-185. | |

| 20 | 顿国强,刘文辉,杜佳兴,等.弧槽双螺旋式排肥器优化设计与试验[J].农业机械学报,2022,53(10):118-125, 174. |

| DUN G Q, LIU W H, DU J X, et al.. Optimal design and experiment of arc-groove double-spiral fertilizer discharge device [J]. Trans. Chin. Soc. Agric. Mach., 2022,53(10):118-125, 174. | |

| 21 | 崔丽霞,王相友,许英超.基于响应面法的马铃薯分选机参数优化及试验[J].中国农机化学报,2021,42(11):80-88. |

| CUI L X, WANG X Y, XU Y C. Parameter optimization and experiment of potato sorter based on response surface method [J]. J. Chin. Agric. Mech., 2021,42(11):80-88. | |

| 22 | BACHERIKOV I V, NOVIKOV A I, PETRISHCHEV E P. Discrete seed feeder designing for mobile apparatus:Early results for PinusSylvestris L. species [J]. Inventions,2021,6(1):14. |

| 23 | 顿国强,吴星澎,纪欣鑫,等.玉米条带摆管式撒肥装置设计及试验[J/OL].吉林大学学报(工学版):1-11[2024-7-15]. . |

| DUN G Q, WU X P, JI X X, et al.. Design and experiment of corn strip swing tube fertilizer spreader [J/OL]. J. Jilin Univ. (Eng. Technol.), 1-11[2024-7-15].. | |

| 24 | 于珍珍,汪春,李海亮,等.升运履带式马铃薯播种机的设计[J].农机化研究,2019,41(3):83-86, 92. |

| YU Z Z, WANG C, LI H L, et al.. Design of up moving crawler potato planter [J]. J. Agric. Mech. Res., 2019,41(3):83-86, 92. | |

| 25 | 顿国强,吴星澎,纪欣鑫,等.斜口螺旋精控排肥器优化设计与试验[J].农业机械学报, 2023,54(7):167-174. |

| DUN G Q, WU X P, JI X X,et al.. Optimization design and experiment of oblique opening spiral precision control fertilizer apparatus [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(7):167-174. |

| [1] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [2] | 岳海霞, 谭波, 魏松, 谢红. 白萝卜气吸式精量排种器结构设计与分析[J]. 中国农业科技导报, 2024, 26(5): 120-128. |

| [3] | 郭带贵, 廖宇兰, 张惜辉, 袁成宇, 吴中野. 木薯种植机参数优化与试验[J]. 中国农业科技导报, 2023, 25(9): 122-130. |

| [4] | 柯昊纯, 李琨, 程瑞锋. 营养液紫外LED杀菌模组仿真与响应面法优化[J]. 中国农业科技导报, 2023, 25(4): 132-146. |

| [5] | 梁玉玥, 郑侃, 夏俊芳. 稻麦兼用排种器检测与吹种装置性能模拟与试验[J]. 中国农业科技导报, 2023, 25(10): 99-108. |

| [6] | 唐楠锐, 周勇, 张国忠, 梁方, 柯烩彬. 搅种型孔式水稻穴播排种器的性能模拟与试验[J]. 中国农业科技导报, 2022, 24(4): 107-115. |

| [7] | 王靖会, 程娇娇, 刘洋, 常佳乐, 王朝辉 . 基于高光谱成像技术鉴别大米品种[J]. 中国农业科技导报, 2021, 23(9): 121-128. |

| [8] | 胡广发, 全腊珍, 邹运梅, 沈徽, 匡新鹏, 黄从辉. 农田残膜机械回收膜土分离装置设计与试验[J]. 中国农业科技导报, 2021, 23(7): 82-92. |

| [9] | 向伟1,2,吴明亮1*,吕江南2,马兰2,全伟1,刘佳杰2,肖乐3. 基于EDEM的油菜移栽成穴装置作业性能仿真与试验研究[J]. 中国农业科技导报, 2019, 21(7): 70-81. |

| [10] | 赵方超,王春光*,乌兰图雅. 螺旋式输送装置参数优化研究[J]. 中国农业科技导报, 2019, 21(6): 70-78. |

| [11] | 夏先飞1,肖宏儒1*,肖苏伟1,李波2,李国平2. 基于混合正交试验的生物质旋压成型多目标优化[J]. 中国农业科技导报, 2019, 21(3): 69-75. |

| [12] | 邓宇玄1,任奕林1*,杨瑞斌2,彭春晖1,苑晓辰1. 水葫芦压缩打包机设计与工艺参数优化[J]. 中国农业科技导报, 2018, 20(8): 54-62. |

| [13] | 徐浩1,陶栋材1*,陶韵晖2,肖博文1. 基于EDEM的水稻槽轮排种器排种仿真与试验研究[J]. 中国农业科技导报, 2018, 20(3): 64-70. |

| [14] | 涂德浴1,2,李安心1,何贵生1. 水稻秸秆冷压成型工艺参数优化[J]. , 2015, 17(3): 56-62. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号