中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (9): 122-130.DOI: 10.13304/j.nykjdb.2022.0892

收稿日期:2022-10-21

接受日期:2023-04-25

出版日期:2023-09-15

发布日期:2023-09-28

通讯作者:

廖宇兰

作者简介:郭带贵E-mail:3014349750@qq.com;

基金资助:

Daigui GUO( ), Yulan LIAO(

), Yulan LIAO( ), Xihui ZHANG, Chengyu YUAN, Zhongye WU

), Xihui ZHANG, Chengyu YUAN, Zhongye WU

Received:2022-10-21

Accepted:2023-04-25

Online:2023-09-15

Published:2023-09-28

Contact:

Yulan LIAO

摘要:

目前木薯种植主要依靠人工,种植劳动强度大,少量木薯种植机由其他果蔬移栽机改装而成,该机型在作业过程中常不能按规定的株行距实现精确地播种导致合格率低、漏种率高,因此,运用中心组合试验设计理论开展作业参数优化试验,分析作业参数对合格率和漏种率的影响规律。以合格率和漏种率为试验指标,前进速度、曲柄转速和机具高度为试验因素,通过响应曲面法进行三因素三水平响应面试验,利用Design Expert软件建立各因素与合格率和漏种率的回归模型,研究各因素及其交互作用对试验指标的影响规律。田间试验结果表明,作业参数组合为前进速度0.89~0.94 m?s-1、曲柄转速43 r?min-1、机具高度383 mm时,种植合格率为95.47%,漏种率2.05%,与模型优化值相对误差小于5%,表明模型可靠。研究结果对提高木薯种植效果具有重要指导意义,可为今后木薯种植机优化设计和参数优化提供参考。

中图分类号:

郭带贵, 廖宇兰, 张惜辉, 袁成宇, 吴中野. 木薯种植机参数优化与试验[J]. 中国农业科技导报, 2023, 25(9): 122-130.

Daigui GUO, Yulan LIAO, Xihui ZHANG, Chengyu YUAN, Zhongye WU. Parameter Optimization and Experiment of Cassava Planter[J]. Journal of Agricultural Science and Technology, 2023, 25(9): 122-130.

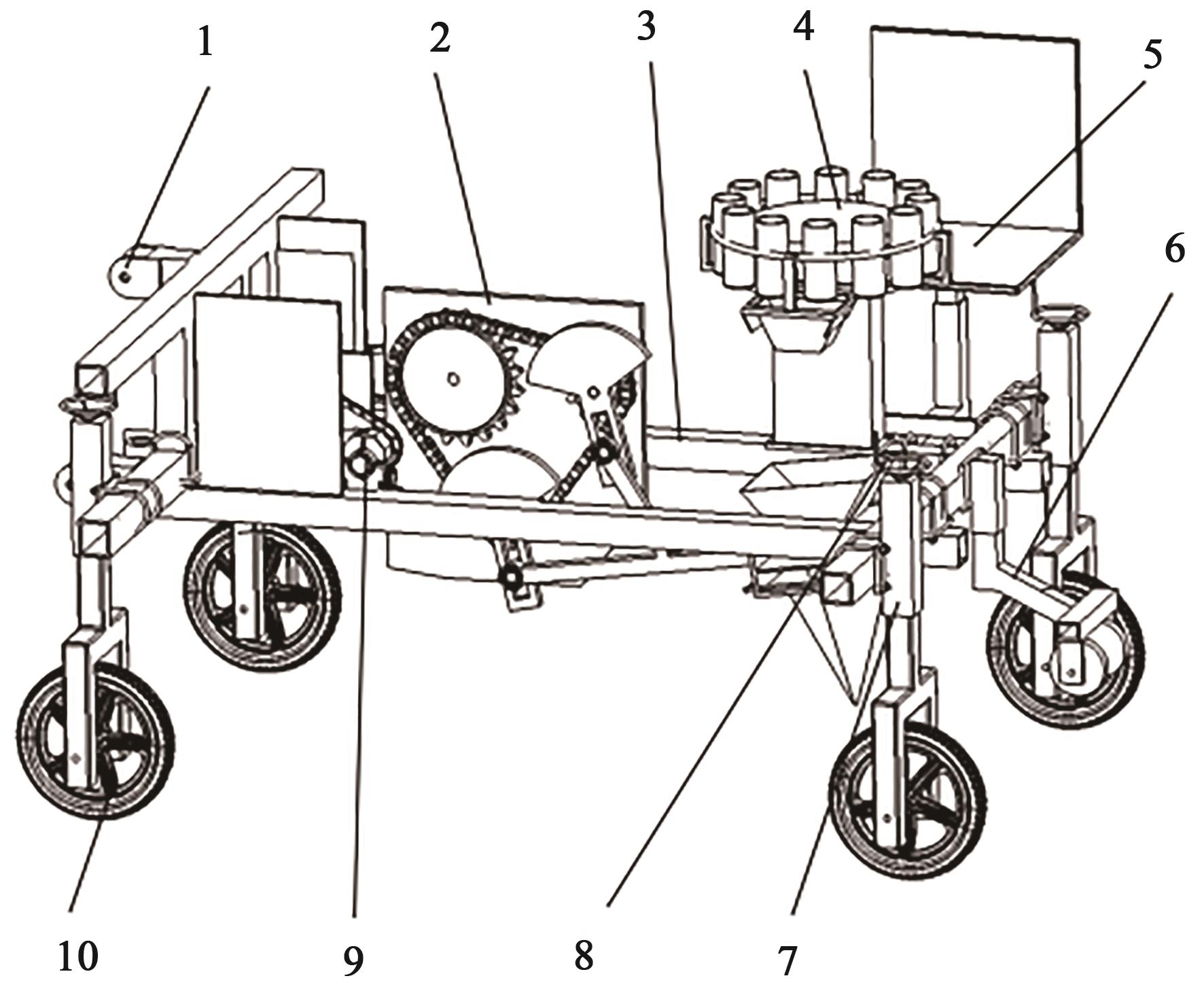

图1 木薯种植机结构注:1—三点悬挂装置;2—播种装置;3—机架;4—分种装置;5—座椅;6—覆土装置;7—机架高度调节装置;8—摇杆;9—减速器;10—行走轮。

Fig. 1 Structural of cassava planterNote: 1—Three point suspension device; 2—Seeding device; 3—Rack; 4—Seeding device; 5—Seats; 6—Earth covering device; 7—Rack height adjustment device; 8—Rocker; 9—Reducer; 10—Traveling wheel.

水平 Level | 因素Factor | ||

|---|---|---|---|

A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm | |

| 1 | 0.4 | 26 | 340 |

| 2 | 0.6 | 34 | 360 |

| 3 | 0.8 | 42 | 380 |

| 4 | 1.0 | 50 | 400 |

| 5 | 1.2 | 58 | 420 |

表1 单因素试验水平

Table 1 Single-factor test levels

水平 Level | 因素Factor | ||

|---|---|---|---|

A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm | |

| 1 | 0.4 | 26 | 340 |

| 2 | 0.6 | 34 | 360 |

| 3 | 0.8 | 42 | 380 |

| 4 | 1.0 | 50 | 400 |

| 5 | 1.2 | 58 | 420 |

编码 Encrypt | A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm |

|---|---|---|---|

| -1 | 0.8 | 34 | 360 |

| 0 | 1.0 | 42 | 380 |

| 1 | 1.2 | 50 | 400 |

表2 试验因素编码

Table 2 Test factor code

编码 Encrypt | A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm |

|---|---|---|---|

| -1 | 0.8 | 34 | 360 |

| 0 | 1.0 | 42 | 380 |

| 1 | 1.2 | 50 | 400 |

序号 No. | A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm | Y1:合格率 Qualification rate/% | Y2:漏种率 Seed leakage rate/% |

|---|---|---|---|---|---|

| 1 | 0 | -1 | 1 | 84.62 | 6.34 |

| 2 | 0 | 0 | 0 | 93.34 | 2.17 |

| 3 | -1 | -1 | 0 | 88.97 | 4.53 |

| 4 | 1 | 1 | 0 | 84.38 | 6.25 |

| 5 | 1 | 0 | -1 | 83.79 | 6.78 |

| 6 | 1 | 0 | 1 | 80.31 | 8.16 |

| 7 | 0 | 0 | 0 | 93.14 | 2.32 |

| 8 | -1 | 0 | -1 | 86.74 | 5.29 |

| 9 | 0 | 1 | 1 | 87.54 | 4.87 |

| 10 | -1 | 1 | 0 | 90.18 | 3.31 |

| 11 | 0 | 0 | 0 | 92.76 | 2.54 |

| 12 | 0 | -1 | -1 | 82.74 | 7.15 |

| 13 | 0 | 0 | 0 | 92.15 | 2.94 |

| 14 | 1 | -1 | 0 | 81.25 | 7.84 |

| 15 | 0 | 0 | 0 | 91.63 | 2.57 |

| 16 | -1 | 0 | 1 | 89.45 | 4.07 |

| 17 | 0 | 1 | -1 | 90.49 | 3.35 |

表3 多因素组合试验方案及结果

Table 3 Multi-factor combination test plan and results

序号 No. | A:前进速度 Forward speed/(m∙s-1) | B:曲柄转速 Crank speed/(r∙min-1) | C:机具高度 Implement height/mm | Y1:合格率 Qualification rate/% | Y2:漏种率 Seed leakage rate/% |

|---|---|---|---|---|---|

| 1 | 0 | -1 | 1 | 84.62 | 6.34 |

| 2 | 0 | 0 | 0 | 93.34 | 2.17 |

| 3 | -1 | -1 | 0 | 88.97 | 4.53 |

| 4 | 1 | 1 | 0 | 84.38 | 6.25 |

| 5 | 1 | 0 | -1 | 83.79 | 6.78 |

| 6 | 1 | 0 | 1 | 80.31 | 8.16 |

| 7 | 0 | 0 | 0 | 93.14 | 2.32 |

| 8 | -1 | 0 | -1 | 86.74 | 5.29 |

| 9 | 0 | 1 | 1 | 87.54 | 4.87 |

| 10 | -1 | 1 | 0 | 90.18 | 3.31 |

| 11 | 0 | 0 | 0 | 92.76 | 2.54 |

| 12 | 0 | -1 | -1 | 82.74 | 7.15 |

| 13 | 0 | 0 | 0 | 92.15 | 2.94 |

| 14 | 1 | -1 | 0 | 81.25 | 7.84 |

| 15 | 0 | 0 | 0 | 91.63 | 2.57 |

| 16 | -1 | 0 | 1 | 89.45 | 4.07 |

| 17 | 0 | 1 | -1 | 90.49 | 3.35 |

来源 Source | 合格率Qualification rate/% | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degrees of freedom | 均方差 Mean squared error | F值 F value | P值 P value | |

| 模型Model | 283.79 | 9 | 31.53 | 15.49 | 0.000 8 |

| A | 81.98 | 1 | 81.98 | 40.28 | 0.000 4 |

| B | 21.74 | 1 | 21.74 | 10.68 | 0.013 7 |

| C | 0.423 2 | 1 | 0.423 2 | 0.207 9 | 0.662 2 |

| AB | 0.921 6 | 1 | 0.921 6 | 0.452 8 | 0.522 6 |

| AC | 9.58 | 1 | 9.58 | 4.71 | 0.066 7 |

| BC | 5.83 | 1 | 5.83 | 2.87 | 0.134 3 |

| A² | 76.34 | 1 | 76.34 | 37.50 | 0.000 5 |

| B² | 23.83 | 1 | 23.83 | 11.71 | 0.011 1 |

| C² | 70.98 | 1 | 70.98 | 34.87 | 0.000 6 |

| 残差Residual | 14.25 | 7 | 2.04 | ||

| 失拟项Lack of fit | 13.43 | 4 | 3.36 | 12.25 | 0.033 5 |

| 纯误差Pure error | 0.822 3 | 3 | 0.274 1 | ||

| 总和Sum | 298.03 | 16 | |||

| R² | 0.952 2 | ||||

表4 合格率方差分析

Table 4 Variance analysis of qualification rate

来源 Source | 合格率Qualification rate/% | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degrees of freedom | 均方差 Mean squared error | F值 F value | P值 P value | |

| 模型Model | 283.79 | 9 | 31.53 | 15.49 | 0.000 8 |

| A | 81.98 | 1 | 81.98 | 40.28 | 0.000 4 |

| B | 21.74 | 1 | 21.74 | 10.68 | 0.013 7 |

| C | 0.423 2 | 1 | 0.423 2 | 0.207 9 | 0.662 2 |

| AB | 0.921 6 | 1 | 0.921 6 | 0.452 8 | 0.522 6 |

| AC | 9.58 | 1 | 9.58 | 4.71 | 0.066 7 |

| BC | 5.83 | 1 | 5.83 | 2.87 | 0.134 3 |

| A² | 76.34 | 1 | 76.34 | 37.50 | 0.000 5 |

| B² | 23.83 | 1 | 23.83 | 11.71 | 0.011 1 |

| C² | 70.98 | 1 | 70.98 | 34.87 | 0.000 6 |

| 残差Residual | 14.25 | 7 | 2.04 | ||

| 失拟项Lack of fit | 13.43 | 4 | 3.36 | 12.25 | 0.033 5 |

| 纯误差Pure error | 0.822 3 | 3 | 0.274 1 | ||

| 总和Sum | 298.03 | 16 | |||

| R² | 0.952 2 | ||||

来源 Source | 漏种率Seed leakage rate/% | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degrees of freedom | 均方差 Mean squared error | F值 F value | P值 P value | |

| 模型Model | 61.75 | 9 | 6.86 | 10.90 | 0.002 4 |

| A | 17.49 | 1 | 17.49 | 27.80 | 0.001 2 |

| B | 5.90 | 1 | 5.90 | 9.37 | 0.018 3 |

| C | 0.094 6 | 1 | 0.094 6 | 0.150 3 | 0.709 7 |

| AB | 0.034 2 | 1 | 0.034 2 | 0.054 4 | 0.822 3 |

| AC | 1.69 | 1 | 1.69 | 2.69 | 0.145 3 |

| BC | 1.36 | 1 | 1.36 | 2.16 | 0.185 4 |

| A² | 16.93 | 1 | 16.93 | 26.90 | 0.001 3 |

| B² | 4.02 | 1 | 4.02 | 6.39 | 0.039 3 |

| C² | 16.02 | 1 | 16.02 | 25.45 | 0.001 5 |

| 残差Residual | 4.41 | 7 | 0.629 3 | ||

| 失拟项Lack of fit | 4.07 | 4 | 1.02 | 9.08 | 0.050 3 |

| 纯误差Pure error | 0.336 3 | 3 | 0.112 1 | ||

| 总和Sum | 66.16 | 16 | |||

| R² | 0.933 4 | ||||

表5 漏种率方差分析

Table 5 Variance analysis of seed leakage rate

来源 Source | 漏种率Seed leakage rate/% | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degrees of freedom | 均方差 Mean squared error | F值 F value | P值 P value | |

| 模型Model | 61.75 | 9 | 6.86 | 10.90 | 0.002 4 |

| A | 17.49 | 1 | 17.49 | 27.80 | 0.001 2 |

| B | 5.90 | 1 | 5.90 | 9.37 | 0.018 3 |

| C | 0.094 6 | 1 | 0.094 6 | 0.150 3 | 0.709 7 |

| AB | 0.034 2 | 1 | 0.034 2 | 0.054 4 | 0.822 3 |

| AC | 1.69 | 1 | 1.69 | 2.69 | 0.145 3 |

| BC | 1.36 | 1 | 1.36 | 2.16 | 0.185 4 |

| A² | 16.93 | 1 | 16.93 | 26.90 | 0.001 3 |

| B² | 4.02 | 1 | 4.02 | 6.39 | 0.039 3 |

| C² | 16.02 | 1 | 16.02 | 25.45 | 0.001 5 |

| 残差Residual | 4.41 | 7 | 0.629 3 | ||

| 失拟项Lack of fit | 4.07 | 4 | 1.02 | 9.08 | 0.050 3 |

| 纯误差Pure error | 0.336 3 | 3 | 0.112 1 | ||

| 总和Sum | 66.16 | 16 | |||

| R² | 0.933 4 | ||||

指标 Indicator | 合格率 Qualification rate/% | 漏种率 Seed leakage rate/% |

|---|---|---|

试验平均值 Test average | 95.47 | 2.05 |

优化值 Optimization value | 93.85 | 1.96 |

相对误差 Relative error | 1.73 | 4.60 |

表6 验证结果

Table 6 Verification result

指标 Indicator | 合格率 Qualification rate/% | 漏种率 Seed leakage rate/% |

|---|---|---|

试验平均值 Test average | 95.47 | 2.05 |

优化值 Optimization value | 93.85 | 1.96 |

相对误差 Relative error | 1.73 | 4.60 |

| 1 | 梁海波,黄洁,安飞飞,等.中国木薯产业现状分析[J].江西农业学报,2016, 28(6):22-26. |

| LIANG H B, HUANG J, AN F F, et al.. Analysis of cassava industry in China [J]. Jiangxi Agric. J., 2016, 28(6): 22-26. | |

| 2 | 陈林涛,牟向伟,薛俊祥,等.国内外木薯机械化种收装备研究现状与展望[J].农业工程,2022,12(2):10-16. |

| CHEN L T, MOU X W, XUE J X, et al..Research status and prospect of cassava mechaninzed planting and harvesting equipment at home and abroad [J]. Agric. Eng., 2022, 12(2):10-16. | |

| 3 | 覃双眉,李明.国内外木薯种植机械研究进展[J].安徽农业科学, 2011, 39(8): 5016-5018. |

| QIN S M, LI M. Research progress of cassava planting machinery at home and abroad [J]. J. Anhui Agric. Sci., 2011, 39(8): 5016-5018. | |

| 4 | 李玲,林晴,邓干然,等.实时切种式木薯种植机漏播监测标记系统设计与试验[J].农机化研究, 2023(1):78-83. |

| LI L, LIN Q, DENG G R, et al.. Design and test of real-time leakage sowing monitoring and marking system for seed-cutting cassava planter [J]. J. Agric. Mechan. Res., 2023(1):78-83. | |

| 5 | 梁欣锐.广西木薯机械化生产关键技术研究[J].广西农业机械化,2015(1):29-31. |

| LIANG X R. Research on the key technology of cassava mechanized production in Guangxi [J]. Guangxi Agric. Mechan., 2015(1):29-31. | |

| 6 | 杨怡,廖宇兰,郑侃,等.木薯田间机械化作业研究现状分析[J].广东农业科学, 2015,42(8):137-140. |

| YANG Y, LIAO Y L, ZHENG K, et al.. Analysis of the current status of mechanized operation in cassava field [J]. Guangdong Agric. Sci., 2015, 42(8):137-140. | |

| 7 | 蒋瑞,黄晖,崔振德.国内外木薯机械化种植技术的研究现状和发展动态[J]. 中国热带农业,2012(3):58-60. |

| JIANG R, HUANG H, CUI Z D. Research status and development trends of cassava mechanized planting technology at home and abroad [J]. China Tropical Agric., 2012(3):58-60. | |

| 8 | 崔振德,邓干然,李玲,等.木薯垄作模式下起垄技术与设备研究进展[J].热带农业工程,2018,42(4):12-16. |

| CUI Z D, DENG G R, LI L, et al.. Research advances of ridging technology and equipment under cassava ridge cuiture model [J]. Trop. Agric. Eng., 2018, 42(4):12-16. | |

| 9 | LUNGKAPIN J, SALOKHE V M, KALSIRISILP R, et al.. Development of a stem cutting unit for a cassava planter [J]. Agric. Eng. Int.: CIGR J., 2007, 9 (4) : 1-16. |

| 10 | LUNGKAPIN J, SALOKHE V M, KALSIRISILP R, et al.. Design and development of a cassava planter [J]. Trans. ASABE, 2009, 52(2):394-399. |

| 11 | OSPINA B, CADAVID L F, MARTHA G,et al.. Mechanizatin possibilities for cassava production in Colombia [C] // Proceedings of the Seventh Regional Workshop Held in Bangkok. Thailand: 2007: 277-287. |

| 12 | 邵仁清,关意昭,周世英.2BMSU/2X旋切开沟式木薯播种机的研制[J].广西农业机械化, 2014(4):34-36. |

| SHAO R Q, GUAN Y Z, ZHOU S Y. Development of 2BMSU/2X rotary cutting and ditching cassava planter [J]. Guangxi Agric. Mechan., 2014(4):34-36. | |

| 13 | 曾伯胜,叶才学,鲁华. 2CMS-2型木薯联合种植机的研究设计[J].广西农业机械化,2011(6):21-22. |

| ZENG B S, YE C X, LU H. Research and design of 2CMS-2 cassava combine planter [J]. Guangxi Agric. Mechan., 2011(6):21-22. | |

| 14 | 崔振德,邓干然,郑爽,等.一种宽窄双行起垄式木薯种植机:CN201910141574.3[P]. 2019-05-14. |

| 15 | 刘炳先,廖宇兰,熊佳,等.木薯收获机抖动链式筛土装置的设计与实验[J].农机化研究,2020,42(6):41-45. |

| LIU B X, LIAO Y L, XIONG J, et al.. Desigh and experiment of dither chain sieving soil device for cassava harvester [J]. J. Agric. Mechan. Res., 2020,42(6):41-45. | |

| 16 | 金鑫,杜新武,杨传华,等.移栽机曲柄滑槽式栽植机构设计与试验[J].农业机械学报, 2016, 47(5):83-90. |

| JIN X, DU X W, YANG C H, et al.. Design and experiment on crank-chute planting mechanism of transplanting machine [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(5):12-21. | |

| 17 | 韩长杰,徐阳,尤佳,等.半自动压缩基质型西瓜钵苗移栽机成穴器参数优化[J].农业工程学报,2019,35(11):48-56. |

| HAN C J, XU Y, YOU J, et al.. Parameter optimization of opener of semi-automatic transplanter for watermelon seedlings raised oncompression substrate [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(11): 48-56. | |

| 18 | 薛忠,张秀梅,陈如约,等.2ZBL-90双行菠萝种植机设计与试验[J].中国农机化学报, 2022, 43(6):9-14. |

| XUE Z, ZHANG X M, CHEN R Y, et al.. Design and experiment of 2ZBL-90 double row pineapple planter [J]. J. Chin. Agric. Mechan., 2022,43(6): 9-14. | |

| 19 | 任露泉.试验设计及其优化[M].北京:科学出版社, 2009:1-259. |

| 20 | 张成军.实验设计与数据处理[M].北京:化学工业出版社,2009:1-175. |

| 21 | 刘智豪,石佳磊,郭朝阳,等.基于Solid Works的装盘式沙漠种植机设计[J].科技创新与应用,2023,13(9):18-21. |

| LIU Z H, SHI J L, GUO C Y, et al.. Design of loading desert planter based on Solid Works [J]. Tech. Innov. Appl., 2023,13(9):18-21. | |

| 22 | 黄柳益.预切种式甘蔗横向种植机开沟器结构优化[J].农业与技术, 2021,41(21):44-47. |

| HUANG L Y. Optimize the structure of pre-cut sugarcane transverse planter [J]. Agric. Technol., 2021,41(21):44-47. |

| [1] | 杨伊琳, 丁俊雄, 吴小华, 王鹏, 孙东亮, 于馨尧, 张振涛, 李栋. 基于响应曲面法优化香菇热风干燥工艺参数[J]. 中国农业科技导报, 2023, 25(6): 154-164. |

| [2] | 柯昊纯, 李琨, 程瑞锋. 营养液紫外LED杀菌模组仿真与响应面法优化[J]. 中国农业科技导报, 2023, 25(4): 132-146. |

| [3] | 何冯光, 邓干然, 崔振德, 郑爽, 李国杰, 李玲, 覃双眉. 自走式木薯茎叶青贮饲料收获机作业性能研究[J]. 中国农业科技导报, 2022, 24(8): 109-115. |

| [4] | 石婷婷, 廖宇兰, 彭绪友, 袁成宇. 单行直插式木薯种植机的设计与优化[J]. 中国农业科技导报, 2022, 24(6): 115-122. |

| [5] | 方芹, 宋世圣, 周婷, 彭才望, 孙松林, 朱海英. 两级分段式黑水虻虫沙滚筒筛分装置设计与试验[J]. 中国农业科技导报, 2022, 24(3): 130-139. |

| [6] | 黄渝岚§, 龙盛风§, 叶兴枝, 李艳英, 申章佑, 周佳, 周灵芝, 劳承英, 韦本辉. 木薯在湖北恩施的农艺性状及产量品质研究[J]. 中国农业科技导报, 2021, 23(9): 46-55. |

| [7] | 王靖会, 程娇娇, 刘洋, 常佳乐, 王朝辉 . 基于高光谱成像技术鉴别大米品种[J]. 中国农业科技导报, 2021, 23(9): 121-128. |

| [8] | 胡广发, 全腊珍, 邹运梅, 沈徽, 匡新鹏, 黄从辉. 农田残膜机械回收膜土分离装置设计与试验[J]. 中国农业科技导报, 2021, 23(7): 82-92. |

| [9] | 向伟1,2,吴明亮1*,吕江南2,马兰2,全伟1,刘佳杰2,肖乐3. 基于EDEM的油菜移栽成穴装置作业性能仿真与试验研究[J]. 中国农业科技导报, 2019, 21(7): 70-81. |

| [10] | 赵方超,王春光*,乌兰图雅. 螺旋式输送装置参数优化研究[J]. 中国农业科技导报, 2019, 21(6): 70-78. |

| [11] | 夏先飞1,肖宏儒1*,肖苏伟1,李波2,李国平2. 基于混合正交试验的生物质旋压成型多目标优化[J]. 中国农业科技导报, 2019, 21(3): 69-75. |

| [12] | 张楠,刘静,牛智有*,史利军,刘朝霞. 颗粒饲料力学特性试验研究[J]. 中国农业科技导报, 2019, 21(2): 82-90. |

| [13] | 邓宇玄1,任奕林1*,杨瑞斌2,彭春晖1,苑晓辰1. 水葫芦压缩打包机设计与工艺参数优化[J]. 中国农业科技导报, 2018, 20(8): 54-62. |

| [14] | 陈新瑶,董星,陈景杰,秦韬,李健*,黄一帆*. 响应曲面法优化猴头菇粗多糖的提取工艺[J]. 中国农业科技导报, 2017, 19(3): 131-136. |

| [15] | 涂德浴1,2,李安心1,何贵生1. 水稻秸秆冷压成型工艺参数优化[J]. , 2015, 17(3): 56-62. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号