中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (2): 89-98.DOI: 10.13304/j.nykjdb.2023.0635

收稿日期:2023-08-23

接受日期:2023-11-16

出版日期:2025-02-15

发布日期:2025-02-14

通讯作者:

黄春光

作者简介:冯长龙E-mail:changlong_feng0919@126.com;

基金资助:

Changlong FENG( ), Chunguang HUANG(

), Chunguang HUANG( ), Chenyang NING, Shuping LI, Kejin CHEN

), Chenyang NING, Shuping LI, Kejin CHEN

Received:2023-08-23

Accepted:2023-11-16

Online:2025-02-15

Published:2025-02-14

Contact:

Chunguang HUANG

摘要:

为实现植树机挖坑机构的低能耗和轻简化,对钻头进行了结构设计和参数优化。应用离散元法建立土壤模型,通过EDEM软件对钻头钻土过程进行动力学仿真。采用Design-Expert软件进行响应面试验方案设计,以切刀刃角、螺旋翼片升角、转速3个因素为自变量,以钻头受到的阻力矩为响应值,构建阻力矩的回归方程并进行方差分析。得出最优参数组合为:切刀刃角为32.778°、螺旋翼片升角为28.316°、转速为160.346 r·min-1,以上参数组合下阻力矩为275.137 N·m,通过验证试验得出误差仅4.38%。通过ANSYS对钻头进行参数优化,优化后质量减轻了34.39%,应力增大了76.28%,此时的安全系数为2.61;变形增大了59.79%,但仍小于1 mm。对优化后钻头进行模态分析发现,各阶固有频率均避开了主要激励频率,避免了共振的发生。以上研究结果可为挖坑机构参数优化提供参考。

中图分类号:

冯长龙, 黄春光, 宁辰阳, 李树平, 陈科锦. 植树机挖坑机构螺旋式钻头性能特性优化研究[J]. 中国农业科技导报, 2025, 27(2): 89-98.

Changlong FENG, Chunguang HUANG, Chenyang NING, Shuping LI, Kejin CHEN. Optimization of Performance and Characteristics of Spiral Drill Bit Excavation Mechanism for Planting Machine[J]. Journal of Agricultural Science and Technology, 2025, 27(2): 89-98.

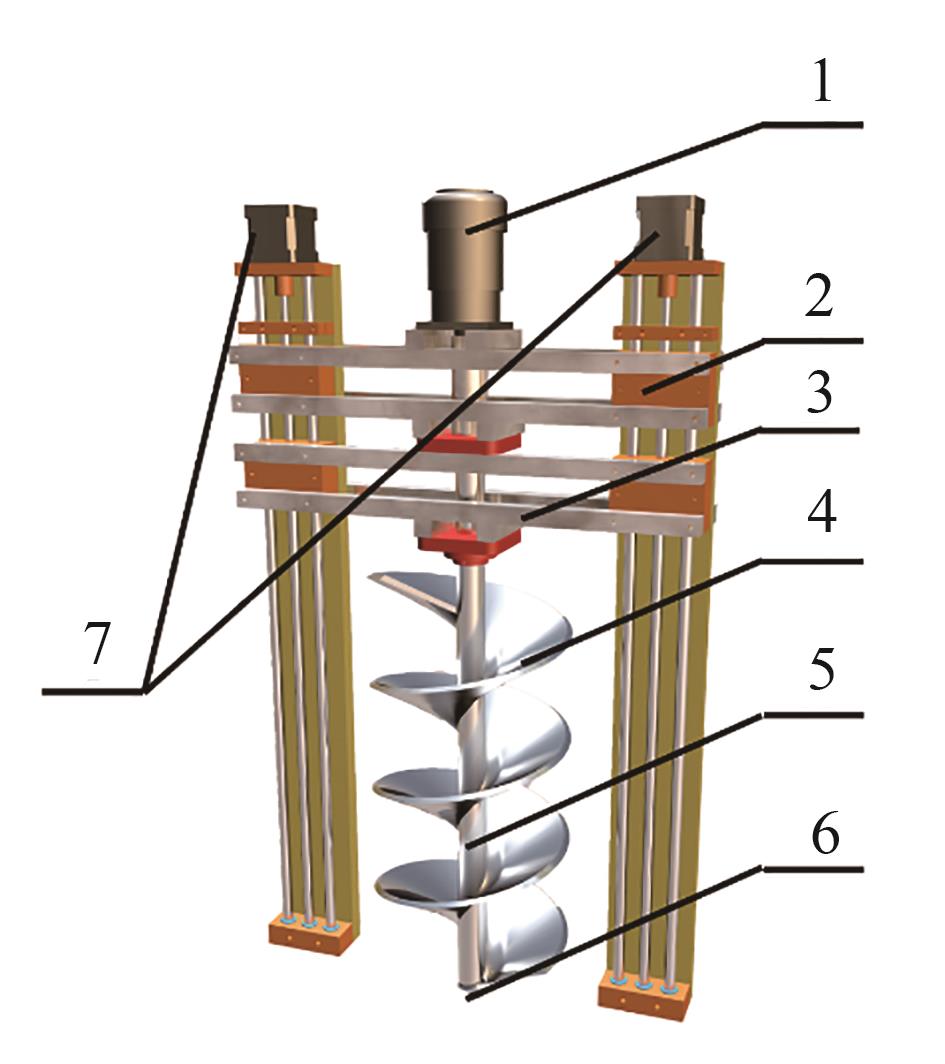

图1 挖坑机构三维模型注:1—挖坑电机;2—滑块;3—横梁支架;4—螺旋翼片;5—钻杆;6—钻头;7—双路平移电机。

Fig. 1 3D model of excavation mechanismNote:1—Trenching motor;2—Slider;3—Slider beam support;4—Helical airfoil;5—Drill pipe;6—Drill bit;7—Dual translation motor.

材料 Material | 泊松比 Poisson ratio | 剪切模量 Shear modulus/Pa | 密度 Density/(kg·m-3) |

|---|---|---|---|

石砾 Gravel | 0.30 | 2.4×1010 | 2550 |

土壤 Soil | 0.38 | 1×106 | 1850 |

不锈钢 Stainless steel | 0.30 | 7.4×1010 | 7750 |

表1 材料参数[20-24]

Table 1 Material parameters[20-24]

材料 Material | 泊松比 Poisson ratio | 剪切模量 Shear modulus/Pa | 密度 Density/(kg·m-3) |

|---|---|---|---|

石砾 Gravel | 0.30 | 2.4×1010 | 2550 |

土壤 Soil | 0.38 | 1×106 | 1850 |

不锈钢 Stainless steel | 0.30 | 7.4×1010 | 7750 |

接触 Contact | 静摩擦系数 Static friction coefficient | 滚动摩擦系数 Rolling friction coefficient | 恢复系数 Restitution coefficient |

|---|---|---|---|

土壤颗粒间 Between soil particles | 0.83 | 0.25 | 0.65 |

石砾颗粒间 Between gravel particles | 0.45 | 0.05 | 0.15 |

土壤与石砾 Soil and gravel | 0.45 | 0.2 | 0.65 |

不锈钢与土壤 Stainless steel and soil | 0.5 | 0.3 | 0.1 |

不锈钢与石砾 Stainless steel and gravel | 0.5 | 0.01 | 0.2 |

表2 接触参数[20-24]

Table 2 Contact parameters[20-24]

接触 Contact | 静摩擦系数 Static friction coefficient | 滚动摩擦系数 Rolling friction coefficient | 恢复系数 Restitution coefficient |

|---|---|---|---|

土壤颗粒间 Between soil particles | 0.83 | 0.25 | 0.65 |

石砾颗粒间 Between gravel particles | 0.45 | 0.05 | 0.15 |

土壤与石砾 Soil and gravel | 0.45 | 0.2 | 0.65 |

不锈钢与土壤 Stainless steel and soil | 0.5 | 0.3 | 0.1 |

不锈钢与石砾 Stainless steel and gravel | 0.5 | 0.01 | 0.2 |

水平 Level | A:切刀刃角 Cutting edge angle/(°) | B:螺旋翼片升角 Helical airfoil lift angle/(°) | C:转速 Rotational speeds/ (r·min-1) |

|---|---|---|---|

| -1 | 30 | 10 | 140 |

| 0 | 45 | 20 | 160 |

| 1 | 60 | 30 | 180 |

表3 试验因素水平

Table 3 Experimental factor levels

水平 Level | A:切刀刃角 Cutting edge angle/(°) | B:螺旋翼片升角 Helical airfoil lift angle/(°) | C:转速 Rotational speeds/ (r·min-1) |

|---|---|---|---|

| -1 | 30 | 10 | 140 |

| 0 | 45 | 20 | 160 |

| 1 | 60 | 30 | 180 |

编号 Code | 因素水平Factor level | M:阻力矩 Resistance torque/(N·m) | ||

|---|---|---|---|---|

A:切刀刃角 Cutting edge angle | B:螺旋翼片升角 Helical airfoil lift angle | C:转速 Rotational speeds | ||

| 1 | -1 | -1 | 0 | 685.475 |

| 2 | 1 | -1 | 0 | 681.554 |

| 3 | -1 | 1 | 0 | 278.468 |

| 4 | 1 | 1 | 0 | 289.596 |

| 5 | -1 | 0 | -1 | 376.185 |

| 6 | 1 | 0 | -1 | 365.417 |

| 7 | -1 | 0 | 1 | 379.904 |

| 8 | 1 | 0 | 1 | 397.908 |

| 9 | 0 | -1 | -1 | 715.795 |

| 10 | 0 | 1 | -1 | 290.69 |

| 11 | 0 | -1 | 1 | 686.357 |

| 12 | 0 | 1 | 1 | 290.833 |

| 13 | 0 | 0 | 0 | 366.207 |

| 14 | 0 | 0 | 0 | 366.207 |

| 15 | 0 | 0 | 0 | 366.207 |

| 16 | 0 | 0 | 0 | 366.207 |

| 17 | 0 | 0 | 0 | 366.207 |

表4 试验方案以及结果

Table 4 Test protocol and results

编号 Code | 因素水平Factor level | M:阻力矩 Resistance torque/(N·m) | ||

|---|---|---|---|---|

A:切刀刃角 Cutting edge angle | B:螺旋翼片升角 Helical airfoil lift angle | C:转速 Rotational speeds | ||

| 1 | -1 | -1 | 0 | 685.475 |

| 2 | 1 | -1 | 0 | 681.554 |

| 3 | -1 | 1 | 0 | 278.468 |

| 4 | 1 | 1 | 0 | 289.596 |

| 5 | -1 | 0 | -1 | 376.185 |

| 6 | 1 | 0 | -1 | 365.417 |

| 7 | -1 | 0 | 1 | 379.904 |

| 8 | 1 | 0 | 1 | 397.908 |

| 9 | 0 | -1 | -1 | 715.795 |

| 10 | 0 | 1 | -1 | 290.69 |

| 11 | 0 | -1 | 1 | 686.357 |

| 12 | 0 | 1 | 1 | 290.833 |

| 13 | 0 | 0 | 0 | 366.207 |

| 14 | 0 | 0 | 0 | 366.207 |

| 15 | 0 | 0 | 0 | 366.207 |

| 16 | 0 | 0 | 0 | 366.207 |

| 17 | 0 | 0 | 0 | 366.207 |

来源 Source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean squares | F | P | 显著性 Significance |

|---|---|---|---|---|---|---|

模型 Model | 3.88×105 | 9 | 4.31×104 | 506.71 | < 0.000 1 | ** |

| A | 26.08 | 1 | 26.08 | 0.31 | 0.596 9 | |

| B | 3.28×105 | 1 | 3.28×105 | 3 857.29 | < 0.000 1 | ** |

| C | 5.98 | 1 | 5.98 | 0.07 | 0.798 5 | |

| AB | 56.62 | 1 | 56.62 | 0.67 | 0.441 3 | |

| AC | 206.96 | 1 | 206.96 | 2.43 | 0.162 6 | |

| BC | 218.76 | 1 | 218.76 | 2.57 | 0.152 7 | |

| A2 | 2.37 | 1 | 2.37 | 0.03 | 0.872 1 | |

| B2 | 5.74×104 | 1 | 5.74×104 | 675.93 | < 0.000 1 | ** |

| C2 | 700.24 | 1 | 700.24 | 8.24 | 0.024 0 | * |

残差 Residual | 595.03 | 7 | 85.00 | |||

失拟项 Lack of fit | 595.03 | 3 | 198.34 | 2.33 | >0.050 0 | |

纯误差 Pure Error | 0 | 4 | 0 | |||

| R2 | 0.998 5 | |||||

调整R2 Adjusted R2 | 0.996 5 | |||||

表5 回归模型的方差分析

Table 5 Variance analysis of regression model

来源 Source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean squares | F | P | 显著性 Significance |

|---|---|---|---|---|---|---|

模型 Model | 3.88×105 | 9 | 4.31×104 | 506.71 | < 0.000 1 | ** |

| A | 26.08 | 1 | 26.08 | 0.31 | 0.596 9 | |

| B | 3.28×105 | 1 | 3.28×105 | 3 857.29 | < 0.000 1 | ** |

| C | 5.98 | 1 | 5.98 | 0.07 | 0.798 5 | |

| AB | 56.62 | 1 | 56.62 | 0.67 | 0.441 3 | |

| AC | 206.96 | 1 | 206.96 | 2.43 | 0.162 6 | |

| BC | 218.76 | 1 | 218.76 | 2.57 | 0.152 7 | |

| A2 | 2.37 | 1 | 2.37 | 0.03 | 0.872 1 | |

| B2 | 5.74×104 | 1 | 5.74×104 | 675.93 | < 0.000 1 | ** |

| C2 | 700.24 | 1 | 700.24 | 8.24 | 0.024 0 | * |

残差 Residual | 595.03 | 7 | 85.00 | |||

失拟项 Lack of fit | 595.03 | 3 | 198.34 | 2.33 | >0.050 0 | |

纯误差 Pure Error | 0 | 4 | 0 | |||

| R2 | 0.998 5 | |||||

调整R2 Adjusted R2 | 0.996 5 | |||||

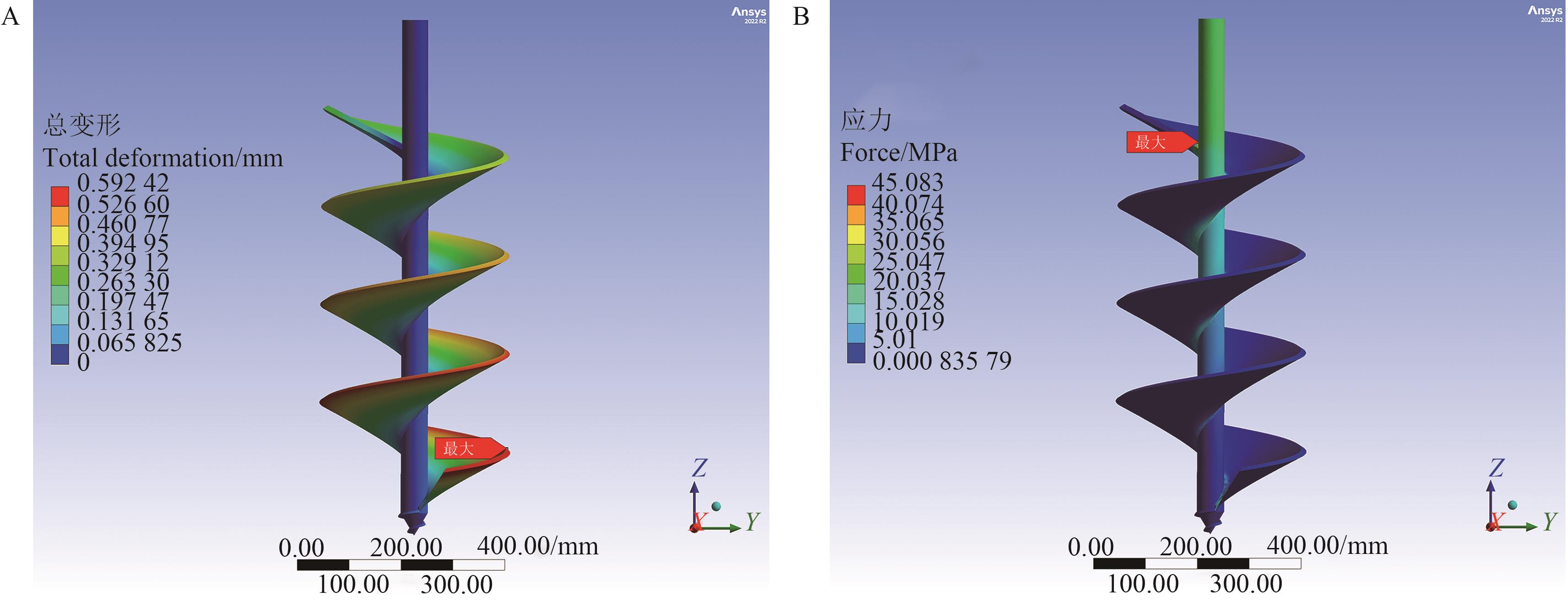

图8 优化前钻头总变形、等效应力云图A:总变形;B:等效应力

Fig. 8 Cloud diagram of total deformation and equivalent forces of the drill bit before optimizationA: Total deformation; B: Equivalent force

图9 优化后总变形、等效应力云图A:总变形;B:等效应力

Fig. 9 Cloud diagram of total deformation and equivalent forces of the drill bit after optimizationA: Total deformation; B: Equivalent force

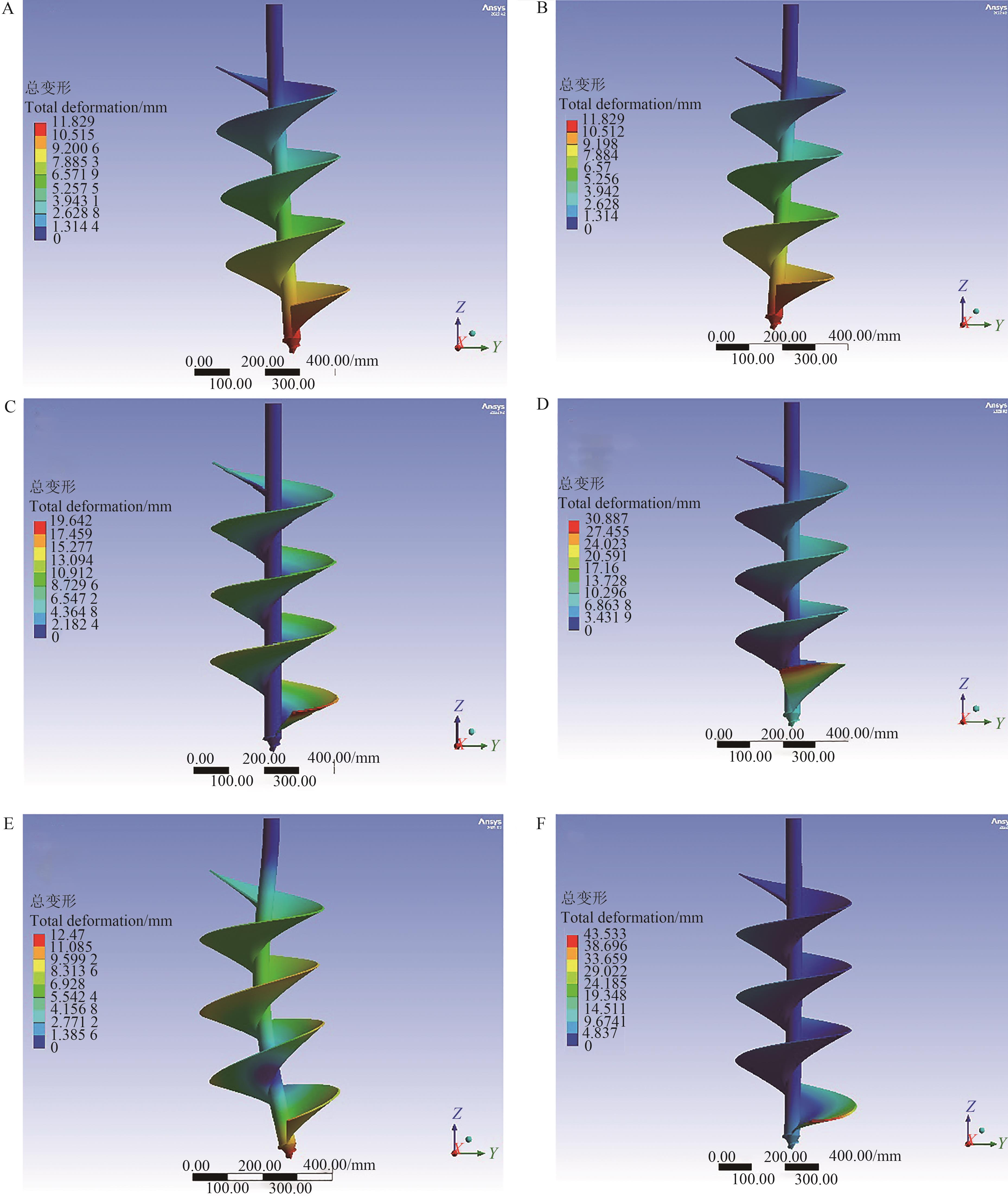

图10 钻头前6阶模态振型仿真A:第1振型;B:第2振型;C: 第3振型;D: 第4振型;E:第5振型;F: 第6振型

Fig. 10 Simulation of the first 6 vibration mode of the drill bitA: First vibration mode; B: Second vibration mode; C: Third vibration mode; D: Fourth vibration mode; E: Fifth vibration mode; F: Sixth vibration mode

阶数 Order | 固有频率 Natural frequency/Hz | 振型 Vibration mode |

|---|---|---|

| 1 | 23.792 | 在YZ平面弯曲Bend at YZ flat |

| 2 | 23.802 | 在YZ平面弯曲Bend at YZ flat |

| 3 | 84.936 | 绕Z轴扭曲Twist around the Z-axis |

| 4 | 129.630 | 绕Z轴扭曲Twist around Z-axis |

| 5 | 132.650 | 在YZ平面扭曲Bend at YZ flat |

| 6 | 141.840 | 在YZ平面扭曲Bend at YZ flat |

表6 钻头前6阶固有频率分析

Table 6 Analysis of the first 6 orders of inherent frequency of the drill bit

阶数 Order | 固有频率 Natural frequency/Hz | 振型 Vibration mode |

|---|---|---|

| 1 | 23.792 | 在YZ平面弯曲Bend at YZ flat |

| 2 | 23.802 | 在YZ平面弯曲Bend at YZ flat |

| 3 | 84.936 | 绕Z轴扭曲Twist around the Z-axis |

| 4 | 129.630 | 绕Z轴扭曲Twist around Z-axis |

| 5 | 132.650 | 在YZ平面扭曲Bend at YZ flat |

| 6 | 141.840 | 在YZ平面扭曲Bend at YZ flat |

| 1 | ZONG W Y, WANG J L, HUANG X M, et al.. Development of a mobile powered hole digger for orchard tree cultivation using a slider-crank feed mechanism [J]. Int. J. Agric. Biol. Eng., 2016, 9(3):48-56. |

| 2 | 于建国,屈锦卫.国内外挖坑机的研究现状及发展趋势[J].农机化研究,2006(12):38-41. |

| YU J G, QU J W. Current research situation and development trend of earth auger in home and abroad [J]. J. Agric. Mech. Res., 2006, 28(12): 38-41. | |

| 3 | 陆建,缪明,卢少颖,等.车载植树挖坑机研究设计与试验[J].中国农机化学报,2014,35(06):44-47, 60. |

| LU J, MIAO M, LU S Y, et al.. Design and test research of digging machine for vehicle planting [J]. J. Chin. Agric. Mech., 2014, 35(6): 44-47, 60. | |

| 4 | 戚开钊,裴新民,靳范,等.MS310型多功能果园作业机挖坑部件的结构设计[J].新疆农机化,2012(2):14-16. |

| 5 | 魏忠彩,李洪文,孙传祝,等.基于多段分离工艺的马铃薯联合收获机设计与试验[J].农业机械学报,2019,50(1):129-140, 112. |

| WEI Z C, LI H W, SUN C Z, et al.. Design and experiment of potato combined harvester based on multi-stage separation technology [J]. Trans. Chin. Soc. Agric. Mach., 2019, 50(1): 129-140, 112. | |

| 6 | ZHANG T, DING X. Drilling forces model for lunar regolith exploration and experimental validation [J]. Acta Astronaut., 2017, 131: 190-203. |

| 7 | 熊良山,师汉民,陈永洁.钻头与钻削研究的历史、现状与发展趋势[J].工具技术,2005(8):11-14. |

| XIONG L S, SHI H M, CHEN Y J. History present situation and future trend of research on drill and drilling process [J]. Tool Eng., 2005(8):11-14. | |

| 8 | SU M. Research on the rapid development of the use and maintenance of earth auger [C]// Proceedings of 2016 International Conference on Economics, Social Science, Arts, Education and Management Engineering. Atlantis Press, 2016: 127-131. |

| 9 | 康杰,孙为云,周喜,等.国内外果木栽植机械研究现状及发展趋势[J].山东工业技术,2019(4):64-65. |

| 10 | 俞国胜,顾正平,钱桦,等.深栽造林钻孔机研制——钻尖结构参数与切刀刃角对钻孔阻力矩的影响[J].北京林业大学学报,2001,23(5):48-51. |

| YU G S, GU Z P, QIAN H, et al.. Deep planting earth auger making and its auger drill bits parameters research [J]. J. Beijing Forestry Univ., 2001, 23(5): 48-51. | |

| 11 | 赵静,朱建国,刘若宸,等.高效深栽牵引式植树机钻螺旋翼片的有限元分析[J].安徽农业科学,2012,40(11):6728-6730. |

| ZHAO J, ZHU J G, LIU R C, et al.. Finite element analysis of the Drill's Wing about efficient and deep planted machine [J]. J. Anhui Agric. Sci., 2012, 40(11):6728-6730. | |

| 12 | 郭贵生,樊相印,吴希锈,等.螺旋升角对钻头工作性能影响规律的研究[J].西北农业大学学报,1995,23(3):88-92. |

| GUO G S, FAN X Y, WU X X, et al.. Effect of screw angle on the screw anger work performance [J]. J. Northwest A&F Univ. (Nat. Sci.), 1995, 23(3):88-92. | |

| 13 | 任工昌,朱俊平,薛文灿,等.挖坑机钻头螺旋面强度分析及结构参数探讨[J].西北农业大学学报,1994,22(3):65-68. |

| REN G C, ZHU J P, XUE W C, et al.. Strength analysis of screw surface and structure parameters study of auger of mounted hole digger[J]. J. Northwest A&F Univ. (Nat. Sci.),1994,22(3):65-68. | |

| 14 | HUANG T, DU M, GU X, et al.. The influence of bit edge shape parameters on bone drilling force based on finite element analysis [J/OL]. Appl. Sci., 2022, 12(17): 8551 [2024-06-14]. . |

| 15 | WANG G F, ZHANG W, JI M, et al.. Numerical simulation and parameter optimization of earth auger in hilly area using EDEM software [J/OL]. Sci. Rep., 2022, 12(1): 19526 [2024-06-14]. . |

| 16 | 杨勇,梁尚明,贺亚博.一种手提式挖坑机的研究分析[J].机械设计与制造,2021(6):126-129. |

| YANG Y, LIANG S M, HE Y B. Research and analysis of a portable digging machine [J]. Mach. Design Manufacture, 2021(6):126-129. | |

| 17 | 蒋开苏.挖坑机钻头升土理论的研究──关于钻头临界速度的商榷[J].中南林学院学报,1997(3):71-75. |

| JIANG K S. A discussion on bit critical speed of hole diggers during soil lifting [J]. J. Central S. Univ. Forestry & Technol.,1997(3):71-75. | |

| 18 | 王宪良,胡红,王庆杰,等.基于离散元的土壤模型参数标定方法[J].农业机械学报,2017,48(12):78-85. |

| WANG X L, HU H, WANG Q J, et al.. Calibration method of soil contact characteristic parameters based on DEM theory [J]. Trans. Chin. Soc. Agric. Mach., 2017,48(12):78-85. | |

| 19 | SHMULEVICH I, ASAF Z, RUBINSTEIN D. Interaction between soil and a wide cutting blade using the discrete element method [J]. Soil Till. Res., 2007, 97(1):37-50. |

| 20 | 姜珊珊.基于离散元法的开沟器试验研究[D].长春:吉林农业大学,2014. |

| JIANG S S. Experimental research of furrow openers based on DEM [D]. Changchun: Jilin Agricultural University, 2014. | |

| 21 | QI J T, AN S G, KAN Z, et al.. Discrete element-based calibration of simulation parameters of Cyperus esculentus L. (tiger nut) planted in sandy soil [J/OL]. J. Food Process. Preservation, 2021,45(7):15631 [2024-06-14]. . |

| 22 | 武涛,黄伟凤,陈学深,等.考虑颗粒间黏结力的黏性土壤离散元模型参数标定[J].华南农业大学学报,2017,38(3):93-98. |

| WU T, HUANG W F, CHEN X S, et al.. Calibration of discrete element model parameters for cohesive soil considering the cohesion between particles [J]. J. South China Agric. Univ., 2017,38(3):93-98. | |

| 23 | 赵淑红,刘汉朋,侯磊涛,等.基于离散元法的免耕深施肥分段式玉米播种开沟器研制[J].农业工程学报,2021,37(13):1-10. |

| ZHAO S H, LIU H P, HOU L T, et al.. Development of deep fertilizing no-tillage segmented maize sowing opener using discrete element method [J]. Trans. Chin. Soc. Agric. Eng.,2021,37 (13):1-10. | |

| 24 | 靳成.基于EDEM的挖坑机钻头-土壤动力学仿真与试验研究[D].福州:福建农林大学,2022. |

| JIN C. Dynamics simulation and experimental investigation of earth auger bit-soil based on EDEM [D]. Fuzhou: Fujian Agriculture and Forestry University,2022. | |

| 25 | 陈健波,蒙海华,黄锦芬,等.丘陵地种植穴规格对尾巨桉生长的影响[J].广西林业科学,2015,44(3):276-278. |

| CHEN J B, MENG H H, HUANG J F, et al.. Effects of planting hole size on growth of Eucalyptus grandis × E. urophylla in hilly ground [J]. Guangxi Forestry Sci.,2015,44(3):276-278. | |

| 26 | 赵忠松,卢博友,王天赐.基于ANSYS的悬挂式挖坑机钻头静力学分析[J].农机化研究,2010,32(6):87-89, 113. |

| ZHAO Z S, LU B Y, WANG T C. Static analysis for the auger of mounted hole digger based on ANSYS [J]. J. Agric. Mech. Res., 2010,32(6),87-89, 113. | |

| 27 | 朱晓鹏,张纪鹏,程联军,等.基于ANSYS Workbench的某轻型货车车架轻量化设计[J]. 青岛大学学报(工程技术版),2014,29(3):70-76. |

| ZHU X P, ZHANG J P, CHEN L J, et al.. Research on lightweight design and optimization of a light duty truck frame based on ANSYS workbench [J]. J. Qingdao Univ. (Eng. Technol.), 2014,29(3)70-76. | |

| 28 | 郭超凡,李粤,姚德宇,等.仿生香蕉秸秆粉碎装置关键部件作业参数优化与试验[J].中国农机化学报,2022,43(1):93-100. |

| GUO C F, LI Y, YAO D Y, et al.. Optimization and experiment of operating parameters of key components of bionic banana straw crushing devices [J]. J. Chin. Agric. Mech., 2022,43(1):93-100. | |

| 29 | 刘春景,唐敦兵,郑加强,等.滴灌梯形迷宫滴头流道水力性能的响应曲面法优化[J].农业工程学报,2011,27(2):46-51. |

| LIU C J, TANG D B, ZHENG J Q, et al.. Optimization of hydraulic performance for drip irrigation trapezoidal labyrinth channel of emitter using response surface methodology [J]. Trans. Chin. Soc. Agric. Eng., 2011, 27(2): 46-51. | |

| 30 | ZHANG Y Y, KONG L Q, SHI J. Finite element analysis and structural optimization of mine man-car skip underframe [J]. Adv. Materials Res., 2013, 842:591-595. |

| [1] | 张如艳, 李绅昊, 朱奇鹏, 冯太纲, 李红波, 邢泽炳, 羡瑜. 生物炭含量对园林绿化废弃物/聚乳酸复合材料物理力学性能影响[J]. 中国农业科技导报, 2025, 27(2): 192-200. |

| [2] | 郗婧怡, 王双庆, 白一彤, 姚秀利, 黄碧璇, 李青怡, 范丽清, 黄世臣, 孙明国. 响应面法优化黑水虻处理餐厨垃圾工艺参数研究[J]. 中国农业科技导报, 2025, 27(1): 241-249. |

| [3] | 傅丽君, 林潇雨, 林建华, 沈慧男, 吴勇镇. 红松茸牛肉酱加工工艺及货架期研究[J]. 中国农业科技导报, 2024, 26(6): 148-158. |

| [4] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [5] | 张岚雄, 郑威, 陈源桉, 沈婧, 邹双全, 伍建榕, 倪林. 樟叶总木脂素提取工艺及其抑菌活性研究[J]. 中国农业科技导报, 2024, 26(5): 138-147. |

| [6] | 刘东玲, 司皓, 郑宝江, 张玉红. 响应面法优化酶解辅助-超声提取菥蓂中的黑芥子苷[J]. 中国农业科技导报, 2024, 26(4): 225-233. |

| [7] | 黄元昊, 全腊珍, 胡广发, 全伟, 石方刚. 多种材料与不同含水率土壤的离散元接触参数标定[J]. 中国农业科技导报, 2024, 26(3): 98-109. |

| [8] | 黄椿, 李粤, 位士全, 高阳, 吴紫晗, 黄麒润, 魏晨辉. 异向双轴香蕉秸秆粉碎还田机设计与试验[J]. 中国农业科技导报, 2024, 26(11): 97-106. |

| [9] | 李琦, 张树林, 张达娟, 贾滢暄, 王泽斌. 响应面法改良牟氏角毛藻培养基[J]. 中国农业科技导报, 2023, 25(8): 225-233. |

| [10] | 赵秀英, 黄晴雯, 曹浩杰, 王杰, 李瑞姣, 聂冬霞, 韩铮, 赵志辉. 响应面法优化禾谷镰刀菌产脱氧雪腐镰刀菌烯醇及其衍生物的液体培养条件[J]. 中国农业科技导报, 2023, 25(7): 222-233. |

| [11] | 李绍波, 张阔, 王佳, 李建平, 刘树腾. 基于CFD的风送喷雾装置风筒参数优化[J]. 中国农业科技导报, 2023, 25(12): 93-102. |

| [12] | 马紫涛, 赵智豪, 全伟, 石方刚, 高晨, 吴明亮. 基于EDEM的水稻残茬秸秆离散元仿真参数标定[J]. 中国农业科技导报, 2023, 25(11): 103-113. |

| [13] | 闫建伟, 魏松, 胡冬军, 刘启合, 张富贵. 白萝卜种子颗粒模型离散元接触参数标定与试验[J]. 中国农业科技导报, 2022, 24(5): 119-128. |

| [14] | 王凯强, 杨雪, 李常风, 段晓, 彭晴, 乔宇, 石波. 响应面法优化低聚木糖诱导大豆抗毒素合成条件[J]. 中国农业科技导报, 2022, 24(10): 208-217. |

| [15] | 全伟, 吴明亮, 官春云, 罗海峰. 油菜钵苗移栽机成穴器外形优化试验研究[J]. 中国农业科技导报, 2021, 23(10): 97-106. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号