中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (12): 93-102.DOI: 10.13304/j.nykjdb.2022.0586

李绍波1( ), 张阔1, 王佳1, 李建平1,2(

), 张阔1, 王佳1, 李建平1,2( ), 刘树腾1

), 刘树腾1

收稿日期:2022-07-13

接受日期:2022-09-21

出版日期:2023-12-15

发布日期:2023-12-12

通讯作者:

李建平

作者简介:李绍波E-mail:sean18135144508@163.com;

基金资助:

Shaobo LI1( ), Kuo ZHANG1, Jia WANG1, Jianping LI1,2(

), Kuo ZHANG1, Jia WANG1, Jianping LI1,2( ), Shuteng LIU1

), Shuteng LIU1

Received:2022-07-13

Accepted:2022-09-21

Online:2023-12-15

Published:2023-12-12

Contact:

Jianping LI

摘要:

喷雾装置中风筒的聚风性能对果园风送喷雾机的作业质量具有重要影响,风筒的出口风速和风场的纵向幅宽是决定喷雾装置作业性能的重要因素。对风筒风场进行仿真模拟,设计对标试验确定了仿真模型与计算的可靠性。设计单因素试验和响应面优化试验分析筒壁与轴线的夹角、风筒长度和风机转速对风筒聚风性能的影响。结果表明:风筒长度和风机转速对风速的影响显著,提升风机转速或降低风筒长度有助于提高风速。风筒长度、筒壁与轴线的夹角和风机转速对纵向幅宽影响显著,影响显著的顺序为风筒长度>筒壁与轴线的夹角>风机转速。风筒最佳参数设计组合:风筒长度为540 mm、筒壁与轴线的夹角为3°、风机转速为2 000 r·min-1,此组合下风送喷雾装置风筒风速为9.21 m·s-1,风场纵向幅宽为1 627 mm。研究结果可为远射程喷雾机喷雾装置结构优化提供参考。

中图分类号:

李绍波, 张阔, 王佳, 李建平, 刘树腾. 基于CFD的风送喷雾装置风筒参数优化[J]. 中国农业科技导报, 2023, 25(12): 93-102.

Shaobo LI, Kuo ZHANG, Jia WANG, Jianping LI, Shuteng LIU. Optimization of Air Duct Parameters of Air Supply Spray Device Based on CFD[J]. Journal of Agricultural Science and Technology, 2023, 25(12): 93-102.

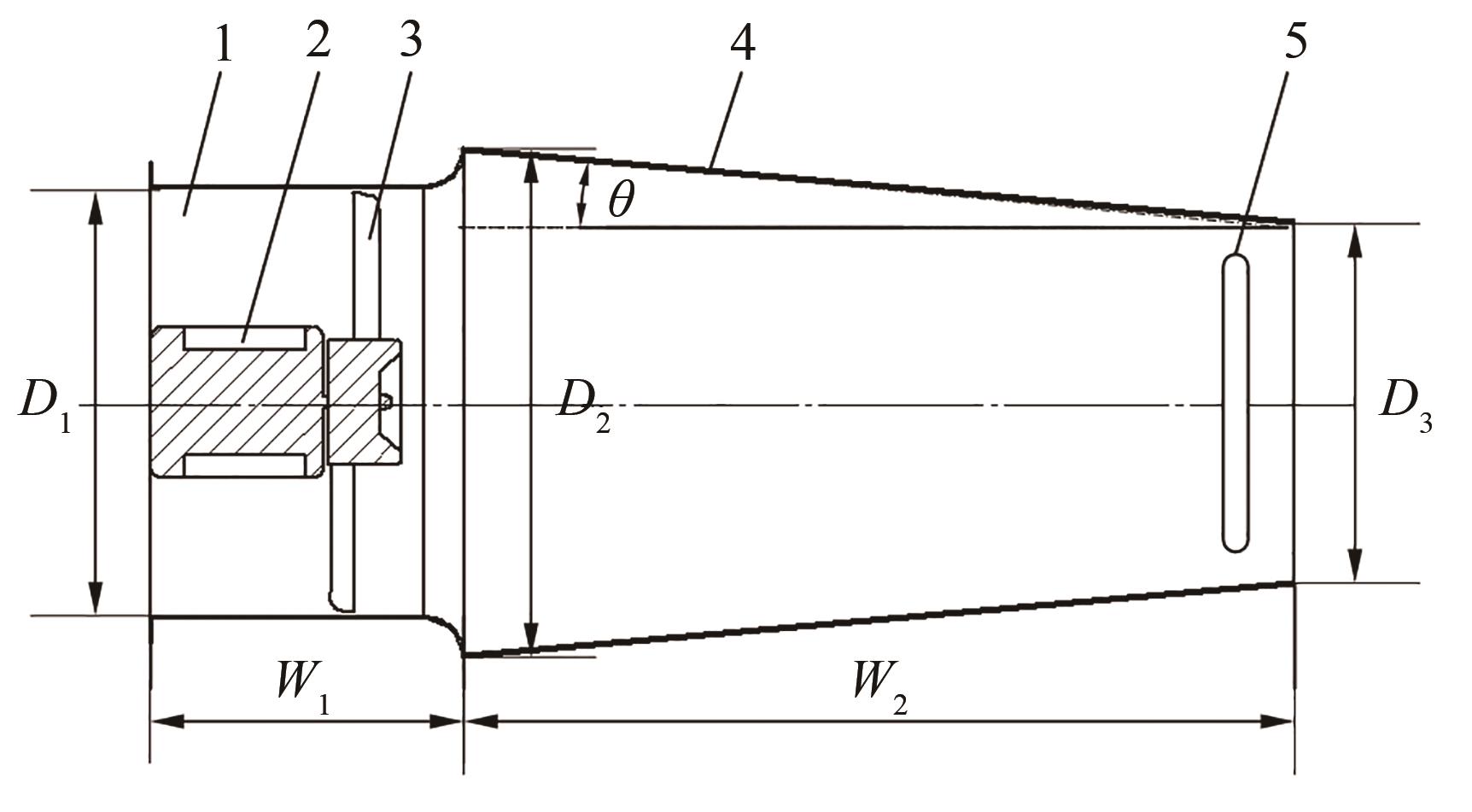

图1 风筒剖视结构注:1—轴流风机;2—电机;3—扇叶;4—风筒;5—环型喷雾装置;D1—风机直径;D2—风筒进口端面直径;D3—风筒出口端面直径;W1—风机宽度;W2—风筒长度;θ—筒壁与轴线的夹角。

Fig. 1 Air duct cross-sectional structureNote:1—Axial flow fan; 2—Motor; 3—Blade; 4—Ram; 5.—Ring spray device; D1—Fan diameter; D2—Diameter of the air duct inlet end face; D3—End face diameter of air duct outlet; W1—Fan width; W2—Length of air duct; θ—Angle between cylinder wall and axis.

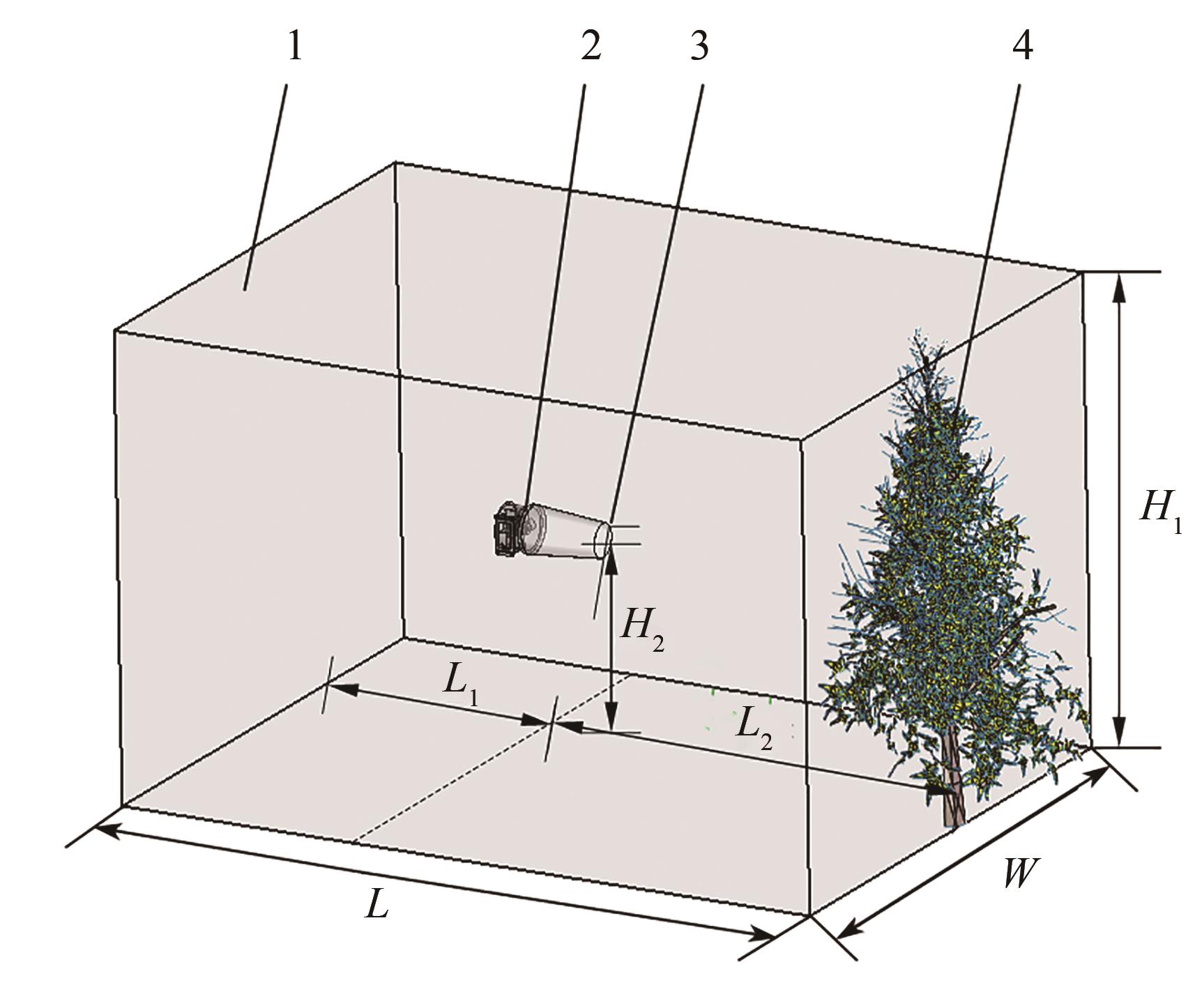

图2 风筒三维空间模型注:1—计算域;2—风机旋转域;3—风筒;4—果树模型;W—计算域宽度;L—计算域长度;H1—计算域高度;L1—风筒出风口距计算域左侧边界的距离;L2—风筒风筒出口距果树的距离;H2—风机轴线与计算域地面的距离。

Fig. 2 Three-dimensional model of air ductNote:1—Computing domain; 2—Rotation domain; 3—Ram; 4—Fruit tree model; W—Width of the computational domain; L—Length of the computational domain; H1—Height of computing domain; L1—Distance between the air duct outlet and the left boundary of the computing domain; L2—Distance between the outlet of air duct and the fruit tree; H2—Distance between the fan axis and the ground of the computing domain.

水平 Level | 因素 Factor | ||

|---|---|---|---|

| A:筒壁与轴线的夹角Angle between cylinder wall and axis/(°) | B:风筒长度Air duct length/mm | C:风机转速Fan speed/ (r·min-1) | |

| -1 | 3 | 400 | 1 500 |

| 0 | 4 | 500 | 2 000 |

| 1 | 5 | 600 | 2 500 |

表1 聚风性能试验因素水平

Table 1 Factor level wind gathering test

水平 Level | 因素 Factor | ||

|---|---|---|---|

| A:筒壁与轴线的夹角Angle between cylinder wall and axis/(°) | B:风筒长度Air duct length/mm | C:风机转速Fan speed/ (r·min-1) | |

| -1 | 3 | 400 | 1 500 |

| 0 | 4 | 500 | 2 000 |

| 1 | 5 | 600 | 2 500 |

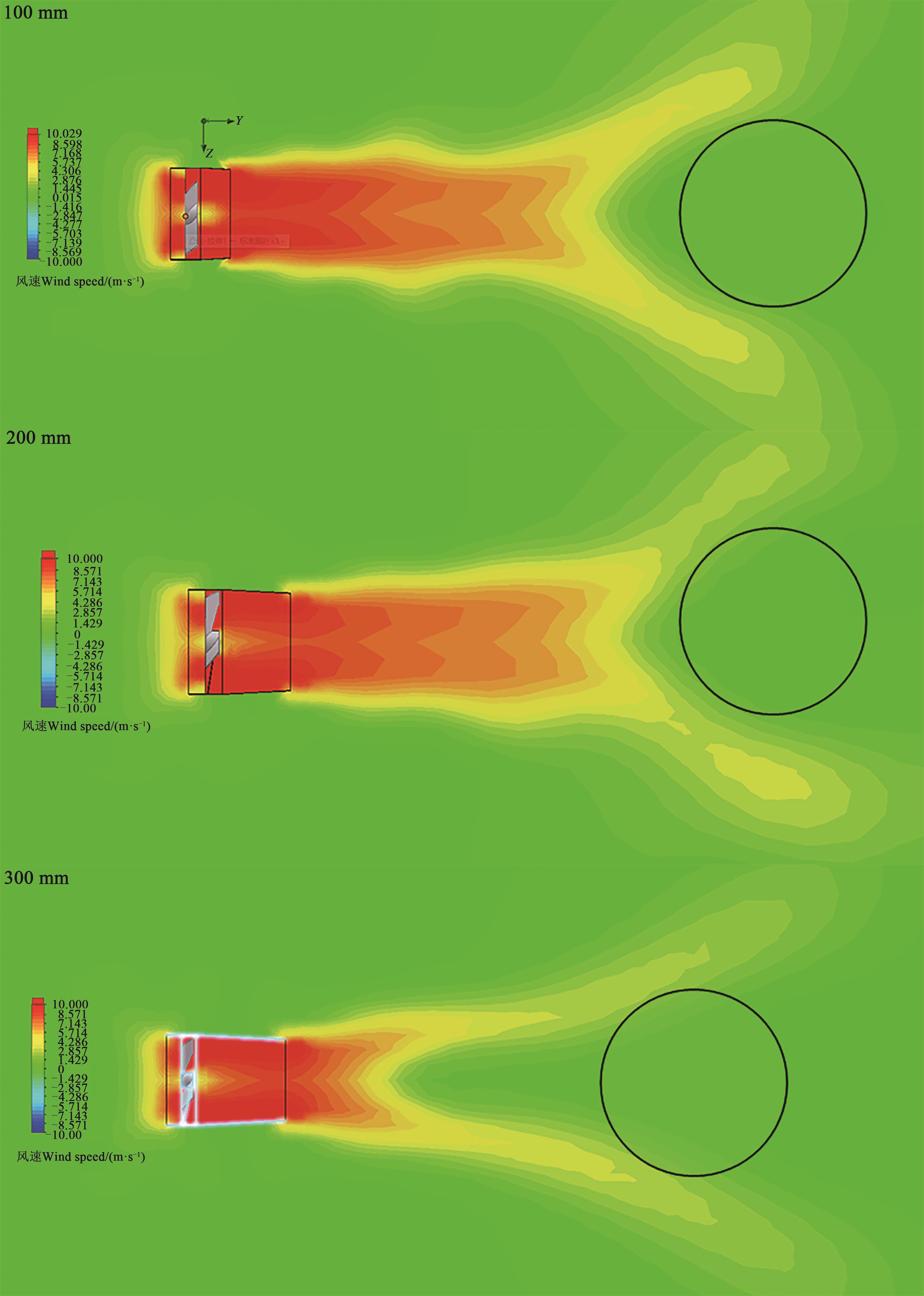

图8 风筒长度100、200和300 mm的风速切面云图注:颜色越深表示风速越大,圆圈区域是气流没有扰动的区域。

Fig. 8 Section cloud images of wind speed with duct lengths of 100, 200 and 300 mmNote:The darker the color, the higher the wind speed, and the circular box area is the area where the airflow is not disturbed.

序号 Number | A | B | C | 风速Wind speed/(m·s-1) | 风场纵向幅宽Longitudinal width of wind field /mm |

|---|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 6.25 | 1 012.23 |

| 2 | 1 | -1 | 0 | 6.94 | 1 205.15 |

| 3 | -1 | 1 | 0 | 7.38 | 1 788.48 |

| 4 | 1 | 1 | 0 | 7.17 | 2 657.45 |

| 5 | -1 | 0 | -1 | 5.26 | 1 245.13 |

| 6 | 1 | 0 | -1 | 4.54 | 1 886.49 |

| 7 | -1 | 0 | 1 | 6.15 | 1 877.75 |

| 8 | 1 | 0 | 1 | 9.18 | 2 250.14 |

| 9 | 0 | -1 | -1 | 4.57 | 1 371.13 |

| 10 | 0 | 1 | -1 | 5.86 | 2 206.46 |

| 11 | 0 | -1 | 1 | 5.61 | 2 017.78 |

| 12 | 0 | 1 | 1 | 9.84 | 2 747.23 |

| 13 | 0 | 0 | 0 | 9.28 | 2 286.36 |

| 14 | 0 | 0 | 0 | 9.49 | 2 150.89 |

| 15 | 0 | 0 | 0 | 8.99 | 2 135.56 |

| 16 | 0 | 0 | 0 | 10.54 | 2 058.55 |

| 17 | 0 | 0 | 0 | 8.65 | 2 350.38 |

表2 响应面方案及其结果

Table 2 Response surface scheme and results

序号 Number | A | B | C | 风速Wind speed/(m·s-1) | 风场纵向幅宽Longitudinal width of wind field /mm |

|---|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 6.25 | 1 012.23 |

| 2 | 1 | -1 | 0 | 6.94 | 1 205.15 |

| 3 | -1 | 1 | 0 | 7.38 | 1 788.48 |

| 4 | 1 | 1 | 0 | 7.17 | 2 657.45 |

| 5 | -1 | 0 | -1 | 5.26 | 1 245.13 |

| 6 | 1 | 0 | -1 | 4.54 | 1 886.49 |

| 7 | -1 | 0 | 1 | 6.15 | 1 877.75 |

| 8 | 1 | 0 | 1 | 9.18 | 2 250.14 |

| 9 | 0 | -1 | -1 | 4.57 | 1 371.13 |

| 10 | 0 | 1 | -1 | 5.86 | 2 206.46 |

| 11 | 0 | -1 | 1 | 5.61 | 2 017.78 |

| 12 | 0 | 1 | 1 | 9.84 | 2 747.23 |

| 13 | 0 | 0 | 0 | 9.28 | 2 286.36 |

| 14 | 0 | 0 | 0 | 9.49 | 2 150.89 |

| 15 | 0 | 0 | 0 | 8.99 | 2 135.56 |

| 16 | 0 | 0 | 0 | 10.54 | 2 058.55 |

| 17 | 0 | 0 | 0 | 8.65 | 2 350.38 |

变异来源 Source of variation | 风速Wind speed | 风场纵向幅宽Longitudinal width of wind field | ||

|---|---|---|---|---|

| F1 | P1 | F2 | P2 | |

| 模型Model | 9.08 | 0.004 1 | 29.63 | <0.000 1 |

| A | 1.45 | 0.268 1 | 39.91 | 0.000 4 |

| B | 8.54 | 0.022 3 | 118.16 | <0.000 1 |

| C | 20.75 | 0.002 6 | 43.70 | 0.000 3 |

| AB | 0.299 2 | 0.601 4 | 8.46 | 0.002 7 |

| AC | 5.56 | 0.049 3 | 0.388 | 0.552 9 |

| BC | 3.11 | 0.121 4 | 0.691 | 0.433 4 |

| A2 | 10.88 | 0.013 1 | 49.17 | 0.000 2 |

| B2 | 7.84 | 0.026 5 | 4.45 | 0.072 8 |

| C2 | 19.54 | 0.003 1 | 0.055 | 0.821 3 |

| 失拟误差 Lack of fit | 1.66 | 0.310 4 | 0.684 | 0.606 8 |

表3 响应面试验结果方差分析

Table 3 Analysis of variance of response surface test

变异来源 Source of variation | 风速Wind speed | 风场纵向幅宽Longitudinal width of wind field | ||

|---|---|---|---|---|

| F1 | P1 | F2 | P2 | |

| 模型Model | 9.08 | 0.004 1 | 29.63 | <0.000 1 |

| A | 1.45 | 0.268 1 | 39.91 | 0.000 4 |

| B | 8.54 | 0.022 3 | 118.16 | <0.000 1 |

| C | 20.75 | 0.002 6 | 43.70 | 0.000 3 |

| AB | 0.299 2 | 0.601 4 | 8.46 | 0.002 7 |

| AC | 5.56 | 0.049 3 | 0.388 | 0.552 9 |

| BC | 3.11 | 0.121 4 | 0.691 | 0.433 4 |

| A2 | 10.88 | 0.013 1 | 49.17 | 0.000 2 |

| B2 | 7.84 | 0.026 5 | 4.45 | 0.072 8 |

| C2 | 19.54 | 0.003 1 | 0.055 | 0.821 3 |

| 失拟误差 Lack of fit | 1.66 | 0.310 4 | 0.684 | 0.606 8 |

试验序号 No. | 风速 Wind speed | 纵向幅宽 Longitudinal width | ||||

|---|---|---|---|---|---|---|

预测值 Predictive value/(m·s-1) | 试验值 Actual value/ (m·s-1) | 相对误差 Relative error/% | 预测值 Predictive value/mm | 试验值 Predictive value/mm | 相对误差 Relative error/% | |

| 1 | 9.25 | 8.84 | 4.63 | 1 575 | 1 650 | 4.55 |

| 2 | 9.37 | 1.28 | 1 620 | 2.78 | ||

| 3 | 9.15 | 1.09 | 1 610 | 2.17 | ||

| 平均Mean | 9.12 | — | 1 627 | — | ||

表4 风速和纵向幅宽优化模型预测值与试验值

Table 4 Predicted and tested values of wind speed and longitudinal width optimization mode

试验序号 No. | 风速 Wind speed | 纵向幅宽 Longitudinal width | ||||

|---|---|---|---|---|---|---|

预测值 Predictive value/(m·s-1) | 试验值 Actual value/ (m·s-1) | 相对误差 Relative error/% | 预测值 Predictive value/mm | 试验值 Predictive value/mm | 相对误差 Relative error/% | |

| 1 | 9.25 | 8.84 | 4.63 | 1 575 | 1 650 | 4.55 |

| 2 | 9.37 | 1.28 | 1 620 | 2.78 | ||

| 3 | 9.15 | 1.09 | 1 610 | 2.17 | ||

| 平均Mean | 9.12 | — | 1 627 | — | ||

| 1 | 华经产业研究院. 2022-2027年中国水果行业市场全景评估及投资方向研究报告[R].华经情报网,2021. |

| 2 | 丁素明,傅锡敏,薛新宇,等.低矮果园自走式风送喷雾机研制与试[J].农业工程学报,2013,29(15): 18-25. |

| DING S M, FU X M, XUE X Y, et al.. Development and test of self-propelled air supply sprayer for low orchard [J]. Chin. Soc. Agric. Eng., 2013,29(15) : 18-25. | |

| 3 | 边永亮,李建平,薛春林,等.单旋翼油动无人机与圆形果园风送喷雾机作业性能对比试验研究[J].中国农业大学学报,2020,25(12):134-141. |

| BIAN Y L, LI J P, XUE C L, et al.. Comparative experimental study on operation performance of single rotor oil powered UAV and round orchard air delivery sprayer [J]. J. China Agric. Univ., 2020,25(12):134-141. | |

| 4 | 周良富,薛新宇,周立新,等.果园变量喷雾技术研究现状与前景分析[J].农业工程学报,2017,33(23):80-92. |

| ZHOU L F, XUE X Y, ZHOU L X, et al.. The present situation and prospect analysis of the variable spray technology in orchard [J]. Chin. Soc. Agric. Eng., 2017,33(23):80-92. | |

| 5 | 翟长远,赵春江,王秀,等.果园风送喷雾精准控制方法研究进展[J].农业工程学报,2018,34(10):1-15. |

| ZHAI C Y, ZHAO C J, WANG X, et al.. Research progress on precision control method of air-fed spraying in orchard [J]. Chin. Soc. Agric. Eng., 2018,34(10) : 1-15. | |

| 6 | KHO L R, EHSANI R, MAJA J M J, et al.. Evaluation of deposition and coverage by an air-assisted sprayer and two air-blast sprayers in a citrus orchard [J]. Tran. ASABE, 2014, 57(4): 1007-1013. |

| 7 | 窦汉杰,翟长远,陈立平,等.果园风送喷雾风力调控方法研究进展[J].农机化研究,2021,43(7):10-18. |

| DOU H J, ZHAI C Y, CHEN L P, et al.. Research progress on wind control methods of air spraying in orchards [J]. Agric. Mech. Res., 201,43(7):10-18 | |

| 8 | 傅锡敏,吕晓兰,丁为民.我国果园植保机械现状与技术需求[J].新疆农机化,2011(1):61-63. |

| FU X M, LYU X L, DING W M, et al.. Current situation and technical demand of orchard plant protection machinery in China [J]. J. Xinjiang Agric. Mech., 2011(1):61-63. | |

| 9 | BIOCCA M, GALLO P. Comparison between horizontal and vertical lamellate patentors for air-blast sprayers [J]. J. Open Agric., 2014, 8(1)12-17. |

| 10 | VAN ZYL J G, GROUT T G, SCHUTTE G C, et al.. Reduced volume spray application in south african citrus orchards: effects on deposition quantity, quality and uniformity [J]. Julius-Kühn-Archiv., 2015 (448): 51-52. |

| 11 | PERGHER G, GUBIANI R, CIVIDINO S R S, et al.. Assessment of spray deposition and recycling rate in the vineyard from a new type of air-assisted tunnel sprayer [J]. Crop Protection, 2013, 45: 6-14. |

| 12 | 戴奋奋.风送喷雾机风量的选择与计算[J].植物保护,2008(6):124-127. |

| DAI F F. Selection and calculation of air volume of air supply sprayer [J]. Plant Prot., 2008(6):124-127. | |

| 13 | 荀露,李君,陆华忠,等.多风筒风送喷雾系统的设计与试验[J].农机化研究,2020,42(8):186-191. |

| XUN L, LI J, LU H Z, et al.. Design and experiment of multi-duct air delivery spray system [J]. Agric. Mech. Res., 2020,42(8):186-191. | |

| 14 | 龚曙光,徐珊,刘黎明,等.风筒内结构对风送式喷雾机效率的影响[J].南方农机,2021,52(22):9-13. |

| DONG S G, XU S, LIU L M, et al.. lnfluence of the inner structure of air duct on the efficiency of air-blast sprayer [J]. China Southern Agric. Mach., 2021,52(22):9-13. | |

| 15 | 魏新华,邵菁,解禄观,等.棉花分行冠内冠上组合风送式喷杆喷雾机设计与试验[J].农业机械学报,2016,47(1):101-107. |

| WEI X H, SHAO J, XIE L G, et al.. Design and test of a combined air-blast spray-rod sprayer for cotton branch crown [J]. Trans. Chin. Soc. Agric. Mach., 2016,47(1) : 101-107. | |

| 16 | JADAV C V, JAIN K K, KHOFIFAH B C. Spray of chemicals as affected by different parameters of air assisted sprayer: a review [J]. J. Cur. Agric. Res., 2019, 7(3): 289 |

| 17 | GARECA C, MOLTO E, CUICA P. Spray pesticide applications in Mediterranean citrus orchards: Canopy deposition and off-target losses [J]. Sci. Total Environ., 2017, 599: 1344-1362. |

| 18 | 韩占忠,王敬,兰小平.Fluent流体工程仿真计算实例与分析[M]北京:北京理工大学出版社,2010:1-321. |

| 19 | 崔志华,傅泽田,祁力钧,等.风送式喷雾机风筒结构对飘移性能的影响[J].农业工程学报,2008(2):111-115. |

| CUI X H, FU Z T, QI L J, et al.. The influence of the structure of the air duct on the drift performance of the air-driven Sprayer [J]. Chin. Soc. Agric. Eng., 2008(2):111-115. | |

| 20 | 边永亮,李建平,杨欣,等.果园多风机风送喷雾机聚风筒聚风特性的试验研究[J].中国农业大学学报,2022,27(5):39-50. |

| BIAN Y L, LI J P, YANG X, et al.. Experimental study on wind collecting characteristics of multi-fan air-supply sprayer in Orchard [J]. J. China Agric. Univ., 2022,27(5) : 39-50. | |

| 21 | 李建平,边永亮,霍鹏,等. 喷雾机风送式环形喷管喷雾装置设计与试验优化[J].农业机械学报,2021,52(9):79-88. |

| LI J P, BIAN Y L, HU P, et al.. Design and experimental optimization of the spray device of the air-driven annular nozzle of the sprayer [J]. Trans. Chin. Soc. Agric. Mach., 2021,52(9) : 79-88. | |

| 22 | 向浩.兰兴欣.于磊.基于SolidWorks软件的风扇自然风模拟仿真分析的研究[J].中国机械,2014(17):218 |

| XIANG H, LAN X X, YU L. Study on simulation and analysis of Fan natural wind based on SolidWorks software [J]. Chin. Mach., 2014(17) : 218 | |

| 23 | 徐奕蒙,李守藏,刘志杰,等.风扇组对气流速度场影响CFD仿真及验证[J].农机化研究,2019,41(10):7-14. |

| XU Y M, LI S C, LIU Z J, et al.. CFD Simulation and verification of the influence of fan groups on the airflow velocity field [J]. Agric. Mech. Res., 2019,41(10) : 7-14. |

| [1] | 李琦, 张树林, 张达娟, 贾滢暄, 王泽斌. 响应面法改良牟氏角毛藻培养基[J]. 中国农业科技导报, 2023, 25(8): 225-233. |

| [2] | 赵秀英, 黄晴雯, 曹浩杰, 王杰, 李瑞姣, 聂冬霞, 韩铮, 赵志辉. 响应面法优化禾谷镰刀菌产脱氧雪腐镰刀菌烯醇及其衍生物的液体培养条件[J]. 中国农业科技导报, 2023, 25(7): 222-233. |

| [3] | 马金智, 朱志平, 卢连水, 张万钦. 通风速率对异位发酵床处理肉鸭粪污的效果研究[J]. 中国农业科技导报, 2022, 24(3): 210-217. |

| [4] | 王凯强, 杨雪, 李常风, 段晓, 彭晴, 乔宇, 石波. 响应面法优化低聚木糖诱导大豆抗毒素合成条件[J]. 中国农业科技导报, 2022, 24(10): 208-217. |

| [5] | 郭文斌, 李瑶, 黄长华, 杜建强, 钱珊珠, 何泽民, 高晶晶. 基于COMSOL的干燥箱物理场分析与结构优化[J]. 中国农业科技导报, 2022, 24(10): 90-98. |

| [6] | 贾瑞庭,蒙仲举*,党晓宏,唐国栋,石涛. 库布齐沙漠200 MWp光伏阵列的截流阻沙效应研究[J]. 中国农业科技导报, 2021, 23(4): 137-144. |

| [7] | 戴阳军1,胡舰1,2,周莹2,左波1,石怡雪1. Plackett-Burman设计及响应面法优化无花果干复合酶解工艺[J]. 中国农业科技导报, 2018, 20(7): 146-153. |

| [8] | 陈金娥,刘慧,赵志刚,张海容*. 响应面法优化超声波提取三七根多糖工艺研究[J]. 中国农业科技导报, 2018, 20(4): 138-146. |

| [9] | 徐澜1,张鹏飞1,雷丽霞1,张海容2,王创云3. 响应面法优化微波辅助提取吴茱萸多糖工艺[J]. 中国农业科技导报, 2016, 18(4): 174-180. |

| [10] | 熊夏宇,曾新安*,王满生,张智宏. 响应面法优化脉冲电场辅助提取油菜花粉中黄酮类物质工艺研究[J]. 中国农业科技导报, 2015, 17(5): 88-93. |

| [11] | 辛崇博,孜力汗,刘晨光,白凤武*. 响应面法优化玉米芯同步糖化发酵预处理条件[J]. , 2013, 15(5): 173-180. |

| [12] | 王金玲1,刘晓平2,高玮华1,赵凤艳3,吕长山3. 解磷巨大芽胞杆菌液体发酵的培养基优化[J]. , 2013, 15(2): 185-192. |

| [13] | 张宁,刘爽,刘冬莲*. 超声波协同固体酸水解花生壳制备乙酰丙酸的研究[J]. , 2013, 15(1): 164-169. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号