Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (7): 222-233.DOI: 10.13304/j.nykjdb.2021.1055

• INNOVATIVE METHODS AND TECHNOLOGIES • Previous Articles

Xiuying ZHAO1,2( ), Qingwen HUANG2, Haojie CAO1,2, Jie WANG2, Ruijiao LI2, Dongxia NIE1,2, Zheng HAN1,2, Zhihui ZHAO1,2(

), Qingwen HUANG2, Haojie CAO1,2, Jie WANG2, Ruijiao LI2, Dongxia NIE1,2, Zheng HAN1,2, Zhihui ZHAO1,2( )

)

Received:2021-12-10

Accepted:2022-03-08

Online:2023-07-15

Published:2023-08-25

Contact:

Zhihui ZHAO

赵秀英1,2( ), 黄晴雯2, 曹浩杰1,2, 王杰2, 李瑞姣2, 聂冬霞1,2, 韩铮1,2, 赵志辉1,2(

), 黄晴雯2, 曹浩杰1,2, 王杰2, 李瑞姣2, 聂冬霞1,2, 韩铮1,2, 赵志辉1,2( )

)

通讯作者:

赵志辉

作者简介:赵秀英 E-mail:zxy99232@163.com;

基金资助:CLC Number:

Xiuying ZHAO, Qingwen HUANG, Haojie CAO, Jie WANG, Ruijiao LI, Dongxia NIE, Zheng HAN, Zhihui ZHAO. Optimization of Liquid Culture Conditions for the Production of Deoxynivalenol and Its Derivatives by Fusarium graminearum Using Response Surface Methodology[J]. Journal of Agricultural Science and Technology, 2023, 25(7): 222-233.

赵秀英, 黄晴雯, 曹浩杰, 王杰, 李瑞姣, 聂冬霞, 韩铮, 赵志辉. 响应面法优化禾谷镰刀菌产脱氧雪腐镰刀菌烯醇及其衍生物的液体培养条件[J]. 中国农业科技导报, 2023, 25(7): 222-233.

因素 Factor | 编码值 Symbol | DON | 15-ADON | |||||

|---|---|---|---|---|---|---|---|---|

| -1 | 0 | 1 | -1 | 0 | 1 | |||

| 培养时间 Incubation time/d | A | 10 | 20 | 30 | 7 | 14 | 21 | |

培养温度 Incubation temperature/℃ | B | 20 | 28 | 35 | 20 | 28 | 35 | |

初始pH Initial pH | C | 4.5 | 6.0 | 7.5 | 4.5 | 6.0 | 7.5 | |

Table 1 Response surface experiment factors and levels

因素 Factor | 编码值 Symbol | DON | 15-ADON | |||||

|---|---|---|---|---|---|---|---|---|

| -1 | 0 | 1 | -1 | 0 | 1 | |||

| 培养时间 Incubation time/d | A | 10 | 20 | 30 | 7 | 14 | 21 | |

培养温度 Incubation temperature/℃ | B | 20 | 28 | 35 | 20 | 28 | 35 | |

初始pH Initial pH | C | 4.5 | 6.0 | 7.5 | 4.5 | 6.0 | 7.5 | |

| 名称Name | 母离子 Precursor ion/(m·z-1) | 子离子 Product ion/(m·z-1) | 碰撞电压 Collision energy/eV | 离子化模式 Ionization mode |

|---|---|---|---|---|

| DON | 297.3 | 203.0*/175.1 | 28/28 | ES+ |

| 3-ADON | 339.1 | 231.2*/203.2 | 16/19 | ES+ |

| 15-ADON | 339.2 | 137.1*/261.2 | 25/16 | ES+ |

Table 2 MS/MS parameters for DON, 3-ADON and 15-ADON

| 名称Name | 母离子 Precursor ion/(m·z-1) | 子离子 Product ion/(m·z-1) | 碰撞电压 Collision energy/eV | 离子化模式 Ionization mode |

|---|---|---|---|---|

| DON | 297.3 | 203.0*/175.1 | 28/28 | ES+ |

| 3-ADON | 339.1 | 231.2*/203.2 | 16/19 | ES+ |

| 15-ADON | 339.2 | 137.1*/261.2 | 25/16 | ES+ |

| 名称Name | 5 μg·L-1 | 50 μg·L-1 | 100 μg·L-1 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

回收率 Recovery/% | 日内精密度 Intra-day precision/% | 日间精密度 Inter-day precision/% | 回收率 Recovery/% | 日内精密度 Intra-day precision/% | 日间精密度 Inter-day precision/% | 回收率 Recovery/% | 日内精密度 Intra-day precision/% | 日间精密度 Inter-day precision/% | |||||

| DON | 103.97 | 7.02 | 5.67 | 83.28 | 7.53 | 7.36 | 81.03 | 11.98 | 3.55 | ||||

| 3-ADON | 86.06 | 3.32 | 5.26 | 82.90 | 4.50 | 4.56 | 80.18 | 3.18 | 7.69 | ||||

| 15-ADON | 90.72 | 5.28 | 6.78 | 87.93 | 4.31 | 7.36 | 81.34 | 2.80 | 6.33 | ||||

Table 3 Recoveries and precisions of DON, 3-ADON, and 15-ADON in liquid culture (n=3)

| 名称Name | 5 μg·L-1 | 50 μg·L-1 | 100 μg·L-1 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

回收率 Recovery/% | 日内精密度 Intra-day precision/% | 日间精密度 Inter-day precision/% | 回收率 Recovery/% | 日内精密度 Intra-day precision/% | 日间精密度 Inter-day precision/% | 回收率 Recovery/% | 日内精密度 Intra-day precision/% | 日间精密度 Inter-day precision/% | |||||

| DON | 103.97 | 7.02 | 5.67 | 83.28 | 7.53 | 7.36 | 81.03 | 11.98 | 3.55 | ||||

| 3-ADON | 86.06 | 3.32 | 5.26 | 82.90 | 4.50 | 4.56 | 80.18 | 3.18 | 7.69 | ||||

| 15-ADON | 90.72 | 5.28 | 6.78 | 87.93 | 4.31 | 7.36 | 81.34 | 2.80 | 6.33 | ||||

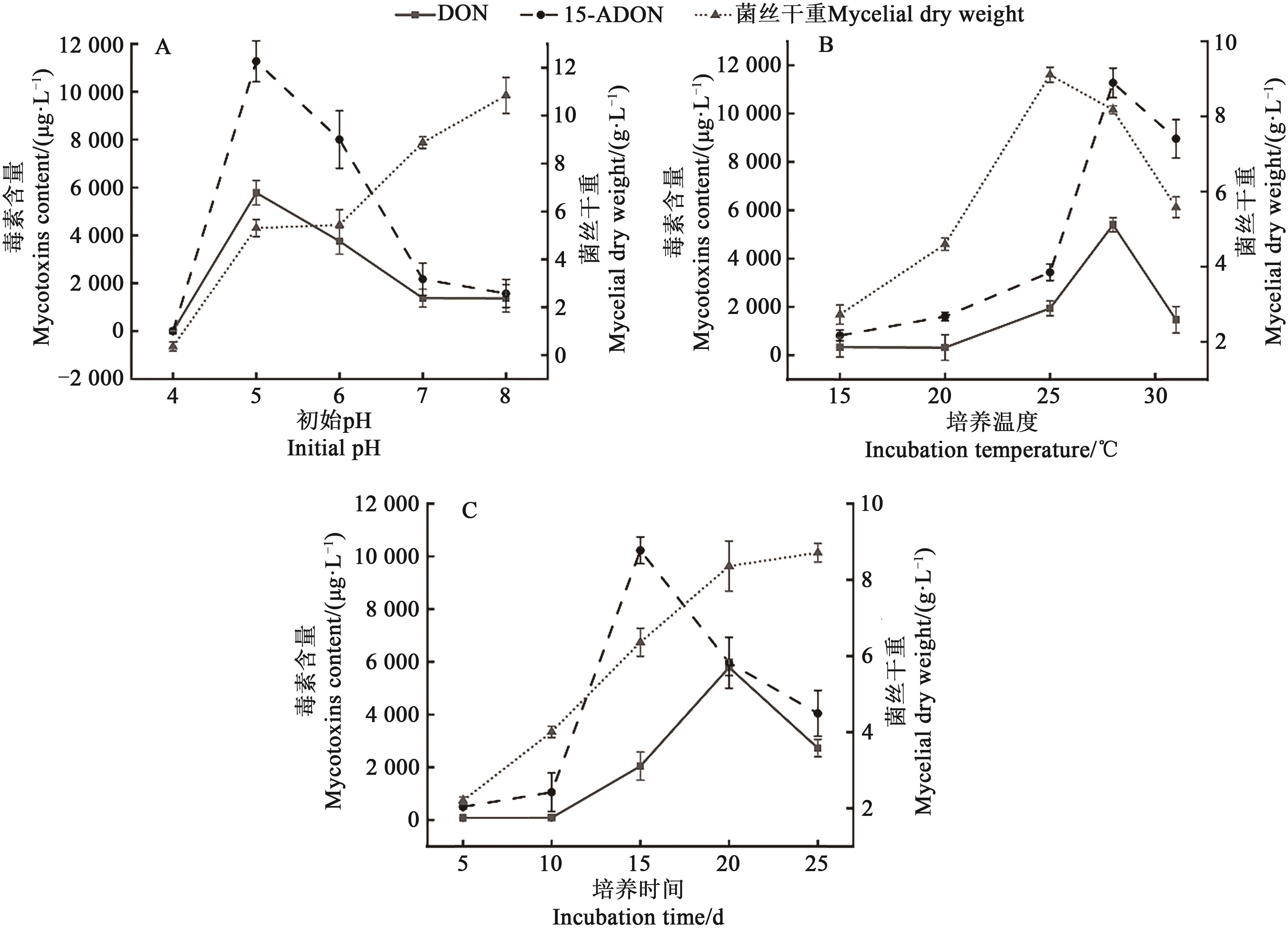

Fig. 3 Growth of strains and production of DON and 15-ADON under different cultural conditionsA: Initial pH; B: Incubation temperature; C: Incubation time

试验号 Test number | 培养时间 Incubation time/d | 培养温度 Incubation temperature/℃ | 初始pH Initial pH | DON产量 Production of DON/(μg·L-1) |

|---|---|---|---|---|

| 1 | 30.00 | 28.00 | 7.50 | 3 428.56 |

| 2 | 20.00 | 28.00 | 6.00 | 5 508.33 |

| 3 | 20.00 | 28.00 | 6.00 | 5 480.50 |

| 4 | 30.00 | 20.00 | 6.00 | 2 427.21 |

| 5 | 10.00 | 35.00 | 6.00 | 68.60 |

| 6 | 30.00 | 28.00 | 4.50 | 378.45 |

| 7 | 30.00 | 35.00 | 6.00 | 1 006.98 |

| 8 | 10.00 | 20.00 | 6.00 | 1 003.23 |

| 9 | 20.00 | 20.00 | 4.50 | 678.46 |

| 10 | 10.00 | 28.00 | 7.50 | 578.55 |

| 11 | 10.00 | 28.00 | 4.50 | 57.98 |

| 12 | 20.00 | 28.00 | 6.00 | 6 677.33 |

| 13 | 20.00 | 35.00 | 7.50 | 1 689.00 |

| 14 | 20.00 | 35.00 | 4.50 | 500.78 |

| 15 | 20.00 | 28.00 | 6.00 | 5 363.87 |

| 16 | 20.00 | 20.00 | 7.50 | 2 677.33 |

| 17 | 20.00 | 28.00 | 6.00 | 5 143.87 |

Table 4 Results for response surface experiments of DON

试验号 Test number | 培养时间 Incubation time/d | 培养温度 Incubation temperature/℃ | 初始pH Initial pH | DON产量 Production of DON/(μg·L-1) |

|---|---|---|---|---|

| 1 | 30.00 | 28.00 | 7.50 | 3 428.56 |

| 2 | 20.00 | 28.00 | 6.00 | 5 508.33 |

| 3 | 20.00 | 28.00 | 6.00 | 5 480.50 |

| 4 | 30.00 | 20.00 | 6.00 | 2 427.21 |

| 5 | 10.00 | 35.00 | 6.00 | 68.60 |

| 6 | 30.00 | 28.00 | 4.50 | 378.45 |

| 7 | 30.00 | 35.00 | 6.00 | 1 006.98 |

| 8 | 10.00 | 20.00 | 6.00 | 1 003.23 |

| 9 | 20.00 | 20.00 | 4.50 | 678.46 |

| 10 | 10.00 | 28.00 | 7.50 | 578.55 |

| 11 | 10.00 | 28.00 | 4.50 | 57.98 |

| 12 | 20.00 | 28.00 | 6.00 | 6 677.33 |

| 13 | 20.00 | 35.00 | 7.50 | 1 689.00 |

| 14 | 20.00 | 35.00 | 4.50 | 500.78 |

| 15 | 20.00 | 28.00 | 6.00 | 5 363.87 |

| 16 | 20.00 | 20.00 | 7.50 | 2 677.33 |

| 17 | 20.00 | 28.00 | 6.00 | 5 143.87 |

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean squares | F值 F value | P值 P value |

|---|---|---|---|---|---|

模型 Model | 82 250 000.00 | 9 | 9 139 000.00 | 36.98** | < 0.000 1 |

| A | 3 860 000.00 | 1 | 3 860 000.00 | 15.62** | 0.005 5 |

| B | 1 550 000.00 | 1 | 1 550 000.00 | 6.27* | 0.040 7 |

| C | 5 786 000.00 | 1 | 5 786 000.00 | 23.41** | 0.001 9 |

| AB | 52 476.25 | 1 | 52 476.25 | 0.21 | 0.658 9 |

| AC | 1 600 000.00 | 1 | 1 600 000.00 | 6.47* | 0.038 4 |

| BC | 158 800.00 | 1 | 158 800.00 | 0.64 | 0.449 1 |

| A2 | 24 090 000.00 | 1 | 24 090 000.00 | 97.48** | <0.000 1 |

| B2 | 19 340 000.00 | 1 | 19 340 000.00 | 78.27** | <0.000 1 |

| C2 | 19 140 000.00 | 1 | 19 140 000.00 | 77.45** | <0.000 1 |

残差 Residual | 1 730 000.00 | 7 | 247 100.00 | ||

失拟项 Lack of Fit | 288 700.00 | 3 | 96 221.44 | 0.27 | 0.846 6 |

纯误差 Pure error | 1 441 000.00 | 4 | 360 300.00 | ||

总误差 Total error | 83 980 000.00 | 16 |

Table 5 Analysis of variance for quadratic regression equation of DON

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean squares | F值 F value | P值 P value |

|---|---|---|---|---|---|

模型 Model | 82 250 000.00 | 9 | 9 139 000.00 | 36.98** | < 0.000 1 |

| A | 3 860 000.00 | 1 | 3 860 000.00 | 15.62** | 0.005 5 |

| B | 1 550 000.00 | 1 | 1 550 000.00 | 6.27* | 0.040 7 |

| C | 5 786 000.00 | 1 | 5 786 000.00 | 23.41** | 0.001 9 |

| AB | 52 476.25 | 1 | 52 476.25 | 0.21 | 0.658 9 |

| AC | 1 600 000.00 | 1 | 1 600 000.00 | 6.47* | 0.038 4 |

| BC | 158 800.00 | 1 | 158 800.00 | 0.64 | 0.449 1 |

| A2 | 24 090 000.00 | 1 | 24 090 000.00 | 97.48** | <0.000 1 |

| B2 | 19 340 000.00 | 1 | 19 340 000.00 | 78.27** | <0.000 1 |

| C2 | 19 140 000.00 | 1 | 19 140 000.00 | 77.45** | <0.000 1 |

残差 Residual | 1 730 000.00 | 7 | 247 100.00 | ||

失拟项 Lack of Fit | 288 700.00 | 3 | 96 221.44 | 0.27 | 0.846 6 |

纯误差 Pure error | 1 441 000.00 | 4 | 360 300.00 | ||

总误差 Total error | 83 980 000.00 | 16 |

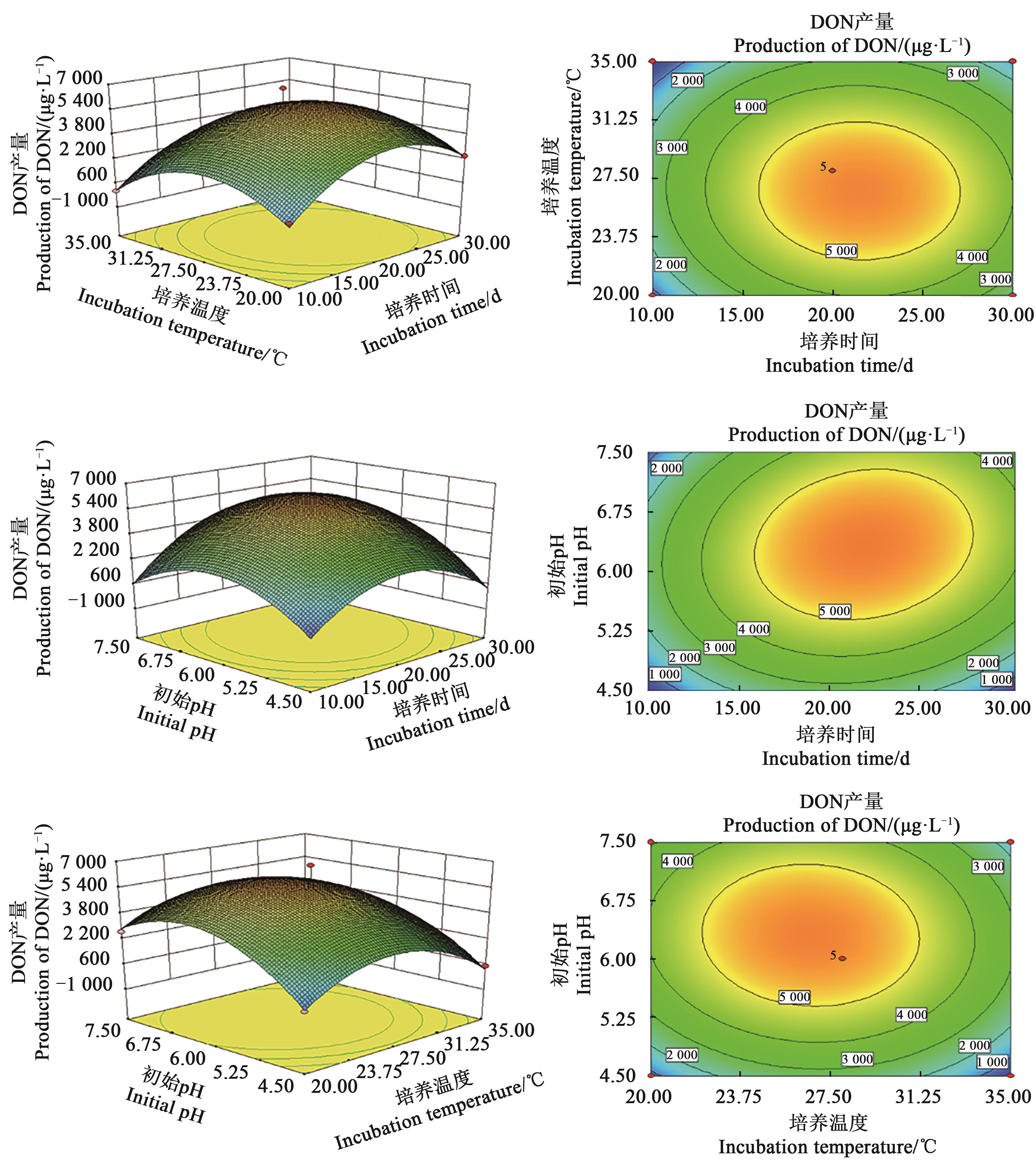

Fig. 4 Response surface and contour map of the interactive effects of incubation time, incubation temperature and initial pH value on the production of DON

试验号 Test number | 培养时间 Incubation time/d | 培养温度 Incubation temperature/℃ | 初始pH Initial pH | 15-ADON产量 Production of 15-ADON/(μg·L-1) |

|---|---|---|---|---|

| 1 | 14.00 | 28.00 | 6.00 | 10 143.80 |

| 2 | 14.00 | 28.00 | 6.00 | 9 622.46 |

| 3 | 14.00 | 28.00 | 6.00 | 10 660.30 |

| 4 | 14.00 | 28.00 | 6.00 | 10 580.40 |

| 5 | 21.00 | 28.00 | 7.50 | 3 140.63 |

| 6 | 14.00 | 28.00 | 6.00 | 13 264.4 |

| 7 | 21.00 | 28.00 | 4.50 | 7 102.70 |

| 8 | 14.00 | 20.00 | 7.50 | 396.05 |

| 9 | 14.00 | 35.00 | 4.50 | 2 072.56 |

| 10 | 21.00 | 35.00 | 6.00 | 1 445.33 |

| 11 | 7.00 | 28.00 | 7.50 | 56.37 |

| 12 | 21.00 | 20.00 | 6.00 | 7 706.35 |

| 13 | 14.00 | 20.00 | 4.50 | 4 538.67 |

| 14 | 7.00 | 28.00 | 4.50 | 86.42 |

| 15 | 14.00 | 35.00 | 7.50 | 614.70 |

| 16 | 7.00 | 35.00 | 6.00 | 35.33 |

| 17 | 7.00 | 20.00 | 6.00 | 19.99 |

Table 6 Results for response surface experiments of 15-ADON

试验号 Test number | 培养时间 Incubation time/d | 培养温度 Incubation temperature/℃ | 初始pH Initial pH | 15-ADON产量 Production of 15-ADON/(μg·L-1) |

|---|---|---|---|---|

| 1 | 14.00 | 28.00 | 6.00 | 10 143.80 |

| 2 | 14.00 | 28.00 | 6.00 | 9 622.46 |

| 3 | 14.00 | 28.00 | 6.00 | 10 660.30 |

| 4 | 14.00 | 28.00 | 6.00 | 10 580.40 |

| 5 | 21.00 | 28.00 | 7.50 | 3 140.63 |

| 6 | 14.00 | 28.00 | 6.00 | 13 264.4 |

| 7 | 21.00 | 28.00 | 4.50 | 7 102.70 |

| 8 | 14.00 | 20.00 | 7.50 | 396.05 |

| 9 | 14.00 | 35.00 | 4.50 | 2 072.56 |

| 10 | 21.00 | 35.00 | 6.00 | 1 445.33 |

| 11 | 7.00 | 28.00 | 7.50 | 56.37 |

| 12 | 21.00 | 20.00 | 6.00 | 7 706.35 |

| 13 | 14.00 | 20.00 | 4.50 | 4 538.67 |

| 14 | 7.00 | 28.00 | 4.50 | 86.42 |

| 15 | 14.00 | 35.00 | 7.50 | 614.70 |

| 16 | 7.00 | 35.00 | 6.00 | 35.33 |

| 17 | 7.00 | 20.00 | 6.00 | 19.99 |

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean squares | F值 F value | P值 P value |

|---|---|---|---|---|---|

模型 Model | 343 200 000.00 | 9 | 38 130 000.00 | 25.55** | 0.000 2 |

| A | 47 970 000.00 | 1 | 47 970 000.00 | 32.14** | 0.000 8 |

| B | 9 017 000.00 | 1 | 9 017 000.00 | 6.04* | 0.043 6 |

| C | 11 920 000.00 | 1 | 11 920 000.00 | 7.98* | 0.025 6 |

| AB | 9 722 000.00 | 1 | 9 722 000.00 | 6.51* | 0.0380 |

| AC | 3 865 000.00 | 1 | 3 865 000.00 | 2.59 | 0.151 6 |

| BC | 1 871 000.00 | 1 | 1 871 000.00 | 1.25 | 0.299 9 |

| A2 | 65 060 000.00 | 1 | 65 060 000.00 | 43.58** | 0.000 3 |

| B2 | 92 500 000.00 | 1 | 92 500 000.00 | 61.97** | 0.000 1 |

| C2 | 78 830 000.00 | 1 | 78 830 000.00 | 52.81** | 0.000 2 |

残差 Residual | 10 450 000.00 | 7 | 1 493 000.00 | ||

失拟项 Lack of Fit | 2 505 000.00 | 3 | 835 200.00 | 0.42 | 0.748 7 |

纯误差 Pure error | 7 944 000.00 | 4 | 1 986 000.00 | ||

总误差 Total error | 353 700 000.00 | 16 |

Table 7 Analysis of variance for quadratic regression equation of 15-ADON

来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean squares | F值 F value | P值 P value |

|---|---|---|---|---|---|

模型 Model | 343 200 000.00 | 9 | 38 130 000.00 | 25.55** | 0.000 2 |

| A | 47 970 000.00 | 1 | 47 970 000.00 | 32.14** | 0.000 8 |

| B | 9 017 000.00 | 1 | 9 017 000.00 | 6.04* | 0.043 6 |

| C | 11 920 000.00 | 1 | 11 920 000.00 | 7.98* | 0.025 6 |

| AB | 9 722 000.00 | 1 | 9 722 000.00 | 6.51* | 0.0380 |

| AC | 3 865 000.00 | 1 | 3 865 000.00 | 2.59 | 0.151 6 |

| BC | 1 871 000.00 | 1 | 1 871 000.00 | 1.25 | 0.299 9 |

| A2 | 65 060 000.00 | 1 | 65 060 000.00 | 43.58** | 0.000 3 |

| B2 | 92 500 000.00 | 1 | 92 500 000.00 | 61.97** | 0.000 1 |

| C2 | 78 830 000.00 | 1 | 78 830 000.00 | 52.81** | 0.000 2 |

残差 Residual | 10 450 000.00 | 7 | 1 493 000.00 | ||

失拟项 Lack of Fit | 2 505 000.00 | 3 | 835 200.00 | 0.42 | 0.748 7 |

纯误差 Pure error | 7 944 000.00 | 4 | 1 986 000.00 | ||

总误差 Total error | 353 700 000.00 | 16 |

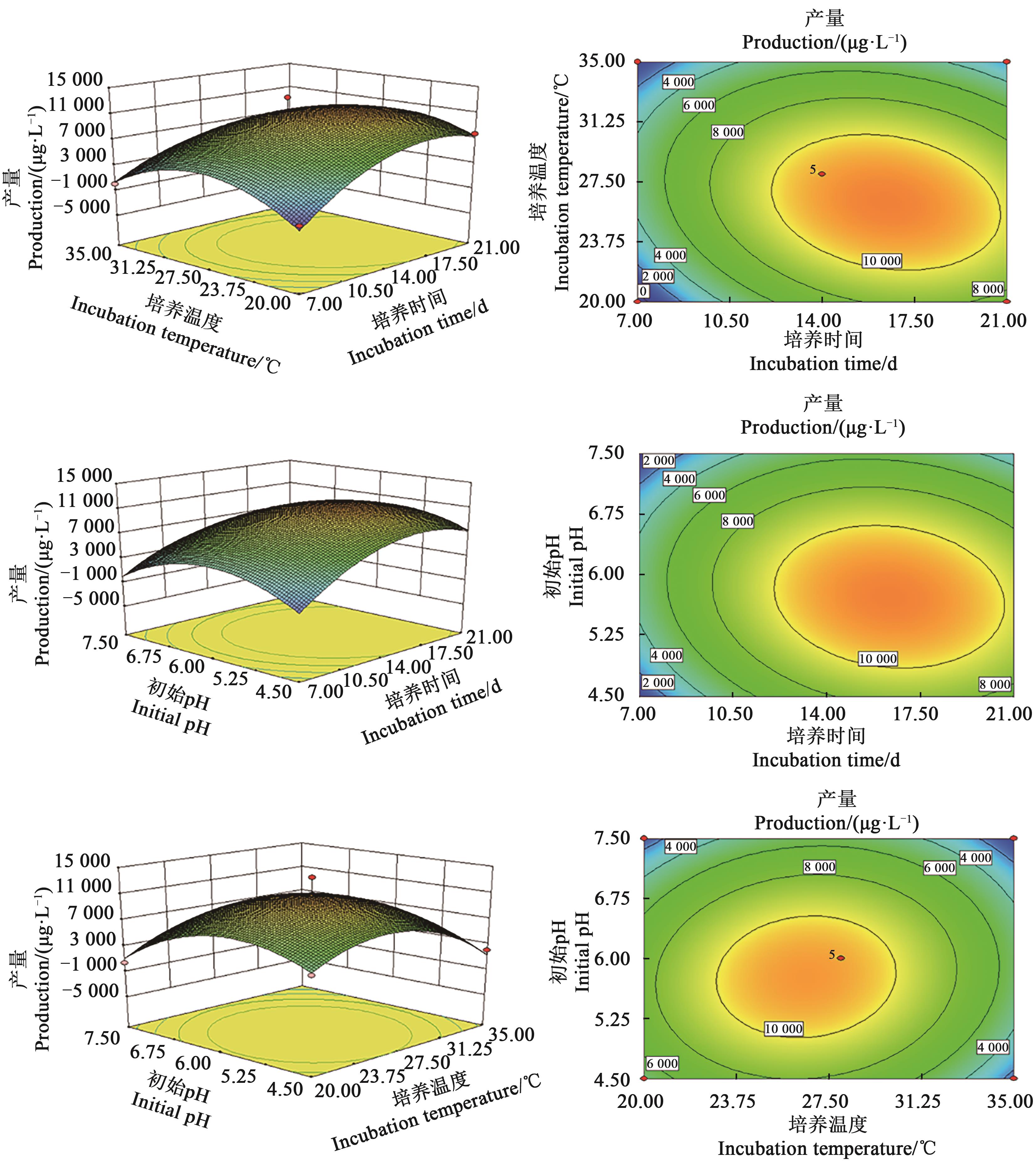

Fig. 5 Response surface and contour map of the interactive effect of incubation time, incubation temperature and initial pH value on the yield of 15-ADON

| 1 | PESTKA J J. Deoxynivalenol: toxicity, mechanisms and animal health risks [J]. Anim. Feed Sci. Technol., 2007, 137(3-4):283-298. |

| 2 | 张嘉城, 方香玲, 南志标. 植物病原镰刀菌产生的毒素种类及其危害[J]. 草业科学, 2021, 38(8):1513-1524. |

| ZHANG J C, FANG X L. NAN Z B. Types and effects of toxins produced by plant pathogenic fungi Fusarium [J]. Pratac. Sci., 2021, 38(8):1513-1524. | |

| 3 | 董峰光, 刘伟德, 冯雪英, 等. 烟台谷类食品脱氧雪腐镰刀菌烯醇及其衍生物污染状况及暴露估[J]. 现代预防医学,2021, 48(13): 2358-2361. |

| DONG F G, LIU W D, FENG X Y, et al.. Contamination status and dietary exposure assessment of deoxynivalenol and its acetylated derivatives in cereal samples of Yantai city [J]. Mod. Prev. Med., 2021, 48(13):2358-2361. | |

| 4 | LI M, SEN M N, HONG X, et al.. Survey of deoxynivalenol contamination in agricultural products in the Chinese market using an ELISA kit [J/OL]. Toxins, 2019, 11(1):6 [2021-11-02]. . |

| 5 | NARVÁEZ A, CASTALDO L, IZZO L, et al.. Deoxynivalenol contamination in cereal-based foodstuffs from Spain: systematic review and meta-analysis approach for exposure assessment [J/OL]. Food Control., 2022, 132:108521 [2021-11-02]. . |

| 6 | 刘慧, 曾祥权, 周玉春, 等. 谷物类食品中脱氧雪腐镰刀菌烯醇(DON)及其衍生物的研究现状[J]. 食品工业科技, 2021,42(18): 435-445. |

| LIU H, ZENG X Q, ZHOU Y C, et al.. Research progress of deoxynivalenol (DON) and its derivatives in cereal foods [J]. Sci. Technol. Food Ind., 2021, 42(18):435-445. | |

| 7 | YU M, CHEN L K, PENG Z, et al.. Mechanism of deoxynivalenol effects on the reproductive system and fetus malformation: current status and future challenges [J]. Toxicol. In Vitro, 2017, 41:150-158. |

| 8 | ZHOU H, GUO G T, DAI H, et al.. Deoxynivalenol: toxicological profiles and perspective views for future research [J]. World Mycotoxin J., 2020, 13(2):179-188. |

| 9 | Commison Regulation (EC) No 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs [J]. Official J. Eur. Union, 2006, 364(1):5-24. |

| 10 | 中华人民共和国国家卫生和计划生育委员会. 食品安全国家标准:食品中真菌毒素限量 [S]. 北京:中国标准出版社,2021. |

| 11 | MIROCHA C J, ABBAS H K, WINDELS C E, et al.. Variation in deoxynivalenol, 15-Acetyldeoxynivalenol, 3-Acetyldeoxynivalenol, and zearalenone production by Fusarium graminearum isolates [J]. Appl. Environ. Microbiol., 1989, 55(5):1315-1316. |

| 12 | GILBERT J, BRÛLÉ-BABEL A, GUERRIERI A T, et al.. Ratio of 3-ADON and 15-ADON isolates of Fusarium graminearum recovered from wheat kernels in Manitoba from 2008 to 2012 [J]. Can. J. Plant Pathol., 2014, 36(1):54-63. |

| 13 | PAYROS D, ALASSANE K I, PIERRON A, et al.. Toxicology of deoxynivalenol and its acetylated and modified forms [J]. Arch. Toxicol., 2016, 90(12):2931-2957. |

| 14 | 姜云晶, 许伟, 陈晓芳, 等. 脱氧雪腐镰刀菌烯醇提取、纯化及含量检测[J]. 中国兽医学报, 2017, 37(9): 1771-1777. |

| JIANG Y J, XU W, CHEN X F, et al.. Extraction, purification and concentration determination of deoxynivalenol [J]. Chin. J. Vet. Sci., 2017, 37(9):1771-1777. | |

| 15 | 郭文博, 韩铮, 杨俊花, 等. 脱氧雪腐镰刀菌烯醇的制备与鉴定[J]. 分析测试学报, 2015, 34(8): 928-933. |

| GUO W B, HAN Z, YANG J H, et al.. Preparation and identification of deoxynivalenol [J]. J. Instrum. Anal., 2015, 34(8): 928-933. | |

| 16 | ZHAO W, XU J W, ZHONG J J. Enhanced production of ganoderic acids in static liquid culture of Ganoderma lucidum under nitrogen-limiting conditions [J]. Bioresour. Technol., 2011, 102(17):8185-8190. |

| 17 | LIN E S, CHEN Y H. Factors affecting mycelial biomass and exopolysaccharide production in submerged cultivation of Antrodia cinnamomea using complex media [J]. Bioresour. Technol., 2007, 98(13):2511-2517. |

| 18 | MILLER J D, TAYLOR A, GREENHALGH R. Production of deoxynivalenol and related compounds in liquid culture by Fusarium graminearum [J]. Can. J. Microbiol., 1983, 29(9):1171-1178. |

| 19 | ZHANG H, WOLF-HALL C. The effect of different carbon sources on phenotypic expression by Fusarium graminearum strains [J]. Eur. J. Plant Pathol., 2010, 127(1):137-148. |

| 20 | GARDINER D M, OSBORNE S, KAZAN K, et al.. Low pH regulates the production of deoxynivalenol by Fusarium graminearum [J]. Microbiology, 2009, 155(9):3149-3156. |

| 21 | GARCIA D, BARROS G, CHULZE S, et al.. Impact of cycling temperatures on Fusarium verticillioides and Fusarium graminearum growth and mycotoxins production in soybean [J]. J. Sci. Food Agric., 2012, 92(15):2952-2959. |

| 22 | 朱柳杨, 陈浩宇, 李敏, 等. 黑曲霉产赭曲霉毒素A合成培养基的设计及产毒优化[J]. 中国酿造, 2017, 36(2): 127-130. |

| ZHU L Y, CHEN H Y, LI M, et al.. Development and optimization of the synthetic medium composition for ochratoxin A production by Aspergillus niger [J]. China Brew., 2017, 36(2): 127-130. | |

| 23 | 甄玉萍, 裴世春, 高建伟, 等. 不同培养条件对禾谷镰刀菌产玉米赤霉烯酮的影响[J]. 食品科学, 2015, 36(21): 168-174. |

| ZHEN Y P, PEI S C, GAO J W, et al.. Effect of different culture conditions on the production of zearalenone by Fusarium graminearum [J]. Food Sci., 2015, 36(21):168-174. | |

| 24 | GARDINER D M, KAZAN K, MANNERS J M. Nutrient profiling reveals potent inducers of trichothecene biosynthesis in Fusarium graminearum [J]. Fungal Genet. Biol., 2009, 46(8):604-613. |

| 25 | MERHEJ J, BOUTIGNY A L, PINSON-GADAIS L, et al.. Acidic pH as a determinant of TRI gene expression and trichothecene B biosynthesis in Fusarium graminearum [J]. Food Addit. Contam., 2010, 27(5):710-717. |

| 26 | PITT J I, TANIWAKI M H, COLE M B. Mycotoxin production in major crops as influenced by growing, harvesting, storage and processing, with emphasis on the achievement of food safety objectives [J]. Food Control, 2013, 32(1):205-215. |

| 27 | 师雯,韩铮,武爱波,等.温度和pH对不同镰刀菌生长及产毒的影响[J].食品工业科技,2015,36(18):117-122. |

| SHI W, HAN Z, WU A B, et al.. Effect of temperature and pH on the growth and mycotoxins production of various Fusarium species [J]. Sci. Technol. Food Ind., 2015, 36(18):117-122. | |

| 28 | 徐华, 吴弼东, 郭磊, 等. 脱氧雪腐镰刀菌烯醇及其乙酰化产物的培养提取及制备[J]. 食品科学, 2015, 36(3):132-136. |

| XU H, WU B D, GUO L, et al.. A Convenient method for preparation and purification of deoxynivalenol and acetyldeoxynivalenol from Fusarium graminearum culture [J]. Food Sci., 2015, 36(3):132-136. | |

| 29 | 李慧芳, 赵利娜, 郑香峰, 等. 1株产桔青霉素扩展青霉的鉴定及其产毒条件优化[J]. 食品科学, 2018, 39(24): 162-167. |

| LI H F, ZHAO L N, ZHEN X F, et al.. Identification of a Penicillium expansum strain producing citrinin and optimization of culture conditions for citrinin production [J]. Food Sci., 2018, 39(24):162-167 | |

| 30 | WU L, QIU L, ZHANG H, et al.. Optimization for the production of deoxynivalenoland zearalenone by Fusarium graminearum using response surface methodology [J/OL]. Toxins, 2017, 9(2):57 [2021-11-02]. . |

| [1] | Kaiqiang WANG, Xue YANG, Changfeng LI, Xiao DUAN, Qing PENG, Yu QIAO, Bo SHI. Optimization of Glyceollins Synthesis Condition Induced by Xylooligosaccharides Based on Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2022, 24(10): 208-217. |

| [2] | GUO Huihui, LIN Congfa, JIANG Yuanbin, LI Zhigang. Optimization of Protocorm Proliferation Medium of Dendrobium huoshanense by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2020, 22(3): 173-180. |

| [3] | LIANG Zhaochao, GUO Xianwei, SONG Yanjuan, MA Tianfu, WANG Feng, WANG Liyan, JING Ruiyong*. Extraction Process of Polysaccharide in Agaricus bisporus Optimized by Response Surface Method and Its Antioxidant Activity in vitro [J]. Journal of Agricultural Science and Technology, 2019, 21(8): 161-168. |

| [4] | WU Qi1,2,3§, ZHANG Yuhui1,2§, SU Rongrong1,2, SUN Bo1,3, WU Qiuyun1,2, XIA Zhilan1,2*. Optimization of Submerged Fermentation Medium of Agaricus blazei Murrill for Mycelial Biomass Accumulation Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2019, 21(3): 152-160. |

| [5] | DAI Yangjun1, HU Jian1,2, ZHOU Ying2, ZUO Bo1, SHI Yixue1. Optimization of Compound Enzymolysis Process of Dried Figs by Plackett-Burman Design and Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2018, 20(7): 146-153. |

| [6] | CHEN Xinyao, DONG Xing, CHEN Jingjie, QIN Tao, LI Jian*, HUANG Yifan*. Optimization of Extraction Process for Crude Polysaccharide from Hericium Erinaceus by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2017, 19(3): 131-136. |

| [7] | XU Lan1, ZHANG Peng-fei1, LEI Li-xia1, ZHANG Hai-rong2, WANG Chuang-yun3. A Microwave-assisted Procedure for the Extraction Polysaccharide from Evodia rutaecarpa Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2016, 18(4): 174-180. |

| [8] | XIONG Xia-yu, ZENG Xin-an*| WANG Man-sheng, ZHANG Zhi-hong. Studies on Optimization of Extraction Technology Assisted by Pulsed Electric Field of Total Flavonolds from Rape Pollen Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2015, 17(5): 88-93. |

| [9] | XIN Chongbo, ZI Lihan, LIU Chenguang, BAI Fengwu*. Response Surface Methodology Application for Optimizing Corncobs Pretreatment Conditions During Simultaneous Saccharification and Ethanol Fermentation [J]. , 2013, 15(5): 173-180. |

| [10] | WANG Jin-ling1, LIU Xiao-ping2, GAO Wei-hua1, ZHAO Feng-yan3, LV Chang-shan3. Medium Optimization for Phosphate-solubilizing Bacteria Bacillus Megaterium in Submerged Fermentation [J]. , 2013, 15(2): 185-192. |

| [11] | WANG Liang1,2, LI Shu1,2, MAO Zhonggui1,2*, ZHAO Fulin3. Optimization of Fermentation Medium for εPolylysine Production by Recombinant Streptomyces sp. FEEL1 [J]. , 2013, 15(1): 76-83. |

| [12] | ZHAO Ya-zhou, TIAN Wen-li, GUO Zhan-bao, GAO Ling-yu, PENG Wen-jun. Optimization of Ethanol Extraction Technology from Propolis by Response Surface Methodology [J]. , 1, 1(1): 85-93. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号