Journal of Agricultural Science and Technology ›› 2022, Vol. 24 ›› Issue (10): 208-217.DOI: 10.13304/j.nykjdb.2022.0073

• INNOVATIVE METHODS AND TECHNOLOGIES • Previous Articles

Kaiqiang WANG1( ), Xue YANG1, Changfeng LI1, Xiao DUAN1, Qing PENG2, Yu QIAO2, Bo SHI2(

), Xue YANG1, Changfeng LI1, Xiao DUAN1, Qing PENG2, Yu QIAO2, Bo SHI2( )

)

Received:2022-01-28

Accepted:2022-06-02

Online:2022-10-15

Published:2022-10-25

Contact:

Bo SHI

王凯强1( ), 杨雪1, 李常风1, 段晓1, 彭晴2, 乔宇2, 石波2(

), 杨雪1, 李常风1, 段晓1, 彭晴2, 乔宇2, 石波2( )

)

通讯作者:

石波

作者简介:王凯强 E-mail:wangkaiqiang@czmc.edu.cn;

基金资助:CLC Number:

Kaiqiang WANG, Xue YANG, Changfeng LI, Xiao DUAN, Qing PENG, Yu QIAO, Bo SHI. Optimization of Glyceollins Synthesis Condition Induced by Xylooligosaccharides Based on Response Surface Methodology[J]. Journal of Agricultural Science and Technology, 2022, 24(10): 208-217.

王凯强, 杨雪, 李常风, 段晓, 彭晴, 乔宇, 石波. 响应面法优化低聚木糖诱导大豆抗毒素合成条件[J]. 中国农业科技导报, 2022, 24(10): 208-217.

| 时间Time/min | 流速Rate/(mL·min-1) | A/% | B/% |

|---|---|---|---|

| 0 | 1.0 | 100 | 0 |

| 17 | 1.0 | 55 | 45 |

| 27 | 1.0 | 10 | 90 |

| 33 | 1.0 | 10 | 90 |

| 34 | 1.0 | 0 | 100 |

| 49 | 1.0 | 0 | 100 |

| 50 | 1.0 | 100 | 0 |

| 65 | 1.0 | 100 | 0 |

Table 1 HPLC gradient elution procedure

| 时间Time/min | 流速Rate/(mL·min-1) | A/% | B/% |

|---|---|---|---|

| 0 | 1.0 | 100 | 0 |

| 17 | 1.0 | 55 | 45 |

| 27 | 1.0 | 10 | 90 |

| 33 | 1.0 | 10 | 90 |

| 34 | 1.0 | 0 | 100 |

| 49 | 1.0 | 0 | 100 |

| 50 | 1.0 | 100 | 0 |

| 65 | 1.0 | 100 | 0 |

| 水平Level | 因素Factor | ||

|---|---|---|---|

X1:诱导时间 Induction time/d | X2:XOS诱导质量浓度 XOS concentration/(g·100 mL-1) | X3:培养温度 Temperature/℃ | |

| -1.682 | 2 | 2.0 | 17 |

| -1.000 | 3 | 3.0 | 21 |

| 0.000 | 4 | 4.0 | 25 |

| +1.000 | 5 | 5.0 | 29 |

| +1.682 | 6 | 6.0 | 33 |

Table 2 Factors and levels for central composite design

| 水平Level | 因素Factor | ||

|---|---|---|---|

X1:诱导时间 Induction time/d | X2:XOS诱导质量浓度 XOS concentration/(g·100 mL-1) | X3:培养温度 Temperature/℃ | |

| -1.682 | 2 | 2.0 | 17 |

| -1.000 | 3 | 3.0 | 21 |

| 0.000 | 4 | 4.0 | 25 |

| +1.000 | 5 | 5.0 | 29 |

| +1.682 | 6 | 6.0 | 33 |

运行 Run | X1:时间 Time/d | X2:质量浓度 Mass concentration/(g·100 mL-1) | X3:温度 Temperature/℃ | 大豆抗毒素含量 GLYs content/(mg·g-1 DW) | |

|---|---|---|---|---|---|

实际值 Actual value | 预测值 Predicted value | ||||

| 1 | 3 | 3 | 21 | 0.935 8 | 1.00 |

| 2 | 5 | 3 | 21 | 0.932 7 | 1.00 |

| 3 | 3 | 5 | 21 | 0.949 0 | 0.96 |

| 4 | 5 | 5 | 21 | 1.047 5 | 1.00 |

| 5 | 3 | 3 | 29 | 0.526 8 | 0.61 |

| 6 | 5 | 3 | 29 | 0.594 0 | 0.62 |

| 7 | 3 | 5 | 29 | 0.807 9 | 0.78 |

| 8 | 5 | 5 | 29 | 0.850 7 | 0.82 |

| 9 | 2 | 4 | 25 | 1.012 5 | 0.95 |

| 10 | 6 | 4 | 25 | 0.964 1 | 0.98 |

| 11 | 4 | 2 | 25 | 1.017 4 | 0.89 |

| 12 | 4 | 6 | 25 | 0.948 3 | 1.02 |

| 13 | 4 | 4 | 17 | 1.002 8 | 0.96 |

| 14 | 4 | 4 | 33 | 0.489 9 | 0.48 |

| 15 | 4 | 4 | 25 | 1.631 6 | 1.39 |

| 16 | 4 | 4 | 25 | 1.350 2 | 1.39 |

| 17 | 4 | 4 | 25 | 1.318 1 | 1.39 |

| 18 | 4 | 4 | 25 | 1.326 0 | 1.39 |

| 19 | 4 | 4 | 25 | 1.308 9 | 1.39 |

| 20 | 4 | 4 | 25 | 1.390 9 | 1.39 |

Table 3 CCD of induction time, XOS concentration and temperature and the GLYs content

运行 Run | X1:时间 Time/d | X2:质量浓度 Mass concentration/(g·100 mL-1) | X3:温度 Temperature/℃ | 大豆抗毒素含量 GLYs content/(mg·g-1 DW) | |

|---|---|---|---|---|---|

实际值 Actual value | 预测值 Predicted value | ||||

| 1 | 3 | 3 | 21 | 0.935 8 | 1.00 |

| 2 | 5 | 3 | 21 | 0.932 7 | 1.00 |

| 3 | 3 | 5 | 21 | 0.949 0 | 0.96 |

| 4 | 5 | 5 | 21 | 1.047 5 | 1.00 |

| 5 | 3 | 3 | 29 | 0.526 8 | 0.61 |

| 6 | 5 | 3 | 29 | 0.594 0 | 0.62 |

| 7 | 3 | 5 | 29 | 0.807 9 | 0.78 |

| 8 | 5 | 5 | 29 | 0.850 7 | 0.82 |

| 9 | 2 | 4 | 25 | 1.012 5 | 0.95 |

| 10 | 6 | 4 | 25 | 0.964 1 | 0.98 |

| 11 | 4 | 2 | 25 | 1.017 4 | 0.89 |

| 12 | 4 | 6 | 25 | 0.948 3 | 1.02 |

| 13 | 4 | 4 | 17 | 1.002 8 | 0.96 |

| 14 | 4 | 4 | 33 | 0.489 9 | 0.48 |

| 15 | 4 | 4 | 25 | 1.631 6 | 1.39 |

| 16 | 4 | 4 | 25 | 1.350 2 | 1.39 |

| 17 | 4 | 4 | 25 | 1.318 1 | 1.39 |

| 18 | 4 | 4 | 25 | 1.326 0 | 1.39 |

| 19 | 4 | 4 | 25 | 1.308 9 | 1.39 |

| 20 | 4 | 4 | 25 | 1.390 9 | 1.39 |

Fig. 1 Confirmation of the glyceollins synthesis from XOS-induced soybean cotyledon tissueA: HPLC chromatogram of XOS-treated cotyledon tissue; B: HPLC chromatogram of untreated cotyledon tissue; C and D: HPLC chromatogram and MS spectrum of separated and purified GLYs

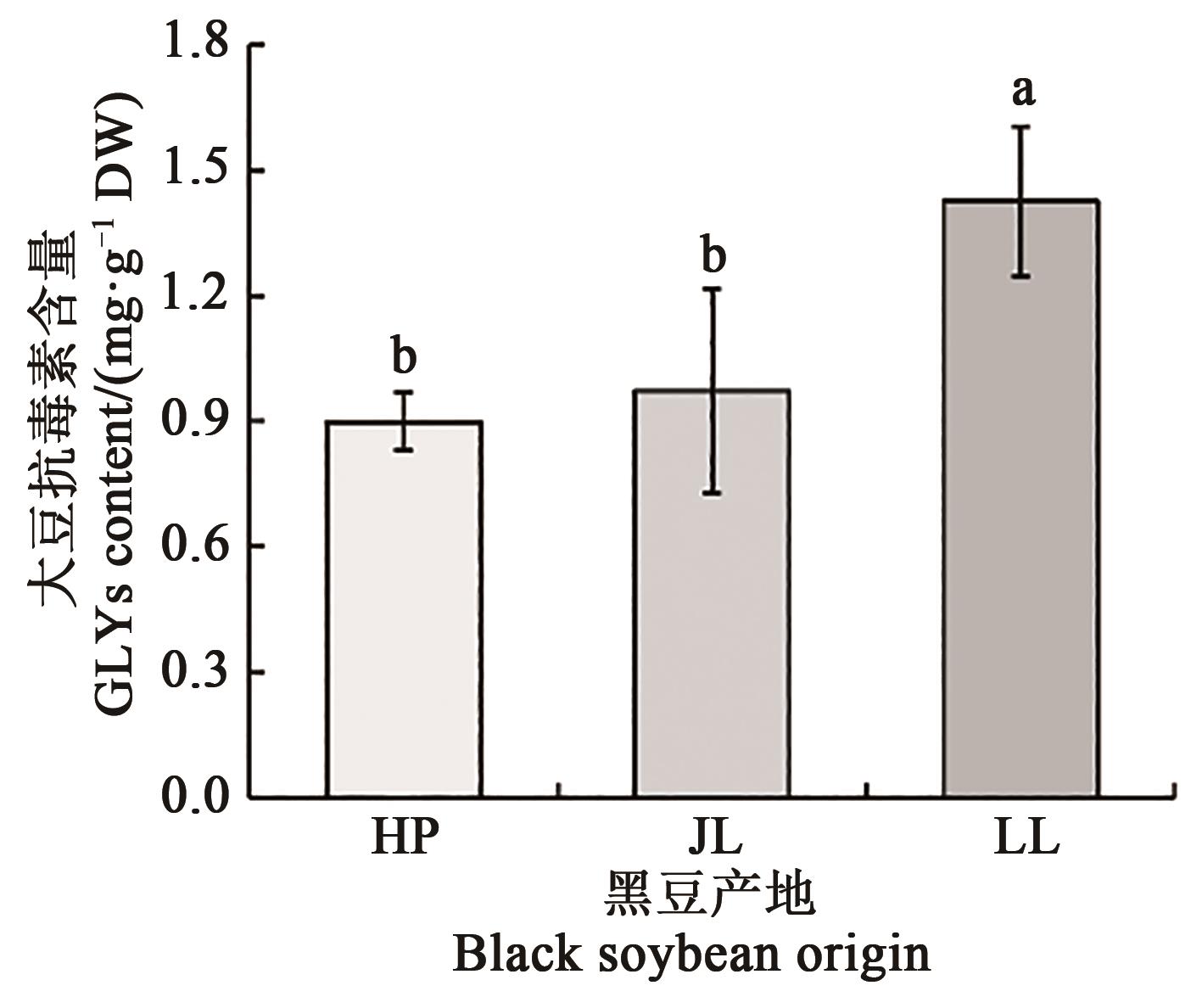

Fig. 2 Synthesized GLYs content from three origins of black soybean under inductionNote:Different lowercase letters indicate significantly differences between different treatments at P<0.05 level.

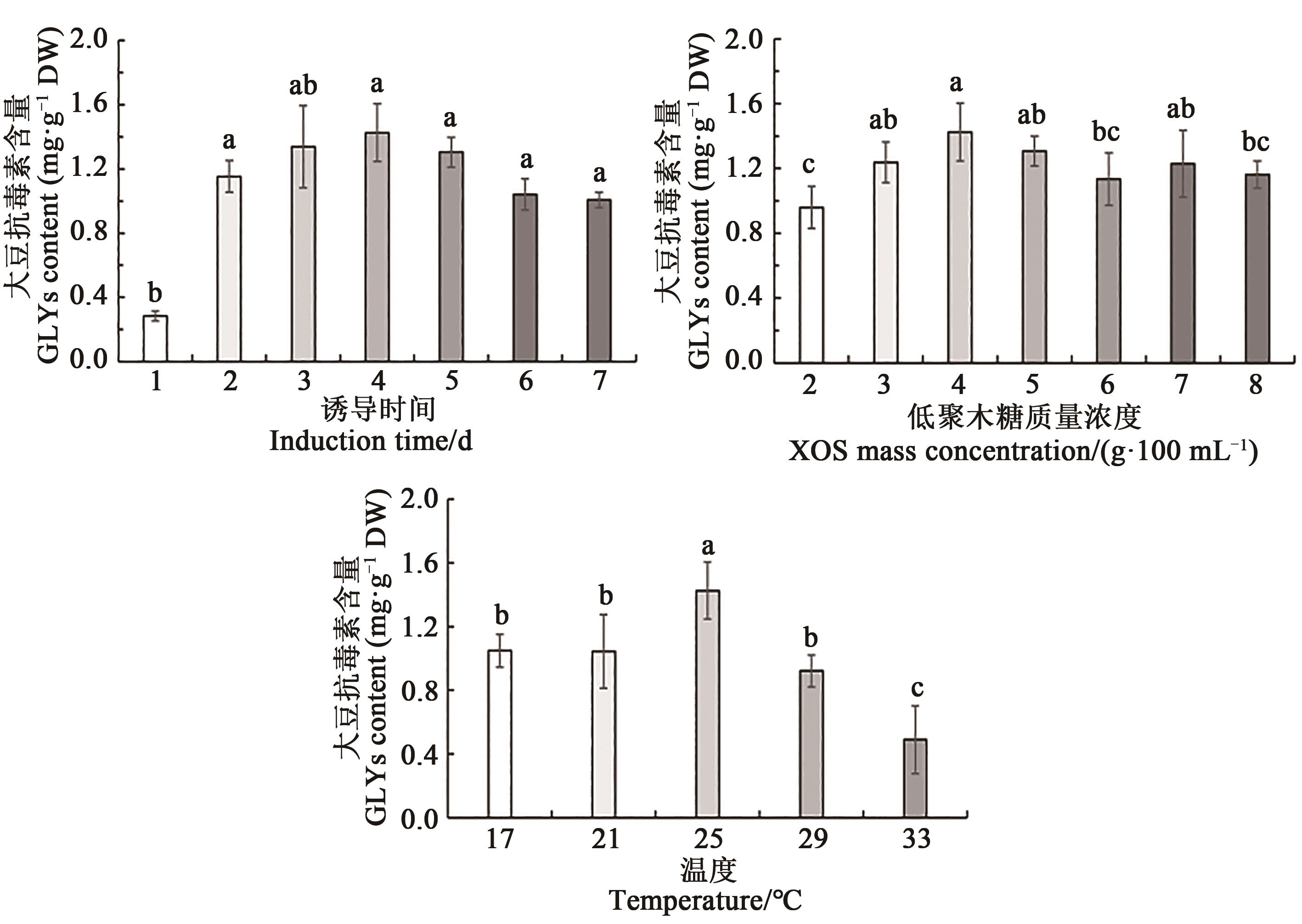

Fig. 3 Synthesized GLYs contents from LL under induction of different factorsNote:Different lowercase letters indicate significantly differences between different treatments at P<0.05 level.

变异来源 Source of variation | 平方和 Sum of squares | 自由度 df | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 1.570 | 9 | 0.170 | 13.780 | 0.000 2 |

| X1 | 1.126×10-3 | 1 | 1.126×10-3 | 0.089 | 0.771 5 |

| X2 | 0.022 | 1 | 0.022 | 1.750 | 0.215 5 |

| X3 | 0.280 | 1 | 0.280 | 21.980 | 0.000 9 |

| X1X2 | 7.450×10-4 | 1 | 7.450×10-4 | 0.059 | 0.813 1 |

| X1X3 | 2.664×10-5 | 1 | 2.664×10-5 | 2.107×10-3 | 0.964 3 |

| X2X3 | 0.021 | 1 | 0.021 | 1.660 | 0.226 6 |

| X | 0.330 | 1 | 0.330 | 25.950 | 0.000 5 |

| X | 0.340 | 1 | 0.340 | 26.620 | 0.000 4 |

| X | 0.810 | 1 | 0.810 | 63.710 | <0.000 1 |

| 残差Residual | 0.130 | 10 | 0.013 | — | — |

| 失拟项Lack of fit | 0.051 | 5 | 0.010 | 0.670 | 0.665 0 |

| 纯误差Pure error | 0.076 | 5 | 0.015 | — | — |

| 总误差Total error | 1.700 | 19 | — | — | — |

Table 4 Credibility for CCD model of induction time, XOS concentration and temperature

变异来源 Source of variation | 平方和 Sum of squares | 自由度 df | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 1.570 | 9 | 0.170 | 13.780 | 0.000 2 |

| X1 | 1.126×10-3 | 1 | 1.126×10-3 | 0.089 | 0.771 5 |

| X2 | 0.022 | 1 | 0.022 | 1.750 | 0.215 5 |

| X3 | 0.280 | 1 | 0.280 | 21.980 | 0.000 9 |

| X1X2 | 7.450×10-4 | 1 | 7.450×10-4 | 0.059 | 0.813 1 |

| X1X3 | 2.664×10-5 | 1 | 2.664×10-5 | 2.107×10-3 | 0.964 3 |

| X2X3 | 0.021 | 1 | 0.021 | 1.660 | 0.226 6 |

| X | 0.330 | 1 | 0.330 | 25.950 | 0.000 5 |

| X | 0.340 | 1 | 0.340 | 26.620 | 0.000 4 |

| X | 0.810 | 1 | 0.810 | 63.710 | <0.000 1 |

| 残差Residual | 0.130 | 10 | 0.013 | — | — |

| 失拟项Lack of fit | 0.051 | 5 | 0.010 | 0.670 | 0.665 0 |

| 纯误差Pure error | 0.076 | 5 | 0.015 | — | — |

| 总误差Total error | 1.700 | 19 | — | — | — |

Fig. 5 Contour and response surface plots for the interactive effects of induction time, XOS mass concentrationA and B: Interactive effect of induction time and XOS concentration; C and D: Interactive effect of temperature and XOS mass concentration; E and F: Interactive effect of temperature and induction time.and temperature on GLYs content

| 1 | 龚凌霄,倪勤学,张英.植物抗毒素研究进展及其作为食品功能性成分的应用前景[J].天然产物研究与开发,2012,24(3):421-425, 377. |

| GONG L X, NI Q X, ZHANG Y. Research on phytoalexins and its application prospect as a food functional component [J]. Nat. Prod. Res. Dev., 2012, 24(3):421-425, 377. | |

| 2 | BAMJI S F, CORBITT C. Glyceollins: soybean phytoalexins that exhibit a wide range of health-promoting effects [J]. J. Funct. Foods, 2017, 34:98-105. |

| 3 | NWACHUKWU I D, LUCIANO F B, UDENIGWE C C. The inducible soybean glyceollin phytoalexins with multifunctional health-promoting properties [J]. Food Res. Int., 2013, 54(1):1208-1216. |

| 4 | KALLI S, ARAYA-CLOUTIER C, LIN Y R, et al.. Enhanced biosynthesis of the natural antimicrobial glyceollins in soybean seedlings by priming and elicitation [J/OL]. Food Chem., 2020, 317:126389 [2021-12-10]. . |

| 5 | KALLI S, ARAYA-CLOUTIER C, DE BRUIJN W J C, et al.. Induction of promising antibacterial prenylated isoflavonoids from different subclasses by sequential elicitation of soybean [J/OL]. Phytochemistry, 2020, 179:112496 [2021-12-10]. . |

| 6 | JAHAN M A, KOVINICH N. Acidity stress for the systemic elicitation of glyceollin phytoalexins in soybean plants [J/OL]. Plant Signal. Behav., 2019, 14(7):1604018 [2021-12-10]. . |

| 7 | ANGELOVA Z, GEORGIEV S, ROOS W. Elicitation of plants [J]. Biotechnol. Biotec. Eq., 2006, 20:72-83. |

| 8 | 滕超,查沛娜,曲玲玉,等.功能性寡糖研究及其在食品中的应用进展[J].食品安全质量检测学报,2014,5(1):123-130. |

| TENG C, ZHA P N, QU L Y, et al.. Progress of research and application in food industry of functional oilgosaccharides [J]. J. Food Saf. Qual., 2014, 5(1):123-130. | |

| 9 | 黄强,张丽华,陶健,等.低聚木糖对植物乳杆菌发酵红枣汁品质的影响[J].食品科技,2021,46(10):7-12. |

| HUANG Q, ZHANG L H, TAO J, et al.. Effect of xylo-oligosaccharide on quality characteristics of jujube juice fermented with Lactobacillus plantarum [J]. Food Sci. Technol., 2021, 46(10):7-12. | |

| 10 | 宁俊,杨海军.功能食品配料——低聚木糖的功能及其应用研究[J].食品安全导刊,2018(10):46-48. |

| NING J, YANG H J. Functional food ingredients—low polysaccharide function and its application research [J]. China Food Saf. Mag., 2018(10):46-48. | |

| 11 | MANISSERI C, GUDIPATI M. Prebiotic activity of purified xylobiose obtained from ragi (Eleusine coracana, Indaf-15) bran [J]. Indian J. Microbiol., 2012, 52(2):251-257. |

| 12 | SAMANTA A K, JAYAPAL N, JAYARAM C, et al.. Xylooligosaccharides as prebiotics from agricultural by-products: production and applications [J]. Bioact. Carbohydr. Diet. Fibre, 2015, 5(1):62-71. |

| 13 | 鲁军.营养功能性食品发展趋势及产品创新[J].轻工标准与质量,2019(5):19. |

| LU J. Development trend and products innovation of nutritional functional food [J]. Stand. Qual. Light Ind., 2019(5):19. | |

| 14 | 田秀红,闫峰,刘鑫峰,等.大豆功能性食品及其开发应用前景[J].中国食物与营养,2008(4):50-53. |

| TIAN X H, YAN F, LIU X F, et al.. Functional soybean food and its prospect of development and application [J]. Food Nutr. China, 2008(4):50-53. | |

| 15 | 罗素亚,郑豆豆,何广正,等.响应面法优化脯氨酸羟化酶转化反应工艺条件[J].生物技术通报,2020,36(6): 157-164. |

| LUO S Y, ZHENG D D, HE G Z, et al.. Optimization of catalytic reaction conditions for L-proline 4-hydroxylase using response surface methodology [J]. Biotechnol. Bull., 2020, 36(6):157-164. | |

| 16 | CHELLADURAI S J S, MURUGAN K, RAY A P, et al.. Optimization of process parameters using response surface methodology: a review [J]. Mater. Today: Proc., 2021, 37:1301-1304. |

| 17 | SHEN J J, ZHU A S, GAO T T, et al.. Optimization of extraction technology of sterols from discarded soybean pod by response surface methodology [J/OL]. Environ. Chall., 2021, 5:100272. [2021-12-10]. . |

| 18 | KUMAR M, DAHUJA A, SACHDEV A, et al.. Evaluation of enzyme and microwave-assisted conditions on extraction of anthocyanins and total phenolics from black soybean (Glycine max L.) seed coat [J]. Int. J. Biol. Macromol., 2019, 135:1070-1081. |

| 19 | 胡佳,石波, EROMOSELE O,等.褐藻酸寡糖诱导下大豆中大豆抗毒素的累积变化[J].中国农业科学,2012,45 (8):1576-1586. |

| HU J, SHI B, EROMOSELE O, et al.. Effects of alginate oilgosaccharides on the accumulation of glyceollins in soybean [J]. Sci. Agric. Sin., 2012, 45(8):1576-1586. | |

| 20 | OJOKOH E, SHI B, LIANG P. Induction of phytochemical glyceollins accumulation in soybean following treatment with biotic elicitor (Aspergillus oryzae) [J]. J. Funct. Foods, 2013, 5(3):1039-1048. |

| 21 | KOHNO Y, KOSO M, KUSE M, et al.. Formal synthesis of soybean phytoalexin glyceollin I [J]. Tetrahedron Lett., 2014, 55(10):1826-1828. |

| 22 | MALIK N, ZHANG Z Q, ERHARDT P. Total synthesis of (±)-glyceollin II and a dihydro derivative [J]. J. Nat. Prod., 2015, 78(12):2940-2947. |

| 23 | 董向艳,李静梅,石波,等.甘薯淀粉加工废渣制备复合寡糖的条件优化及其活性评价[J].中国农业科学, 2014,47(15):3044-3057. |

| DONG X Y, LI J M, SHI B, et al.. Optimization and functional assessment of oligosaccharides compound prepared by sweet potato residue [J]. Sci. Agric. Sin., 2014, 47(15):3044-3057. | |

| 24 | 张迷敏,李静梅,乔宇,等.褐藻酸寡糖诱导下大豆营养成分的变化[J].中国农业科学,2015,48(16): 3239-3248. |

| ZHANG M M, LI J M, QIAO Y, et al.. Changes in nutritional properties of soybeans induced by alginate oligosaccharides [J]. Sci. Agric. Sin., 2015, 48(16):3239-3248. | |

| 25 | PENG Q, ZHANG M M, GAO L, et al.. Effects of alginate oligosaccharides with different molecular weights and guluronic to mannuronic acid ratios on glyceollin induction and accumulation in soybeans [J]. J. Food Sci. Technol., 2018, 55(5):1850-1858. |

| 26 | VADIVEL A K A, SUKUMARAN A, LI X Y, et al.. Soybean isoflavonoids: role of GmMYB176 interactome and 14-3-3 proteins [J]. Phytochem. Rev., 2016, 15(3):391-403. |

| [1] | Yue WU, Yun’an WANG, Ha’nan SONG, Weijun GUAN, Nan LI. Primary Culture and Differentiation Potential of Mesenchymal Stem Cells from Gushi Chicken Umbilical Cord [J]. Journal of Agricultural Science and Technology, 2022, 24(9): 79-87. |

| [2] | Zengyun WEI, Fangjuan DONG, Yilan BO. Optimization of Ultrasonic⁃assisted Extraction of Polysaccharides from Astragalus by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2022, 24(4): 203-209. |

| [3] | Wanwan ZHANG, Meisheng YI. Application and Development Prospect of Fish Stem Cell in Breeding [J]. Journal of Agricultural Science and Technology, 2022, 24(2): 26-32. |

| [4] | JIA Mingliang, FANG Hefang, LI Tongjian, WEN Feng, HAN Xingjie, JIN Hongguang, XU Lingling, LIAO Liang*. Study on in vitro Cultivation of Lilium orential ‘Sorbonne’ [J]. Journal of Agricultural Science and Technology, 2021, 23(1): 51-57. |

| [5] | GUO Huihui, LIN Congfa, JIANG Yuanbin, LI Zhigang. Optimization of Protocorm Proliferation Medium of Dendrobium huoshanense by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2020, 22(3): 173-180. |

| [6] |

JIA Mingliang, FANG Hefang, LI Tongjian, WEN Feng, HAN Xingjie,JIN Hongguang,XU Lingling, LIAO Liang*.

Callus Induction and Differentiation of Akebia trifoliate (Thunb.) Koidz.

[J]. Journal of Agricultural Science and Technology, 2020, 22(3): 181-187.

|

| [7] | LI Wenjie, LI Meiyang*, GONG Hui. Research on Induction and Suspension Culture of Adventitious Root of Valeriana officinalis [J]. Journal of Agricultural Science and Technology, 2020, 22(1): 179-186. |

| [8] | LIANG Zhaochao, GUO Xianwei, SONG Yanjuan, MA Tianfu, WANG Feng, WANG Liyan, JING Ruiyong*. Extraction Process of Polysaccharide in Agaricus bisporus Optimized by Response Surface Method and Its Antioxidant Activity in vitro [J]. Journal of Agricultural Science and Technology, 2019, 21(8): 161-168. |

| [9] | WU Qi1,2,3§, ZHANG Yuhui1,2§, SU Rongrong1,2, SUN Bo1,3, WU Qiuyun1,2, XIA Zhilan1,2*. Optimization of Submerged Fermentation Medium of Agaricus blazei Murrill for Mycelial Biomass Accumulation Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2019, 21(3): 152-160. |

| [10] | DAI Yangjun1, HU Jian1,2, ZHOU Ying2, ZUO Bo1, SHI Yixue1. Optimization of Compound Enzymolysis Process of Dried Figs by Plackett-Burman Design and Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2018, 20(7): 146-153. |

| [11] | JIANG Jinglong1, JIANG Chao1, LI Li2, SHEN Jixue1, TIAN Yun1, REN Xuming1. Studies on Effects of Different Conditions on Induction Rate of Hairy Roots in Cucumis sativus L. [J]. Journal of Agricultural Science and Technology, 2017, 19(4): 24-30. |

| [12] | CHEN Xinyao, DONG Xing, CHEN Jingjie, QIN Tao, LI Jian*, HUANG Yifan*. Optimization of Extraction Process for Crude Polysaccharide from Hericium Erinaceus by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2017, 19(3): 131-136. |

| [13] | XU Lan1, ZHANG Peng-fei1, LEI Li-xia1, ZHANG Hai-rong2, WANG Chuang-yun3. A Microwave-assisted Procedure for the Extraction Polysaccharide from Evodia rutaecarpa Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2016, 18(4): 174-180. |

| [14] | XIONG Xia-yu, ZENG Xin-an*| WANG Man-sheng, ZHANG Zhi-hong. Studies on Optimization of Extraction Technology Assisted by Pulsed Electric Field of Total Flavonolds from Rape Pollen Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2015, 17(5): 88-93. |

| [15] | WANG Cheng-long1,2, ZHOU Mei-liang2, DONG Xue-ni1,2, TANG Yi-xiong2, SHAO Ji-ron. Optimization and Comparison of Two Regeneration System of Alfalfa (Medicago sativa L.) [J]. , 2015, 17(4): 53-61. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号