Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (6): 144-153.DOI: 10.13304/j.nykjdb.2022.0209

• FOOD QUALITY & PROCESSING AND STORAGE • Previous Articles

Dongmeng ZHANG1( ), Dongping YAO2, Jun WU2, Qiuhong LUO1, Wen ZHUANG2, Xionglun LIU1, Qiyun DENG2, Bin BAI2(

), Dongping YAO2, Jun WU2, Qiuhong LUO1, Wen ZHUANG2, Xionglun LIU1, Qiyun DENG2, Bin BAI2( )

)

Received:2022-03-20

Accepted:2022-05-07

Online:2023-06-01

Published:2023-07-28

Contact:

Bin BAI

张冬梦1( ), 姚栋萍2, 吴俊2, 罗秋红1, 庄文2, 刘雄伦1, 邓启云2, 柏斌2(

), 姚栋萍2, 吴俊2, 罗秋红1, 庄文2, 刘雄伦1, 邓启云2, 柏斌2( )

)

通讯作者:

柏斌

作者简介:张冬梦 E-mail:2468171415@qq.com;

基金资助:CLC Number:

Dongmeng ZHANG, Dongping YAO, Jun WU, Qiuhong LUO, Wen ZHUANG, Xionglun LIU, Qiyun DENG, Bin BAI. Effect of Natural Low Temperature on Cooking and Eating Quality of Rice During Grain Filling Stage[J]. Journal of Agricultural Science and Technology, 2023, 25(6): 144-153.

张冬梦, 姚栋萍, 吴俊, 罗秋红, 庄文, 刘雄伦, 邓启云, 柏斌. 灌浆期田间自然低温对稻米蒸煮食味品质的影响[J]. 中国农业科技导报, 2023, 25(6): 144-153.

品种 Variety | 处理 Treatment | 直链淀粉含量 Apparent amylose content/% | 增幅 Rate of increase/% |

|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 14.30±0.28 b | 12.6 |

| LT | 16.10±0.14 a | ||

Y两优900 Y liangyou 900 | CT | 13.05±0.07 b | 28.4 |

| LT | 16.75±0.21 a | ||

Y两优1928 Y liangyou1928 | CT | 13.10±0.14 b | 32.8 |

| LT | 17.40±0.00 a | ||

黄华占 Huanghuazhan | CT | 14.55±0.07 b | 11.7 |

| LT | 16.25±0.21 a | ||

Y两优911 Y liangyou 911 | CT | 10.55±0.07 b | 47.4 |

| LT | 15.55±0.07 a | ||

野香优油丝 Yexiangyouyousi | CT | 13.50±0.14 b | 29.6 |

| LT | 17.50±0.00 a | ||

桃优香占 Taoyouxiangzhan | CT | 13.65±0.07 b | 24.5 |

| LT | 17.00±0.00 a |

Table 1 Effect on amylose content of natural low temperature during grain filling stage of rice

品种 Variety | 处理 Treatment | 直链淀粉含量 Apparent amylose content/% | 增幅 Rate of increase/% |

|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 14.30±0.28 b | 12.6 |

| LT | 16.10±0.14 a | ||

Y两优900 Y liangyou 900 | CT | 13.05±0.07 b | 28.4 |

| LT | 16.75±0.21 a | ||

Y两优1928 Y liangyou1928 | CT | 13.10±0.14 b | 32.8 |

| LT | 17.40±0.00 a | ||

黄华占 Huanghuazhan | CT | 14.55±0.07 b | 11.7 |

| LT | 16.25±0.21 a | ||

Y两优911 Y liangyou 911 | CT | 10.55±0.07 b | 47.4 |

| LT | 15.55±0.07 a | ||

野香优油丝 Yexiangyouyousi | CT | 13.50±0.14 b | 29.6 |

| LT | 17.50±0.00 a | ||

桃优香占 Taoyouxiangzhan | CT | 13.65±0.07 b | 24.5 |

| LT | 17.00±0.00 a |

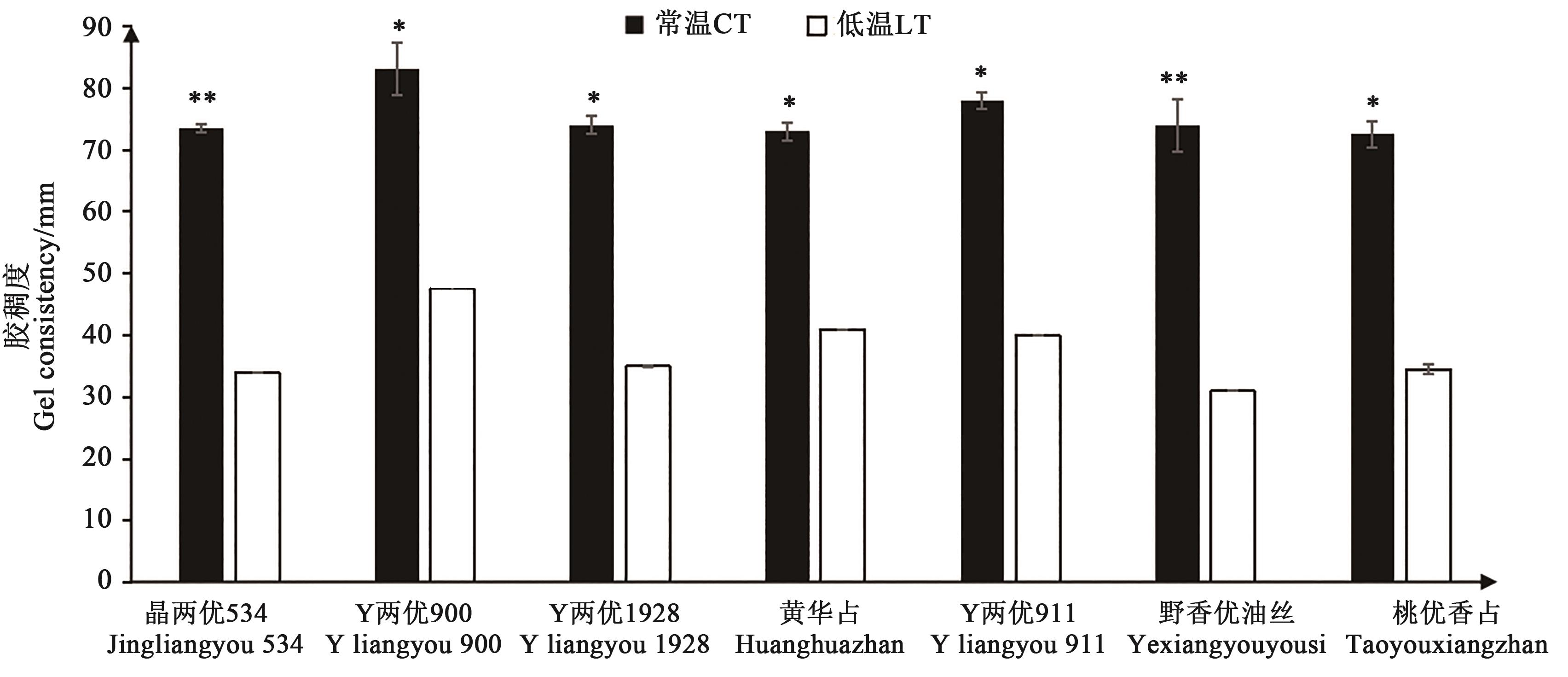

Fig. 2 Effect on gel consistency of natural low temperature during grain filling stage of riceNote: * and ** indicate significant differences between different treatments of same variety at P<0.05 and P<0.01 levels, respectively.

品种 Variety | 处理 Treatment | 峰值黏度 PV/cP | 谷值黏度 TV/cP | 崩解值 BD/cP | 最终黏度 CPV/cP | 消减值 SB/cP | 峰值时间 PT/min | 糊化温度 GT/℃ |

|---|---|---|---|---|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 2 985±3 a | 1 719±38 a | 1 266±35 a | 2 652±46 a | 933±8 b | 5.97±0.05 b | 79.68±0.11 b |

| LT | 1 493±10 b | 1 123±23 b | 371±13 b | 2 471±42 b | 1 349±19 a | 6.04±0.05 a | 93.10±0.07 a | |

Y两优900 Y liangyou 900 | CT | 3 080±21 a | 1 621±18 a | 1 460±4 a | 2 389±11 a | 769±6 b | 5.68±0.014 b | 84.73±0.60 b |

| LT | 1 812±5 b | 1 321±28 b | 491±33 b | 2 422±25 a | 1 101±4 a | 6.17±0.05 a | 91.90±0.57 a | |

Y两优1928 Y liangyou 1928 | CT | 3 177±7 a | 2 007±8 a | 1 171±1 a | 2 749±7 a | 743±1 b | 6.08±0.01 b | 78.73±0.04 b |

| LT | 1 410±7 b | 1 210±4 b | 200±11 b | 2 368±32 b | 1 158±36 a | 6.34±0.09 a | 98.83±0.04 a | |

黄华占 Huanghuazhan | CT | 2 690±15 a | 1 394±10 a | 1 296±5 a | 2 264±9 a | 870±1 b | 5.74±0.01 b | 78.69±0.08 b |

| LT | 1 628±3 b | 1 201±15 b | 428±12 b | 2 456±16 a | 1 256±1 a | 6.07±0.09 a | 93.08±0.11 a | |

Y两优911 Y liangyou 911 | CT | 2 559±43 a | 1 346±16 a | 1 213±28 a | 2 039±31 b | 693±16 b | 5.57±0.05 b | 84.75±0.64 b |

| LT | 1 998±4 b | 1 348±4 a | 650±8 b | 2 699±24 a | 1 351±20 a | 6.09±0.02 a | 91.90±0.49 a | |

野香优油丝 Yexiangyouyousi | CT | 1 217±13 a | 637±27 b | 580±13 a | 1 193±47 b | 556±21 b | 5.60±0.10 b | 87.48±1.17 b |

| LT | 1 160±24 b | 953±9 a | 208±15 b | 2 149±61 a | 1 197±52 a | 6.04±0.05 a | 93.20±0.07 a | |

桃优香占 Taoyouxiangzhan | CT | 1 435±45 a | 723±14 b | 712±31 a | 1 252±11 b | 529±3 b | 5.57±0.06 b | 79.13±0.67 b |

| LT | 1 406±21 a | 1 140±7 a | 266±13 b | 2 379±52 a | 1 239±45 a | 6.17±0.05 a | 93.88±0.04 a |

Table 2 Effect on characteristic parameters of rice RVA spectrum of natural low temperature during grain filling stage of rice

品种 Variety | 处理 Treatment | 峰值黏度 PV/cP | 谷值黏度 TV/cP | 崩解值 BD/cP | 最终黏度 CPV/cP | 消减值 SB/cP | 峰值时间 PT/min | 糊化温度 GT/℃ |

|---|---|---|---|---|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 2 985±3 a | 1 719±38 a | 1 266±35 a | 2 652±46 a | 933±8 b | 5.97±0.05 b | 79.68±0.11 b |

| LT | 1 493±10 b | 1 123±23 b | 371±13 b | 2 471±42 b | 1 349±19 a | 6.04±0.05 a | 93.10±0.07 a | |

Y两优900 Y liangyou 900 | CT | 3 080±21 a | 1 621±18 a | 1 460±4 a | 2 389±11 a | 769±6 b | 5.68±0.014 b | 84.73±0.60 b |

| LT | 1 812±5 b | 1 321±28 b | 491±33 b | 2 422±25 a | 1 101±4 a | 6.17±0.05 a | 91.90±0.57 a | |

Y两优1928 Y liangyou 1928 | CT | 3 177±7 a | 2 007±8 a | 1 171±1 a | 2 749±7 a | 743±1 b | 6.08±0.01 b | 78.73±0.04 b |

| LT | 1 410±7 b | 1 210±4 b | 200±11 b | 2 368±32 b | 1 158±36 a | 6.34±0.09 a | 98.83±0.04 a | |

黄华占 Huanghuazhan | CT | 2 690±15 a | 1 394±10 a | 1 296±5 a | 2 264±9 a | 870±1 b | 5.74±0.01 b | 78.69±0.08 b |

| LT | 1 628±3 b | 1 201±15 b | 428±12 b | 2 456±16 a | 1 256±1 a | 6.07±0.09 a | 93.08±0.11 a | |

Y两优911 Y liangyou 911 | CT | 2 559±43 a | 1 346±16 a | 1 213±28 a | 2 039±31 b | 693±16 b | 5.57±0.05 b | 84.75±0.64 b |

| LT | 1 998±4 b | 1 348±4 a | 650±8 b | 2 699±24 a | 1 351±20 a | 6.09±0.02 a | 91.90±0.49 a | |

野香优油丝 Yexiangyouyousi | CT | 1 217±13 a | 637±27 b | 580±13 a | 1 193±47 b | 556±21 b | 5.60±0.10 b | 87.48±1.17 b |

| LT | 1 160±24 b | 953±9 a | 208±15 b | 2 149±61 a | 1 197±52 a | 6.04±0.05 a | 93.20±0.07 a | |

桃优香占 Taoyouxiangzhan | CT | 1 435±45 a | 723±14 b | 712±31 a | 1 252±11 b | 529±3 b | 5.57±0.06 b | 79.13±0.67 b |

| LT | 1 406±21 a | 1 140±7 a | 266±13 b | 2 379±52 a | 1 239±45 a | 6.17±0.05 a | 93.88±0.04 a |

品种 Variety | 处理 Treatment | 硬度 Hardness/kgf | 黏度 Viscosity/kgf | 食味值 Taste value |

|---|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 2.85±0.27 a | 0.36±0.02 a | 67.85±1.06 a |

| LT | 2.99±0.62 a | 0.11±0.03 b | 55.30±4.10 b | |

| 变幅Amplitude/% | 4.91 | 69.44 | 18.50 | |

Y两优900 Y liangyou 900 | CT | 2.40±0.13 b | 0.30±0.01 a | 69.15±0.49 a |

| LT | 3.04±0.07 a | 0.12±0.03 b | 53.15±0.78 b | |

| 变幅Amplitude/% | 26.67 | 60.00 | 23.14 | |

Y两优1928 Y liangyou 1928 | CT | 2.68±0.19 b | 0.25±0.03 a | 70.20±1.70 a |

| LT | 4.04±0.04 a | 0.03±0.01 b | 51.05±1.20 b | |

| 变幅Amplitude/% | 50.75 | 88.00 | 27.28 | |

黄华占 Huanghuazhan | CT | 2.86±0.03 b | 0.30±0.02 a | 63.05±2.47 a |

| LT | 3.34±0.13 a | 0.06±0.00 b | 53.60±1.41 b | |

| 变幅Amplitude/% | 16.78 | 80.00 | 14.99 | |

Y两优911 Y liangyou 911 | CT | 2.90±0.05 a | 0.21±0.04 a | 62.40±1.13 a |

| LT | 3.06±0.05 a | 0.06±0.01 b | 56.70±0.99 b | |

| 变幅Amplitude/% | 5.52 | 71.43 | 9.13 | |

野香优油丝 Yexiangyouyousi | CT | 3.23±0.25 b | 0.13±0.00 a | 58.00±0.57 a |

| LT | 3.98±0.01 a | 0.03±0.01 b | 48.11±0.28 b | |

| 变幅Amplitude/% | 23.22 | 76.92 | 17.05 | |

桃优香占 Taoyouxiangzhan | CT | 2.91±0.25 b | 0.17±0.03 a | 64.25±0.21 a |

| LT | 3.93±0.11 a | 0.04±0.01 b | 51.55±0.64 b | |

| 变幅Amplitude/% | 35.05 | 76.47 | 19.77 |

Table 3 Effect on hardness, viscosity and taste value of natural low temperature during grain filling stage of rice

品种 Variety | 处理 Treatment | 硬度 Hardness/kgf | 黏度 Viscosity/kgf | 食味值 Taste value |

|---|---|---|---|---|

晶两优534 Jingliangyou 534 | CT | 2.85±0.27 a | 0.36±0.02 a | 67.85±1.06 a |

| LT | 2.99±0.62 a | 0.11±0.03 b | 55.30±4.10 b | |

| 变幅Amplitude/% | 4.91 | 69.44 | 18.50 | |

Y两优900 Y liangyou 900 | CT | 2.40±0.13 b | 0.30±0.01 a | 69.15±0.49 a |

| LT | 3.04±0.07 a | 0.12±0.03 b | 53.15±0.78 b | |

| 变幅Amplitude/% | 26.67 | 60.00 | 23.14 | |

Y两优1928 Y liangyou 1928 | CT | 2.68±0.19 b | 0.25±0.03 a | 70.20±1.70 a |

| LT | 4.04±0.04 a | 0.03±0.01 b | 51.05±1.20 b | |

| 变幅Amplitude/% | 50.75 | 88.00 | 27.28 | |

黄华占 Huanghuazhan | CT | 2.86±0.03 b | 0.30±0.02 a | 63.05±2.47 a |

| LT | 3.34±0.13 a | 0.06±0.00 b | 53.60±1.41 b | |

| 变幅Amplitude/% | 16.78 | 80.00 | 14.99 | |

Y两优911 Y liangyou 911 | CT | 2.90±0.05 a | 0.21±0.04 a | 62.40±1.13 a |

| LT | 3.06±0.05 a | 0.06±0.01 b | 56.70±0.99 b | |

| 变幅Amplitude/% | 5.52 | 71.43 | 9.13 | |

野香优油丝 Yexiangyouyousi | CT | 3.23±0.25 b | 0.13±0.00 a | 58.00±0.57 a |

| LT | 3.98±0.01 a | 0.03±0.01 b | 48.11±0.28 b | |

| 变幅Amplitude/% | 23.22 | 76.92 | 17.05 | |

桃优香占 Taoyouxiangzhan | CT | 2.91±0.25 b | 0.17±0.03 a | 64.25±0.21 a |

| LT | 3.93±0.11 a | 0.04±0.01 b | 51.55±0.64 b | |

| 变幅Amplitude/% | 35.05 | 76.47 | 19.77 |

指标 Index | 食味值 Taste value | 日均温ADT | 崩解值 BD | 消减值SB | 糊化温度GT | 峰值黏度PV | 谷值黏度TV | 最终黏度CPV | 峰值时间PT | 直链淀粉含量AAC | 胶稠度GC | 硬度 Hardness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 日均温ADT | 0.874** | |||||||||||

| 崩解值BD | 0.918** | 0.863** | ||||||||||

| 消减值SB | -0.685** | -0.910** | -0.598* | |||||||||

| 糊化温度GT | -0.889** | -0.900** | 0.835** | 0.751** | ||||||||

| 峰值温度PV | 0.843** | 0.626* | 0.922** | -0.344 | -0.688** | |||||||

| 谷值黏度TV | 0.569* | 0.233 | 0.627* | 0.042 | -0.358 | 0.879** | ||||||

| 最终黏度CPV | 0.021 | -0.374 | 0.119 | 0.640* | 0.181 | 0.467 | 0.795** | |||||

| 峰值时间PT | -0.551* | -0.789** | -0.576* | 0.801** | 0.651* | -0.227 | 0.251 | 0.680** | ||||

直链淀粉含量 AAC | -0.805** | -0.923** | -0.800** | 0.801** | 0.742** | -0.614** | -0.251 | 0.294 | 0.800** | |||

| 胶稠度GC | 0.890** | 0.974** | 0.879** | 0.684** | -0.871** | 0.684** | 0.296 | -0.317 | -0.779** | -0.893** | ||

| 硬度Hardness | -0.857** | -0.674** | -0.833** | -0.746** | 0.742** | -0.746** | -0.478 | -0.061 | 0.556* | 0.730** | -0.763** | |

| 黏度Viscosity | 0.905** | 0.841** | 0.938** | -0.598* | -0.869** | 0.861** | 0.579* | 0.082 | -0.520 | -0.688** | 0.858** | -0.796** |

Table 4 Correlation analysis of food taste value, average daily temperature and physical and chemical indexes in 40 d after the beginning of ear

指标 Index | 食味值 Taste value | 日均温ADT | 崩解值 BD | 消减值SB | 糊化温度GT | 峰值黏度PV | 谷值黏度TV | 最终黏度CPV | 峰值时间PT | 直链淀粉含量AAC | 胶稠度GC | 硬度 Hardness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 日均温ADT | 0.874** | |||||||||||

| 崩解值BD | 0.918** | 0.863** | ||||||||||

| 消减值SB | -0.685** | -0.910** | -0.598* | |||||||||

| 糊化温度GT | -0.889** | -0.900** | 0.835** | 0.751** | ||||||||

| 峰值温度PV | 0.843** | 0.626* | 0.922** | -0.344 | -0.688** | |||||||

| 谷值黏度TV | 0.569* | 0.233 | 0.627* | 0.042 | -0.358 | 0.879** | ||||||

| 最终黏度CPV | 0.021 | -0.374 | 0.119 | 0.640* | 0.181 | 0.467 | 0.795** | |||||

| 峰值时间PT | -0.551* | -0.789** | -0.576* | 0.801** | 0.651* | -0.227 | 0.251 | 0.680** | ||||

直链淀粉含量 AAC | -0.805** | -0.923** | -0.800** | 0.801** | 0.742** | -0.614** | -0.251 | 0.294 | 0.800** | |||

| 胶稠度GC | 0.890** | 0.974** | 0.879** | 0.684** | -0.871** | 0.684** | 0.296 | -0.317 | -0.779** | -0.893** | ||

| 硬度Hardness | -0.857** | -0.674** | -0.833** | -0.746** | 0.742** | -0.746** | -0.478 | -0.061 | 0.556* | 0.730** | -0.763** | |

| 黏度Viscosity | 0.905** | 0.841** | 0.938** | -0.598* | -0.869** | 0.861** | 0.579* | 0.082 | -0.520 | -0.688** | 0.858** | -0.796** |

品种名称 Variety | 直链淀粉含量 AAC | 胶稠度 GC | 谷值黏度 PV | 崩解值 BD | 消减值 SB | 糊化温度 GT | 峰值时间 PT |

|---|---|---|---|---|---|---|---|

晶两优534 Jingliangyou 534 | 1.27 | -0.66 | -0.90 | -0.48 | 0.86 | -0.30 | 1.68 |

Y两优900 Y liangyou 900 | -0.61 | 1.36 | -0.48 | -0.03 | 0.94 | 0.86 | -0.54 |

Y两优1928 Y liangyou 1928 | -1.12 | -0.47 | -1.18 | -1.57 | 0.44 | -1.47 | 0.73 |

黄华占 Huanghuazhan | 1.44 | 1.18 | -0.39 | -0.12 | 0.86 | -0.50 | 0.41 |

Y两优911 Y liangyou 911 | 0.07 | 0.26 | 0.41 | 1.79 | -0.67 | 0.86 | -0.86 |

野香优油丝 Yexiangyouyousi | -0.78 | -1.39 | 1.20 | 0.16 | -1.09 | 1.25 | -0.23 |

桃优香占 Taoyouxiangzhan | -0.27 | -0.29 | 1.34 | 0.25 | -1.34 | -0.69 | -1.18 |

Table 5 Physical and chemical indexes of natural low temperature starch of different rice varieties at filling stage were treated by SPSS

品种名称 Variety | 直链淀粉含量 AAC | 胶稠度 GC | 谷值黏度 PV | 崩解值 BD | 消减值 SB | 糊化温度 GT | 峰值时间 PT |

|---|---|---|---|---|---|---|---|

晶两优534 Jingliangyou 534 | 1.27 | -0.66 | -0.90 | -0.48 | 0.86 | -0.30 | 1.68 |

Y两优900 Y liangyou 900 | -0.61 | 1.36 | -0.48 | -0.03 | 0.94 | 0.86 | -0.54 |

Y两优1928 Y liangyou 1928 | -1.12 | -0.47 | -1.18 | -1.57 | 0.44 | -1.47 | 0.73 |

黄华占 Huanghuazhan | 1.44 | 1.18 | -0.39 | -0.12 | 0.86 | -0.50 | 0.41 |

Y两优911 Y liangyou 911 | 0.07 | 0.26 | 0.41 | 1.79 | -0.67 | 0.86 | -0.86 |

野香优油丝 Yexiangyouyousi | -0.78 | -1.39 | 1.20 | 0.16 | -1.09 | 1.25 | -0.23 |

桃优香占 Taoyouxiangzhan | -0.27 | -0.29 | 1.34 | 0.25 | -1.34 | -0.69 | -1.18 |

品种 Variety | 主成分值Principal component value | 隶属函数Ux | 综合评价值D value | ||

|---|---|---|---|---|---|

| F1 | F2 | U1 | U2 | ||

晶两优534 Jingliangyou 534 | -2.00 | 1.22 | 0.10 | 0.81 | 0.29 |

Y两优900 Y liangyou 900 | 0.25 | 1.12 | 0.59 | 0.79 | 0.50 |

Y两优1928 Y liangyou 1928 | -2.45 | -0.24 | 0.00 | 0.46 | 0.14 |

黄华占 Huanghuazhan | -0.86 | 1.98 | 0.35 | 1.00 | 0.45 |

Y两优911 Y liangyou 911 | 2.14 | -0.24 | 1.00 | 0.46 | 0.58 |

野香优油丝 Yexiangyouyousi | 1.49 | -2.15 | 0.86 | 0.00 | 0.38 |

桃优香占 Taoyouxiangzhan | 1.43 | -1.70 | 0.85 | 0.11 | 0.40 |

| 权重WX | 0.44 | 0.30 | |||

Table 6 Principal component value, membership function value, weight value and comprehensive evaluation value of natural low temperature in different rice varieties at filling stage

品种 Variety | 主成分值Principal component value | 隶属函数Ux | 综合评价值D value | ||

|---|---|---|---|---|---|

| F1 | F2 | U1 | U2 | ||

晶两优534 Jingliangyou 534 | -2.00 | 1.22 | 0.10 | 0.81 | 0.29 |

Y两优900 Y liangyou 900 | 0.25 | 1.12 | 0.59 | 0.79 | 0.50 |

Y两优1928 Y liangyou 1928 | -2.45 | -0.24 | 0.00 | 0.46 | 0.14 |

黄华占 Huanghuazhan | -0.86 | 1.98 | 0.35 | 1.00 | 0.45 |

Y两优911 Y liangyou 911 | 2.14 | -0.24 | 1.00 | 0.46 | 0.58 |

野香优油丝 Yexiangyouyousi | 1.49 | -2.15 | 0.86 | 0.00 | 0.38 |

桃优香占 Taoyouxiangzhan | 1.43 | -1.70 | 0.85 | 0.11 | 0.40 |

| 权重WX | 0.44 | 0.30 | |||

| 1 | 旷娜,周蔚,张相,等. 再生季稻米蒸煮食味品质与糊化特性、淀粉晶体结构研究[J]. 中国粮油学报, 2021, 36(1): 21-26. |

| KUANG N, ZHOU W, ZHANG X, et al.. The research of ratoon rice on cooking and eating quality and the paste property and starch crystal structure [J]. J. Chin. Cereals Oils Association, 2021, 36(1): 21-26. | |

| 2 | CALINGACION M, LABORTE A, NELSON A, et al.. Diversity of global rice markets and the science required for consumer-targeted rice breeding [J/OL]. PLoS ONE, 2014, 9(1), e85106 [2022-02-20]. . |

| 3 | TIAN Z X, QIAN Q, LIU Q Q, et al.. Allelic diversities in rice starch biosynthesis lead to a diverse array of rice eating and cooking qualities [J]. Proc. Nat. Acad. Sci. USA, 2009, 106(51): 21760-21765. |

| 4 | ZENG D L, TIAN Z X, RAO Y C, et al.. Rational design of high-yield and superior-quality rice [J/OL]. Nat. Plants, 2017, 3:17031 [2022-02-20]. . |

| 5 | 赵春芳,岳红亮,黄双杰,等. 南粳系列水稻品种的食味品质与稻米理化特性[J]. 中国农业科学, 2019, 52(5): 909-920. |

| ZHAO C F, YUE H L, HUANG S J, et al.. Eating quality and physicochemical properties in Nanjing rice varieties [J]. Sci. Agric. Sin., 2019, 52(5): 909-920. | |

| 6 | 吴殿星, 舒庆尧, 夏英武. 低表观直链淀粉含量早籼稻的胚乳外观快速识别及其品质改良应用分析[J]. 作物学报, 2000,26(6): 763-768. |

| WU D X, SHU Q Y, XIA Y W. Rapid identification of early indica rice with low AAC and analysis of its application in quality improvement [J]. Acta Agron. Sin., 2000,26(6):763-768. | |

| 7 | JENKINS P J, DONALD A M. The influence of amylose on starch granule structure [J]. Int. J. Biol. Macromol., 1995, 17(6):315-321. |

| 8 | 吴殿星, 舒庆尧, 夏英武. 胚乳外观标记与RVA谱理化指标相结合辅助改良早籼稻食用品质[J]. 中国水稻科学, 2002, 16(1): 80-82. |

| WU D X, SHU Q Y, XIA Y W. Endosperm appearance marker and physical /chemical indicato r of RVA profile combined- assisted selection for the improvement of eating quality of early Indica rice [J]. Chin. J. Rice Sci., 2002, 16(1):80-82. | |

| 9 | HORI K, SUZUKI K, IIJIMA K, et al.. Variation in cooking and eating quality traits in Japanese rice germplasm accessions [J]. Breed. Sci., 2016, 66(2): 309-318. |

| 10 | 符冠富, 王丹英, 李华, 等. 水稻不同生育期温光条件对籽粒充实和米质的影响[J].中国农业气象, 2009, 30(3): 375-382, 387. |

| FU G F, WANG D Y, LI H, et al.. Influence of temperature and sunlight conditions on rice grain filling and quality in different growth stages [J]. Chin. J. Agrometeorol., 2009, 30(3):375-382, 387. | |

| 11 | 莫惠栋. 我国稻米品质的改良[J].中国农业科学, 1993, 26(4):8-14. |

| MO H D. Improvement of rice quality in China [J]. Sci. Agric. Sin., 1993, 26(4):8-14. | |

| 12 | 林洪鑫, 胡启锋, 肖宇龙, 等.寒露风对双季晚稻品种产量构成和品质的影响[J].江西农业学报, 2016, 28(5):20-23. |

| LIN H X, HU Q F, XIAO Y L, et al.. Effect of cold dew wind on quality,yield and yield components of double cropping late rice varieties [J]. Acta Agric. Jiangxi, 2016, 28(5):20-23. | |

| 13 | 蒋李健.结实期温度胁迫对水稻产量和品质的影响[D].扬州: 扬州大学, 2009. |

| JIANG L J. Effects of temperature stress during grain filling stage on rice grain productivity and quality [D]. Yangzhou:Yangzhou University, 2009. | |

| 14 | 王士强, 宋晓慧, 赵海红, 等. 孕穗期低温胁迫对寒地水稻产量和品质的影响[J]. 农业现代化研究, 2016, 37(3):579-586. |

| WANG S Q, SONG X H, ZHAO H H, et al.. Effect of cold stress at booting stage on rice yield and quality in the cold region [J]. Res. Agric. Mod., 2016, 37(3):579-586. | |

| 15 | 段彬伍,孙成效,朱智伟,等. 稻米直链淀粉的测定 分光光度法: [S].北京:中国标准出版社,2014. |

| 16 | 段彬伍,朱智伟,方长云,等. 米质测定方法: [S].北京:中国标准出版社,2017. |

| 17 | 雷玲,孙辉,姜薇莉. 大米及米粉糊化特性测定 快速粘度仪法: [S].北京:中国标准出版社,2010. |

| 18 | YAO D P, WU J, LUO Q H, et al.. Comprehensive evaluation of high temperature tolerance of six rice varieties during grain-filling period based on key starch physicochemical indexes [J/OL]. LWT-Food Sci. Technol., 2021, 148:111804[2022-02-20]. . |

| 19 | YANO K, MORINAKA Y, WANG F, et al.. GWAS with principal component analysis identifies a gene comprehensively controlling rice architecture [J]. Proc. Natl. Acad. Sci. USA, 2019, 116(42): 21262-21267. |

| 20 | 姜丽娜, 马建辉, 樊婷婷, 等. 孕穗期低温对小麦生理抗寒性的影响[J]. 麦类作物学报, 2014, 34(10): 1373-1382. |

| JIANG L N, MA J H, FAN T T, et al.. Effects of low temperature at booting stage on physiological cold resistance of wheat [J]. J. Triticeae Crops, 2014, 34(10): 1373-1382. | |

| 21 | 张玉华. 稻米直链淀粉含量及其影响因素研究[J]. 黑龙江农业科学, 2002(3):34-37. |

| ZHANG Y H. Content of amylose in rice and its influential factors [J]. Heilongjiang Agric. Sci., 2002(3):34-37. | |

| 22 | 金正勋, 秋太权, 孙艳丽, 等. 稻米蒸煮食味品质特性间的相关性研究[J].东北农业大学学报, 2001, 32(1): 1-7. |

| JIN Z X, QIU T Q, SUN Y L, et al.. Study on the correlation of the cooking and eating quality properties of rice grain [J]. J. Northeast Agric. Univ., 2001, 32(1):1-7. | |

| 23 | BAO J S, YING Y N, ZHOU X, et al.. Relationships among starch biosynthesizing protein content, fine structure and functionality in rice [J/OL]. Carbohyd. Polym., 2020, 237: 116118 [2022-02-20].. |

| 24 | YAO D P, WU J, LUO Q H, et al.. Influence of high natural field temperature during grain filling stage on the morphological structure and physicochemical properties of rice (Oryza sativa L.) starch [J/OL]. Food Chem., 2020,310(3):125817[2022-02-20]. . |

| 25 | 宋广树, 孙忠富, 王夏, 等. 不同生育时期低温处理对水稻品质的影响[J]. 中国农学通报, 2011, 27(18): 174-179. |

| SONG G S, SUN Z F, WANG X, et al.. Effect of low temperature on rice quality in different growth period [J]. Chin. Agric. Sci. Bull., 2011, 27(18):174-179. | |

| 26 | 程方民, 丁元树, 朱碧岩. 稻米直链淀粉含量的形成及其与灌浆结实期温度的关系[J]. 生态学报, 2000,20(4):646-652. |

| CHENG F M, DING Y S, ZHU B Y. The formation of amylose content in rice grain and its relation with field temperature [J]. Acta Ecolo. Sin., 2000,20(4):646-652. | |

| 27 | ZHONG L J, CHENG F M, WEN X, et al.. The deterioration of eating and cooking quality caused by high temperature during grain filling in early-season indica rice cultivars [J]. J. Agron. Crop Sci., 2005, 191(3): 218-225. |

| [1] | Hongyuan LIU, Zhihua ZHOU, Guangxin ZHAO, Yanjun WANG, Nana WANG. Effects of Modified Cellulose on Germination and Dryland Soil Physicochemical Properties of Upland Rice [J]. Journal of Agricultural Science and Technology, 2023, 25(5): 168-175. |

| [2] | Fenfang XIAO, Conghe ZHANG, Hui WANG, Yafeng YE, Daolin ZHANG, Heting WANG, Bo LI, Yuejin WU, Binmei LIU. Simulation and Optimization of Pneumatic Conveying System for Hybrid Rice Pollen Collection Device [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 110-122. |

| [3] | Xiaoxia DING, Shengjun MA, Wenfeng CHEN, Aogang ZHANG, Hongchao YU, Yilihanmujiang Jiapaer. Effects of Rhizobia Inoculated On Content of Main Active Ingredients in Licorice and Multivariate Statistical Analysis [J]. Journal of Agricultural Science and Technology, 2023, 25(3): 212-220. |

| [4] | Linjiang YIN, Wei LI, Weiquan ZHAO, Zulun ZHAO, Sisi LYU, Xiaoqiong SUN. Research on Characteristics and Coverage Extraction of Rice Multi-phase Vegetation Index [J]. Journal of Agricultural Science and Technology, 2023, 25(2): 83-98. |

| [5] | Zompur CHU, Guangfeng MAO, Min WU, Hongkai WU. Relationship Between Electrical Conductivity of Seed Soaking Solution and Seed Vigor in Rice (Oryza sativa L.) [J]. Journal of Agricultural Science and Technology, 2023, 25(1): 35-41. |

| [6] | Wei WANG, Lijuan XIE, Dongya XIAO, Gensheng CHEN, Liang XIE, Ziming WU, Xugen SHI, Huijie LI. Research on the Green Control Technology Model of Diseases and Insects in Double-cropping Rice in Jiangxi Province [J]. Journal of Agricultural Science and Technology, 2022, 24(9): 129-138. |

| [7] | Hui JIN, Wei WANG, Chendong YAN, Wei WANG, Xiying LI. Isolation, Identification and Adaptability of Trichoderma spp. for Biocontrol of Rice Sheath Blight [J]. Journal of Agricultural Science and Technology, 2022, 24(9): 139-148. |

| [8] | Yuanwei CHEN, Huabin ZHENG, Weiqin WANG, Na KUANG, Youyi LUO, Dan ZOU, Qiyuan TANG. Effect of Mowing Treatment on the Main Season Whole Plant Biomass and Silage Quality and Yield in Regeneration Season of Ratooning Rice [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 161-171. |

| [9] | Shuangya WEN, Nan SHI, Chongyi CHEN, Haiyan HU, Zhiqiang GAO. Research on Light Use Efficiency of Rice Based on Eddy Covariance Method [J]. Journal of Agricultural Science and Technology, 2022, 24(7): 159-166. |

| [10] | Huibin KE, Yong ZHOU, Guozhong ZHANG, Wen LYU, Yan LIU, Lin HUANG. Design and Experiment of Pneumatic Fertilizer Collecting and Discharging Device for Ratooning Rice [J]. Journal of Agricultural Science and Technology, 2022, 24(6): 106-114. |

| [11] | Qionghua LI, Lin ZHANG, Xinru HAN, Lili SONG. Temporal and Spatial Analysis of Total Factor Productivity of Double Cropping Rice in China and Its Countermeasures [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 15-23. |

| [12] | Nanrui TANG, Yong ZHOU, Guozhong ZHANG, Fang LIANG, Huibin KE. Performance Simulation and Experiment of Stirred and Bunch Rice Seeding Device [J]. Journal of Agricultural Science and Technology, 2022, 24(4): 107-115. |

| [13] | Tao YANG, Xiaoqian MA, Quan ZHANG, Hongliang ZHANG. Research Progress of Histone Modification in Rice [J]. Journal of Agricultural Science and Technology, 2022, 24(4): 11-20. |

| [14] | Linlin DONG, Jinfang ZHA, Mingxing SHEN, Haihou WANG, Linlin SHI, Yueyue TAO, Xinwei ZHOU, Changying LU. Effect of Long-term Straw Returning on Soil Organic Carbon Fractions Composition in Rice-Wheat Rotation Ecosystem [J]. Journal of Agricultural Science and Technology, 2022, 24(3): 166-175. |

| [15] | Zhenjia HE, Wangtao FAN, Yichun DU, Qilong WANG. Effects of Water and Fertilizer Coupling on the Physical and Chemical Properties of Rice Soil and Yield Based on Soil Organic Reconstruction [J]. Journal of Agricultural Science and Technology, 2022, 24(3): 176-185. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号