Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (7): 204-216.DOI: 10.13304/j.nykjdb.2024.0050

• BIO-MANUFACTURING & RESOURCE AND ECOLOGY • Previous Articles

Xianhua DING1( ), Shuangdui YAN2, Ming YAN3(

), Shuangdui YAN2, Ming YAN3( )

)

Received:2024-01-18

Accepted:2024-03-11

Online:2025-07-15

Published:2025-07-11

Contact:

Ming YAN

通讯作者:

闫明

作者简介:丁献华E-mail: dingxianhua2007@163.com;

基金资助:CLC Number:

Xianhua DING, Shuangdui YAN, Ming YAN. Preparation and Characteristics of High-quality Biochar Fuel by Pressurized Torrefaction of Pine Sawdust[J]. Journal of Agricultural Science and Technology, 2025, 27(7): 204-216.

丁献华, 闫双堆, 闫明. 松木木屑加压烘焙制备高品质生物焦燃料及其特性研究[J]. 中国农业科技导报, 2025, 27(7): 204-216.

样品 Sample | 工业成分Proximate composition/% | 元素分析 Ultimate analysis/% | 高位发热量HHV/(MJ·kg-1) | |||||

|---|---|---|---|---|---|---|---|---|

挥发分 Vdaf | 固定碳 FCdaf | 碳C | 氢H | 氮N | 氧O△ | 硫S | ||

| CS | 84.09±2.06 a | 15.91±0.81 c | 46.71±0.96 c | 5.38±0.53 b | 0.25±0.01 c | 47.51±1.85 a | 0.15±0.01 b | 14.99±0.75 c |

| CS-230-AP | 76.35±2.00 b | 22.65±1.57 b | 54.84±1.42 b | 5.47±0.14 b | 0.76±0.03 a | 38.80±0.96 b | 0.13±0.00 b | 19.44±0.26 b |

| CS-230-0.5 | 70.70±1.70 b | 27.30±2.30 b | 57.94±2.55 b | 4.98±1.11 c | 0.50±0.04 b | 36.48±0.64 b | 0.10±0.00 b | 20.20±1.20 b |

| CS-230-1.0 | 66.02±2.11 b | 33.98±2.11 a | 63.32±0.95 a | 5.05±0.31 c | 0.59±0.02 b | 30.92±2.02 b | 0.12±0.01 b | 23.12±1.62 a |

| CS-230-1.5 | 63.85±3.14 c | 36.15±1.72 a | 65.97±3.09 a | 5.70±0.28 a | 0.48±0.07 b | 27.65±1.72 c | 0.20±0.01 a | 25.54±1.14 a |

| CS-230-2.0 | 63.01±2.36 c | 36.99±2.85 a | 67.00±0.52 a | 5.35±0.32 b | 0.45±0.07 b | 27.06±1.39 c | 0.14±0.01 b | 25.49±0.81 a |

Table 1 Proximate composition and ultimate analysis of CS samples and pressurized torrefied semi-char

样品 Sample | 工业成分Proximate composition/% | 元素分析 Ultimate analysis/% | 高位发热量HHV/(MJ·kg-1) | |||||

|---|---|---|---|---|---|---|---|---|

挥发分 Vdaf | 固定碳 FCdaf | 碳C | 氢H | 氮N | 氧O△ | 硫S | ||

| CS | 84.09±2.06 a | 15.91±0.81 c | 46.71±0.96 c | 5.38±0.53 b | 0.25±0.01 c | 47.51±1.85 a | 0.15±0.01 b | 14.99±0.75 c |

| CS-230-AP | 76.35±2.00 b | 22.65±1.57 b | 54.84±1.42 b | 5.47±0.14 b | 0.76±0.03 a | 38.80±0.96 b | 0.13±0.00 b | 19.44±0.26 b |

| CS-230-0.5 | 70.70±1.70 b | 27.30±2.30 b | 57.94±2.55 b | 4.98±1.11 c | 0.50±0.04 b | 36.48±0.64 b | 0.10±0.00 b | 20.20±1.20 b |

| CS-230-1.0 | 66.02±2.11 b | 33.98±2.11 a | 63.32±0.95 a | 5.05±0.31 c | 0.59±0.02 b | 30.92±2.02 b | 0.12±0.01 b | 23.12±1.62 a |

| CS-230-1.5 | 63.85±3.14 c | 36.15±1.72 a | 65.97±3.09 a | 5.70±0.28 a | 0.48±0.07 b | 27.65±1.72 c | 0.20±0.01 a | 25.54±1.14 a |

| CS-230-2.0 | 63.01±2.36 c | 36.99±2.85 a | 67.00±0.52 a | 5.35±0.32 b | 0.45±0.07 b | 27.06±1.39 c | 0.14±0.01 b | 25.49±0.81 a |

样品 Sample | 工业成分Proximate composition/% | 元素分析Ultimate analysis/% | 高位发热量HHV/(MJ·kg-1) | |||||

|---|---|---|---|---|---|---|---|---|

挥发分 Vdaf | 固定碳 FCdaf | 碳C | 氢H | 氮N | 氧O△ | 硫S | ||

| CS | 84.09±2.06 a | 15.91±0.81 e | 46.71±0.96 c | 5.38±0.53 a | 0.25±0.01 c | 47.51±1.85 a | 0.15±0.01 a | 14.99±0.75 c |

| CS-200-1.5 | 75.83±2.92 b | 24.17±0.97 d | 54.20±0.96 b | 4.85±0.32 b | 0.38±0.02 b | 40.49±1.24 a | 0.08±0.01 b | 18.02±0.52 b |

| CS-230-1.5 | 63.85±2.46 c | 36.15±2.07 c | 65.97±2.42 a | 5.70±0.24 a | 0.48±0.02 b | 27.65±0.66 b | 0.20±0.00 a | 25.54±1.26 a |

| CS-260-1.5 | 53.40±1.90 d | 46.60±1.30 b | 68.78±1.55 a | 5.39±0.75 a | 0.49±0.02 b | 25.25±0.40 b | 0.09±0.00 b | 26.48±1.03 a |

| CS-290-1.5 | 45.74±1.83 e | 54.26±2.55 a | 71.71±3.01 a | 5.63±1.04 a | 0.66±0.01 a | 22.39±1.63 b | 0.15±0.01 a | 28.15±1.33 a |

Table 2 Proximate composition and ultimate analysis of CS samples and pressurized torrefied semi-char

样品 Sample | 工业成分Proximate composition/% | 元素分析Ultimate analysis/% | 高位发热量HHV/(MJ·kg-1) | |||||

|---|---|---|---|---|---|---|---|---|

挥发分 Vdaf | 固定碳 FCdaf | 碳C | 氢H | 氮N | 氧O△ | 硫S | ||

| CS | 84.09±2.06 a | 15.91±0.81 e | 46.71±0.96 c | 5.38±0.53 a | 0.25±0.01 c | 47.51±1.85 a | 0.15±0.01 a | 14.99±0.75 c |

| CS-200-1.5 | 75.83±2.92 b | 24.17±0.97 d | 54.20±0.96 b | 4.85±0.32 b | 0.38±0.02 b | 40.49±1.24 a | 0.08±0.01 b | 18.02±0.52 b |

| CS-230-1.5 | 63.85±2.46 c | 36.15±2.07 c | 65.97±2.42 a | 5.70±0.24 a | 0.48±0.02 b | 27.65±0.66 b | 0.20±0.00 a | 25.54±1.26 a |

| CS-260-1.5 | 53.40±1.90 d | 46.60±1.30 b | 68.78±1.55 a | 5.39±0.75 a | 0.49±0.02 b | 25.25±0.40 b | 0.09±0.00 b | 26.48±1.03 a |

| CS-290-1.5 | 45.74±1.83 e | 54.26±2.55 a | 71.71±3.01 a | 5.63±1.04 a | 0.66±0.01 a | 22.39±1.63 b | 0.15±0.01 a | 28.15±1.33 a |

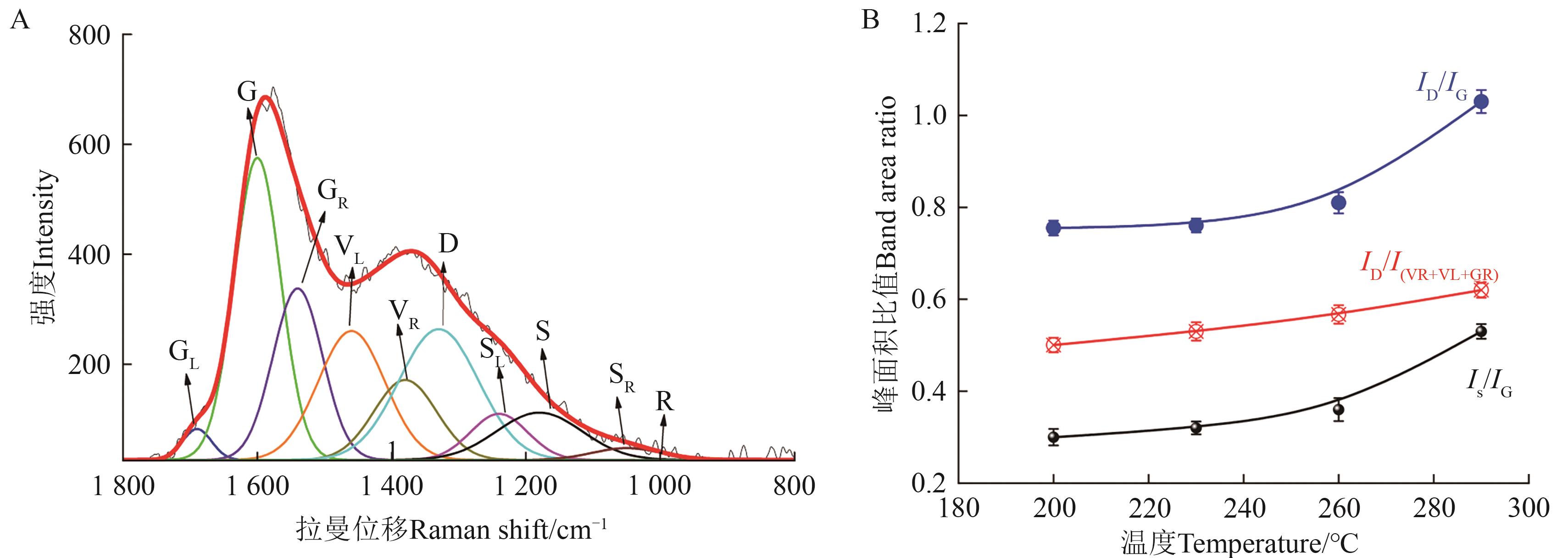

Fig. 5 Raman peak splitting results of CS pressurized torrefied semi-char at different temperaturesA:Raman splitting of CS-230-1.5;B:Peak area results of each sample

样品 Sample | 比表面积 Specific surface area/(m2·g-1) | 总孔体积 Total pore volume/(cm3·g-1) | 平均孔径 Average pore size/nm |

|---|---|---|---|

| CS | 27.47 | 0.042 9 | 3.23 |

| CS-230-AP | 25.03 | 0.047 3 | 5.12 |

| CS-200-1.5 | 24.25 | 0.043 9 | 4.78 |

| CS-230-1.5 | 37.69 | 0.056 8 | 4.38 |

| CS-260-1.5 | 38.92 | 0.068 3 | 3.99 |

| CS-290-1.5 | 40.02 | 0.070 4 | 3.52 |

Table 3 BET test results of solid semi-char at different temperatures and CS sample

样品 Sample | 比表面积 Specific surface area/(m2·g-1) | 总孔体积 Total pore volume/(cm3·g-1) | 平均孔径 Average pore size/nm |

|---|---|---|---|

| CS | 27.47 | 0.042 9 | 3.23 |

| CS-230-AP | 25.03 | 0.047 3 | 5.12 |

| CS-200-1.5 | 24.25 | 0.043 9 | 4.78 |

| CS-230-1.5 | 37.69 | 0.056 8 | 4.38 |

| CS-260-1.5 | 38.92 | 0.068 3 | 3.99 |

| CS-290-1.5 | 40.02 | 0.070 4 | 3.52 |

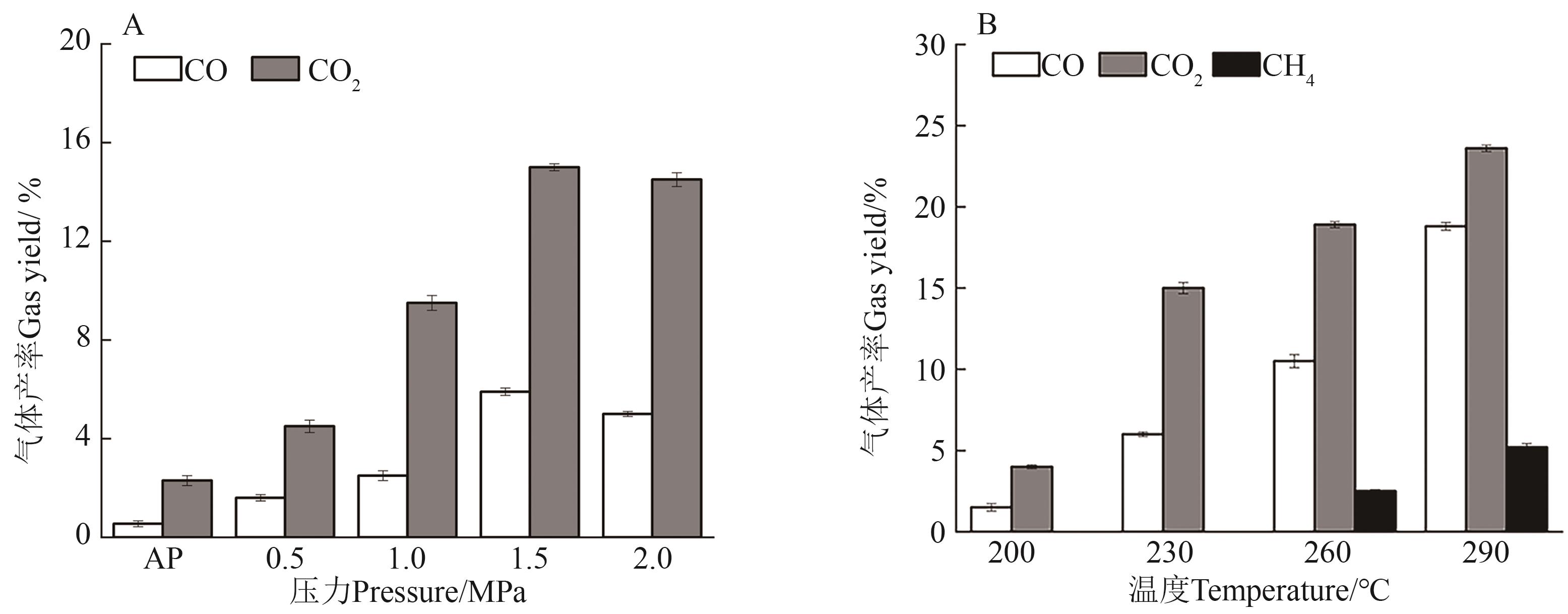

Fig. 10 Compositions of torrefied gas products under different pressures and temperaturesA:Gas distribution at 230 ℃ and different pressures;B:Gas distribution at 1.5 MPa and different temperatures

| [1] | FIELD C B, CAMPBELL J E, LOBELL D B.Biomass energy:the scale of the potential resource [J]. Trends Ecol. Evol., 2008,23(2):65-72. |

| [2] | LONG H L, LI X B, WANG H, et al.. Biomass resources and their bioenergy potential estimation:a review [J]. Renew.Sustain. Energy Rev., 2013, 26: 344-352. |

| [3] | QUADER M A, AHMED S, GHAZILLA R A R, et al.. A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing [J]. Renew. Sustain. Energy Rev., 2015,50:594-614. |

| [4] | 严云,何强,沙建雄,等.污泥-杏壳基生物质炭的制备工艺优化及对亚甲基蓝吸附研究[J].化工新型材料,2022,50(11):278-282. |

| YAN Y, HE Q, SHA J X, et al.. Optimization of the preparation process of sludge-apricot shell-based biomass carbon and its adsorption towards methylene blue [J]. New Chem. Mater.,2022,50(11):278-282. | |

| [5] | BACH Q V, SKREIBERG Ø. Upgrading biomass fuels via wet torrefaction:a review and comparison with dry torrefaction [J].Renew. Sustain. Energy Rev., 2016,54: 665-677. |

| [6] | 孙启祥,彭镇华,张齐生.自然状态下杉木木材挥发物成分及其对人体身心健康的影响[J].安徽农业大学学报,2004,31(2):158-163. |

| SUN Q X, PENG Z H, ZHANG Q S. Volatiles of wood of Chinese fir in nature and its effect on human health [J]. J.Anhui Agric. Univ., 2004,31(2):158-163. | |

| [7] | 金紫霖,张启翔,潘会堂,等.芳香植物的特性及对人体健康的作用[J].湖北农业科学,2009,48(5):1245-1247. |

| JIN Z L, ZHANG Q X, PAN H T, et al.. The aromatic characteristics and healthy effects of the aromatic plants [J].Hubei Agric. Sci., 2009, 48(5):1245-1247. | |

| [8] | DING Y M, HUANG B Q, LI K Y, et al.. Thermal interaction analysis of isolated hemicellulose and cellulose by kinetic parameters during biomass pyrolysis [J/OL]. Energy, 2020, 195:117010 [2023-12-18]. . |

| [9] | STRANDBERG M, OLOFSSON I, POMMER L, et al.. Effects of temperature and residence time on continuous torrefaction of spruce wood [J]. Fuel Process. Technol., 2015,134:387-398. |

| [10] | TOOR S S, ROSENDAHL L, RUDOLF A. Hydrothermal liquefaction of biomass:a review of subcritical water technologies [J]. Energy, 2011, 36(5):2328-2342. |

| [11] | TONG S, SUN Y M, LI X, et al.. Gas-pressurized torrefaction of biomass wastes:Roles of pressure and secondary reactions [J/OL].Bioresour. Technol., 2020, 313:123640 [2023-12-18]. . |

| [12] | MATALI S, RAHMAN N A, IDRIS S S, et al.. Lignocellulosic biomass solid fuel properties enhancement via torrefaction [J].Procedia Eng., 2016,148:671-678. |

| [13] | NHUCHHEN D R, BASU P. Experimental investigation of mildly pressurized torrefaction in air and nitrogen [J]. Energy Fuels, 2014, 28(5):3110-3121. |

| [14] | 丁亮,张永奇,黄戒介,等.热解压力对生物质焦结构及气化反应性能的影响[J].燃料化学学报,2014,42(11):1309-1315. |

| DING L, ZHANG Y Q, HUANG J J, et al.. Effects of pyrolysis pressure on the properties and gasification reactivities of biomass chars [J]. J. Fuel Chem. Technol., 2014, 42(11):1309-1315. | |

| [15] | WANNAPEERA J, WORASUWANNARAK N. Upgrading of woody biomass by torrefaction under pressure [J]. J. Anal. Appl. Pyrolysis, 2012, 96:173-180. |

| [16] | AGAR D, DEMARTINI N, HUPA M. Influence of elevated pressure on the torrefaction of wood [J]. Energy Fuels, 2016, 30(3):2127-2136. |

| [17] | 张传佳,李安心,涂德浴.水稻秸秆成型燃料热解特性试验研究[J].中国农业科技导报,2017,19(7):95-100. |

| ZHANG C J, LI A X, TU D Y. The experimental study on pyrolysis characteristics of rice straw briquette fuel [J]. J. Agric.Sci. Technol., 2017, 19(7):95-100. | |

| [18] | 肖军,沈来宏,王泽明,等.生物质加压热重分析研究[J].燃烧科学与技术,2005,11(5):415-420. |

| XIAO J, SHEN L H, WANG Z M, et al.. Pressurized thermogravimetric analysis of pyrolysis of biomass [J].J.Combust. Sci. Technol., 2005, 11(5): 415-420. | |

| [19] | SONOBE T, WORASUWANNARAK N.Kinetic analyses of biomass pyrolysis using the distributed activation energy model [J]. Fuel, 2008, 87(3):414-421. |

| [20] | DE CAPRARIIS B, SANTARELLI M L, SCARSELLA M, et al..Kinetic analysis of biomass pyrolysis using a double distributed activation energy model [J]. J. Therm. Anal.Calorim., 2015, 121(3): 1403-1410. |

| [21] | 严云,刘洪,曹芮,等.农林废弃生物质的热解特性及动力学研究[J].化工新型材料,2020,48(1):148-151, 156. |

| YAN Y, LIU H, CAO R, et al.. Study on pyrolysis characteristics and kinetics of waste biomass in agriculture and forestry [J]. New Chem. Mater., 2020, 48(1):148-151, 156. | |

| [22] | LIU X G, LI B Q, MIURA K. Analysis of pyrolysis and gasification reactions of hydrothermally and supercritically upgraded low-rank coal by using a new distributed activation energy model [J]. Fuel Process. Technol., 2001, 69(1):1-12. |

| [23] | SATTASATHUCHANA S, PARNTHONG J, YOUNGIAN S,et al..Energy efficiency of bio-coal derived from hydrothermal carbonized biomass:Assessment as sustainable solid fuel for municipal biopower plant [J/OL]. Appl. Therm. Eng., 2023, 221:119789 [2024-12-30]. . |

| [24] | 陈勇,陈登宇,孙琰,等.烘焙脱氧预处理对生物质秸秆燃料品质的影响[J].科学技术与工程,2015,15(11):205-209. |

| CHEN Y, CHEN D Y, SUN Y, et al.. Effect of torrefaction on the fuel properties of biomass straw [J]. Sci. Technol. Eng., 2015, 15(11):205-209. | |

| [25] | XIN S Z, YANG H P, CHEN Y Q, et al.. Chemical structure evolution of char during the pyrolysis of cellulose [J]. J. Anal.Appl. Pyrolysis, 2015, 116:263-271. |

| [26] | 周亚运,肖军,吕潇,等.预处理生物质的热解实验研究[J].东南大学学报(自然科学版),2016,46(2):317-325. |

| ZHOU Y Y, XIAO J, LYU X, et al.. Experimental study on pyrolysis of pretreated biomass [J]. J. Southeast Univ.(Nat. Sci.), 2016, 46(2):317-325. | |

| [27] | 宫聚辉,邵婷婷,路平,等.煤和沙柳的O2/CO2混合燃烧特性及相互作用研究[J].中国农业科技导报,2017,19(10):96-106. |

| GONG J H, SHAO T T, LU P, et al.. Combustion characteristic and interaction of coal and Salix Psammophila under O2/CO2 atmosphere [J]. J. Agric. Sci. Technol., 2017, 19(10):96-106. | |

| [28] | 苏允泓,任菊荣,孙云娟,等.烘焙提升生物质燃料品质的研究[J].林产化学与工业,2023,43(2):27-35. |

| SU Y H, REN J R, SUN Y J, et al.. Improving the quality of biofuel by torrefaction [J].Chem.Ind.For.Prod.,2023,43(2):27-35. | |

| [29] | SETKIT N, LI X, YAO H, et al.. Torrefaction under mechanical pressure of 10-70 atMPa 250 ℃ and its effect on pyrolysis behaviours of Leucaena wood [J/OL].Bioresour.Technol., 2021, 338:125503 [2023-12-18]. . |

| [30] | LI X J, HAYASHI J I, LI C Z. FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal [J]. Fuel, 2006, 85(12/13):1700-1707. |

| [1] | Huiyan QIAO, Yali SHI, Haojian HAN. Research Progress of Cellulase Derived from Microorganisms [J]. Journal of Agricultural Science and Technology, 2025, 27(5): 21-38. |

| [2] | Huijun LI, Weijian ZHANG, Weijian WU, Gaoyang LI, Yijie CHEN, Fengcheng HUANG, Yongxiang HUANG, Zhong LIN, Zhen ZHEN. Effects of Sea Rice on Soil Chemical Properties and Microbial Community Structure in Coastal Solonchaks [J]. Journal of Agricultural Science and Technology, 2023, 25(9): 147-156. |

| [3] | Xingsheng YIN, Lingfeng BAO, Yongyu PU, Jiali SUN, Qing ZHANG, Haiping LI, Mingying YANG, Yueping LIN, Huaixin WANG, Yonghong HE, Peiwen YANG. Effects of Chemical Fertilizer Reduction Combined with Bio-organic Fertilization on Tobacco Soil Characteristics and Tobacco Bacterial Wilt Control [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 122-131. |

| [4] | Peixin LIANG, Rong TANG, Jianguo LIU. Effects of Mixed Saline-alkali Stress on Photosynthetic Physiology and Yield in Cyperus esculentus L. [J]. Journal of Agricultural Science and Technology, 2023, 25(12): 195-204. |

| [5] | Yajuan WEI, Jing GUO, Yunhu XIE, Xiangfei WANG, Shan JIN. Study on Branching Architecture of Clipping Hedysarum scoparium in Desert-oasis Ecotone of Jilantai [J]. Journal of Agricultural Science and Technology, 2023, 25(11): 207-217. |

| [6] | Yuanwei CHEN, Huabin ZHENG, Weiqin WANG, Na KUANG, Youyi LUO, Dan ZOU, Qiyuan TANG. Effect of Mowing Treatment on the Main Season Whole Plant Biomass and Silage Quality and Yield in Regeneration Season of Ratooning Rice [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 161-171. |

| [7] | Yue GU, Jinggui WU. Study on Dynamic Effects of Organic Materials on Soil Carbon, Nitrogen and Microbial Biomass [J]. Journal of Agricultural Science and Technology, 2022, 24(4): 126-133. |

| [8] | FAN Hongye, LI Yaoyao, LU Xiaju, GU Shenghao, GUO Xinyu, , LIU Yuhua. [J]. Journal of Agricultural Science and Technology, 2021, 23(9): 112-120. |

| [9] | ZHU Lixia, CHEN Jutian, XU Siwei, CHEN Rubing, LI Lili. Dynamics of Soil Microbial Biomass Carbon and Nitrogen After Biochar Application [J]. Journal of Agricultural Science and Technology, 2021, 23(8): 193-200. |

| [10] | HUANG Qingyang, JIANG Chao, YU Yuanchun, XIE Zubin. Effects of Different Straw Biochar Substrate on the Physiological Properties of Cosmos bipinnatus [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 147-153. |

| [11] | TAN Jinghong, WU Qixia*, ZHU Jianqiang, KE Xinyao, MA Hongyu. Study on the Optimal Nitrogen Application Rate for Transplanted Cotton following Wheat Harvest in Jianghan Plain [J]. Journal of Agricultural Science and Technology, 2020, 22(9): 122-131. |

| [12] | ZHANG Panpan, LIU Jingbao*, HUANG Lu, QIAO Jiangfang, LI Chuan, ZHANG Meiwei. Effects of Reducing Nitrogen Applications on Yield and Biomass Distribution of Mechanized Harvesting Maize Varieties [J]. Journal of Agricultural Science and Technology, 2020, 22(3): 108-118. |

| [13] | WANG Wei, LI Yong, WANG Wei, BIAN Xue, LI Xiying*. Anti-disease Effect and Mechanism of Y-S-Y12 Strain Fermentation Mixed with Biomass Pyrolysis Solution on Pepper Anthracnose [J]. Journal of Agricultural Science and Technology, 2020, 22(10): 129-138. |

| [14] | XIA Xianfei1, XIAO Hongru1*, XIAO Suwei1, LI Bo2, LI Guoping2. Multi-objective Optimization of the Biomass Densification Process Based on Mixed-level Orthogonal Array Design [J]. Journal of Agricultural Science and Technology, 2019, 21(3): 69-75. |

| [15] | WU Qi1,2,3§, ZHANG Yuhui1,2§, SU Rongrong1,2, SUN Bo1,3, WU Qiuyun1,2, XIA Zhilan1,2*. Optimization of Submerged Fermentation Medium of Agaricus blazei Murrill for Mycelial Biomass Accumulation Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2019, 21(3): 152-160. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号