Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (6): 104-112.DOI: 10.13304/j.nykjdb.2024.0092

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Gang ZHENG1( ), Peng XU2, Dongquan CHEN2, Songmei YANG1, Minsheng WU1, Ranbing YANG1(

), Peng XU2, Dongquan CHEN2, Songmei YANG1, Minsheng WU1, Ranbing YANG1( )

)

Received:2024-02-02

Accepted:2024-03-22

Online:2025-06-15

Published:2025-06-23

Contact:

Ranbing YANG

郑刚1( ), 许鹏2, 陈栋泉2, 杨松梅1, 吴敏生1, 杨然兵1(

), 许鹏2, 陈栋泉2, 杨松梅1, 吴敏生1, 杨然兵1( )

)

通讯作者:

杨然兵

作者简介:郑刚 E-mail:3067709228@qq.com;

基金资助:CLC Number:

Gang ZHENG, Peng XU, Dongquan CHEN, Songmei YANG, Minsheng WU, Ranbing YANG. Design and Experimentation of Conveying and Separating Device for Fresh-eating Sweet Potato Harvester in Sandy Soil[J]. Journal of Agricultural Science and Technology, 2025, 27(6): 104-112.

郑刚, 许鹏, 陈栋泉, 杨松梅, 吴敏生, 杨然兵. 沙地鲜食甘薯收获机输送分离装置设计与试验[J]. 中国农业科技导报, 2025, 27(6): 104-112.

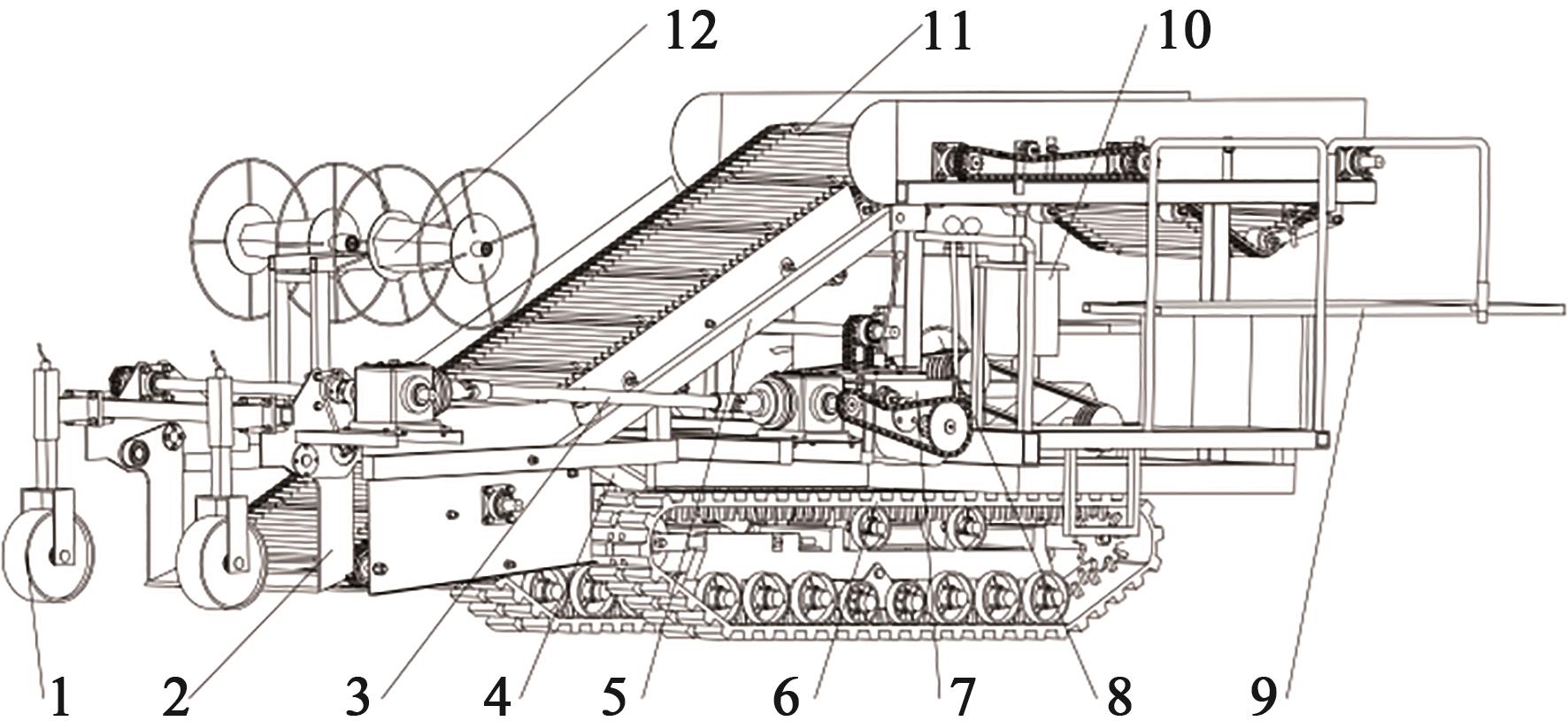

Fig. 1 Structure of fresh-eating sweet potato harvester in sandy soilNote: 1—Depth limiting device; 2—Digging device; 3—Universal transmission shaft; 4—Hydraulic cylinder; 5—Frame; 6—Crawler chassis; 7—Gearbox; 8—Engine; 9—Pickup platform; 10—Control cabinet; 11—Conveying and separating device; 12—Film collecting device.

水平 Level | 试验因素 Experimental factors | ||

|---|---|---|---|

| A:线速度 Line speed/(m·s-1) | B:振幅 Amplitude/mm | C:挖掘深度 Digging depth/mm | |

| 1.682 | 0.40 | 30 | 260 |

| 1 | 0.37 | 26 | 248 |

| 0 | 0.32 | 20 | 230 |

| -1 | 0.27 | 14 | 212 |

| -1.682 | 0.24 | 10 | 200 |

Tab.1 Table of experimental factor levels and their coding

水平 Level | 试验因素 Experimental factors | ||

|---|---|---|---|

| A:线速度 Line speed/(m·s-1) | B:振幅 Amplitude/mm | C:挖掘深度 Digging depth/mm | |

| 1.682 | 0.40 | 30 | 260 |

| 1 | 0.37 | 26 | 248 |

| 0 | 0.32 | 20 | 230 |

| -1 | 0.27 | 14 | 212 |

| -1.682 | 0.24 | 10 | 200 |

序号 Number | 试验因素 Experimental factors | BR:破皮率 Skin breaking rate/% | LR:损失率 Loss rate/% | ||

|---|---|---|---|---|---|

| A/(m·s-1) | B/mm | C/mm | |||

| 1 | 0.32 | 20 | 230 | 1.07 | 0.93 |

| 2 | 0.32 | 20 | 230 | 1.12 | 0.85 |

| 3 | 0.37 | 14 | 212 | 1.47 | 1.51 |

| 4 | 0.24 | 20 | 230 | 0.97 | 0.51 |

| 5 | 0.32 | 20 | 260 | 1.63 | 1.35 |

| 6 | 0.32 | 20 | 230 | 1.10 | 0.88 |

| 7 | 0.32 | 30 | 230 | 1.82 | 0.78 |

| 8 | 0.37 | 14 | 248 | 1.34 | 1.76 |

| 9 | 0.32 | 20 | 230 | 1.09 | 0.95 |

| 10 | 0.27 | 14 | 212 | 1.24 | 0.57 |

| 11 | 0.40 | 20 | 230 | 1.58 | 1.92 |

| 12 | 0.32 | 20 | 230 | 1.14 | 0.86 |

| 13 | 0.32 | 20 | 200 | 1.78 | 0.87 |

| 14 | 0.27 | 14 | 248 | 1.05 | 0.62 |

| 15 | 0.27 | 26 | 212 | 1.54 | 0.54 |

| 16 | 0.37 | 26 | 212 | 1.85 | 1.35 |

| 17 | 0.32 | 10 | 230 | 0.89 | 1.03 |

| 18 | 0.32 | 20 | 230 | 1.06 | 0.95 |

| 19 | 0.27 | 26 | 248 | 1.51 | 0.58 |

| 20 | 0.37 | 26 | 248 | 1.96 | 1.57 |

| 21 | 0.32 | 20 | 230 | 1.15 | 0.97 |

| 22 | 0.32 | 20 | 230 | 1.05 | 0.99 |

| 23 | 0.32 | 20 | 230 | 1.08 | 0.92 |

Table 2 Program and result of orthogonal test

序号 Number | 试验因素 Experimental factors | BR:破皮率 Skin breaking rate/% | LR:损失率 Loss rate/% | ||

|---|---|---|---|---|---|

| A/(m·s-1) | B/mm | C/mm | |||

| 1 | 0.32 | 20 | 230 | 1.07 | 0.93 |

| 2 | 0.32 | 20 | 230 | 1.12 | 0.85 |

| 3 | 0.37 | 14 | 212 | 1.47 | 1.51 |

| 4 | 0.24 | 20 | 230 | 0.97 | 0.51 |

| 5 | 0.32 | 20 | 260 | 1.63 | 1.35 |

| 6 | 0.32 | 20 | 230 | 1.10 | 0.88 |

| 7 | 0.32 | 30 | 230 | 1.82 | 0.78 |

| 8 | 0.37 | 14 | 248 | 1.34 | 1.76 |

| 9 | 0.32 | 20 | 230 | 1.09 | 0.95 |

| 10 | 0.27 | 14 | 212 | 1.24 | 0.57 |

| 11 | 0.40 | 20 | 230 | 1.58 | 1.92 |

| 12 | 0.32 | 20 | 230 | 1.14 | 0.86 |

| 13 | 0.32 | 20 | 200 | 1.78 | 0.87 |

| 14 | 0.27 | 14 | 248 | 1.05 | 0.62 |

| 15 | 0.27 | 26 | 212 | 1.54 | 0.54 |

| 16 | 0.37 | 26 | 212 | 1.85 | 1.35 |

| 17 | 0.32 | 10 | 230 | 0.89 | 1.03 |

| 18 | 0.32 | 20 | 230 | 1.06 | 0.95 |

| 19 | 0.27 | 26 | 248 | 1.51 | 0.58 |

| 20 | 0.37 | 26 | 248 | 1.96 | 1.57 |

| 21 | 0.32 | 20 | 230 | 1.15 | 0.97 |

| 22 | 0.32 | 20 | 230 | 1.05 | 0.99 |

| 23 | 0.32 | 20 | 230 | 1.08 | 0.92 |

来源 Source | BR:破皮率 Skin breaking rate | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型 Model | 2.250 0 | 9 | 0.249 5 | 122.30 | <0.000 1** |

| A | 0.387 9 | 1 | 0.387 9 | 190.12 | <0.000 1** |

| B | 0.808 2 | 1 | 0.808 2 | 396.11 | <0.000 1** |

| C | 0.017 7 | 1 | 0.017 7 | 8.68 | 0.011 4* |

| AB | 0.007 2 | 1 | 0.007 2 | 3.53 | 0.082 9 |

| AC | 0.005 0 | 1 | 0.005 0 | 2.45 | 0.141 5 |

| BC | 0.020 0 | 1 | 0.020 0 | 9.80 | 0.008 0** |

| A2 | 0.074 8 | 1 | 0.074 8 | 36.67 | <0.000 1** |

| B2 | 0.144 8 | 1 | 0.144 8 | 70.96 | <0.000 1** |

| C2 | 0.766 6 | 1 | 0.766 6 | 375.73 | <0.000 1** |

| 残差 Residual | 0.026 5 | 13 | 0.002 0 | ||

| 失拟项 Lack of fit | 0.016 7 | 5 | 0.003 3 | 2.72 | 0.100 4 |

| 误差 Error | 0.009 8 | 8 | 0.001 2 | ||

| 总和 Total | 2.270 0 | 22 | |||

Table 3 Variance analysis of skin breaking rate

来源 Source | BR:破皮率 Skin breaking rate | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型 Model | 2.250 0 | 9 | 0.249 5 | 122.30 | <0.000 1** |

| A | 0.387 9 | 1 | 0.387 9 | 190.12 | <0.000 1** |

| B | 0.808 2 | 1 | 0.808 2 | 396.11 | <0.000 1** |

| C | 0.017 7 | 1 | 0.017 7 | 8.68 | 0.011 4* |

| AB | 0.007 2 | 1 | 0.007 2 | 3.53 | 0.082 9 |

| AC | 0.005 0 | 1 | 0.005 0 | 2.45 | 0.141 5 |

| BC | 0.020 0 | 1 | 0.020 0 | 9.80 | 0.008 0** |

| A2 | 0.074 8 | 1 | 0.074 8 | 36.67 | <0.000 1** |

| B2 | 0.144 8 | 1 | 0.144 8 | 70.96 | <0.000 1** |

| C2 | 0.766 6 | 1 | 0.766 6 | 375.73 | <0.000 1** |

| 残差 Residual | 0.026 5 | 13 | 0.002 0 | ||

| 失拟项 Lack of fit | 0.016 7 | 5 | 0.003 3 | 2.72 | 0.100 4 |

| 误差 Error | 0.009 8 | 8 | 0.001 2 | ||

| 总和 Total | 2.270 0 | 22 | |||

| 来源 Source | LR:损失率 Loss rate | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型 Model | 3.30 | 9 | 0.3666 | 97.35 | <0.0001** |

| A | 2.870 0 | 1 | 2.870 0 | 762.010 0 | <0.000 1** |

| B | 0.051 6 | 1 | 0.051 6 | 13.710 0 | 0.002 7** |

| C | 0.136 4 | 1 | 0.136 4 | 36.230 0 | <0.000 1** |

| AB | 0.009 8 | 1 | 0.009 8 | 2.600 0 | 0.130 7 |

| AC | 0.018 1 | 1 | 0.018 1 | 4.790 0 | 0.047 4* |

| BC | 0.000 2 | 1 | 0.000 2 | 0.053 1 | 0.821 3 |

| A2 | 0.152 1 | 1 | 0.152 1 | 40.390 0 | <0.000 1** |

| B2 | 0.002 9 | 1 | 0.002 9 | 0.757 5 | 0.399 9 |

| C2 | 0.056 0 | 1 | 0.056 0 | 14.860 0 | 0.002 0** |

| 残差 Residual | 0.049 0 | 13 | 0.003 8 | ||

| 失拟项 Lack of fit | 0.029 6 | 5 | 0.005 9 | 2.450 0 | 0.125 0 |

| 误差 Error | 0.019 4 | 8 | 0.002 4 | ||

| 总和 Total | 3.350 0 | 22 | |||

Table 4 Variance analysis of loss rate

| 来源 Source | LR:损失率 Loss rate | ||||

|---|---|---|---|---|---|

平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | F值 F value | P值 P value | |

| 模型 Model | 3.30 | 9 | 0.3666 | 97.35 | <0.0001** |

| A | 2.870 0 | 1 | 2.870 0 | 762.010 0 | <0.000 1** |

| B | 0.051 6 | 1 | 0.051 6 | 13.710 0 | 0.002 7** |

| C | 0.136 4 | 1 | 0.136 4 | 36.230 0 | <0.000 1** |

| AB | 0.009 8 | 1 | 0.009 8 | 2.600 0 | 0.130 7 |

| AC | 0.018 1 | 1 | 0.018 1 | 4.790 0 | 0.047 4* |

| BC | 0.000 2 | 1 | 0.000 2 | 0.053 1 | 0.821 3 |

| A2 | 0.152 1 | 1 | 0.152 1 | 40.390 0 | <0.000 1** |

| B2 | 0.002 9 | 1 | 0.002 9 | 0.757 5 | 0.399 9 |

| C2 | 0.056 0 | 1 | 0.056 0 | 14.860 0 | 0.002 0** |

| 残差 Residual | 0.049 0 | 13 | 0.003 8 | ||

| 失拟项 Lack of fit | 0.029 6 | 5 | 0.005 9 | 2.450 0 | 0.125 0 |

| 误差 Error | 0.019 4 | 8 | 0.002 4 | ||

| 总和 Total | 3.350 0 | 22 | |||

| 指标Index | 平均值 Average value | 优化值 Optimized value | 相对误差 Relative error |

|---|---|---|---|

| 破皮率 Skin breaking rate/% | 0.866 | 0.851 | 1.763 |

| 损失率 Loss rate/% | 0.694 | 0.678 | 2.360 |

Table 5 Verification result

| 指标Index | 平均值 Average value | 优化值 Optimized value | 相对误差 Relative error |

|---|---|---|---|

| 破皮率 Skin breaking rate/% | 0.866 | 0.851 | 1.763 |

| 损失率 Loss rate/% | 0.694 | 0.678 | 2.360 |

| 1 | ZHANG J, JIA C, WU Y, et al.. Life cycle energy efficiency and environmental impact assessment of bioethanol production from sweet potato based on different production modes [J/OL]. PLoS One, 2017, 12(7):e0180685 [2023-06-15]. . |

| 2 | KATO K, NAGANE M, AIHARA N, et al.. Lipid-soluble polyphenols from sweet potato exert antitumor activity and enhance chemosensitivity in breast cancer [J]. J. Clin. Biochem. Nutr., 2021, 68(3):193-200. |

| 3 | 李强,赵海,靳艳玲,等.中国甘薯产业助力国家粮食安全的分析与展望[J].江苏农业学报, 2022, 38(6):1484-1491. |

| LI Q, ZHAO H, JIN Y L, et al.. Analysis and perspectives of sweetpotato industry contributing to national food security in China [J]. Jiangsu J. Agric. Sci., 2022, 38(6):1484-1491. | |

| 4 | 谢一芝,边小峰,贾赵东,等.中国鲜食甘薯产业发展现状及其发展前景[J].江苏农业学报, 2022, 38(6):1694-1701. |

| XIE Y Z, BIAN X F, JIA Z D, et al.. Development status and prospect of fresh sweet potato industry in China [J]. Jiangsu J. Agric. Sci., 2022, 38(6): 1694-1701. | |

| 5 | 王欣,李强,曹清河,等.中国甘薯产业和种业发展现状与未来展望[J].中国农业科学, 2021, 54(3):483-492. |

| WANG X, LI Q, CAO Q H, et al.. Current status and future prospective of sweet potato production and seed industry in China [J]. Sci. Agric. Sin., 2021, 54(3):483-492. | |

| 6 | 张晓光,王群,金嘉丰,等.彰武县沙地甘薯生态高效栽培关键技术[J].农业开发与装备, 2020(2):194, 147. |

| 7 | 胡良龙,胡志超,王冰 等.国内甘薯生产机械化研究进展与趋势[J].中国农机化, 2012(2):14-16. |

| HU L L, HU Z C, WANG B, et al.. Research development and trend of sweet potato (lpomoea batatas Lam.) production mechanization in China [J]. Chin. Agric. Mech., 2012(2):14-16. | |

| 8 | 胡良龙,田立佳,计福来,等.国内甘薯生产收获机械化制因思索与探讨[J].中国农机化, 2011(3):16-18. |

| HU L L, TIAN L J, JI F L, et al.. Analysis and discussion on the restriction causations for harvesting mechanization of sweet potato in China [J]. Chin. Agric. Mech., 2011(3):16-18. | |

| 9 | 侯国强,韩休海,陈维刚.马铃薯收获机工作原理与伤薯问题产生机理研究[J].农机使用与维修, 2021(8):20-21. |

| 10 | 吴俊.基于EDEM的宝塔菜收获机的设计及仿真分析[D].宁夏:宁夏大学, 2018. |

| WU J. Design and simulation analysis of artichok combine harvester based on EDEM [D]. Ningxia: Ningxia University, 2018. | |

| 11 | 杨红光,胡志超,王冰,等.马铃薯收获机械化技术研究进展[J].中国农机化学报, 2019, 40(11):27-34. |

| YANG H G, HU Z C, WANG B, et al.. Research progress of harvesting mechanization technology of potato [J]. J. Chin. Agric. Mech., 2019, 40(11):27-34. | |

| 12 | 吕金庆,孙贺,兑瀚,等.粘重土壤下马铃薯挖掘机分离输送装置改进设计与试验[J].农业机械学报, 2017, 48(11):146-155. |

| LÜ J Q, SUN H, DUI H, et al.. Design and experiment on conveyor separation device of potato digger under heavy soil condition [J]. Trans. Chin. Soc. Agric Mach., 2017, 48(11):146-155. | |

| 13 | 魏忠彩,李洪文,苏国粱,等.低位铺放双重缓冲马铃薯收获机设计与试验[J].农业机械学报, 2019, 50(9):140-152. |

| WEI Z C, LI H W, SU G L, et al.. Design and experiment of potato harvester using double cushions for low laying separation technology [J]. Trans. Chin. Soc. Agric Mach, 2019, 50(9):140-152. | |

| 14 | 申海洋,王冰,胡良龙,等.4UZL-1型甘薯联合收获机薯块交接输送机构设计[J].农业工程学报, 2020, 36(17):9-17. |

| SHEN H Y, WANG B, HU L L, et al.. Design of potato connecting and conveying mechanism for 4UZL-1 type sweet potato combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2020, 36(17):9-17. | |

| 15 | 申海洋,王公仆,胡良龙,等.4UZL-1型甘薯联合收获机刮板链提升机构设计与台架试验[J].中国农机化学报, 2021, 42(9):7-17, 121. |

| SHEN H Y, WANG G P, HU L L, et al.. Design and bench test of scraper chain lifting mechanism of 4UZL-1 sweet potato combine harvester [J]. J. Chin. Agric. Mech., 2021, 42(9):7-17, 121. | |

| 16 | 李彦彬,张兆国,王圆明,等.马铃薯收获机多级输送分离装置设计与试验[J].沈阳农业大学学报, 2021, 52(6):758-768. |

| LI Y B, ZHANG Z G, WANG Y M, et al.. Design and experiment of multistage conveying and separating device for potato harvester [J]. J. Shenyang Agric. Univ., 2021, 52(6):758-768. | |

| 17 | 韩嫣,屈雪,黄东,等.甘薯收获环节损失率测算及影响因素分析[J].西南农业学报, 2019, 32(6):1383-1390. |

| HAN Y, QU X, HUANG D, et al.. Harvest loss rate of sweet potato and its influencing factors [J]. Southwest China J. Agric. Sci., 2019, 32(6):1383-1390. | |

| 18 | 李季成,吕伊宁,孙玉凯,等.马铃薯收获机分离升运装置设计与试验——基于当量半径法[J].农机化研究, 2022, 44(12):199-206, 256. |

| LI J C, LÜ Y N, SUN Y K, et al.. Design and experiment of separating and lifting device of potato harvester—based on equivalent radius method [J]. J. Agric. Mech. Res., 2022, 44(12):199-206, 256. | |

| 19 | 魏忠彩,王业炜,李学强,等.弹性揉搓式马铃薯联合收获机设计与试验[J].农业工程学报, 2023, 39(14):60-69. |

| WEI Z C, WANG Y W, LI X Q, et al.. Design and experiments of the potato combine harvester with elastic rubbing technology [J]. Trans. Chin. Soc. Agric Eng., 2023, 39(14):60-69. | |

| 20 | 杨摄,郑明军,吴文江,等.基于离散元的风沙沙粒物理特性参数标定[J].石家庄铁道大学学报(自然科学版), 2021, 34(1):49-57. |

| YANG S, ZHENG M J; WU W J, et al.. Calibration of physical characteristics of wind sand particles based on discrete element method [J]. J. Shijiazhuang Tiedao Univ. (Nat. Sci.), 2021, 34(1):49-57. | |

| 21 | 张兆国,王法安,张永成,等.自走式三七收获机设计与试验[J].农业机械学报, 2016, 47(S1):234-240. |

| ZHANG Z G, WANG F A, ZHANG Y C, et al.. Design and experiment of self-propelled panax notoginseng harvester [J]. Trans. Chin. Soc. Agric. Mach, 2016, 47(S1):234-240. | |

| 22 | 程祥勋.新型甘薯收获机关键装置设计与试验[D].泰安:山东农业大学, 2019. |

| CHENG X X, Design and experiment of key equipment for new sweet potato harvester [D]. Tai'an: Shandong Agricultural University, 2019. | |

| 23 | 杨然兵,张建,尚书旗,等.甘薯联合收获机二级输送分离装置的设计与试验[J/OL].吉林大学学报(工学版): 1-14 [2023-06-15]. . |

| YANG R B, ZHANG J, SHANG S Q, et al.. Design and test of secondary conveyor separator device for sweet potato combine harvester [J/OL]. J. Jilin Univ. (Eng. Tech.): 1-14 [2023-06-15]. . | |

| 24 | 赵永飞,周建东,刘志刚,等. 农业机械推广鉴定大纲 薯类收获机:DG/T 078—2022 [S]. 北京:中国标准出版社,2022. |

| [1] | Yupeng ZHAO, Yaozu FENG, Zhiguo WANG, Yanbo FU, Bolang CHEN, Qingyong BIAN, Xiaojuan RAO. Effect of Oxygenated Water Input on Nitrogen Nitrification and Mineralization in Sandy Soil [J]. Journal of Agricultural Science and Technology, 2025, 27(3): 194-205. |

| [2] | Wencheng CONG, Limin YUAN, Zhongju MENG, Yu YANG. Effects of Corncob on Capillary Water Transport and Evaporation Characteristics of Sandy Soil [J]. Journal of Agricultural Science and Technology, 2024, 26(2): 198-207. |

| [3] | Haiyan GAO, Limin YUAN, Shengnan ZHANG, Deren YAN. Effects of Water-soluble Sand Fixing Agent on Soil Evaporation in Sandy Land [J]. Journal of Agricultural Science and Technology, 2024, 26(12): 138-144. |

| [4] | Lijuan HE, Zhongju MENG, Xiaohong DANG, Tao LYU. Effects of Planting Glycyrrhizauralensis on Mechanical Composition and Nutrients of Aeolian Sandy Soil [J]. Journal of Agricultural Science and Technology, 2022, 24(2): 169-176. |

| [5] | YIN Quanyu1, LI Yang1, ZHANG Yulan1, WANG Shengcai2, FANG Ming2,LI Hongguang2, WANG Xinfa3, LIU Guoshun1*. Dynamic Effect of Interaction between Biochar and Soil Texture on Soil Nitrate Nitrogen Amount [J]. Journal of Agricultural Science and Technology, 2019, 21(6): 143-151. |

| [6] | LI Yan, SHI Yi, WANG Yuxiang, HE Xuwen*. Effect and Evaluation of Municipal Sludge Improved Sand Soil on Rape Growth [J]. Journal of Agricultural Science and Technology, 2018, 20(6): 88-95. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号