中国农业科技导报 ›› 2023, Vol. 25 ›› Issue (6): 107-116.DOI: 10.13304/j.nykjdb.2021.0961

• 智慧农业 农机装备 • 上一篇

收稿日期:2021-11-09

接受日期:2022-01-18

出版日期:2023-06-01

发布日期:2023-07-28

作者简介:张丽珍 E-mail:lzzhang@shou.edu.cn

基金资助:Received:2021-11-09

Accepted:2022-01-18

Online:2023-06-01

Published:2023-07-28

摘要:

为研究离心式投饲机中抛料盘对饲料破碎率的影响,通过分析饲料颗粒在抛料盘上的运动,确定影响破碎率的因素。利用EDEM软件建立饲料颗粒黏结模型进行单因素试验,得到各个因素对破碎率的影响情况。根据单因素结果设计并进行三因素三水平正交试验,建立饲料破碎率与抛料盘肋板个数、抛料盘倾角、肋板曲率半径等因素之间的二次多元回归模型并解析,后对离心盘的结构参数进行优化。结果表明,各因素对饲料破碎率影响的大小顺序依次为:肋板曲率半径>肋板个数>抛料盘倾角。肋板个数与肋板曲率半径交互作用对破碎率的影响较为明显。经回归分析和优化可知,当肋板个数为6个、抛料盘倾角为12.8°、肋板曲率半径为71.5 mm时,破碎率达到最小值2.13%;验证结果表明,优化后的抛料盘使饲料破碎率平均降低38.8%。研究结果可以为离心式投饲机抛料盘的性能优化提供参考。

中图分类号:

张丽珍, 朱倓. 离心式投饲机抛料盘对饲料破碎率的影响[J]. 中国农业科技导报, 2023, 25(6): 107-116.

Lizhen ZHANG, Tan ZHU. Influence of Centrifugal Disc of Centrifugal Feeder on Breaking Rate[J]. Journal of Agricultural Science and Technology, 2023, 25(6): 107-116.

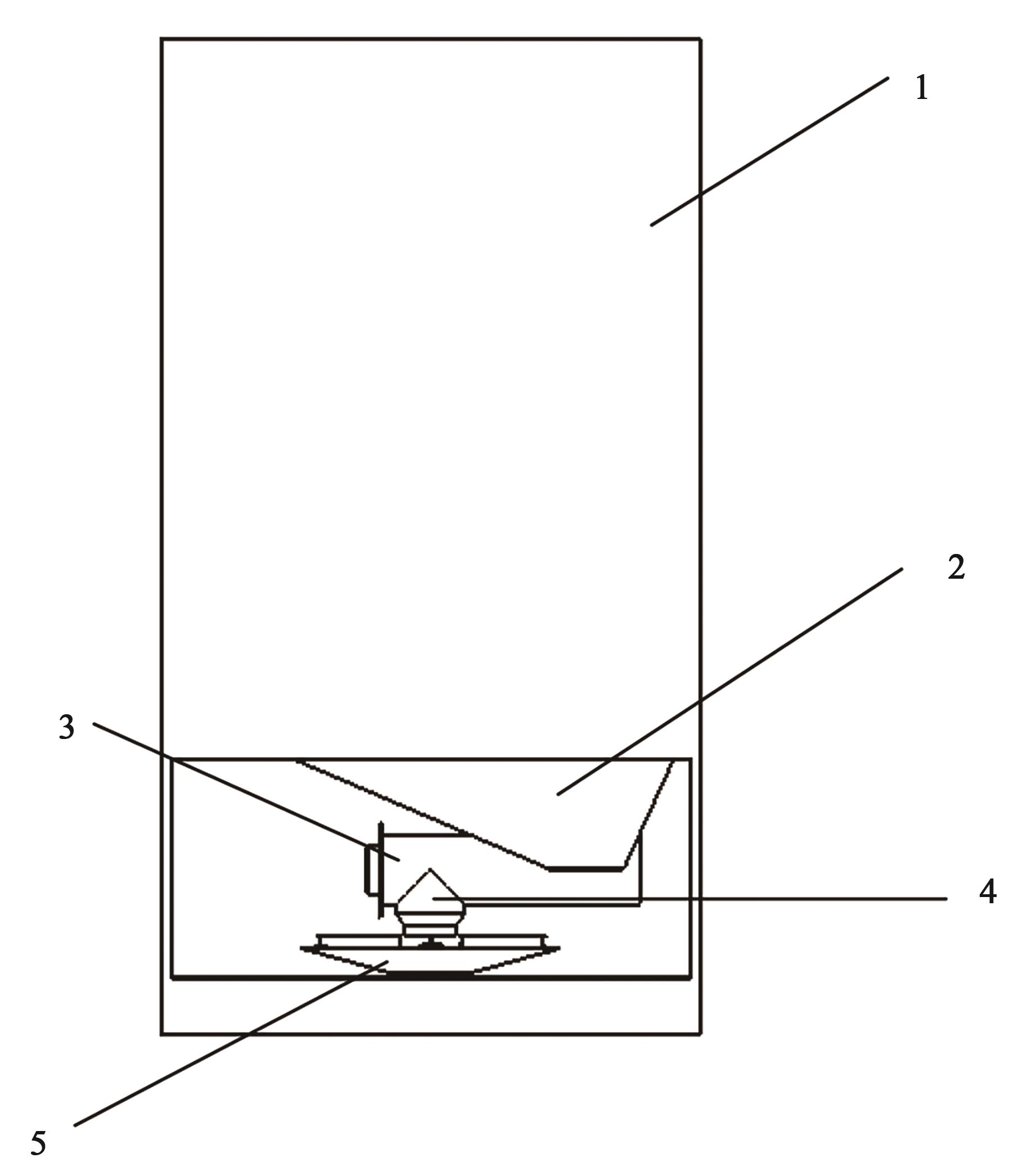

图1 投饲机结构注:1—投饲机外壳;2—料箱;3—送料轴;4—落料口;5—抛料盘。

Fig. 1 Structure of feeding machineNote: 1—Feeder shell;2—Material box;3—Feeding shaft;4—Blanking port;5—Centrifugal disc.

| 参数名称Parameter | 数值Value |

|---|---|

| 饲料密度Feed density | 700 |

| 泊松比Poisson’s ratio | 0.3 |

| 剪切模量Shear modulus | 3.5×107 |

| 饲料-饲料碰撞恢复系数 Feed-feed collision recovery coefficient | 0.340 |

| 饲料-饲料静摩擦系数 Feed-feed static friction coefficient | 0.163 |

| 饲料-饲料动摩擦系数 Feed-feed dynamic friction coefficient | 0.035 |

| 饲料-抛料盘碰撞恢复系数 Feed-disc collision recovery coefficient | 0.175 |

| 饲料-抛料盘静摩擦系数 Feed-disc static friction coefficient | 0.353 |

| 饲料-抛料盘动摩擦系数 Feed-disc dynamic friction coefficient | 0.125 |

表 1 物性参数

Table.1 Material properties of particles

| 参数名称Parameter | 数值Value |

|---|---|

| 饲料密度Feed density | 700 |

| 泊松比Poisson’s ratio | 0.3 |

| 剪切模量Shear modulus | 3.5×107 |

| 饲料-饲料碰撞恢复系数 Feed-feed collision recovery coefficient | 0.340 |

| 饲料-饲料静摩擦系数 Feed-feed static friction coefficient | 0.163 |

| 饲料-饲料动摩擦系数 Feed-feed dynamic friction coefficient | 0.035 |

| 饲料-抛料盘碰撞恢复系数 Feed-disc collision recovery coefficient | 0.175 |

| 饲料-抛料盘静摩擦系数 Feed-disc static friction coefficient | 0.353 |

| 饲料-抛料盘动摩擦系数 Feed-disc dynamic friction coefficient | 0.125 |

| 水平 Level | 因素Factor | ||

|---|---|---|---|

| A:盘倾角 Tilt angle of disc/(°) | B:肋板个数 Number of ribs | C:曲率半径 Radius of curvature/mm | |

| -1 | 10 | 4 | 60 |

| 0 | 15 | 5 | 70 |

| 1 | 20 | 6 | 80 |

表 2 试验因素编码

Table 2 Coding of factors

| 水平 Level | 因素Factor | ||

|---|---|---|---|

| A:盘倾角 Tilt angle of disc/(°) | B:肋板个数 Number of ribs | C:曲率半径 Radius of curvature/mm | |

| -1 | 10 | 4 | 60 |

| 0 | 15 | 5 | 70 |

| 1 | 20 | 6 | 80 |

序号 Number | 因素Factor | 破碎率 Breakage rate/% | ||

|---|---|---|---|---|

盘倾角 Tilt angle of disc/(°) | 肋板个数 Number of ribs | 曲率半径 Radius of curvature/mm | ||

| 1 | 20 | 4 | 70 | 2.76 |

| 2 | 15 | 6 | 70 | 2.24 |

| 3 | 15 | 6 | 70 | 2.25 |

| 4 | 15 | 6 | 70 | 2.29 |

| 5 | 10 | 6 | 60 | 3.73 |

表 3 三因素三水平正交试验结果

Table 3 Results of three factor and three level orthogonal test

序号 Number | 因素Factor | 破碎率 Breakage rate/% | ||

|---|---|---|---|---|

盘倾角 Tilt angle of disc/(°) | 肋板个数 Number of ribs | 曲率半径 Radius of curvature/mm | ||

| 1 | 20 | 4 | 70 | 2.76 |

| 2 | 15 | 6 | 70 | 2.24 |

| 3 | 15 | 6 | 70 | 2.25 |

| 4 | 15 | 6 | 70 | 2.29 |

| 5 | 10 | 6 | 60 | 3.73 |

序号 Number | 因素Factor | 破碎率 Breakage rate/% | ||

|---|---|---|---|---|

盘倾角 Tilt angle of disc/(°) | 肋板个数 Number of ribs | 曲率半径 Radius of curvature/mm | ||

| 6 | 10 | 5 | 80 | 2.34 |

| 7 | 10 | 6 | 80 | 3.22 |

| 8 | 20 | 4 | 60 | 4.58 |

| 9 | 20 | 5 | 70 | 3.37 |

| 10 | 15 | 5 | 60 | 2.77 |

| 11 | 15 | 4 | 80 | 1.53 |

| 12 | 15 | 5 | 60 | 2.71 |

| 13 | 10 | 4 | 60 | 4.03 |

| 14 | 20 | 4 | 80 | 1.98 |

| 15 | 10 | 4 | 70 | 2.38 |

| 16 | 15 | 5 | 60 | 2.79 |

| 17 | 20 | 6 | 60 | 4.39 |

| 18 | 15 | 6 | 60 | 2.74 |

| 19 | 20 | 6 | 80 | 3.88 |

| 20 | 20 | 5 | 70 | 2.87 |

表 3 三因素三水平正交试验结果 (续表Continued)

Table 3 Results of three factor and three level orthogonal test

序号 Number | 因素Factor | 破碎率 Breakage rate/% | ||

|---|---|---|---|---|

盘倾角 Tilt angle of disc/(°) | 肋板个数 Number of ribs | 曲率半径 Radius of curvature/mm | ||

| 6 | 10 | 5 | 80 | 2.34 |

| 7 | 10 | 6 | 80 | 3.22 |

| 8 | 20 | 4 | 60 | 4.58 |

| 9 | 20 | 5 | 70 | 3.37 |

| 10 | 15 | 5 | 60 | 2.77 |

| 11 | 15 | 4 | 80 | 1.53 |

| 12 | 15 | 5 | 60 | 2.71 |

| 13 | 10 | 4 | 60 | 4.03 |

| 14 | 20 | 4 | 80 | 1.98 |

| 15 | 10 | 4 | 70 | 2.38 |

| 16 | 15 | 5 | 60 | 2.79 |

| 17 | 20 | 6 | 60 | 4.39 |

| 18 | 15 | 6 | 60 | 2.74 |

| 19 | 20 | 6 | 80 | 3.88 |

| 20 | 20 | 5 | 70 | 2.87 |

来源 Source | 方差 Variance | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|

| 模型Model | 12.36 | 1.37 | 25.41 | <0.000 1 |

| A | 0.785 7 | 0.785 7 | 14.53 | 0.003 4 |

| B | 0.973 4 | 0.973 4 | 18.00 | 0.001 7 |

| C | 4.21 | 4.21 | 77.93 | <0.000 1 |

| AB | 0.085 1 | 0.085 1 | 1.57 | 0.238 2 |

| AC | 0.036 9 | 0.036 9 | 0.68 | 0.427 8 |

| BC | 1.40 | 1.40 | 25.93 | 0.000 5 |

| A² | 3.89 | 3.89 | 71.97 | <0.000 1 |

| B² | 0.254 7 | 0.254 7 | 4.71 | 0.055 1 |

| C² | 1.02 | 1.02 | 18.85 | 0.001 5 |

| 残差Residual | 0.540 7 | 0.054 1 | — | — |

| 失拟项Lack of fit | 0.410 8 | 0.082 2 | 3.16 | 0.116 0 |

| 误差Pure error | 0.129 9 | 0.026 0 | — | — |

| 总和Total | 12.90 | — | — | — |

表4 方差分析结果

Table 4 Variance analysis

来源 Source | 方差 Variance | 均方 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|

| 模型Model | 12.36 | 1.37 | 25.41 | <0.000 1 |

| A | 0.785 7 | 0.785 7 | 14.53 | 0.003 4 |

| B | 0.973 4 | 0.973 4 | 18.00 | 0.001 7 |

| C | 4.21 | 4.21 | 77.93 | <0.000 1 |

| AB | 0.085 1 | 0.085 1 | 1.57 | 0.238 2 |

| AC | 0.036 9 | 0.036 9 | 0.68 | 0.427 8 |

| BC | 1.40 | 1.40 | 25.93 | 0.000 5 |

| A² | 3.89 | 3.89 | 71.97 | <0.000 1 |

| B² | 0.254 7 | 0.254 7 | 4.71 | 0.055 1 |

| C² | 1.02 | 1.02 | 18.85 | 0.001 5 |

| 残差Residual | 0.540 7 | 0.054 1 | — | — |

| 失拟项Lack of fit | 0.410 8 | 0.082 2 | 3.16 | 0.116 0 |

| 误差Pure error | 0.129 9 | 0.026 0 | — | — |

| 总和Total | 12.90 | — | — | — |

| 1 | 吴强泽.池塘养殖智能投饲系统的研究[D].南京:南京农业大学, 2016. |

| WU Q Z.Researsh on intelligent feeding ship system of pond aguaculture. [D]. Nanjing: Nanjing Agricultural University, 2016. | |

| 2 | 郭子淳,黄家怿,王水传,等.智能投饵船研究现状与展望[J].农业机械学报, 2020, 51(): 385-396, 404. |

| GUO Z C, HUANG J Y, WANG S C, et al.. Research and prospect of intelligent bait-dropping boat [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(S1): 385-396, 404. | |

| 3 | 于泽,姜忠爱,张靖铎,等.水产养殖自动投饵机发展现状[J].河北渔业, 2020(1): 57-60. |

| YU Z, JIANG Z A, ZHANG J D, et al.. Development status of automatic feeding machine for aquaculture [J]. Hebei Fish., 2020(1): 57-60. | |

| 4 | 唐荣,沈逸,许鹏,等.池塘养殖全自动精准投饲系统设计与应用[J].农业工程学报, 2021, 37(9): 289-296. |

| TANG R, SHEN Y, XU P, et al.. Design and application of the automatic precision feeding system of pond aquaculture [J]. Trans. Chin. Soc. Agric. Eng., 2021, 37(9): 289-296. | |

| 5 | 杨朦朦.池塘养殖精准投喂量投饵机的研究[D] .上海:上海海洋大学, 2018. |

| YANG M M. The research on the precise feeding machine of pond farming [D]. Shanghai: Shanghai Ocean University, 2018. | |

| 6 | 张丽珍,马迪红,胡庆松,等.移动式双盘对称抛料投饵系统的设计与试验[J].机械设计, 2018, 35(9): 73-78. |

| ZHANG L Z, MA D H, HU Q S, et al.. Design and experiment of mobile symmetric double-disk feeding system [J]. J. Machine Design, 2018, 35(9): 73-78. | |

| 7 | 马迪红.虾塘移动式投饵系统设计与实验[D] .上海:上海海洋大学,2017. |

| MA D H. The design and experiment of movable shrimp feeding system [D]. Shanghai: Shanghai Ocean University, 2017. | |

| 8 | 胡庆松,程文平,李俊.移动式虾塘投饵装置偏心抖料及抛饵系统优化与试验[J].上海海洋大学学报, 2016, 25(5): 794-800. |

| HU Q S, CHENG W P, LI J. Eccentric shaking and bait throwing system optimization and experiment of the mobile shrimp feeding machine [J]. J. Shanghai Ocean Univ.,2016, 25(5): 794-800. | |

| 9 | 曾智伟,马旭,曹秀龙,等.离散元法在农业工程研究中的应用现状和展望[J].农业机械学报, 2021, 52(4): 1-20. |

| ZENG Z W, MA X, CAO X L, et al.. Application status and prospect of discrete element method in agricultural engineering research [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(4): 1-20. | |

| 10 | OSKOOEI P R, MOHAMMADINIA A, ARULRAJAH A, et al.. DEM modeling and experimental analysis of the breakage behavior of recycled crushed brick particles [J/OL]. Transport. Geotech., 2021, 30: 100586 [2021-10-22]. . |

| 11 | CLEARY P W. DEM modelling of particulate flow in a screw feeder [J]. Prog. Comput. Fluid Dy., 2007, 7(2-4): 128-138. |

| 12 | VILLETTE S, COINTAULT F, PIRON E, et al.. Centrifugal spreading: an analytical model for the motion of fertiliser particles on aspinning disc [J]. Biosyst. Eng., 2005, 92(2): 157-164. |

| 13 | ROZBROJ J, ZEGZULKA J, NECAS J. Use of DEM in the determination of rriction parameters on a physical comparative model of a vertical screw conveyor [J]. Chem. Biochem. Eng. Quarterly, 2015, 29(1): 25-34. |

| 14 | ABBOU-OU-CHERIF E M, PIRON E, CHATEAUNEUF A, et al.. On-the-field simulation of fertilizer spreading: Part 3-Control of disk inclination for uniform application on undulating fields [J]. Comput. Electron. Agric., 2019, 158: 150-158. |

| 15 | 任万军,吴振元,李蒙良,等.水稻无人机撒肥系统设计与试验[J].农业机械学报, 2021, 52(3): 88-98. |

| REN W J, WU Z Y, LI M L, et al.. Design and experiment of UAV fertilization spreader system for rice [J]. Trans. Chin. Soc. Agric. Mach., 2021, 52(3): 88-98. | |

| 16 | 牟孝栋,姜慧新,孙延成,等.青贮玉米收获机碟盘式籽粒破碎装置仿真优化与试验[J].农业机械学报, 2020, 51(): 218-226. |

| MOU X D, JIANG H X, SUN Y C, et al.. Simulation optimization and experiment of disc-type grain crushing device of silage corn harvester [J]. Trans. Chin. Soc. Agric. Mach., 2020, 51(S1): 218-226. | |

| 17 | 廖庆喜,张朋玲,廖宜涛,等.基于EDEM的离心式排种器排种性能数值模拟[J].农业机械学报, 2014, 45(2): 109-114. |

| LIAO Q X, ZHANG P L, LIAO Y T, et al.. Numerical simulation on seeding performance of centrifugal rape-seed metering device based on EDEM [J]. Trans. Chin. Soc. Agric. Mach., 2014, 45(2): 109-114. | |

| 18 | 胡永光,杨叶成,肖宏儒,等.茶园施肥机离心撒肥过程仿真与参数优化[J].农业机械学报, 2016, 47(5): 77-82. |

| HU Y G, YANG Y C, XIAO H R, et al.. Simulation and parameter optimization of centrifugal fertilizer spreader for tea plants [J]. Trans. Chin. Soc. Agric. Mach., 2016, 47(5): 77-82. | |

| 19 | 李仲斌,王凌冰,罗永攀.基于离散元法的单辊破碎机磨损分析[J].烧结球团, 2021, 46(1): 49-54. |

| LI Z B, WANG L B, LUO Y P, et al.. Wear analysis of single roll crusher based on discrete element method [J]. Sinter. Pelletiz., 2021, 46(1): 49-54. | |

| 20 | 武秋俊,张勇,刘浩宇,等.非规则物料黏结颗粒下的惯性圆锥破碎机仿真[J].烧结球团, 2020, 45(4): 55-60. |

| WU Q J, ZHANG Y, LIU H Y, et al.. Simulation research on inertial cone crusher with irregular material bonded particles [J]. Sinter. Pelletiz., 2020, 45(4): 55-60. | |

| 21 | 张成. 立轴冲击式破碎机流场分析与优化设计研究[D] .贵阳:贵州大学,2019. |

| ZHANG C. Study on flow field analysis and optimization design of vertical shaft impact crusher [D]. Guiyang: Guizhou University, 2019. | |

| 22 | 黄鹏鹏,肖观发,李成,等.基于EDEM的物料破碎效果仿真分析[J].矿山机械, 2014, 42(10): 76-80. |

| HUANG P P, XIAO G F, LI C, et al.. Simulation analysis of material crushing effect based on edem [J]. Mining Proc. Equip., 2014, 42(10): 76-80. | |

| 23 | 张瑞华,芮筱亭,赵宏立,等.基于离散单元法的发射装药挤压破碎模拟实验[J].爆炸与冲击, 2021, 41(6):15-23. |

| ZHANG R H, RUI X T, ZHAO H L, et al.. Simulational test on compression and fracture of propellant charge based on the discrete element method [J]. Explosion Shock Waves, 2021, 41(6): 15-23. | |

| 24 | 贾富国,韩燕龙,刘扬,等.稻谷颗粒物料堆积角模拟预测方法[J].农业工程学报, 2014, 30(11): 254-260. |

| JIA F G, HAN Y L, LIU Y, et al.. Simulation prediction method of repose angle for rice particle materials [J]. Trans. Chin. Soc. Agric. Eng., 2014, 30(11): 254-260. | |

| 25 | 李永祥,李飞翔,徐雪萌,等.基于颗粒缩放的小麦粉离散元参数标定[J].农业工程学报, 2019, 35(16): 320-327. |

| LI Y X, LI F X, XU X M, et al.. Parameter calibration of wheat flour for discrete element method simulation based on particle scaling [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(16): 320-327. | |

| 26 | 王志鹏,李永祥,徐雪萌.基于堆积实验的小米离散元参数标定[J].中国粮油学报, 2021, 36(2): 115-120. |

| WANG Z P, LI Y X, XU X M, et al.. Parameter calibration of millet discrete element based on stacking experiment [J]. J. Chin. Cereals Oils Association, 2021, 36(2): 115-120. | |

| 27 | 谷坚,葛一健,徐英士,等. 投饲机: [S]. 北京:中国标准出版社,2011. |

| 28 | 杨叶成.茶园离心撒肥装置工作参数优化与试验研究[D].镇江:江苏大学,2016. |

| YANG Y C. Operating parameter optimization and experiment on centrifugal fertilizer distributor for tea fields [D]. Zhenjiang:Jiangsu University, 2016. | |

| 29 | 邵恺怿,牛智有,于重洋,等.水产颗粒饲料悬浮速度测定与分析[J].中国农业科技导报, 2022,24(3):128-137. |

| SHAO K Y, NIU Z Y, YU C Y, et al.. Measurement and analysis on suspension velocity of aquaculture pellets feed [J]. J. Agric. Sci. Technol., 2022,24(3): 128-137. | |

| 30 | 王志勇,冯书庆,林礼群,等.网箱养殖平台自动投饲系统设计与试验分析[J].渔业现代化,2020,47(5):52-58. |

| [1] | 韦海龙, 程乙, 宋碧, 邹军, 左晋, 李蕾, 张军, 刘代铃, 曾涛, 付敬锋, 魏盛. 不同播期下鲜食糯玉米籽粒灌浆特性及其与气象因子的关系[J]. 中国农业科技导报, 2023, 25(4): 45-55. |

| [2] | 李金荣, 周彤, 林一琪, 黄祚骅, 盛亮菁, 张飞萍, 吴松青. 基于响应面法的粘质沙雷氏菌BRC-CXG2发酵培养基优化[J]. 中国农业科技导报, 2022, 24(8): 133-143. |

| [3] | 麻吉亮, 张蕙杰, 李宁辉, 岳慧丽. 不同经营规模下绿豆产业生产技术效率分析——以吉林省白城市绿豆生产为例[J]. 中国农业科技导报, 2022, 24(8): 9-17. |

| [4] | 唐楠锐, 周勇, 张国忠, 梁方, 柯烩彬. 搅种型孔式水稻穴播排种器的性能模拟与试验[J]. 中国农业科技导报, 2022, 24(4): 107-115. |

| [5] | 杨亮彦, 黎雅楠, 范鸿建, 王雅婷. 毛乌素沙地蒸散发时空分布及影响因素分析[J]. 中国农业科技导报, 2022, 24(10): 169-178. |

| [6] | 胡婷, 全伟, 吴明亮, 李林. 双垄四行花生垄作播种机种沟开沟器设计与试验[J]. 中国农业科技导报, 2021, 23(9): 129-137. |

| [7] | 李泰, 卢士军, 黄家章, 陈磊, 范协裕. 苹果品质评价标准研究进展[J]. 中国农业科技导报, 2021, 23(11): 121-130. |

| [8] | 刘慧霞, 孙宗玖, 石宇堃, 武文超, 郑丽, 艾提剑. 准噶尔盆地梭梭沙质荒漠土壤有机碳分布特征的研究[J]. 中国农业科技导报, 2021, 23(11): 147-155. |

| [9] | 刘星宏, 张青青, 张广鹏, 李宏. 塔里木河下游植物群落空间分布及影响因素分析[J]. 中国农业科技导报, 2021, 23(10): 131-144. |

| [10] | 殷全玉1,刘健豪1,刘国顺1,杨欣铃2,李小福2,张玉兰1,李阳1,叶红朝3*. 连续4年施用生物炭对植烟褐土微生物群落结构的影响[J]. 中国农业科技导报, 2021, 23(1): 176-185. |

| [11] | 顿国强1,于春玲1,郭艳玲1*,杨永振1,叶金1,纪文义2,刘宇轩1. 叠片式啮合圆弧齿轮排肥器设计与仿真试验[J]. 中国农业科技导报, 2020, 22(5): 78-85. |

| [12] | 李宝军1,任奕林1*,李猛1,陈佃贞1,欧阳家乐1,蒯婕2,周广生2. 基于茎秆生物力学特性的油菜抗倒调控机制研究[J]. 中国农业科技导报, 2020, 22(12): 68-76. |

| [13] | 康家鑫1,刘大为1,李旭1*,谢方平1,黄敏2,郑华斌2. 育秧泥浆处理装置曲柄滑块振动筛设计与参数优选[J]. 中国农业科技导报, 2020, 22(10): 85-92. |

| [14] | 杨宗辉1,蔡鸿毅1,覃诚2,刘合光1. 我国粮食生产的时空格局及其影响因素分析[J]. 中国农业科技导报, 2018, 20(9): 1-11. |

| [15] | 张军红1,2,侯新2. 毛乌素沙地油蒿植冠下土壤粒径特征及其影响因素分析[J]. 中国农业科技导报, 2018, 20(1): 95-102. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号