Journal of Agricultural Science and Technology ›› 2024, Vol. 26 ›› Issue (4): 225-233.DOI: 10.13304/j.nykjdb.2022.0964

• INNOVATIVE METHODS AND TECHNOLOGIES • Previous Articles

Dongling LIU1( ), Hao SI1, Baojiang ZHENG2, Yuhong ZHANG1(

), Hao SI1, Baojiang ZHENG2, Yuhong ZHANG1( )

)

Received:2022-11-06

Accepted:2023-02-07

Online:2024-04-15

Published:2024-04-23

Contact:

Yuhong ZHANG

通讯作者:

张玉红

作者简介:刘东玲 E-mail:898890042@qq.com;

基金资助:CLC Number:

Dongling LIU, Hao SI, Baojiang ZHENG, Yuhong ZHANG. Optimization of Enzyme Assisted-ultrasonic Extraction of Sinigrin in Thlaspi arvense Seeds by Response Surface Methodology[J]. Journal of Agricultural Science and Technology, 2024, 26(4): 225-233.

刘东玲, 司皓, 郑宝江, 张玉红. 响应面法优化酶解辅助-超声提取菥蓂中的黑芥子苷[J]. 中国农业科技导报, 2024, 26(4): 225-233.

| 水平Level | 因素Factor | ||

|---|---|---|---|

A:酶添加量 Amount of enzyme added/% | B:酶解时间 Enzymatic hydrolysis time/min | C:酶解温度 Enzymatic hydrolysis temperature/℃ | |

| -1 | 2 | 15 | 45 |

| 0 | 3 | 20 | 50 |

| 1 | 4 | 25 | 55 |

Table 1 Response surface experimental factor level table

| 水平Level | 因素Factor | ||

|---|---|---|---|

A:酶添加量 Amount of enzyme added/% | B:酶解时间 Enzymatic hydrolysis time/min | C:酶解温度 Enzymatic hydrolysis temperature/℃ | |

| -1 | 2 | 15 | 45 |

| 0 | 3 | 20 | 50 |

| 1 | 4 | 25 | 55 |

Fig. 2 Yield of sinigrin in T. arvense underdifferent enzymesNote: Different lowercase letters indicate significant differences between different enzymes at P<0.05 level.

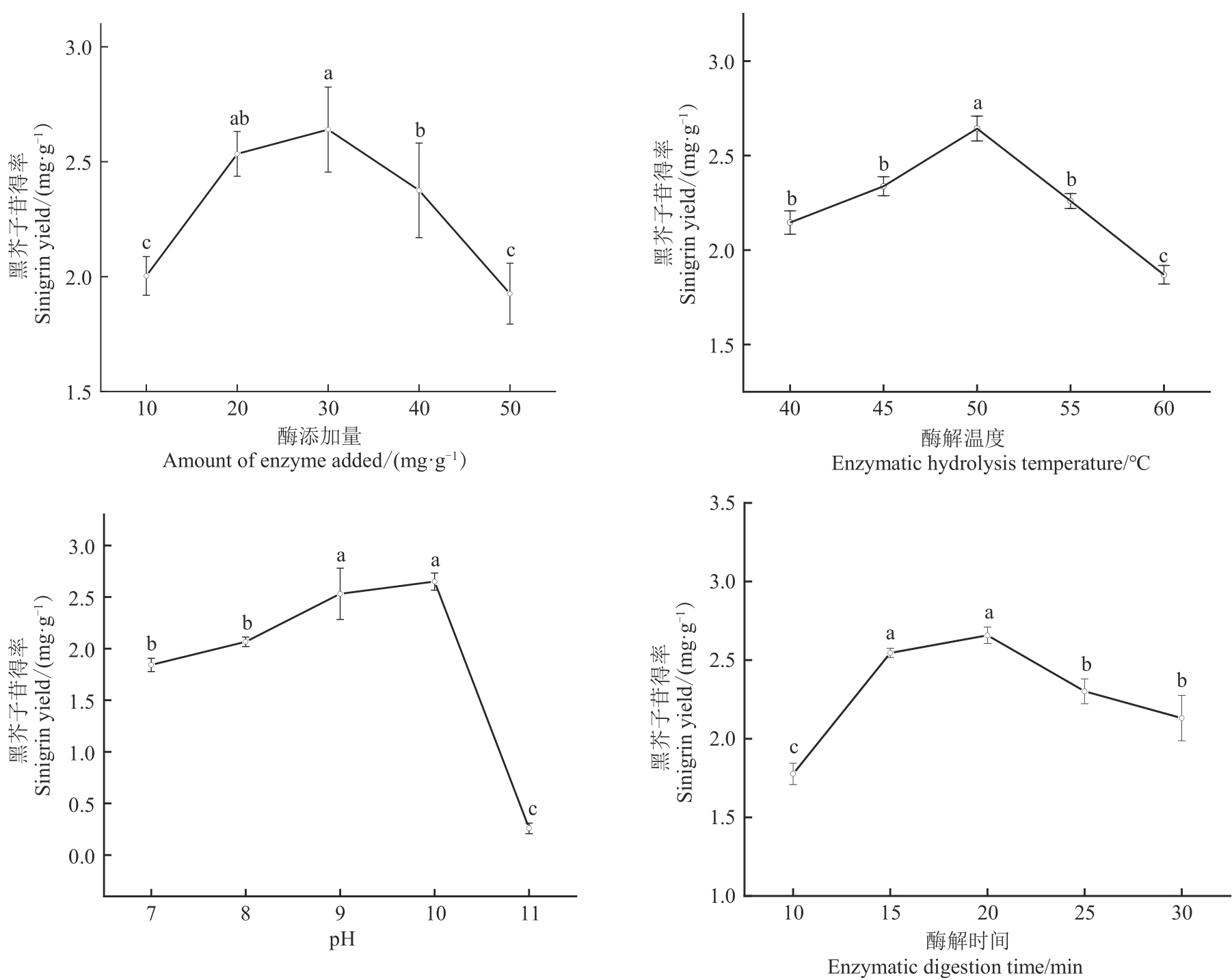

Fig. 3 Yield of sinigrin in T. arvense under different factorsNote:Different lowercase letters indicate significant differences between different treatments at P<0.05 level.

编号 Code | 因素 Factor | Y:黑芥子苷得率 Sinigrin yield/(mg·g-1) | |||

|---|---|---|---|---|---|

A:酶添加量 Amount of enzyme added/% | B:酶解时间 Enzymatic hydrolysis time/min | C:酶解温度 Enzymatic hydrolysis temperature/℃ | 实际值 Actual value | 预测值 Predicted value | |

| 1 | 2 | 15 | 50 | 2.50 | 2.52 |

| 2 | 3 | 15 | 45 | 2.61 | 2.60 |

| 3 | 2 | 25 | 50 | 2.36 | 2.37 |

| 4 | 4 | 15 | 50 | 2.45 | 2.44 |

| 5 | 3 | 20 | 50 | 2.63 | 2.67 |

| 6 | 4 | 25 | 50 | 2.30 | 2.34 |

| 7 | 3 | 20 | 50 | 2.69 | 2.67 |

| 8 | 4 | 20 | 55 | 2.34 | 2.35 |

| 9 | 3 | 20 | 50 | 2.70 | 2.67 |

| 10 | 3 | 20 | 50 | 2.67 | 2.67 |

| 11 | 3 | 20 | 50 | 2.65 | 2.67 |

| 12 | 3 | 15 | 55 | 2.46 | 2.47 |

| 13 | 4 | 20 | 45 | 2.35 | 2.38 |

| 14 | 2 | 20 | 45 | 2.45 | 2.45 |

| 15 | 3 | 25 | 55 | 2.41 | 2.43 |

| 16 | 2 | 20 | 55 | 2.41 | 2.39 |

| 17 | 3 | 25 | 45 | 2.39 | 2.39 |

Table 2 Response surface design and results

编号 Code | 因素 Factor | Y:黑芥子苷得率 Sinigrin yield/(mg·g-1) | |||

|---|---|---|---|---|---|

A:酶添加量 Amount of enzyme added/% | B:酶解时间 Enzymatic hydrolysis time/min | C:酶解温度 Enzymatic hydrolysis temperature/℃ | 实际值 Actual value | 预测值 Predicted value | |

| 1 | 2 | 15 | 50 | 2.50 | 2.52 |

| 2 | 3 | 15 | 45 | 2.61 | 2.60 |

| 3 | 2 | 25 | 50 | 2.36 | 2.37 |

| 4 | 4 | 15 | 50 | 2.45 | 2.44 |

| 5 | 3 | 20 | 50 | 2.63 | 2.67 |

| 6 | 4 | 25 | 50 | 2.30 | 2.34 |

| 7 | 3 | 20 | 50 | 2.69 | 2.67 |

| 8 | 4 | 20 | 55 | 2.34 | 2.35 |

| 9 | 3 | 20 | 50 | 2.70 | 2.67 |

| 10 | 3 | 20 | 50 | 2.67 | 2.67 |

| 11 | 3 | 20 | 50 | 2.65 | 2.67 |

| 12 | 3 | 15 | 55 | 2.46 | 2.47 |

| 13 | 4 | 20 | 45 | 2.35 | 2.38 |

| 14 | 2 | 20 | 45 | 2.45 | 2.45 |

| 15 | 3 | 25 | 55 | 2.41 | 2.43 |

| 16 | 2 | 20 | 55 | 2.41 | 2.39 |

| 17 | 3 | 25 | 45 | 2.39 | 2.39 |

来源 Source | 自由度 Degree of freedom | 平方和 Sum of squares | 均方 Mean square | F值 F valve | P值 P valve |

|---|---|---|---|---|---|

| 模型 Model | 9 | 0.270 | 0.030 | 34.84 | <0.000 1 |

| A | 1 | 6.050×10-3 | 6.050×10-3 | 6.97 | 0.033 5 |

| B | 1 | 0.031 | 0.031 | 35.98 | 0.000 5 |

| C | 1 | 4.050×10-3 | 4.050×10-3 | 4.66 | 0.067 7 |

| AB | 1 | 6.250×10-4 | 6.250×10-4 | 0.72 | 0.424 3 |

| AC | 1 | 2.250×10-4 | 2.250×10-4 | 0.26 | 0.626 4 |

| BC | 1 | 7.225×10-3 | 7.225×10-3 | 8.32 | 0.023 5 |

| A2 | 1 | 0.110 | 0.110 | 132.38 | <0.000 1 |

| B2 | 1 | 0.031 | 0.031 | 35.23 | 0.000 6 |

| C2 | 1 | 0.056 | 0.056 | 64.39 | <0.000 1 |

| 残差Residual | 7 | 6.080×10-3 | 8.686×10-4 | ||

| 失拟项Lack of fit | 3 | 2.800×10-3 | 9.333×10-4 | 1.14 | 0.434 6 |

| 误差Error | 4 | 3.280×10-3 | 8.200×10-4 | ||

| 总离差Total deviation | 16 | 0.280 |

Table 3 Results of variance analysis of response surface regression equation

来源 Source | 自由度 Degree of freedom | 平方和 Sum of squares | 均方 Mean square | F值 F valve | P值 P valve |

|---|---|---|---|---|---|

| 模型 Model | 9 | 0.270 | 0.030 | 34.84 | <0.000 1 |

| A | 1 | 6.050×10-3 | 6.050×10-3 | 6.97 | 0.033 5 |

| B | 1 | 0.031 | 0.031 | 35.98 | 0.000 5 |

| C | 1 | 4.050×10-3 | 4.050×10-3 | 4.66 | 0.067 7 |

| AB | 1 | 6.250×10-4 | 6.250×10-4 | 0.72 | 0.424 3 |

| AC | 1 | 2.250×10-4 | 2.250×10-4 | 0.26 | 0.626 4 |

| BC | 1 | 7.225×10-3 | 7.225×10-3 | 8.32 | 0.023 5 |

| A2 | 1 | 0.110 | 0.110 | 132.38 | <0.000 1 |

| B2 | 1 | 0.031 | 0.031 | 35.23 | 0.000 6 |

| C2 | 1 | 0.056 | 0.056 | 64.39 | <0.000 1 |

| 残差Residual | 7 | 6.080×10-3 | 8.686×10-4 | ||

| 失拟项Lack of fit | 3 | 2.800×10-3 | 9.333×10-4 | 1.14 | 0.434 6 |

| 误差Error | 4 | 3.280×10-3 | 8.200×10-4 | ||

| 总离差Total deviation | 16 | 0.280 |

| 指标Index | 响应值 Response value |

|---|---|

| 标准偏差Standard deviation | 0.029 0 |

| 变异系数Coefficient of variable/% | 1.180 0 |

| 拟合系数R2 | 0.978 2 |

| 调整系数 R2Adj | 0.950 1 |

| 预测系数 R2Pred | 0.820 7 |

Table 4 Confidence analysis

| 指标Index | 响应值 Response value |

|---|---|

| 标准偏差Standard deviation | 0.029 0 |

| 变异系数Coefficient of variable/% | 1.180 0 |

| 拟合系数R2 | 0.978 2 |

| 调整系数 R2Adj | 0.950 1 |

| 预测系数 R2Pred | 0.820 7 |

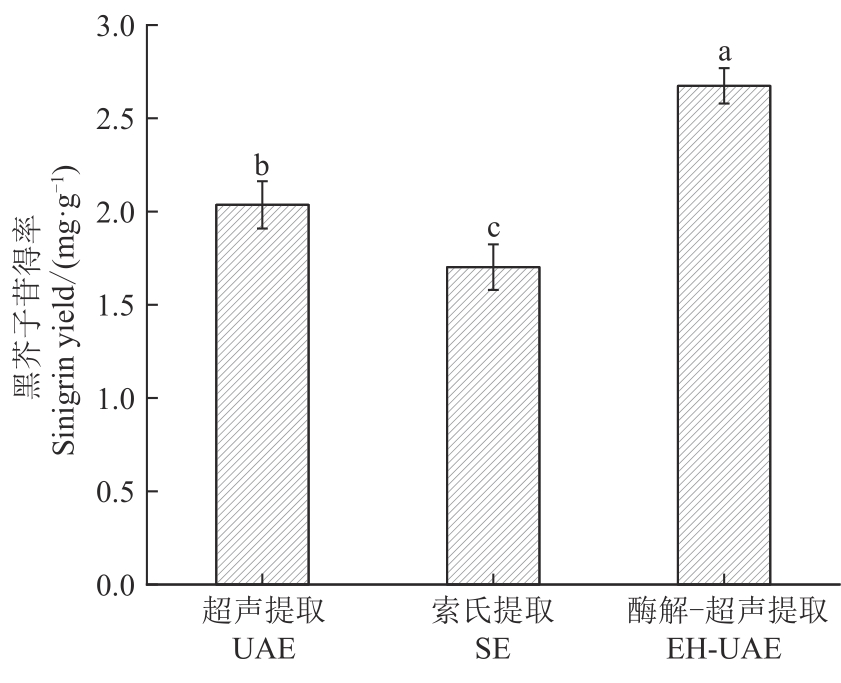

Fig. 6 Yield of sinigrin by different extraction methodsNote:Different lowercase letters indicate significant differences between different methods at P<0.05 level.

| 1 | 刘静果,张宝山,张玉红,等.中草药菥蓂的研究现状及展望[J].江苏农业科学,2020,48(22):15-21. |

| LIU J G, ZHANG B S, ZHANG Y H, et al.. The research status and prospect of Chinese herbal medicine Thlaspi arvense [J]. Jiangsu Agric. Sci., 2020, 48(22):15-21. | |

| 2 | 中国科学院中国植物志编辑委员会.中国植物志[M].北京:科学出版社,1987:80-84. |

| 3 | MALIHEH E, TARA J N, FMEGHAN M, et al.. Generating pennycress (Thlaspi arvense) seed triacylglycerols and acetyl-triacylglycerols containing medium-chain fatty acids [J/OL]. Front. Energy Res., 2021, 9:620118 [2022-10-03]. . |

| 4 | 国家药典委员会.中国药典(一部)[M].北京:中国医药科技出版社,2020:321. |

| 5 | LIU J G, CHEN M, ZHANG Y H, et al.. Analyses of the oil content, fatty acid composition, and antioxidant activity in seeds of Thlaspi arvense L. from different provenances and correlations with environmental factors [J/OL]. Chem. Biol. Technol. Agric, 2022, 9(1):11 [2022-10-03]. https:/doi.org/10.1186/S40538-021-00276-X. |

| 6 | CHEN S X, ERIK A. Update on glucosinolate metabolism and transport [J]. Plant Physiol. Biochem., 2001, 39(9):743-758. |

| 7 | MAZUMDER A, DWIVEDI A, DU PLESSIS J. Sinigrin and its therapeutic benefits [J/OL]. Molecules, 2016, 21(4):416 [2022-10-03]. . |

| 8 | DRVENICA I, BLAZEVIC I, BOSKOVIC P, et al.. Sinigrin encapsulation in liposomes: influence on in vitro digestion and antioxidant potential [J]. Polish J. Food Nutr. Sci., 2021,71(4):441-449. |

| 9 | LOZANO-BAENA M D, TASSET I, OBREGON-CANO S, et al.. Antigenotoxicity and tumor growing inhibition by leafy Brassica carinata and sinigrin [J]. Molecules, 2015, 20(9):15748-15765. |

| 10 | LI S Q, LIN J W, WEI J F, et al.. Sinigrin impedes the breast cancer cell growth through the inhibition of PI3K/AKT/mTOR phosphorylation-mediated cell cycle arrest [J]. J. Environ. Pathol. Tox., 2022, 41(3):33-43. |

| 11 | ABBAS Q, HASSAN M, RAZA H, et al.. In vitro, in vivo and in silico anti-hyperglycemic inhibition by sinigrin [J]. Asian Pac. J. Trop. Med., 2017, 10(4):352-358. |

| 12 | NAZEAM J, MOHAMMED E Z, RAAFAT M, et al.. Based on principles and insights of COVID-19 epidemiology, genome sequencing, and pathogenesis: retrospective analysis of sinigrin and prolixinRX (Fluphenazine) provides off-label drug candidates [J]. SLAS Discov., 2020, 25(10):1123-1140. |

| 13 | 黄文红,冯玉红,李嘉诚,等.Plackett-Burman设计和响应面法优化芥子中硫苷的超声波提取工艺[J].中国粮油学报, 2016,31(7):76-81. |

| HUANG W H, FENG Y H, LI J C, et al.. Optimization of ultrasound extraction of sinigrin from mustard seed by Plackett-Burman design and response surface methodology [J]. J. Chin. Cereals Oils Assoc., 2016, 31(7):76-81. | |

| 14 | WANG T, LIANG H, YUAN Q. Optimization of ultrasonic-stimulated solvent extraction of sinigrin from Indian mustard seed (Brassica juncea L.) using response surface methodology [J]. Phytochem. Analysis, 2011, 22:205-213. |

| 15 | 张佳杰,薛敏,魏天晔,等.烟碱提取方法研究进展[J].食品安全质量检测学报,2018,9(10):11-16. |

| ZHANG J J, XUE M, WEI T Y, et al.. Research progress of extraction methods of nicotine [J]. J. Food Saf. Qual., 2018, 9(10):11-16. | |

| 16 | 吴非,李钊,周琪,等.超声波辅助水酶法提取米胚油及其成分分析[J].食品科学,2020,41(24):233-241. |

| WU F, LI Z, ZHOU Q, et al.. Ultrasonic-assisted aqueous enzymatic extraction and chemical composition of rice germ oil [J]. Food Sci., 2020, 41(24):233-241. | |

| 17 | 高淼,马晓军.超声波辅助水酶法提取棕榈油工艺优化及其成分分析[J].天津科技大学报,2021,36(4):14-19. |

| GAO M, MA X J. Optimization of ultrasound-assisted enzymatic aqueous extractionof palm oil and its composition analysis [J]. J. Tianjin Univ. Sci. Technol., 2021, 36(4):14-19. | |

| 18 | WEI C, XIAO K, LI H L, et al.. Optimization of ultrasound assisted aqueous enzymatic extraction of oil from Cinnamomum camphora seeds [J/OL]. LWT-Food Sci. Technol., 2022, 164:113689 [2022-10-03]. . |

| 19 | 靳俊莹.水酶法提取油莎豆油及其副产物的开发利用[D].郑州:河南工业大学,2021. |

| JIN J Y. Studies on aqueous enzymatic extraction of Cyperus esculentus oil and its byproduct application [D]. Zhengzhou: Henan University of Technology, 2021. | |

| 20 | 赵自通,陈复生,张丽芬,等.酶制剂在植物油脂与蛋白质提取过程中应用的研究进展[J].食品研究与开发,2017,38(19):201-210. |

| ZHAO Z T, CHEN F S, ZHANG L F, et al.. Advances in application of enzyme preparations in the extraction of vegetable oils and protein [J]. Food Res. Dev., 2017, 38(19):201-210. | |

| 21 | 张庆芬,李占君,李晓雪,等.匀浆结合超声-微波协同提取桔梗中桔梗皂D和党参炔苷工艺研究[J].森林工程,2022,38(5):110-120. |

| ZHANG Q F, LI Z J, LI X X, et al.. Homogenate pretreatment followed by ultrasonic-microwave synergisticextraction of platycodin D and lobetyolin from the Platycodon radix [J]. For. Eng., 2022, 38(5):110-120. | |

| 22 | AWASTHI S, SARASWATHI N T. Sinigrin, a major glucosinolate from cruciferous vegetables restrains non-enzymatic glycation of albumin [J]. Int. J. Biol. Macromol., 2016, 83:410-415. |

| 23 | TEKLEHAYMANOT T, WANG H J, LIANG J L, et al.. Variation in plant morphology and sinigrin content in ethiopian mustard (Brassica carinata L.) [J]. Hortic. Plant J., 2019, 5(5):205-212. |

| 24 | 柯秀梅,杨荣平,王云红,等.藏药菥蓂中黑芥子苷对黄嘌呤致小鼠高尿酸作用的研究[J].天然产物研究与开发,2015,27(8):1407-1410. |

| KE X M, YANG R P, WANG Y H, et al.. Effect of sinigrin on high uric acid in mice induced by xanthanine [J]. Nat. Prod. Res. Dev., 2015, 27(8):1407-1410. | |

| 25 | 黄志慧,张一宁,李娜娜,等.增补UV-B辐射对菥蓂生理特性及次生代谢产物的影响[J].植物研究,2022,42(6):1079-1087. |

| HUANG Z H, ZHANG Y N, LI N N, et al.. Responses of supplemental UV-B radiation to physiological properties and secondary metabolites of Thlaspi arvense [J]. Bull. Bot. Res., 2022, 42(6):1079-1087. |

| [1] | Xiuying ZHAO, Qingwen HUANG, Haojie CAO, Jie WANG, Ruijiao LI, Dongxia NIE, Zheng HAN, Zhihui ZHAO. Optimization of Liquid Culture Conditions for the Production of Deoxynivalenol and Its Derivatives by Fusarium graminearum Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 222-233. |

| [2] | Kaiqiang WANG, Xue YANG, Changfeng LI, Xiao DUAN, Qing PENG, Yu QIAO, Bo SHI. Optimization of Glyceollins Synthesis Condition Induced by Xylooligosaccharides Based on Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2022, 24(10): 208-217. |

| [3] | GUO Huihui, LIN Congfa, JIANG Yuanbin, LI Zhigang. Optimization of Protocorm Proliferation Medium of Dendrobium huoshanense by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2020, 22(3): 173-180. |

| [4] | LIANG Zhaochao, GUO Xianwei, SONG Yanjuan, MA Tianfu, WANG Feng, WANG Liyan, JING Ruiyong*. Extraction Process of Polysaccharide in Agaricus bisporus Optimized by Response Surface Method and Its Antioxidant Activity in vitro [J]. Journal of Agricultural Science and Technology, 2019, 21(8): 161-168. |

| [5] | WU Qi1,2,3§, ZHANG Yuhui1,2§, SU Rongrong1,2, SUN Bo1,3, WU Qiuyun1,2, XIA Zhilan1,2*. Optimization of Submerged Fermentation Medium of Agaricus blazei Murrill for Mycelial Biomass Accumulation Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2019, 21(3): 152-160. |

| [6] | DAI Yangjun1, HU Jian1,2, ZHOU Ying2, ZUO Bo1, SHI Yixue1. Optimization of Compound Enzymolysis Process of Dried Figs by Plackett-Burman Design and Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2018, 20(7): 146-153. |

| [7] | CHEN Xinyao, DONG Xing, CHEN Jingjie, QIN Tao, LI Jian*, HUANG Yifan*. Optimization of Extraction Process for Crude Polysaccharide from Hericium Erinaceus by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2017, 19(3): 131-136. |

| [8] | XU Lan1, ZHANG Peng-fei1, LEI Li-xia1, ZHANG Hai-rong2, WANG Chuang-yun3. A Microwave-assisted Procedure for the Extraction Polysaccharide from Evodia rutaecarpa Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2016, 18(4): 174-180. |

| [9] | XIONG Xia-yu, ZENG Xin-an*| WANG Man-sheng, ZHANG Zhi-hong. Studies on Optimization of Extraction Technology Assisted by Pulsed Electric Field of Total Flavonolds from Rape Pollen Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2015, 17(5): 88-93. |

| [10] | XIN Chongbo, ZI Lihan, LIU Chenguang, BAI Fengwu*. Response Surface Methodology Application for Optimizing Corncobs Pretreatment Conditions During Simultaneous Saccharification and Ethanol Fermentation [J]. , 2013, 15(5): 173-180. |

| [11] | WANG Jin-ling1, LIU Xiao-ping2, GAO Wei-hua1, ZHAO Feng-yan3, LV Chang-shan3. Medium Optimization for Phosphate-solubilizing Bacteria Bacillus Megaterium in Submerged Fermentation [J]. , 2013, 15(2): 185-192. |

| [12] | WANG Liang1,2, LI Shu1,2, MAO Zhonggui1,2*, ZHAO Fulin3. Optimization of Fermentation Medium for εPolylysine Production by Recombinant Streptomyces sp. FEEL1 [J]. , 2013, 15(1): 76-83. |

| [13] | ZHAO Ya-zhou, TIAN Wen-li, GUO Zhan-bao, GAO Ling-yu, PENG Wen-jun. Optimization of Ethanol Extraction Technology from Propolis by Response Surface Methodology [J]. , 1, 1(1): 85-93. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号