Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (2): 99-107.DOI: 10.13304/j.nykjdb.2024.0351

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Received:2024-04-30

Accepted:2024-08-25

Online:2025-02-15

Published:2025-02-14

Contact:

Lazhen QUAN

通讯作者:

全腊珍

作者简介:胡跃腾 E-mail:1006746543@qq.com;

基金资助:CLC Number:

Yueteng HU, Lazhen QUAN. Design and Testing of Film Picking Device for Southern Farmland Residual Film Picking Machine[J]. Journal of Agricultural Science and Technology, 2025, 27(2): 99-107.

胡跃腾, 全腊珍. 南方农田残膜捡拾机捡膜装置的设计及试验[J]. 中国农业科技导报, 2025, 27(2): 99-107.

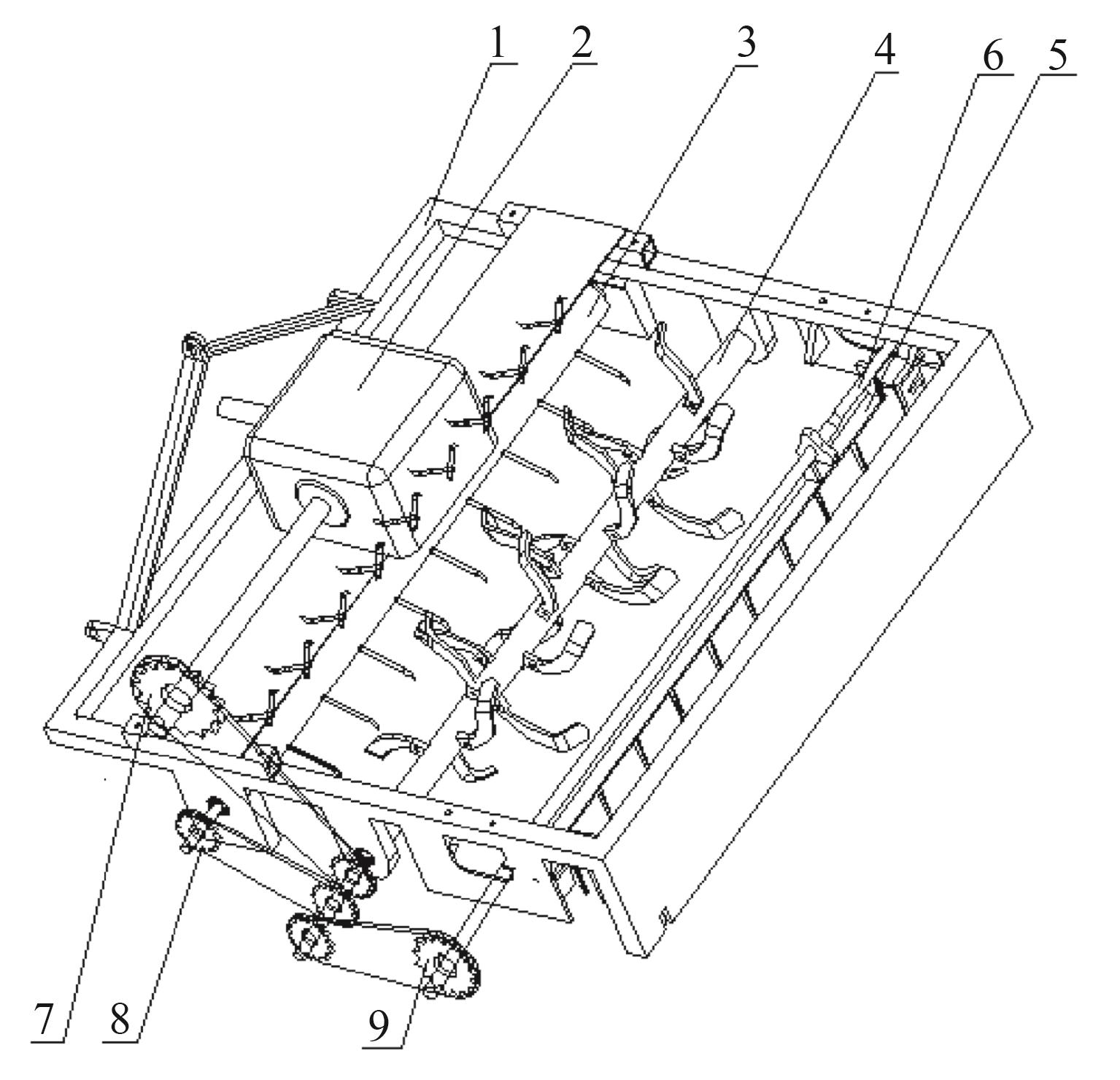

Fig. 1 Shaft side structure of residual film picking machineNote:1—Rack; 2—Gearbox; 3—Bent toothed membrane roller for topsoil layer; 4—Loosening and rotary tillage blade set; 5—Vertical membrane tying teeth group in deep soil layers; 6—Cam mechanism; 7—The first chain transmission mechanism; 8—The second chain transmission mechanism; 9— The third chain transmission mechanism.

| 参数Parameter | 数值Value |

|---|---|

尺寸(长×宽×高) Size (length × width × height)/mm | 1 180×1 280×242 |

结构质量 Structural quality/kg | 225 |

配套动力 Supporting power/kW | 70 |

作业速度 Operating speed/(km·h-1) | 2~8 |

作业幅宽 Operating width/mm | 1 200 |

综合回收率 Comprehensive recovery rate/% | 81 |

Table 2 Main technical parameters of film recovery machine

| 参数Parameter | 数值Value |

|---|---|

尺寸(长×宽×高) Size (length × width × height)/mm | 1 180×1 280×242 |

结构质量 Structural quality/kg | 225 |

配套动力 Supporting power/kW | 70 |

作业速度 Operating speed/(km·h-1) | 2~8 |

作业幅宽 Operating width/mm | 1 200 |

综合回收率 Comprehensive recovery rate/% | 81 |

| 参数Parameter | 数值Value |

|---|---|

密度 Density ρ/(t∙m-3) | 7.85×10-9 |

弹性模量 Elastic modulus/MPa | 2.1×10-5 |

泊松比 Poisson’s ratio | 0.29 |

屈服强度 Yield strength/MPa | 690 |

许用应力 Allowable stress/MPa | 690/1.34≈515 |

Table 3 Material characteristic parameters of Q690 steel

| 参数Parameter | 数值Value |

|---|---|

密度 Density ρ/(t∙m-3) | 7.85×10-9 |

弹性模量 Elastic modulus/MPa | 2.1×10-5 |

泊松比 Poisson’s ratio | 0.29 |

屈服强度 Yield strength/MPa | 690 |

许用应力 Allowable stress/MPa | 690/1.34≈515 |

| 特性Characterics | 残膜1 Film 1 | 残膜2 Film 2 | ||||

|---|---|---|---|---|---|---|

膜厚 Thickness/mm | 0.010 | 0.006 | ||||

初始长度 Initial length/mm | 100 | 100 | 100 | 100 | 100 | 100 |

拉断长度 Break length/mm | 208 | 194 | 190 | 163 | 179 | 159 |

最大拉断力 Maximum tensile strength/N | 0.27 | 0.23 | 0.19 | 0.40 | 0.45 | 0.39 |

延展率 Extension rate/% | 108 | 94 | 90 | 63 | 79 | 59 |

Table 4 Characterics of residual film

| 特性Characterics | 残膜1 Film 1 | 残膜2 Film 2 | ||||

|---|---|---|---|---|---|---|

膜厚 Thickness/mm | 0.010 | 0.006 | ||||

初始长度 Initial length/mm | 100 | 100 | 100 | 100 | 100 | 100 |

拉断长度 Break length/mm | 208 | 194 | 190 | 163 | 179 | 159 |

最大拉断力 Maximum tensile strength/N | 0.27 | 0.23 | 0.19 | 0.40 | 0.45 | 0.39 |

延展率 Extension rate/% | 108 | 94 | 90 | 63 | 79 | 59 |

序号 Number | A:入土深度 Deepth into soil/mm | B:行走速度 Walking speed/(km·h-1) | C:输出转速 Output speed/(r·min-1) | Y:捡拾率 Pickup rate/% |

|---|---|---|---|---|

| 1 | 20 | 3 | 150 | 80.2 |

| 2 | 20 | 5 | 300 | 81.8 |

| 3 | 20 | 7 | 450 | 79.9 |

| 4 | 30 | 5 | 450 | 85.9 |

| 5 | 30 | 7 | 150 | 79.0 |

| 6 | 30 | 3 | 300 | 81.2 |

| 7 | 40 | 7 | 300 | 82.3 |

| 8 | 40 | 3 | 450 | 85.0 |

| 9 | 40 | 5 | 150 | 80.9 |

Table 5 Orthogonal test results

序号 Number | A:入土深度 Deepth into soil/mm | B:行走速度 Walking speed/(km·h-1) | C:输出转速 Output speed/(r·min-1) | Y:捡拾率 Pickup rate/% |

|---|---|---|---|---|

| 1 | 20 | 3 | 150 | 80.2 |

| 2 | 20 | 5 | 300 | 81.8 |

| 3 | 20 | 7 | 450 | 79.9 |

| 4 | 30 | 5 | 450 | 85.9 |

| 5 | 30 | 7 | 150 | 79.0 |

| 6 | 30 | 3 | 300 | 81.2 |

| 7 | 40 | 7 | 300 | 82.3 |

| 8 | 40 | 3 | 450 | 85.0 |

| 9 | 40 | 5 | 150 | 80.9 |

参数 Parameter | A:入土深度 Deepth into soil | B:行走速度 Walking speed | C:输出转速 Output speed |

|---|---|---|---|

| K1 | 242.91 | 237.33 | 241.07 |

| K2 | 248.22 | 249.62 | 246.33 |

| K3 | 247.02 | 240.31 | 249.86 |

| k1 | 80.97 | 79.11 | 80.35 |

| k2 | 82.73 | 83.21 | 82.11 |

| k3 | 82.34 | 80.10 | 83.28 |

| 极差R | 5.31 | 12.29 | 8.79 |

因素顺序 Factor ranking | B>C>A | ||

较优方案 Optimal solution | A2,B2,C3 | ||

Table 6 Range analysis of test results

参数 Parameter | A:入土深度 Deepth into soil | B:行走速度 Walking speed | C:输出转速 Output speed |

|---|---|---|---|

| K1 | 242.91 | 237.33 | 241.07 |

| K2 | 248.22 | 249.62 | 246.33 |

| K3 | 247.02 | 240.31 | 249.86 |

| k1 | 80.97 | 79.11 | 80.35 |

| k2 | 82.73 | 83.21 | 82.11 |

| k3 | 82.34 | 80.10 | 83.28 |

| 极差R | 5.31 | 12.29 | 8.79 |

因素顺序 Factor ranking | B>C>A | ||

较优方案 Optimal solution | A2,B2,C3 | ||

| 1 | 陈学庚,温才妃.提高机械化程度防控残膜污染[N].中国科学报,2024-05-21(001). |

| 2 | 温浩军,陈学庚,陈浩,等.农田地膜回收机械应用现状与发展[J].农业环境科学学报,2024,43(6):1271-1277. |

| WEN H J, CHEN X G, CHEN H, et al.. Application status and development of farmland mulch recycling machinery [J]. J. Agro-Environ. Sci., 2024, 43(6):1271-1277. | |

| 3 | 包翠荣.农田“白色污染”治理迫在眉睫[J].生态经济,2018,34(2):6-9. |

| 4 | 刘玲,陈玉兰.新疆农用地膜使用现状问题及防治对策[J].河北农业科学,2023,27(4):102-104. |

| LIU L, CHEN Y L. Current situation,problems and control measures of agricultural mulch film use in Xinjiang [J]. J. Hebei Agric. Sci., 2023, 27(4): 102-104. | |

| 5 | 刘凌,蒋丽煌,魏丽梅.新疆地区农田残膜回收机械应用现状分析与未来展望[J].农业工程与装备,2023,50(4):4-5, 8. |

| LIU L, JIANG L H, WEI L M. Analysis of the current application status and future prospects of agricultural residue film recycling machinery in Xinjiang region [J]. Agric. Eng. Equip., 2023, 50(4):4-5, 8. | |

| 6 | 李伟,李明军,赵恒章,等.地膜覆盖种植技术及残膜污染防控[J].农业工程,2024,14(06):65-71. |

| LI W, LI M J, ZHAO H Z, et al.. Plastic film covering planting technology and residual film pollution prevention and control [J]. Agric. Eng., 2024, 14(6):65-71. | |

| 7 | 代良羽,高维常,杨松花,等.贵州省农田地膜残留现状及污染防治对策[J].农学学报,2024,14(5):40-46. |

| DAI L Y, GAO W C, YANG S H, et al.. Status of farmland plastic film residue and pollution control countermeasures in Guizhou province [J]. J. Agric., 2024,14(5):40-46. | |

| 8 | 蒋骏,王俊鹏,贾志宽.宁南旱地春小麦地膜覆盖栽培试验初报[J].干旱地区农业研究,1998,16(1):41-44. |

| 9 | 张峰.废旧地膜回收利用技术的应用[J].中国资源综合利用,2013,31(5):36-38. |

| FENG Z. The technology application of technology recycling of extension of residueresidue mulch film [J]. China Resour. Comprehensive Utilization, 2013,31(5):36-38. | |

| 10 | 郝文录, 刘恒新, 朱良,等. 农业机械试验条件 测定方法的一般规定 [S].北京:中国标准出版社,2008. |

| 11 | 李梦哲.全田土下微膜覆盖对冬小麦耗水特性和产量形成的影响[D].保定:河北农业大学,2013. |

| LI M Z. Effects of Soil-coated ultrathin plastic-film mulchingon water consumption characteristics and yield formation of winter wheat [D]. Baoding: Hebei Agricultural University, 2013. | |

| 12 | 吕贻忠,李保国.土壤学[M].北京:中国农业出版社,2006:1-238. |

| 13 | 王志超,李仙岳,史海滨,等.农膜残留对土壤水动力参数及土壤结构的影响[J].农业机械学报,2015,46(5):101-106, 140. |

| WANG Z C, LI X Y, SHI H B, et al.. Effects of residual plastic film on soil hydrodynamic parameters and soil structure [J]. Trans. Chin. Soc. Agric. Mach., 2015, 46(5):101-106, 140. | |

| 14 | 中国农业机械化科学研究院.农业机械设计手册[M].北京:中国农业科学技术出版社,2007:1-1885. |

| 15 | 穆道欢, 杨宛章.残膜回收机弹齿式捡拾机构的设计及试验研究[J].农机化研究,2015,37(11):91-94. |

| MU D H, YANG W Z. Design and experimental research on spring-tooth picking mechanism of residual film collector [J]. J. Agric. Mech. Res., 2015, 37(11):91-94. | |

| 16 | 杨树川,邵金龙,杨术明,等.基于 Solidworks & SimMechanics 的机构运动分析与仿真[J].河北工业科技,2011,28(4):221-225. |

| YANG S C, SHAO J L, YANG S M, et al.. Solidworks/SimMechanics-based mechanism kinematic analysis and simulation [J]. Hebei J. Ind. Sci. Technol., 2011,28(4):221-225. | |

| 17 | 李雅昔,王宏斌,李晓莉.基于 SolidWorks 与 Matlab 的凸轮机构设计与仿真运动分析[J].河北工业科技,2015,32(3):252-256. |

| LI Y X, WANG H B, LI X L. Design and simulation of the cam profile based on Matlab and SolidWorks [J]. Hebei J. Ind. Sci. Technol., 2015, 32(3):252-256. | |

| 18 | 邰淑彩,孙韫玉,何娟娟.应用数理统计[M].第2版.武汉:武汉大学出版社,2005:1-371. |

| 19 | 陈海涛,房川,冀晓娜,等.TDR300在测量土壤水分中的应用[J].生命科学仪器,2007,5(10):51-52. |

| CHEN H T, FANG C, JI X N, et al.. Application of TDR300 measuring soil moisture [J]. Life Sci. Instrum., 2007,5(10):51-52. | |

| 20 | 李炳君,彭永杰,卢伟乐,等. GB13735—2017[M]. 北京:中国标准出版社 2017. |

| 21 | 李亚丽. 1FM-110 型地膜回收机的设计与研究[D].兰州:甘肃农业大学,2016 |

| LI Y L. Design and research on 1FM-110 plastic film recovery machine [D]. Lanzhou: Gansu Agricultural University, 2016. | |

| 22 | 陈发,史建新,王学农,等.弧型齿残膜捡拾滚筒捡膜的机理[J].农业机械学报,2006,37(6):36-41. |

| CHEN F, SHI J X, WANG X N, et al.. Study on collecting principle of arc-type tooth roller for collecting plastic residue [J]. Trans. Chin.Soc. Agric. Mach., 2006, 37(6):36-41. | |

| 23 | 李云雁,胡传荣.试验设计与数据处理[M].第2版.北京:化学工业出版社,2008:124-130. |

| 24 | 陈魁.试验设计与分析[M].北京:清华大学出版社,2005:72-74. |

| [1] | Xin LI, Yucheng NIE, Jie YANG, Xiaojun JIN, Yong CHEN, Jialin YU. Development and Simulation Analysis of Parallel Weeding Robot Based on a Double Spraying System [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 108-115. |

| [2] | Chun HUANG, Yue LI, Shiquan WEI, Yang GAO, Zihan WU, Qirun HUANG, Chenhui WEI. Design and Experiment of Double Shafts Banana Straw Crushing and Returning Machine with Different Rotational Directions [J]. Journal of Agricultural Science and Technology, 2024, 26(11): 97-106. |

| [3] | Yang GAO, Yue LI, Shiquan WEI, Chun HUANG, Zihan WU, Chenhui WEI, Qirun HUANG. Design and Experiment of a Banana Straw Crushing and Returning Machine with Rotting Agent Spraying Device [J]. Journal of Agricultural Science and Technology, 2024, 26(9): 93-104. |

| [4] | Jiaqiang ZHENG, Huichun ZHANG, Youlin XU, Hongping ZHOU. Research Review on Modeling and Simulation for Pesticide Spraying System [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 76-90. |

| [5] | Shaobo LI, Kuo ZHANG, Jia WANG, Jianping LI, Shuteng LIU. Optimization of Air Duct Parameters of Air Supply Spray Device Based on CFD [J]. Journal of Agricultural Science and Technology, 2023, 25(12): 93-102. |

| [6] | HU Guangfa, QUAN Lazhen, ZOU Yunmei, SHEN Hui, KUANG Xinpeng, HUANG Conghui. Design and Experiment of Devices to Separate Membrane from Soil for Mechanical Recycle of Farmland Residual Membrane [J]. Journal of Agricultural Science and Technology, 2021, 23(7): 82-92. |

| [7] | LIU Dezhu, ZHOU Yong, ZHANG Guozhong, ZHANG Mengyue, KE Huibin, YANG Quanjun. Design and Experiment of Pneumatic Double-side Fertilizer Devices for Ratoon Rice [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 77-85. |

| [8] | XIAO Feifei, JIANG Ping, HU Wenwu, LIAO Ronghua, ZHANG Danhui, JIN Sheng. Recognition Algorithm of Extremum Point Clustering Seedling Belt Based on Offset Compensation Model [J]. Journal of Agricultural Science and Technology, 2021, 23(5): 86-97. |

| [9] | GE Yi\|yuan1, WANG Jin\|wu2*, LI Ya\|qin1, WEI Tian\|lu1. Study on Returning Machine of Rice High Straw for Quickly Rotted [J]. , 2014, 16(6): 81-88. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号