Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (12): 93-102.DOI: 10.13304/j.nykjdb.2022.0586

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Shaobo LI1( ), Kuo ZHANG1, Jia WANG1, Jianping LI1,2(

), Kuo ZHANG1, Jia WANG1, Jianping LI1,2( ), Shuteng LIU1

), Shuteng LIU1

Received:2022-07-13

Accepted:2022-09-21

Online:2023-12-15

Published:2023-12-12

Contact:

Jianping LI

李绍波1( ), 张阔1, 王佳1, 李建平1,2(

), 张阔1, 王佳1, 李建平1,2( ), 刘树腾1

), 刘树腾1

通讯作者:

李建平

作者简介:李绍波E-mail:sean18135144508@163.com;

基金资助:CLC Number:

Shaobo LI, Kuo ZHANG, Jia WANG, Jianping LI, Shuteng LIU. Optimization of Air Duct Parameters of Air Supply Spray Device Based on CFD[J]. Journal of Agricultural Science and Technology, 2023, 25(12): 93-102.

李绍波, 张阔, 王佳, 李建平, 刘树腾. 基于CFD的风送喷雾装置风筒参数优化[J]. 中国农业科技导报, 2023, 25(12): 93-102.

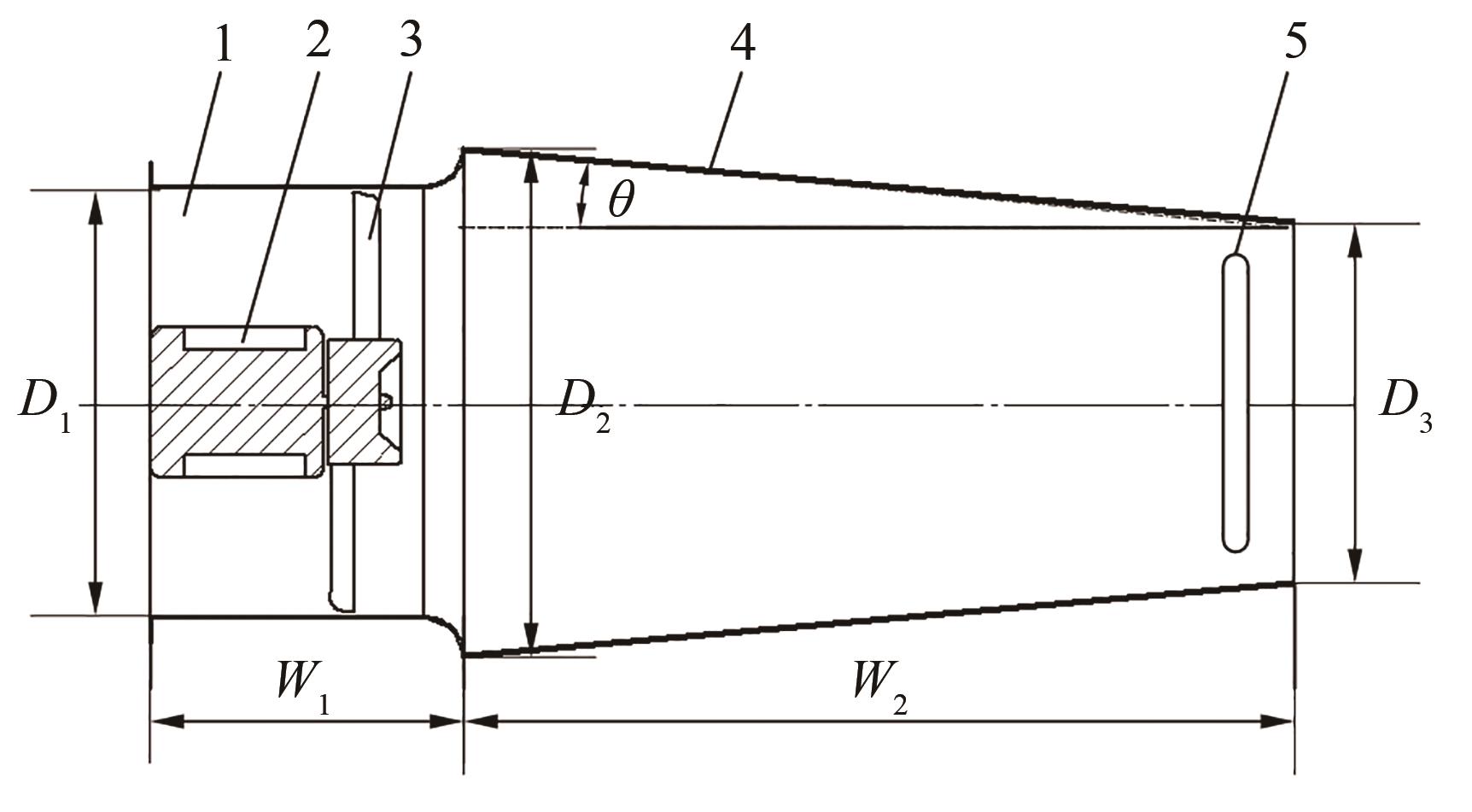

Fig. 1 Air duct cross-sectional structureNote:1—Axial flow fan; 2—Motor; 3—Blade; 4—Ram; 5.—Ring spray device; D1—Fan diameter; D2—Diameter of the air duct inlet end face; D3—End face diameter of air duct outlet; W1—Fan width; W2—Length of air duct; θ—Angle between cylinder wall and axis.

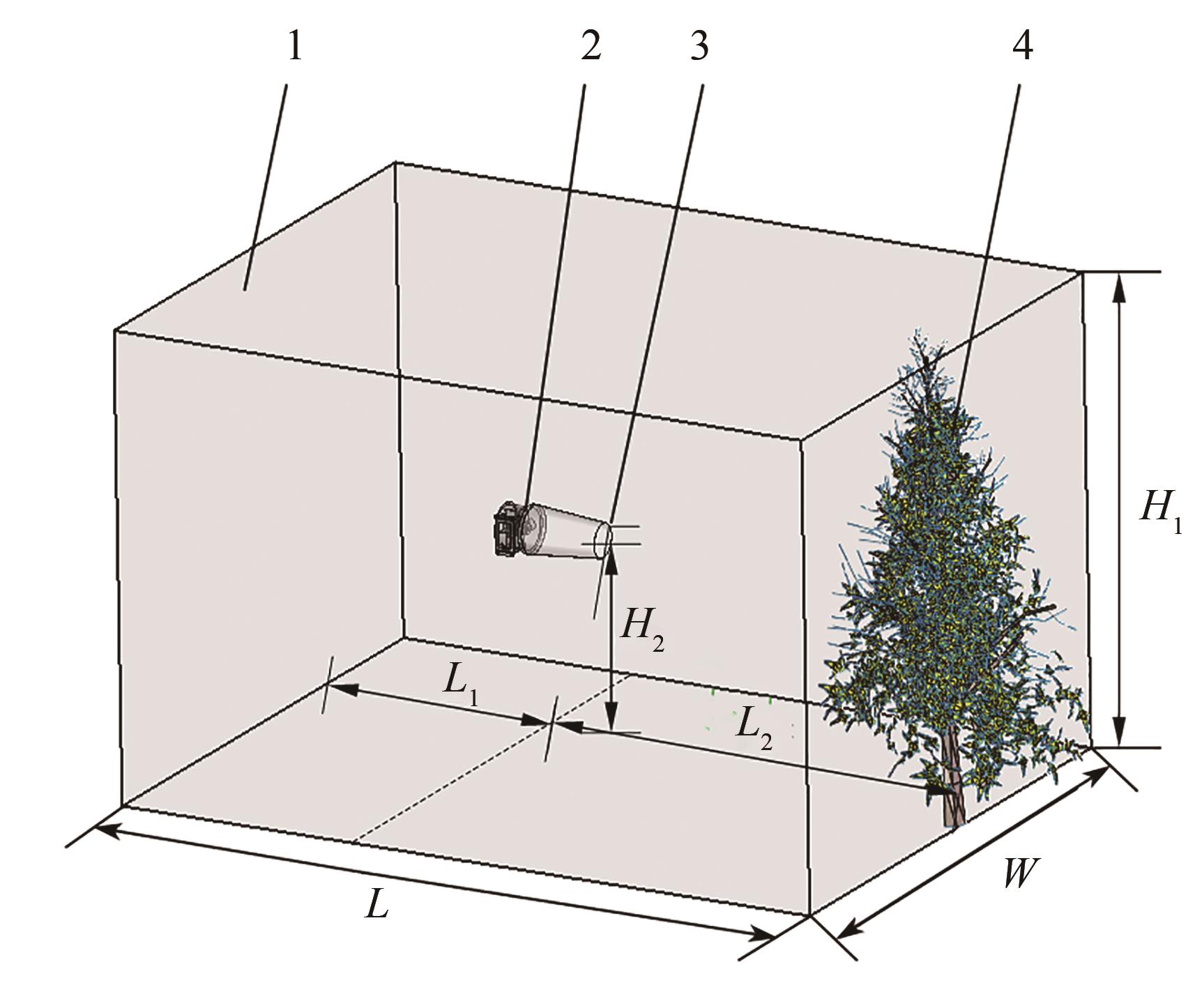

Fig. 2 Three-dimensional model of air ductNote:1—Computing domain; 2—Rotation domain; 3—Ram; 4—Fruit tree model; W—Width of the computational domain; L—Length of the computational domain; H1—Height of computing domain; L1—Distance between the air duct outlet and the left boundary of the computing domain; L2—Distance between the outlet of air duct and the fruit tree; H2—Distance between the fan axis and the ground of the computing domain.

水平 Level | 因素 Factor | ||

|---|---|---|---|

| A:筒壁与轴线的夹角Angle between cylinder wall and axis/(°) | B:风筒长度Air duct length/mm | C:风机转速Fan speed/ (r·min-1) | |

| -1 | 3 | 400 | 1 500 |

| 0 | 4 | 500 | 2 000 |

| 1 | 5 | 600 | 2 500 |

Table 1 Factor level wind gathering test

水平 Level | 因素 Factor | ||

|---|---|---|---|

| A:筒壁与轴线的夹角Angle between cylinder wall and axis/(°) | B:风筒长度Air duct length/mm | C:风机转速Fan speed/ (r·min-1) | |

| -1 | 3 | 400 | 1 500 |

| 0 | 4 | 500 | 2 000 |

| 1 | 5 | 600 | 2 500 |

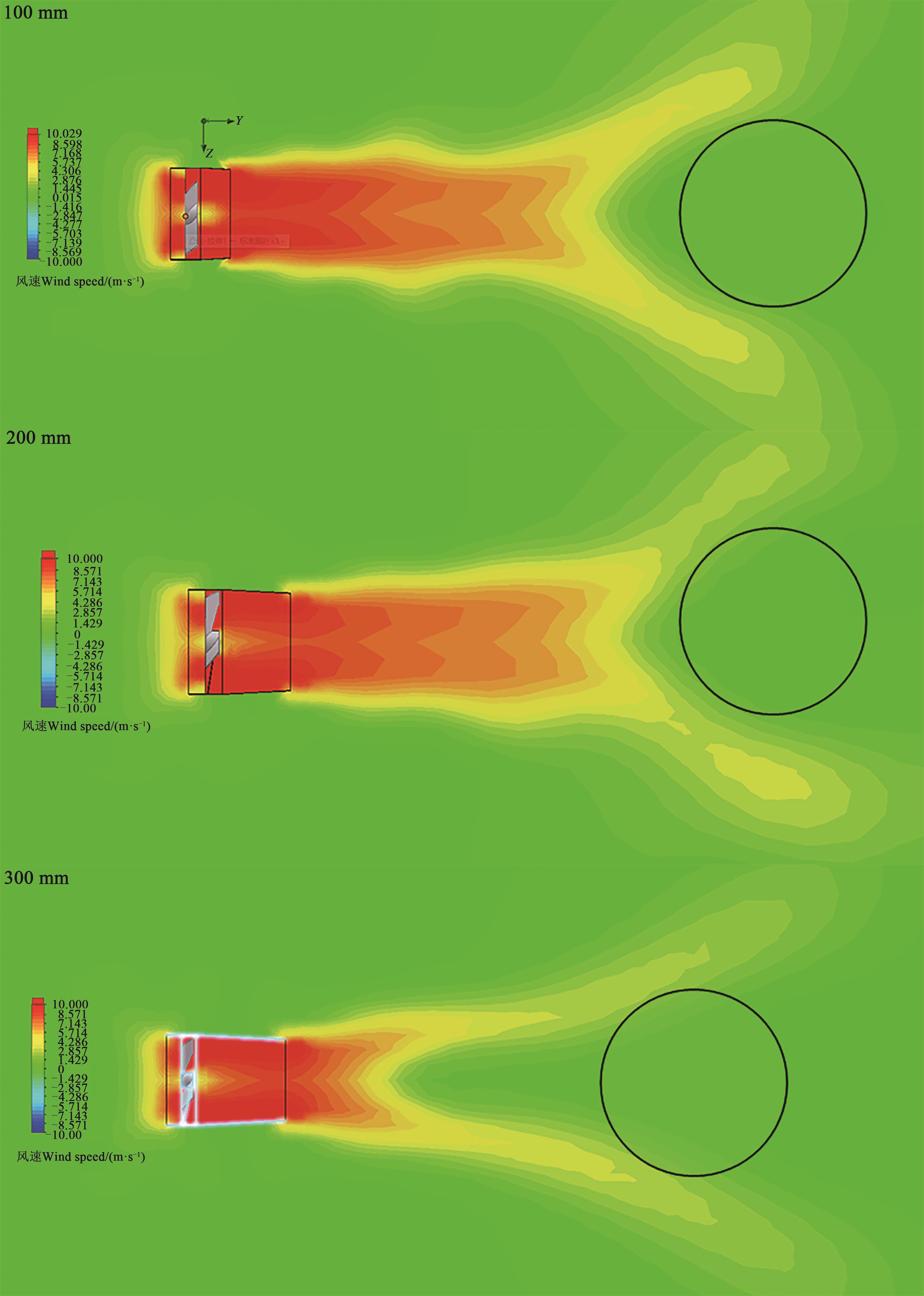

Fig. 8 Section cloud images of wind speed with duct lengths of 100, 200 and 300 mmNote:The darker the color, the higher the wind speed, and the circular box area is the area where the airflow is not disturbed.

序号 Number | A | B | C | 风速Wind speed/(m·s-1) | 风场纵向幅宽Longitudinal width of wind field /mm |

|---|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 6.25 | 1 012.23 |

| 2 | 1 | -1 | 0 | 6.94 | 1 205.15 |

| 3 | -1 | 1 | 0 | 7.38 | 1 788.48 |

| 4 | 1 | 1 | 0 | 7.17 | 2 657.45 |

| 5 | -1 | 0 | -1 | 5.26 | 1 245.13 |

| 6 | 1 | 0 | -1 | 4.54 | 1 886.49 |

| 7 | -1 | 0 | 1 | 6.15 | 1 877.75 |

| 8 | 1 | 0 | 1 | 9.18 | 2 250.14 |

| 9 | 0 | -1 | -1 | 4.57 | 1 371.13 |

| 10 | 0 | 1 | -1 | 5.86 | 2 206.46 |

| 11 | 0 | -1 | 1 | 5.61 | 2 017.78 |

| 12 | 0 | 1 | 1 | 9.84 | 2 747.23 |

| 13 | 0 | 0 | 0 | 9.28 | 2 286.36 |

| 14 | 0 | 0 | 0 | 9.49 | 2 150.89 |

| 15 | 0 | 0 | 0 | 8.99 | 2 135.56 |

| 16 | 0 | 0 | 0 | 10.54 | 2 058.55 |

| 17 | 0 | 0 | 0 | 8.65 | 2 350.38 |

Table 2 Response surface scheme and results

序号 Number | A | B | C | 风速Wind speed/(m·s-1) | 风场纵向幅宽Longitudinal width of wind field /mm |

|---|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 6.25 | 1 012.23 |

| 2 | 1 | -1 | 0 | 6.94 | 1 205.15 |

| 3 | -1 | 1 | 0 | 7.38 | 1 788.48 |

| 4 | 1 | 1 | 0 | 7.17 | 2 657.45 |

| 5 | -1 | 0 | -1 | 5.26 | 1 245.13 |

| 6 | 1 | 0 | -1 | 4.54 | 1 886.49 |

| 7 | -1 | 0 | 1 | 6.15 | 1 877.75 |

| 8 | 1 | 0 | 1 | 9.18 | 2 250.14 |

| 9 | 0 | -1 | -1 | 4.57 | 1 371.13 |

| 10 | 0 | 1 | -1 | 5.86 | 2 206.46 |

| 11 | 0 | -1 | 1 | 5.61 | 2 017.78 |

| 12 | 0 | 1 | 1 | 9.84 | 2 747.23 |

| 13 | 0 | 0 | 0 | 9.28 | 2 286.36 |

| 14 | 0 | 0 | 0 | 9.49 | 2 150.89 |

| 15 | 0 | 0 | 0 | 8.99 | 2 135.56 |

| 16 | 0 | 0 | 0 | 10.54 | 2 058.55 |

| 17 | 0 | 0 | 0 | 8.65 | 2 350.38 |

变异来源 Source of variation | 风速Wind speed | 风场纵向幅宽Longitudinal width of wind field | ||

|---|---|---|---|---|

| F1 | P1 | F2 | P2 | |

| 模型Model | 9.08 | 0.004 1 | 29.63 | <0.000 1 |

| A | 1.45 | 0.268 1 | 39.91 | 0.000 4 |

| B | 8.54 | 0.022 3 | 118.16 | <0.000 1 |

| C | 20.75 | 0.002 6 | 43.70 | 0.000 3 |

| AB | 0.299 2 | 0.601 4 | 8.46 | 0.002 7 |

| AC | 5.56 | 0.049 3 | 0.388 | 0.552 9 |

| BC | 3.11 | 0.121 4 | 0.691 | 0.433 4 |

| A2 | 10.88 | 0.013 1 | 49.17 | 0.000 2 |

| B2 | 7.84 | 0.026 5 | 4.45 | 0.072 8 |

| C2 | 19.54 | 0.003 1 | 0.055 | 0.821 3 |

| 失拟误差 Lack of fit | 1.66 | 0.310 4 | 0.684 | 0.606 8 |

Table 3 Analysis of variance of response surface test

变异来源 Source of variation | 风速Wind speed | 风场纵向幅宽Longitudinal width of wind field | ||

|---|---|---|---|---|

| F1 | P1 | F2 | P2 | |

| 模型Model | 9.08 | 0.004 1 | 29.63 | <0.000 1 |

| A | 1.45 | 0.268 1 | 39.91 | 0.000 4 |

| B | 8.54 | 0.022 3 | 118.16 | <0.000 1 |

| C | 20.75 | 0.002 6 | 43.70 | 0.000 3 |

| AB | 0.299 2 | 0.601 4 | 8.46 | 0.002 7 |

| AC | 5.56 | 0.049 3 | 0.388 | 0.552 9 |

| BC | 3.11 | 0.121 4 | 0.691 | 0.433 4 |

| A2 | 10.88 | 0.013 1 | 49.17 | 0.000 2 |

| B2 | 7.84 | 0.026 5 | 4.45 | 0.072 8 |

| C2 | 19.54 | 0.003 1 | 0.055 | 0.821 3 |

| 失拟误差 Lack of fit | 1.66 | 0.310 4 | 0.684 | 0.606 8 |

试验序号 No. | 风速 Wind speed | 纵向幅宽 Longitudinal width | ||||

|---|---|---|---|---|---|---|

预测值 Predictive value/(m·s-1) | 试验值 Actual value/ (m·s-1) | 相对误差 Relative error/% | 预测值 Predictive value/mm | 试验值 Predictive value/mm | 相对误差 Relative error/% | |

| 1 | 9.25 | 8.84 | 4.63 | 1 575 | 1 650 | 4.55 |

| 2 | 9.37 | 1.28 | 1 620 | 2.78 | ||

| 3 | 9.15 | 1.09 | 1 610 | 2.17 | ||

| 平均Mean | 9.12 | — | 1 627 | — | ||

Table 4 Predicted and tested values of wind speed and longitudinal width optimization mode

试验序号 No. | 风速 Wind speed | 纵向幅宽 Longitudinal width | ||||

|---|---|---|---|---|---|---|

预测值 Predictive value/(m·s-1) | 试验值 Actual value/ (m·s-1) | 相对误差 Relative error/% | 预测值 Predictive value/mm | 试验值 Predictive value/mm | 相对误差 Relative error/% | |

| 1 | 9.25 | 8.84 | 4.63 | 1 575 | 1 650 | 4.55 |

| 2 | 9.37 | 1.28 | 1 620 | 2.78 | ||

| 3 | 9.15 | 1.09 | 1 610 | 2.17 | ||

| 平均Mean | 9.12 | — | 1 627 | — | ||

| 1 | 华经产业研究院. 2022-2027年中国水果行业市场全景评估及投资方向研究报告[R].华经情报网,2021. |

| 2 | 丁素明,傅锡敏,薛新宇,等.低矮果园自走式风送喷雾机研制与试[J].农业工程学报,2013,29(15): 18-25. |

| DING S M, FU X M, XUE X Y, et al.. Development and test of self-propelled air supply sprayer for low orchard [J]. Chin. Soc. Agric. Eng., 2013,29(15) : 18-25. | |

| 3 | 边永亮,李建平,薛春林,等.单旋翼油动无人机与圆形果园风送喷雾机作业性能对比试验研究[J].中国农业大学学报,2020,25(12):134-141. |

| BIAN Y L, LI J P, XUE C L, et al.. Comparative experimental study on operation performance of single rotor oil powered UAV and round orchard air delivery sprayer [J]. J. China Agric. Univ., 2020,25(12):134-141. | |

| 4 | 周良富,薛新宇,周立新,等.果园变量喷雾技术研究现状与前景分析[J].农业工程学报,2017,33(23):80-92. |

| ZHOU L F, XUE X Y, ZHOU L X, et al.. The present situation and prospect analysis of the variable spray technology in orchard [J]. Chin. Soc. Agric. Eng., 2017,33(23):80-92. | |

| 5 | 翟长远,赵春江,王秀,等.果园风送喷雾精准控制方法研究进展[J].农业工程学报,2018,34(10):1-15. |

| ZHAI C Y, ZHAO C J, WANG X, et al.. Research progress on precision control method of air-fed spraying in orchard [J]. Chin. Soc. Agric. Eng., 2018,34(10) : 1-15. | |

| 6 | KHO L R, EHSANI R, MAJA J M J, et al.. Evaluation of deposition and coverage by an air-assisted sprayer and two air-blast sprayers in a citrus orchard [J]. Tran. ASABE, 2014, 57(4): 1007-1013. |

| 7 | 窦汉杰,翟长远,陈立平,等.果园风送喷雾风力调控方法研究进展[J].农机化研究,2021,43(7):10-18. |

| DOU H J, ZHAI C Y, CHEN L P, et al.. Research progress on wind control methods of air spraying in orchards [J]. Agric. Mech. Res., 201,43(7):10-18 | |

| 8 | 傅锡敏,吕晓兰,丁为民.我国果园植保机械现状与技术需求[J].新疆农机化,2011(1):61-63. |

| FU X M, LYU X L, DING W M, et al.. Current situation and technical demand of orchard plant protection machinery in China [J]. J. Xinjiang Agric. Mech., 2011(1):61-63. | |

| 9 | BIOCCA M, GALLO P. Comparison between horizontal and vertical lamellate patentors for air-blast sprayers [J]. J. Open Agric., 2014, 8(1)12-17. |

| 10 | VAN ZYL J G, GROUT T G, SCHUTTE G C, et al.. Reduced volume spray application in south african citrus orchards: effects on deposition quantity, quality and uniformity [J]. Julius-Kühn-Archiv., 2015 (448): 51-52. |

| 11 | PERGHER G, GUBIANI R, CIVIDINO S R S, et al.. Assessment of spray deposition and recycling rate in the vineyard from a new type of air-assisted tunnel sprayer [J]. Crop Protection, 2013, 45: 6-14. |

| 12 | 戴奋奋.风送喷雾机风量的选择与计算[J].植物保护,2008(6):124-127. |

| DAI F F. Selection and calculation of air volume of air supply sprayer [J]. Plant Prot., 2008(6):124-127. | |

| 13 | 荀露,李君,陆华忠,等.多风筒风送喷雾系统的设计与试验[J].农机化研究,2020,42(8):186-191. |

| XUN L, LI J, LU H Z, et al.. Design and experiment of multi-duct air delivery spray system [J]. Agric. Mech. Res., 2020,42(8):186-191. | |

| 14 | 龚曙光,徐珊,刘黎明,等.风筒内结构对风送式喷雾机效率的影响[J].南方农机,2021,52(22):9-13. |

| DONG S G, XU S, LIU L M, et al.. lnfluence of the inner structure of air duct on the efficiency of air-blast sprayer [J]. China Southern Agric. Mach., 2021,52(22):9-13. | |

| 15 | 魏新华,邵菁,解禄观,等.棉花分行冠内冠上组合风送式喷杆喷雾机设计与试验[J].农业机械学报,2016,47(1):101-107. |

| WEI X H, SHAO J, XIE L G, et al.. Design and test of a combined air-blast spray-rod sprayer for cotton branch crown [J]. Trans. Chin. Soc. Agric. Mach., 2016,47(1) : 101-107. | |

| 16 | JADAV C V, JAIN K K, KHOFIFAH B C. Spray of chemicals as affected by different parameters of air assisted sprayer: a review [J]. J. Cur. Agric. Res., 2019, 7(3): 289 |

| 17 | GARECA C, MOLTO E, CUICA P. Spray pesticide applications in Mediterranean citrus orchards: Canopy deposition and off-target losses [J]. Sci. Total Environ., 2017, 599: 1344-1362. |

| 18 | 韩占忠,王敬,兰小平.Fluent流体工程仿真计算实例与分析[M]北京:北京理工大学出版社,2010:1-321. |

| 19 | 崔志华,傅泽田,祁力钧,等.风送式喷雾机风筒结构对飘移性能的影响[J].农业工程学报,2008(2):111-115. |

| CUI X H, FU Z T, QI L J, et al.. The influence of the structure of the air duct on the drift performance of the air-driven Sprayer [J]. Chin. Soc. Agric. Eng., 2008(2):111-115. | |

| 20 | 边永亮,李建平,杨欣,等.果园多风机风送喷雾机聚风筒聚风特性的试验研究[J].中国农业大学学报,2022,27(5):39-50. |

| BIAN Y L, LI J P, YANG X, et al.. Experimental study on wind collecting characteristics of multi-fan air-supply sprayer in Orchard [J]. J. China Agric. Univ., 2022,27(5) : 39-50. | |

| 21 | 李建平,边永亮,霍鹏,等. 喷雾机风送式环形喷管喷雾装置设计与试验优化[J].农业机械学报,2021,52(9):79-88. |

| LI J P, BIAN Y L, HU P, et al.. Design and experimental optimization of the spray device of the air-driven annular nozzle of the sprayer [J]. Trans. Chin. Soc. Agric. Mach., 2021,52(9) : 79-88. | |

| 22 | 向浩.兰兴欣.于磊.基于SolidWorks软件的风扇自然风模拟仿真分析的研究[J].中国机械,2014(17):218 |

| XIANG H, LAN X X, YU L. Study on simulation and analysis of Fan natural wind based on SolidWorks software [J]. Chin. Mach., 2014(17) : 218 | |

| 23 | 徐奕蒙,李守藏,刘志杰,等.风扇组对气流速度场影响CFD仿真及验证[J].农机化研究,2019,41(10):7-14. |

| XU Y M, LI S C, LIU Z J, et al.. CFD Simulation and verification of the influence of fan groups on the airflow velocity field [J]. Agric. Mech. Res., 2019,41(10) : 7-14. |

| [1] | Xiuying ZHAO, Qingwen HUANG, Haojie CAO, Jie WANG, Ruijiao LI, Dongxia NIE, Zheng HAN, Zhihui ZHAO. Optimization of Liquid Culture Conditions for the Production of Deoxynivalenol and Its Derivatives by Fusarium graminearum Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 222-233. |

| [2] | Yilin YANG, Junxiong DING, Xiaohua WU, Peng WANG, Dongliang SUN, Xinyao YU, Zhentao ZHANG, Dong LI. Optimization of Hot-air Drying Process Parameters of Lentinus edodes Based on Response Surface [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 154-164. |

| [3] | Kaiqiang WANG, Xue YANG, Changfeng LI, Xiao DUAN, Qing PENG, Yu QIAO, Bo SHI. Optimization of Glyceollins Synthesis Condition Induced by Xylooligosaccharides Based on Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2022, 24(10): 208-217. |

| [4] | GUO Huihui, LIN Congfa, JIANG Yuanbin, LI Zhigang. Optimization of Protocorm Proliferation Medium of Dendrobium huoshanense by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2020, 22(3): 173-180. |

| [5] | LIANG Zhaochao, GUO Xianwei, SONG Yanjuan, MA Tianfu, WANG Feng, WANG Liyan, JING Ruiyong*. Extraction Process of Polysaccharide in Agaricus bisporus Optimized by Response Surface Method and Its Antioxidant Activity in vitro [J]. Journal of Agricultural Science and Technology, 2019, 21(8): 161-168. |

| [6] | WU Qi1,2,3§, ZHANG Yuhui1,2§, SU Rongrong1,2, SUN Bo1,3, WU Qiuyun1,2, XIA Zhilan1,2*. Optimization of Submerged Fermentation Medium of Agaricus blazei Murrill for Mycelial Biomass Accumulation Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2019, 21(3): 152-160. |

| [7] | DAI Yangjun1, HU Jian1,2, ZHOU Ying2, ZUO Bo1, SHI Yixue1. Optimization of Compound Enzymolysis Process of Dried Figs by Plackett-Burman Design and Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2018, 20(7): 146-153. |

| [8] | CHEN Jine, LIU Hui, ZHAO Zhigang, ZHANG Hairong*. Optimization of Ultrasound-assisted Extraction of Panax notoginseng Root Polysaccharides Using Response Surface Methology [J]. Journal of Agricultural Science and Technology, 2018, 20(4): 138-146. |

| [9] | CHEN Xinyao, DONG Xing, CHEN Jingjie, QIN Tao, LI Jian*, HUANG Yifan*. Optimization of Extraction Process for Crude Polysaccharide from Hericium Erinaceus by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2017, 19(3): 131-136. |

| [10] | XU Lan1, ZHANG Peng-fei1, LEI Li-xia1, ZHANG Hai-rong2, WANG Chuang-yun3. A Microwave-assisted Procedure for the Extraction Polysaccharide from Evodia rutaecarpa Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2016, 18(4): 174-180. |

| [11] | XIONG Xia-yu, ZENG Xin-an*| WANG Man-sheng, ZHANG Zhi-hong. Studies on Optimization of Extraction Technology Assisted by Pulsed Electric Field of Total Flavonolds from Rape Pollen Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2015, 17(5): 88-93. |

| [12] | XIN Chongbo, ZI Lihan, LIU Chenguang, BAI Fengwu*. Response Surface Methodology Application for Optimizing Corncobs Pretreatment Conditions During Simultaneous Saccharification and Ethanol Fermentation [J]. , 2013, 15(5): 173-180. |

| [13] | WANG Jin-ling1, LIU Xiao-ping2, GAO Wei-hua1, ZHAO Feng-yan3, LV Chang-shan3. Medium Optimization for Phosphate-solubilizing Bacteria Bacillus Megaterium in Submerged Fermentation [J]. , 2013, 15(2): 185-192. |

| [14] | WANG Liang1,2, LI Shu1,2, MAO Zhonggui1,2*, ZHAO Fulin3. Optimization of Fermentation Medium for εPolylysine Production by Recombinant Streptomyces sp. FEEL1 [J]. , 2013, 15(1): 76-83. |

| [15] | ZHANG Ning, LIU Shuang, LIU Donglian*. Studies on Preparation of Levulinic Acid from Peanut Shells with Synergistic Hydrolysis of Ultrasonic Pretreatment and Solid Acid [J]. , 2013, 15(1): 164-169. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号