Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (2): 89-98.DOI: 10.13304/j.nykjdb.2023.0635

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Changlong FENG( ), Chunguang HUANG(

), Chunguang HUANG( ), Chenyang NING, Shuping LI, Kejin CHEN

), Chenyang NING, Shuping LI, Kejin CHEN

Received:2023-08-23

Accepted:2023-11-16

Online:2025-02-15

Published:2025-02-14

Contact:

Chunguang HUANG

通讯作者:

黄春光

作者简介:冯长龙E-mail:changlong_feng0919@126.com;

基金资助:CLC Number:

Changlong FENG, Chunguang HUANG, Chenyang NING, Shuping LI, Kejin CHEN. Optimization of Performance and Characteristics of Spiral Drill Bit Excavation Mechanism for Planting Machine[J]. Journal of Agricultural Science and Technology, 2025, 27(2): 89-98.

冯长龙, 黄春光, 宁辰阳, 李树平, 陈科锦. 植树机挖坑机构螺旋式钻头性能特性优化研究[J]. 中国农业科技导报, 2025, 27(2): 89-98.

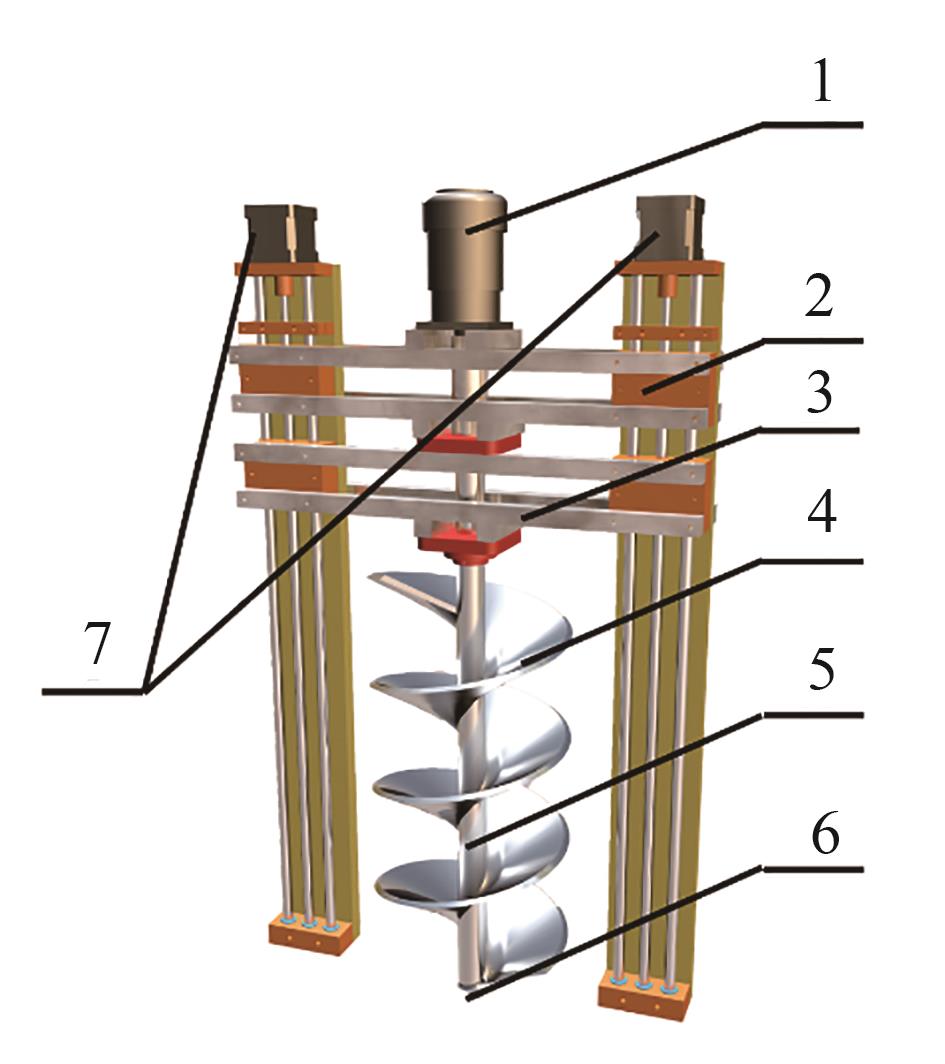

Fig. 1 3D model of excavation mechanismNote:1—Trenching motor;2—Slider;3—Slider beam support;4—Helical airfoil;5—Drill pipe;6—Drill bit;7—Dual translation motor.

材料 Material | 泊松比 Poisson ratio | 剪切模量 Shear modulus/Pa | 密度 Density/(kg·m-3) |

|---|---|---|---|

石砾 Gravel | 0.30 | 2.4×1010 | 2550 |

土壤 Soil | 0.38 | 1×106 | 1850 |

不锈钢 Stainless steel | 0.30 | 7.4×1010 | 7750 |

Table 1 Material parameters[20-24]

材料 Material | 泊松比 Poisson ratio | 剪切模量 Shear modulus/Pa | 密度 Density/(kg·m-3) |

|---|---|---|---|

石砾 Gravel | 0.30 | 2.4×1010 | 2550 |

土壤 Soil | 0.38 | 1×106 | 1850 |

不锈钢 Stainless steel | 0.30 | 7.4×1010 | 7750 |

接触 Contact | 静摩擦系数 Static friction coefficient | 滚动摩擦系数 Rolling friction coefficient | 恢复系数 Restitution coefficient |

|---|---|---|---|

土壤颗粒间 Between soil particles | 0.83 | 0.25 | 0.65 |

石砾颗粒间 Between gravel particles | 0.45 | 0.05 | 0.15 |

土壤与石砾 Soil and gravel | 0.45 | 0.2 | 0.65 |

不锈钢与土壤 Stainless steel and soil | 0.5 | 0.3 | 0.1 |

不锈钢与石砾 Stainless steel and gravel | 0.5 | 0.01 | 0.2 |

Table 2 Contact parameters[20-24]

接触 Contact | 静摩擦系数 Static friction coefficient | 滚动摩擦系数 Rolling friction coefficient | 恢复系数 Restitution coefficient |

|---|---|---|---|

土壤颗粒间 Between soil particles | 0.83 | 0.25 | 0.65 |

石砾颗粒间 Between gravel particles | 0.45 | 0.05 | 0.15 |

土壤与石砾 Soil and gravel | 0.45 | 0.2 | 0.65 |

不锈钢与土壤 Stainless steel and soil | 0.5 | 0.3 | 0.1 |

不锈钢与石砾 Stainless steel and gravel | 0.5 | 0.01 | 0.2 |

水平 Level | A:切刀刃角 Cutting edge angle/(°) | B:螺旋翼片升角 Helical airfoil lift angle/(°) | C:转速 Rotational speeds/ (r·min-1) |

|---|---|---|---|

| -1 | 30 | 10 | 140 |

| 0 | 45 | 20 | 160 |

| 1 | 60 | 30 | 180 |

Table 3 Experimental factor levels

水平 Level | A:切刀刃角 Cutting edge angle/(°) | B:螺旋翼片升角 Helical airfoil lift angle/(°) | C:转速 Rotational speeds/ (r·min-1) |

|---|---|---|---|

| -1 | 30 | 10 | 140 |

| 0 | 45 | 20 | 160 |

| 1 | 60 | 30 | 180 |

编号 Code | 因素水平Factor level | M:阻力矩 Resistance torque/(N·m) | ||

|---|---|---|---|---|

A:切刀刃角 Cutting edge angle | B:螺旋翼片升角 Helical airfoil lift angle | C:转速 Rotational speeds | ||

| 1 | -1 | -1 | 0 | 685.475 |

| 2 | 1 | -1 | 0 | 681.554 |

| 3 | -1 | 1 | 0 | 278.468 |

| 4 | 1 | 1 | 0 | 289.596 |

| 5 | -1 | 0 | -1 | 376.185 |

| 6 | 1 | 0 | -1 | 365.417 |

| 7 | -1 | 0 | 1 | 379.904 |

| 8 | 1 | 0 | 1 | 397.908 |

| 9 | 0 | -1 | -1 | 715.795 |

| 10 | 0 | 1 | -1 | 290.69 |

| 11 | 0 | -1 | 1 | 686.357 |

| 12 | 0 | 1 | 1 | 290.833 |

| 13 | 0 | 0 | 0 | 366.207 |

| 14 | 0 | 0 | 0 | 366.207 |

| 15 | 0 | 0 | 0 | 366.207 |

| 16 | 0 | 0 | 0 | 366.207 |

| 17 | 0 | 0 | 0 | 366.207 |

Table 4 Test protocol and results

编号 Code | 因素水平Factor level | M:阻力矩 Resistance torque/(N·m) | ||

|---|---|---|---|---|

A:切刀刃角 Cutting edge angle | B:螺旋翼片升角 Helical airfoil lift angle | C:转速 Rotational speeds | ||

| 1 | -1 | -1 | 0 | 685.475 |

| 2 | 1 | -1 | 0 | 681.554 |

| 3 | -1 | 1 | 0 | 278.468 |

| 4 | 1 | 1 | 0 | 289.596 |

| 5 | -1 | 0 | -1 | 376.185 |

| 6 | 1 | 0 | -1 | 365.417 |

| 7 | -1 | 0 | 1 | 379.904 |

| 8 | 1 | 0 | 1 | 397.908 |

| 9 | 0 | -1 | -1 | 715.795 |

| 10 | 0 | 1 | -1 | 290.69 |

| 11 | 0 | -1 | 1 | 686.357 |

| 12 | 0 | 1 | 1 | 290.833 |

| 13 | 0 | 0 | 0 | 366.207 |

| 14 | 0 | 0 | 0 | 366.207 |

| 15 | 0 | 0 | 0 | 366.207 |

| 16 | 0 | 0 | 0 | 366.207 |

| 17 | 0 | 0 | 0 | 366.207 |

来源 Source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean squares | F | P | 显著性 Significance |

|---|---|---|---|---|---|---|

模型 Model | 3.88×105 | 9 | 4.31×104 | 506.71 | < 0.000 1 | ** |

| A | 26.08 | 1 | 26.08 | 0.31 | 0.596 9 | |

| B | 3.28×105 | 1 | 3.28×105 | 3 857.29 | < 0.000 1 | ** |

| C | 5.98 | 1 | 5.98 | 0.07 | 0.798 5 | |

| AB | 56.62 | 1 | 56.62 | 0.67 | 0.441 3 | |

| AC | 206.96 | 1 | 206.96 | 2.43 | 0.162 6 | |

| BC | 218.76 | 1 | 218.76 | 2.57 | 0.152 7 | |

| A2 | 2.37 | 1 | 2.37 | 0.03 | 0.872 1 | |

| B2 | 5.74×104 | 1 | 5.74×104 | 675.93 | < 0.000 1 | ** |

| C2 | 700.24 | 1 | 700.24 | 8.24 | 0.024 0 | * |

残差 Residual | 595.03 | 7 | 85.00 | |||

失拟项 Lack of fit | 595.03 | 3 | 198.34 | 2.33 | >0.050 0 | |

纯误差 Pure Error | 0 | 4 | 0 | |||

| R2 | 0.998 5 | |||||

调整R2 Adjusted R2 | 0.996 5 | |||||

Table 5 Variance analysis of regression model

来源 Source | 平方和 Sum of squares | 自由度 Freedom | 均方 Mean squares | F | P | 显著性 Significance |

|---|---|---|---|---|---|---|

模型 Model | 3.88×105 | 9 | 4.31×104 | 506.71 | < 0.000 1 | ** |

| A | 26.08 | 1 | 26.08 | 0.31 | 0.596 9 | |

| B | 3.28×105 | 1 | 3.28×105 | 3 857.29 | < 0.000 1 | ** |

| C | 5.98 | 1 | 5.98 | 0.07 | 0.798 5 | |

| AB | 56.62 | 1 | 56.62 | 0.67 | 0.441 3 | |

| AC | 206.96 | 1 | 206.96 | 2.43 | 0.162 6 | |

| BC | 218.76 | 1 | 218.76 | 2.57 | 0.152 7 | |

| A2 | 2.37 | 1 | 2.37 | 0.03 | 0.872 1 | |

| B2 | 5.74×104 | 1 | 5.74×104 | 675.93 | < 0.000 1 | ** |

| C2 | 700.24 | 1 | 700.24 | 8.24 | 0.024 0 | * |

残差 Residual | 595.03 | 7 | 85.00 | |||

失拟项 Lack of fit | 595.03 | 3 | 198.34 | 2.33 | >0.050 0 | |

纯误差 Pure Error | 0 | 4 | 0 | |||

| R2 | 0.998 5 | |||||

调整R2 Adjusted R2 | 0.996 5 | |||||

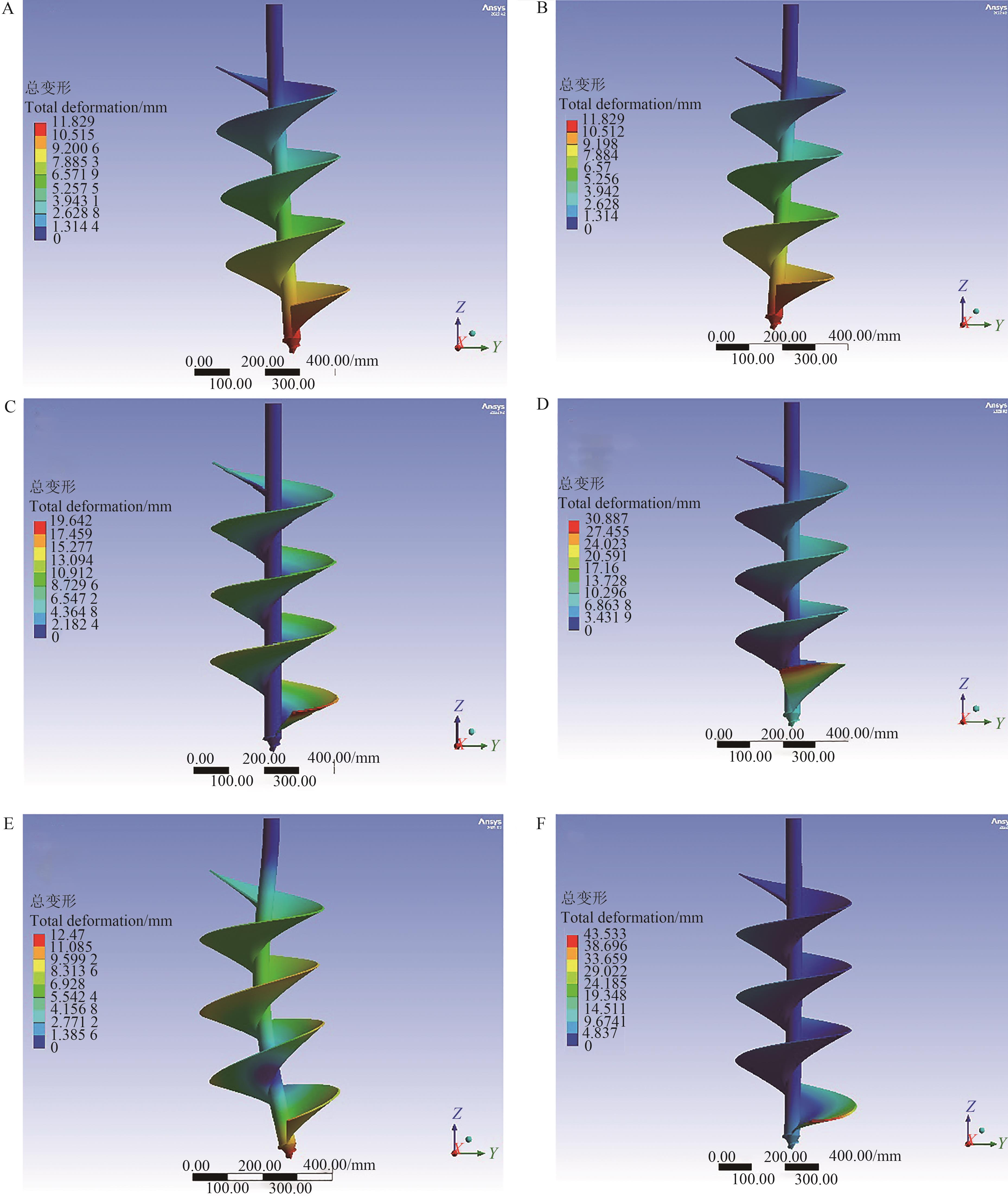

Fig. 10 Simulation of the first 6 vibration mode of the drill bitA: First vibration mode; B: Second vibration mode; C: Third vibration mode; D: Fourth vibration mode; E: Fifth vibration mode; F: Sixth vibration mode

阶数 Order | 固有频率 Natural frequency/Hz | 振型 Vibration mode |

|---|---|---|

| 1 | 23.792 | 在YZ平面弯曲Bend at YZ flat |

| 2 | 23.802 | 在YZ平面弯曲Bend at YZ flat |

| 3 | 84.936 | 绕Z轴扭曲Twist around the Z-axis |

| 4 | 129.630 | 绕Z轴扭曲Twist around Z-axis |

| 5 | 132.650 | 在YZ平面扭曲Bend at YZ flat |

| 6 | 141.840 | 在YZ平面扭曲Bend at YZ flat |

Table 6 Analysis of the first 6 orders of inherent frequency of the drill bit

阶数 Order | 固有频率 Natural frequency/Hz | 振型 Vibration mode |

|---|---|---|

| 1 | 23.792 | 在YZ平面弯曲Bend at YZ flat |

| 2 | 23.802 | 在YZ平面弯曲Bend at YZ flat |

| 3 | 84.936 | 绕Z轴扭曲Twist around the Z-axis |

| 4 | 129.630 | 绕Z轴扭曲Twist around Z-axis |

| 5 | 132.650 | 在YZ平面扭曲Bend at YZ flat |

| 6 | 141.840 | 在YZ平面扭曲Bend at YZ flat |

| 1 | ZONG W Y, WANG J L, HUANG X M, et al.. Development of a mobile powered hole digger for orchard tree cultivation using a slider-crank feed mechanism [J]. Int. J. Agric. Biol. Eng., 2016, 9(3):48-56. |

| 2 | 于建国,屈锦卫.国内外挖坑机的研究现状及发展趋势[J].农机化研究,2006(12):38-41. |

| YU J G, QU J W. Current research situation and development trend of earth auger in home and abroad [J]. J. Agric. Mech. Res., 2006, 28(12): 38-41. | |

| 3 | 陆建,缪明,卢少颖,等.车载植树挖坑机研究设计与试验[J].中国农机化学报,2014,35(06):44-47, 60. |

| LU J, MIAO M, LU S Y, et al.. Design and test research of digging machine for vehicle planting [J]. J. Chin. Agric. Mech., 2014, 35(6): 44-47, 60. | |

| 4 | 戚开钊,裴新民,靳范,等.MS310型多功能果园作业机挖坑部件的结构设计[J].新疆农机化,2012(2):14-16. |

| 5 | 魏忠彩,李洪文,孙传祝,等.基于多段分离工艺的马铃薯联合收获机设计与试验[J].农业机械学报,2019,50(1):129-140, 112. |

| WEI Z C, LI H W, SUN C Z, et al.. Design and experiment of potato combined harvester based on multi-stage separation technology [J]. Trans. Chin. Soc. Agric. Mach., 2019, 50(1): 129-140, 112. | |

| 6 | ZHANG T, DING X. Drilling forces model for lunar regolith exploration and experimental validation [J]. Acta Astronaut., 2017, 131: 190-203. |

| 7 | 熊良山,师汉民,陈永洁.钻头与钻削研究的历史、现状与发展趋势[J].工具技术,2005(8):11-14. |

| XIONG L S, SHI H M, CHEN Y J. History present situation and future trend of research on drill and drilling process [J]. Tool Eng., 2005(8):11-14. | |

| 8 | SU M. Research on the rapid development of the use and maintenance of earth auger [C]// Proceedings of 2016 International Conference on Economics, Social Science, Arts, Education and Management Engineering. Atlantis Press, 2016: 127-131. |

| 9 | 康杰,孙为云,周喜,等.国内外果木栽植机械研究现状及发展趋势[J].山东工业技术,2019(4):64-65. |

| 10 | 俞国胜,顾正平,钱桦,等.深栽造林钻孔机研制——钻尖结构参数与切刀刃角对钻孔阻力矩的影响[J].北京林业大学学报,2001,23(5):48-51. |

| YU G S, GU Z P, QIAN H, et al.. Deep planting earth auger making and its auger drill bits parameters research [J]. J. Beijing Forestry Univ., 2001, 23(5): 48-51. | |

| 11 | 赵静,朱建国,刘若宸,等.高效深栽牵引式植树机钻螺旋翼片的有限元分析[J].安徽农业科学,2012,40(11):6728-6730. |

| ZHAO J, ZHU J G, LIU R C, et al.. Finite element analysis of the Drill's Wing about efficient and deep planted machine [J]. J. Anhui Agric. Sci., 2012, 40(11):6728-6730. | |

| 12 | 郭贵生,樊相印,吴希锈,等.螺旋升角对钻头工作性能影响规律的研究[J].西北农业大学学报,1995,23(3):88-92. |

| GUO G S, FAN X Y, WU X X, et al.. Effect of screw angle on the screw anger work performance [J]. J. Northwest A&F Univ. (Nat. Sci.), 1995, 23(3):88-92. | |

| 13 | 任工昌,朱俊平,薛文灿,等.挖坑机钻头螺旋面强度分析及结构参数探讨[J].西北农业大学学报,1994,22(3):65-68. |

| REN G C, ZHU J P, XUE W C, et al.. Strength analysis of screw surface and structure parameters study of auger of mounted hole digger[J]. J. Northwest A&F Univ. (Nat. Sci.),1994,22(3):65-68. | |

| 14 | HUANG T, DU M, GU X, et al.. The influence of bit edge shape parameters on bone drilling force based on finite element analysis [J/OL]. Appl. Sci., 2022, 12(17): 8551 [2024-06-14]. . |

| 15 | WANG G F, ZHANG W, JI M, et al.. Numerical simulation and parameter optimization of earth auger in hilly area using EDEM software [J/OL]. Sci. Rep., 2022, 12(1): 19526 [2024-06-14]. . |

| 16 | 杨勇,梁尚明,贺亚博.一种手提式挖坑机的研究分析[J].机械设计与制造,2021(6):126-129. |

| YANG Y, LIANG S M, HE Y B. Research and analysis of a portable digging machine [J]. Mach. Design Manufacture, 2021(6):126-129. | |

| 17 | 蒋开苏.挖坑机钻头升土理论的研究──关于钻头临界速度的商榷[J].中南林学院学报,1997(3):71-75. |

| JIANG K S. A discussion on bit critical speed of hole diggers during soil lifting [J]. J. Central S. Univ. Forestry & Technol.,1997(3):71-75. | |

| 18 | 王宪良,胡红,王庆杰,等.基于离散元的土壤模型参数标定方法[J].农业机械学报,2017,48(12):78-85. |

| WANG X L, HU H, WANG Q J, et al.. Calibration method of soil contact characteristic parameters based on DEM theory [J]. Trans. Chin. Soc. Agric. Mach., 2017,48(12):78-85. | |

| 19 | SHMULEVICH I, ASAF Z, RUBINSTEIN D. Interaction between soil and a wide cutting blade using the discrete element method [J]. Soil Till. Res., 2007, 97(1):37-50. |

| 20 | 姜珊珊.基于离散元法的开沟器试验研究[D].长春:吉林农业大学,2014. |

| JIANG S S. Experimental research of furrow openers based on DEM [D]. Changchun: Jilin Agricultural University, 2014. | |

| 21 | QI J T, AN S G, KAN Z, et al.. Discrete element-based calibration of simulation parameters of Cyperus esculentus L. (tiger nut) planted in sandy soil [J/OL]. J. Food Process. Preservation, 2021,45(7):15631 [2024-06-14]. . |

| 22 | 武涛,黄伟凤,陈学深,等.考虑颗粒间黏结力的黏性土壤离散元模型参数标定[J].华南农业大学学报,2017,38(3):93-98. |

| WU T, HUANG W F, CHEN X S, et al.. Calibration of discrete element model parameters for cohesive soil considering the cohesion between particles [J]. J. South China Agric. Univ., 2017,38(3):93-98. | |

| 23 | 赵淑红,刘汉朋,侯磊涛,等.基于离散元法的免耕深施肥分段式玉米播种开沟器研制[J].农业工程学报,2021,37(13):1-10. |

| ZHAO S H, LIU H P, HOU L T, et al.. Development of deep fertilizing no-tillage segmented maize sowing opener using discrete element method [J]. Trans. Chin. Soc. Agric. Eng.,2021,37 (13):1-10. | |

| 24 | 靳成.基于EDEM的挖坑机钻头-土壤动力学仿真与试验研究[D].福州:福建农林大学,2022. |

| JIN C. Dynamics simulation and experimental investigation of earth auger bit-soil based on EDEM [D]. Fuzhou: Fujian Agriculture and Forestry University,2022. | |

| 25 | 陈健波,蒙海华,黄锦芬,等.丘陵地种植穴规格对尾巨桉生长的影响[J].广西林业科学,2015,44(3):276-278. |

| CHEN J B, MENG H H, HUANG J F, et al.. Effects of planting hole size on growth of Eucalyptus grandis × E. urophylla in hilly ground [J]. Guangxi Forestry Sci.,2015,44(3):276-278. | |

| 26 | 赵忠松,卢博友,王天赐.基于ANSYS的悬挂式挖坑机钻头静力学分析[J].农机化研究,2010,32(6):87-89, 113. |

| ZHAO Z S, LU B Y, WANG T C. Static analysis for the auger of mounted hole digger based on ANSYS [J]. J. Agric. Mech. Res., 2010,32(6),87-89, 113. | |

| 27 | 朱晓鹏,张纪鹏,程联军,等.基于ANSYS Workbench的某轻型货车车架轻量化设计[J]. 青岛大学学报(工程技术版),2014,29(3):70-76. |

| ZHU X P, ZHANG J P, CHEN L J, et al.. Research on lightweight design and optimization of a light duty truck frame based on ANSYS workbench [J]. J. Qingdao Univ. (Eng. Technol.), 2014,29(3)70-76. | |

| 28 | 郭超凡,李粤,姚德宇,等.仿生香蕉秸秆粉碎装置关键部件作业参数优化与试验[J].中国农机化学报,2022,43(1):93-100. |

| GUO C F, LI Y, YAO D Y, et al.. Optimization and experiment of operating parameters of key components of bionic banana straw crushing devices [J]. J. Chin. Agric. Mech., 2022,43(1):93-100. | |

| 29 | 刘春景,唐敦兵,郑加强,等.滴灌梯形迷宫滴头流道水力性能的响应曲面法优化[J].农业工程学报,2011,27(2):46-51. |

| LIU C J, TANG D B, ZHENG J Q, et al.. Optimization of hydraulic performance for drip irrigation trapezoidal labyrinth channel of emitter using response surface methodology [J]. Trans. Chin. Soc. Agric. Eng., 2011, 27(2): 46-51. | |

| 30 | ZHANG Y Y, KONG L Q, SHI J. Finite element analysis and structural optimization of mine man-car skip underframe [J]. Adv. Materials Res., 2013, 842:591-595. |

| [1] | Ruyan ZHANG, Shenhao LI, Qipeng ZHU, Taigang FENG, Hongbo LI, Zebing XING, Yu XIAN. Effect of Biochar Content on Physical and Mechanical Properties of Garden Greening Waste/polylactic Acid Composites [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 192-200. |

| [2] | Jingyi XI, Shuangqing WANG, Yitong BAI, Xiuli YAO, Bixuan HUANG, Qingyi LI, Liqing FAN, Shichen HUANG, Mingguo SUN. Study on Optimization of Processing Parameters Using Hermetia illucens Larva to Treat Food Waste by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 241-249. |

| [3] | Lijun FU, Xiaoyu LIN, Jianhua LIN, Huinan SHEN, Yongzhen WU. Research on Processing Technology and Shelf Life of Red Matsutake Beef Sauce [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 148-158. |

| [4] | Guoqiang DUN, Xingpeng WU, Xinxin JI, Fuli ZHANG, Wenyi JI, Yongzhen YANG. Simulation and Optimization of Soybean Plot Metering Device with Double Swing Plate [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 82-90. |

| [5] | Dongling LIU, Hao SI, Baojiang ZHENG, Yuhong ZHANG. Optimization of Enzyme Assisted-ultrasonic Extraction of Sinigrin in Thlaspi arvense Seeds by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 225-233. |

| [6] | Yuanhao HUANG, Lazhen QUAN, Guangfa HU, Wei QUAN, Fanggang SHI. Calibration of Discrete Element Contact Parameters for Various Materials and Soils with Different Moisture Content [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 98-109. |

| [7] | Lin CHEN, Nanhui YU, Lizong WANG, Jijun FAN, Gang LEI, Xiaopeng LIU, Long ZHOU, Jin ZHOU. Measurement of Contact Parameters and Discrete Element Simulation Calibration of Rice Bran and Broken Rice [J]. Journal of Agricultural Science and Technology, 2024, 26(2): 127-136. |

| [8] | Chun HUANG, Yue LI, Shiquan WEI, Yang GAO, Zihan WU, Qirun HUANG, Chenhui WEI. Design and Experiment of Double Shafts Banana Straw Crushing and Returning Machine with Different Rotational Directions [J]. Journal of Agricultural Science and Technology, 2024, 26(11): 97-106. |

| [9] | Xiuying ZHAO, Qingwen HUANG, Haojie CAO, Jie WANG, Ruijiao LI, Dongxia NIE, Zheng HAN, Zhihui ZHAO. Optimization of Liquid Culture Conditions for the Production of Deoxynivalenol and Its Derivatives by Fusarium graminearum Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 222-233. |

| [10] | Zitao MA, Zhihao ZHAO, Wei QUAN, Fanggang SHI, Chen GAO, Mingliang WU. Calibration of Discrete Element Parameter of Rice Stubble Straw Based on EDEM [J]. Journal of Agricultural Science and Technology, 2023, 25(11): 103-113. |

| [11] | Feixiang LI, Peng WANG, Yunfei WANG, Yuefeng GE, Kaiyi TANG, Dezhi LI. Calibration of Discrete Element Parameters of Corn Coated Seeds Based on Stacking Test [J]. Journal of Agricultural Science and Technology, 2022, 24(7): 97-107. |

| [12] | Jianwei YAN, Song WEI, Dongjun HU, Qihe LIU, Fuigui ZHANG. Parameter Calibration of Radish Seeds with Different Filling Particle Radius by DEM [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 119-128. |

| [13] | Kaiqiang WANG, Xue YANG, Changfeng LI, Xiao DUAN, Qing PENG, Yu QIAO, Bo SHI. Optimization of Glyceollins Synthesis Condition Induced by Xylooligosaccharides Based on Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2022, 24(10): 208-217. |

| [14] | QUAN Wei, WU Mingliang, GUAN Chunyun, LUO Haifeng. Experimental Study on the Shape Optimization of Soil Opener for Rapeseed Pot Seedling Transplanter [J]. Journal of Agricultural Science and Technology, 2021, 23(10): 97-106. |

| [15] | GUO Huihui, LIN Congfa, JIANG Yuanbin, LI Zhigang. Optimization of Protocorm Proliferation Medium of Dendrobium huoshanense by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2020, 22(3): 173-180. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号