Journal of Agricultural Science and Technology ›› 2022, Vol. 24 ›› Issue (4): 107-115.DOI: 10.13304/j.nykjdb.2020.0975

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles Next Articles

Nanrui TANG( ), Yong ZHOU(

), Yong ZHOU( ), Guozhong ZHANG, Fang LIANG, Huibin KE

), Guozhong ZHANG, Fang LIANG, Huibin KE

Received:2020-11-18

Accepted:2021-03-04

Online:2022-04-15

Published:2022-04-19

Contact:

Yong ZHOU

通讯作者:

周勇

作者简介:唐楠锐 E-mail:tnr@webmail.hzau.edu.cn;

基金资助:CLC Number:

Nanrui TANG, Yong ZHOU, Guozhong ZHANG, Fang LIANG, Huibin KE. Performance Simulation and Experiment of Stirred and Bunch Rice Seeding Device[J]. Journal of Agricultural Science and Technology, 2022, 24(4): 107-115.

唐楠锐, 周勇, 张国忠, 梁方, 柯烩彬. 搅种型孔式水稻穴播排种器的性能模拟与试验[J]. 中国农业科技导报, 2022, 24(4): 107-115.

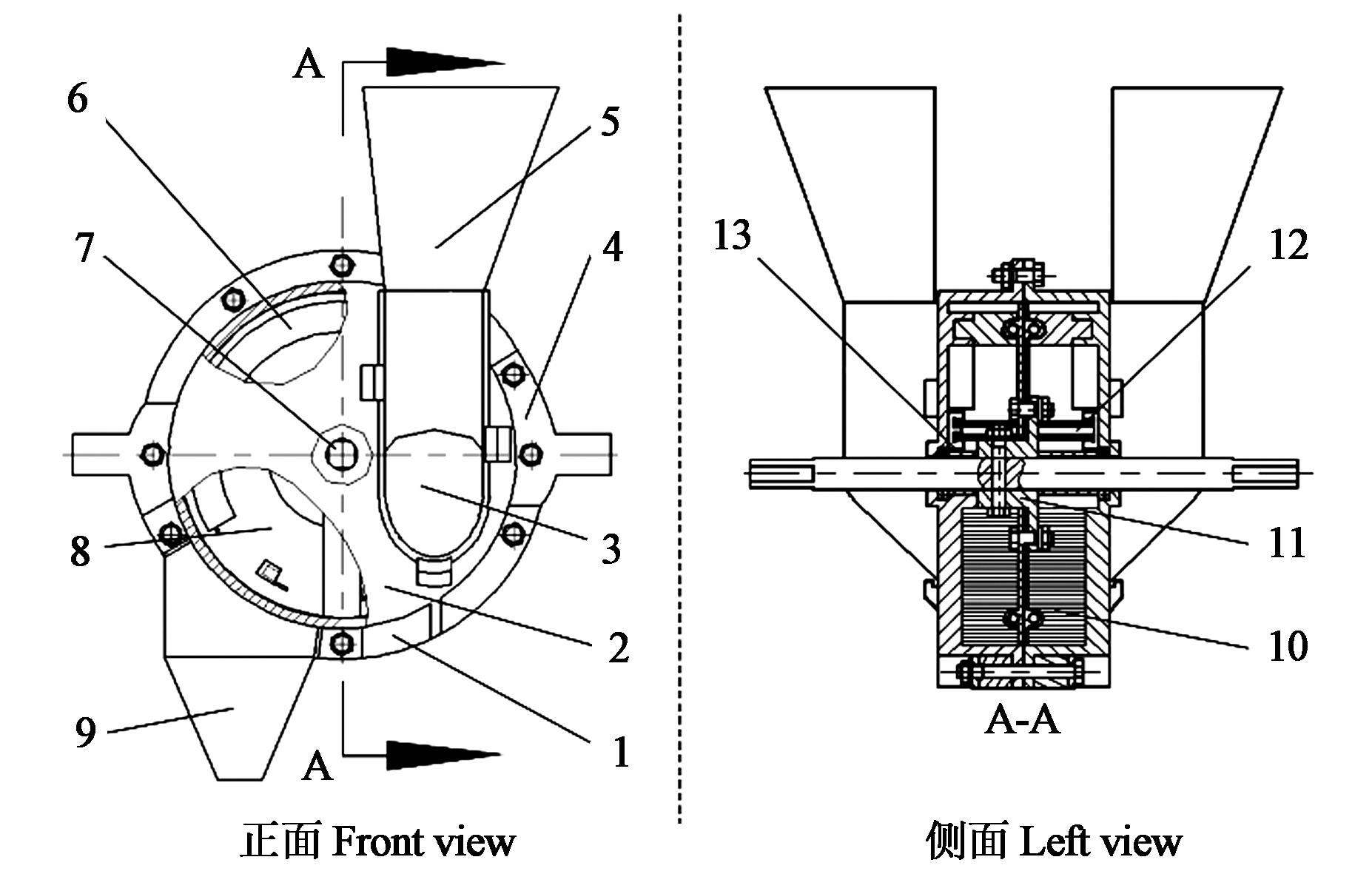

Fig. 1 Structure of seed metering deviceNote:1—Unload block; 2—Left and right shell; 3—Seeding tube; 4—Positioning bracket; 5—Seed box; 6—Seed protection area; 7—Seeding shaft; 8—Seeding plate; 9—Seeding mouth; 10—Barrier brush; 11—Flange plate; 12—Cleaning brush; 13—Axle sleeve.

| 项目Items | 泊松比Poisson’s ratio | 剪切模量Shear modulus/Pa | 密度Density/(kg·m-3) |

|---|---|---|---|

| 水稻种子Rice seed | 0.3 | 1.82×108 | 1 125 |

| 外壳shell | 0.5 | 1.77×108 | 1 180 |

| 种刷Brush | 0.4 | 1.00×108 | 1 150 |

Table 1 Material parameters

| 项目Items | 泊松比Poisson’s ratio | 剪切模量Shear modulus/Pa | 密度Density/(kg·m-3) |

|---|---|---|---|

| 水稻种子Rice seed | 0.3 | 1.82×108 | 1 125 |

| 外壳shell | 0.5 | 1.77×108 | 1 180 |

| 种刷Brush | 0.4 | 1.00×108 | 1 150 |

| 项目Item | 弹性恢复系数 Coefficient of restitution | 滑动摩擦系数 Coefficient of sliding friction | 滚动摩擦系数 Coefficient of rolling friction |

|---|---|---|---|

| 水稻种子Rice seed | 0.30 | 0.56 | 0.01 |

| 水稻-外壳Rice-shell | 0.50 | 0.50 | 0.01 |

| 种刷-水稻Brush-rice | 0.45 | 0.50 | 0.01 |

Table 2 Contact parameter between materials[14]

| 项目Item | 弹性恢复系数 Coefficient of restitution | 滑动摩擦系数 Coefficient of sliding friction | 滚动摩擦系数 Coefficient of rolling friction |

|---|---|---|---|

| 水稻种子Rice seed | 0.30 | 0.56 | 0.01 |

| 水稻-外壳Rice-shell | 0.50 | 0.50 | 0.01 |

| 种刷-水稻Brush-rice | 0.45 | 0.50 | 0.01 |

水平 Level | A:型孔深度 Hole depth/mm | B:排种盘转速 Rotation speed of seeding disc/(r·min-1) | C:种层高度 Seed layer height /mm |

|---|---|---|---|

| 1 | 7.0 | 30 | 50 |

| 2 | 6.8 | 25 | 45 |

| 3 | 6.6 | 20 | 40 |

Table 3 Test factor and level

水平 Level | A:型孔深度 Hole depth/mm | B:排种盘转速 Rotation speed of seeding disc/(r·min-1) | C:种层高度 Seed layer height /mm |

|---|---|---|---|

| 1 | 7.0 | 30 | 50 |

| 2 | 6.8 | 25 | 45 |

| 3 | 6.6 | 20 | 40 |

转速 Rotating speed /(r·min-1) | 漏播率 Leak seeding rate/% | 合格率 Pass rate/% | 重播率 Repeat seeding rate/% |

|---|---|---|---|

| 25 | 1.22 | 89.22 | 9.55 |

| 29 | 2.22 | 86.66 | 11.12 |

| 33 | 3.33 | 85.34 | 11.67 |

| 37 | 3.33 | 80.00 | 16.67 |

Table 4 Influence of rotational speed on the metering performance

转速 Rotating speed /(r·min-1) | 漏播率 Leak seeding rate/% | 合格率 Pass rate/% | 重播率 Repeat seeding rate/% |

|---|---|---|---|

| 25 | 1.22 | 89.22 | 9.55 |

| 29 | 2.22 | 86.66 | 11.12 |

| 33 | 3.33 | 85.34 | 11.67 |

| 37 | 3.33 | 80.00 | 16.67 |

试验号 Test number | A | B | C | 穴粒合格指数 Qualified rate of the hole number/% | 漏播指数 Seeding omission index/% | 穴距合格指数 Qualified rate of hole spacing/% |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 80.0 | 13.3 | 74.3 |

| 2 | 1 | 2 | 3 | 75.8 | 13.6 | 73.8 |

| 3 | 1 | 3 | 2 | 83.0 | 11.0 | 77.8 |

| 4 | 2 | 1 | 3 | 80.6 | 14.9 | 71.2 |

| 5 | 2 | 2 | 2 | 74.6 | 17.5 | 66.1 |

| 6 | 2 | 3 | 1 | 84.9 | 6.8 | 86.1 |

| 7 | 3 | 1 | 2 | 81.5 | 9.2 | 81.3 |

| 8 | 3 | 2 | 1 | 83.9 | 6.5 | 86.9 |

| 9 | 3 | 3 | 3 | 85.7 | 1.8 | 96.4 |

Table 5 Test scheme and results

试验号 Test number | A | B | C | 穴粒合格指数 Qualified rate of the hole number/% | 漏播指数 Seeding omission index/% | 穴距合格指数 Qualified rate of hole spacing/% |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 80.0 | 13.3 | 74.3 |

| 2 | 1 | 2 | 3 | 75.8 | 13.6 | 73.8 |

| 3 | 1 | 3 | 2 | 83.0 | 11.0 | 77.8 |

| 4 | 2 | 1 | 3 | 80.6 | 14.9 | 71.2 |

| 5 | 2 | 2 | 2 | 74.6 | 17.5 | 66.1 |

| 6 | 2 | 3 | 1 | 84.9 | 6.8 | 86.1 |

| 7 | 3 | 1 | 2 | 81.5 | 9.2 | 81.3 |

| 8 | 3 | 2 | 1 | 83.9 | 6.5 | 86.9 |

| 9 | 3 | 3 | 3 | 85.7 | 1.8 | 96.4 |

试验指标 Test index | 方差来源 Source of Variance | 离差平方和 Sum of squared deviations | 自由度 Degree of freedom | F | P |

|---|---|---|---|---|---|

穴粒合格指数 Qualified rate of the hole number | A | 30.442 | 2 | 3.28 | 0.234 |

| B | 62.842 | 2 | 6.77 | 0.129 | |

| C | 16.442 | 2 | 1.77 | 0.361 | |

| 误差Error | 9.282 | 2 | — | — | |

漏播指数 Seeding omission index | A | 98.749 | 2 | 52.65 | 0.019* |

| B | 74.209 | 2 | 37.97 | 0.026* | |

| C | 21.296 | 2 | 11.35 | 0.081 | |

| 误差Error | 1.876 | 2 | — | — | |

穴距合格指数 Qualified rate of hole spacing | A | 355.709 | 2 | 66.34 | 0.015* |

| B | 249.389 | 2 | 46.51 | 0.021* | |

| C | 87.296 | 2 | 16.28 | 0.058 | |

| 误差Error | 5.362 | 2 | — | — |

Table 6 Variance analysis result

试验指标 Test index | 方差来源 Source of Variance | 离差平方和 Sum of squared deviations | 自由度 Degree of freedom | F | P |

|---|---|---|---|---|---|

穴粒合格指数 Qualified rate of the hole number | A | 30.442 | 2 | 3.28 | 0.234 |

| B | 62.842 | 2 | 6.77 | 0.129 | |

| C | 16.442 | 2 | 1.77 | 0.361 | |

| 误差Error | 9.282 | 2 | — | — | |

漏播指数 Seeding omission index | A | 98.749 | 2 | 52.65 | 0.019* |

| B | 74.209 | 2 | 37.97 | 0.026* | |

| C | 21.296 | 2 | 11.35 | 0.081 | |

| 误差Error | 1.876 | 2 | — | — | |

穴距合格指数 Qualified rate of hole spacing | A | 355.709 | 2 | 66.34 | 0.015* |

| B | 249.389 | 2 | 46.51 | 0.021* | |

| C | 87.296 | 2 | 16.28 | 0.058 | |

| 误差Error | 5.362 | 2 | — | — |

| 1 | 张国忠,罗锡文,臧英,等.水稻芽种气力播种技术研究概况[C]//中国农业工程学会学术年会2011年学术年会论文集. 重庆:中国农业工程学会,2011. |

| 2 | 罗锡文,王在满,蒋恩臣,等.型孔轮式排种器弹性随动护种带装置设计[J].农业机械学报,2008,39(12):60-63. |

| LUO X W, WANG Z M, JIANG E C, et al.. Design of disassemble rubber guard device for cell wheel feed [J]. Trans. Chin. Soc. Agric. Machin., 2008, 39(12):60-63. | |

| 3 | 张国忠,臧英,罗锡文,等.水稻气力式排种器导向型搅种装置的设计与试验[J].农业工程学报,2013,29(12):1-8. |

| ZHANG G Z, ZANG Y, LUO X W, et al.. Design and experiment of oriented seed churning device on pneumatic seed metering device for rice [J]. Trans. Chin. Soc. Agric. Eng., 2013, 29(12):1-8. | |

| 4 | 张翔,杨然兵,尚书旗.内侧充种圆盘排种器防伤种装置的设计[J].农机化研究,2014,36(10):75-78. |

| ZHANG X, YANG R B, SHANG S Q. Design of the anti-injury device for the inside of the disc seeding device [J]. J. Agric. Mech. Res., 2014, 36(10):75-78.. | |

| 5 | 廖庆喜,张朋玲,廖宜涛,等.基于EDEM的离心式排种器排种性能数值模拟[J].农业机械学报,2014,45(2):109-114. |

| LIAO Q X, ZHANG P L, LIAO Y T, et al.. Numerical simulation on seeding performance of centrifugal rape-seed metering device based on EDEM [J]. Trans. Chin. Soc. Agric. Machin., 2014, 45(2):109-114.. | |

| 6 | 张涛,刘飞,赵满全,等.基于离散元的排种器排种室内玉米种群运动规律[J].农业工程学报,2016,32(22):27-35. |

| ZHANG T, LIU F, ZHAO M Q, et al.. Movement law of maize population in seed room of seed metering device based on discrete element method [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(22):27-35. | |

| 7 | 丛锦玲,廖庆喜,曹秀英,等.油菜小麦兼用排种盘的排种器充种性能[J].农业工程学报,2014,30(8):30-39. |

| CONG J L, LIAO Q X, CAO X Y, et al.. Seed filling performance of dual-purpose seed plate in metering device for both rapeseed & wheat seed [J]. Trans. Chin. Soc. Agric. Eng., 2014, 30(8):30-39. | |

| 8 | 张泽平,马成林.精播排种器及排种理论研究进展[J].吉林工业大学学报,1995,25(4):112-117. |

| ZHANG Z P, MA C L. The Development of the seed-metering device for precision planter and its theoretical study [J]. J. Jilin Univ. Technol., 1995, 25(4):112-117. | |

| 9 | 刘宏新.大豆密植平播机关键部件研究及整体设计[M]. 北京:中国农业出版社,2007:1-173. |

| LIU H X. Research on Key Components and whole design of soybean planting and planting machine [M]. Beijing: China Agricultural Press, 2007. | |

| 10 | 李兆东,王晴晴,张亚兰,等.倾斜抛物线型孔轮式小麦供种装置设计与试验[J].农业机械学报,2018,49(5):123-131. |

| LI Z D, WANG Q Q, ZHANG Y L, et al.. Design and experiment of inclined parabolic cell wheel in seed feeding device for wheat [J]. Trans. Chin. Soc. Agric. Mach., 2018, 49(5):123-131. | |

| 11 | 于恩中.水稻芽种物料特性的试验研究[D].长春:吉林农业大学,2004. |

| YU E Z. Experimental study on material characteristics of rice bud seeds [D]. Changchun: Jilin Agricultural University, 2004. | |

| 12 | 张国忠,张沙沙,杨文平,等.双腔侧充种式水稻精量穴播排种器的设计与试验[J].农业工程学报,2016,32(8):9-17. |

| ZHANG G Z, ZHANG S S, YANG W P, et al.. Design and experiment of double cavity side-filled precision hole seed metering device for rice [J]. Tran. Chin. Soc. Agric. Eng., 2016, 32(8):9-17. | |

| 13 | 王云霞,梁志杰,张东兴,等.基于离散元的玉米种子颗粒模型种间接触参数标定[J].农业工程学报,2016,32(22):36-42. |

| WANG Y X, LIANG Z J, ZHANG D X, et al.. Calibration method of contact characteristic parameters for corn seeds based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(22):36-42. | |

| 14 | 徐浩,陶栋材,陶韵晖,等.基于EDEM的水稻槽轮排种器排种仿真与试验研究[J].中国农业科技导报,2017,20(3):64-70. |

| XU H, TAO D C, TAO Y H, et al.. Simulation and experimental research on rice seed metering device based on EDEM [J]. J. Agric. Sci. Technol., 2017, 20(3):64-70. | |

| 15 | 杨兆文,刘星福,李问盈. 单粒(精密)播种机试验方法: [S].北京:中国标准出版社, 2005. |

| 16 | 李小利.勺式取种与活塞扎穴组合式水稻排种器研究[D].哈尔滨:东北农业大学,2018. |

| LI X L. Study on rice seed metering device with spoon-type seed collecting and piston hole-setting [D]. Harbin: Northeast Agricultural University, 2018. | |

| 17 | 陈福德.玉米精密排种器排种性能的试验研究[D].呼和浩特:内蒙古农业大学,2012. |

| CHEN F D. Experimental study on the seeding performance of corn precision seeder [D]. Hohhot: Inner Mongolia Agricultural University, 2012. | |

| 18 | 邢赫,王在满,罗锡文,等.气力式水稻穴播机播种精度与田间成苗率关系的试验研究[J].农业工程学报,2018, 34(336):50-56. |

| XING H, WANG Z M, LUO X W, et al.. Experimental study on relationship of seeding precision and germination rate in field of pneumatic rice hill-drop drilling planter [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(336):50-56. | |

| 19 | ZHANG G Z, YING Z, LUO X W, et al.. Design and indoor simulated experiment of pneumatic rice seed metering device [J]. Int. J. Agric. Biol. Eng., 2015, 8(4):10-18. |

| [1] | Tao YANG, Xiaoqian MA, Quan ZHANG, Hongliang ZHANG. Research Progress of Histone Modification in Rice [J]. Journal of Agricultural Science and Technology, 2022, 24(4): 11-20. |

| [2] | Linlin DONG, Jinfang ZHA, Mingxing SHEN, Haihou WANG, Linlin SHI, Yueyue TAO, Xinwei ZHOU, Changying LU. Effect of Long-term Straw Returning on Soil Organic Carbon Fractions Composition in Rice-Wheat Rotation Ecosystem [J]. Journal of Agricultural Science and Technology, 2022, 24(3): 166-175. |

| [3] | Zhenjia HE, Wangtao FAN, Yichun DU, Qilong WANG. Effects of Water and Fertilizer Coupling on the Physical and Chemical Properties of Rice Soil and Yield Based on Soil Organic Reconstruction [J]. Journal of Agricultural Science and Technology, 2022, 24(3): 176-185. |

| [4] | Hui XU, Yangyang ZHAO, Dongyue SUN, Yuanyuan KE, Lele ZHANG, Xiang CHEN, Fengzhen WEI, Jincai LI. Progress in Integrated Rice-crayfish Farming System [J]. Journal of Agricultural Science and Technology, 2022, 24(2): 160-168. |

| [5] | Xiaoqian MA, Tao YANG, Quan ZHANG, Hongliang ZHANG. Development Status and Prospect of Rice New Breeding Technology [J]. Journal of Agricultural Science and Technology, 2022, 24(1): 24-30. |

| [6] | HU Ting, QUAN Wei, WU Mingliang, LI Lin. Design and Experiment of Seed Channel Opener for Double Ridge Four Row Peanut Seeder [J]. Journal of Agricultural Science and Technology, 2021, 23(9): 129-137. |

| [7] | XI Min, XU Youzun, SUN Xueyuan, WU Wenge, ZHOU Yongjin. Effects of Nitrogen Fertilizer Topdressing on Grain Filling and Milling Quality of the Rice with High Grain Chalkiness [J]. Journal of Agricultural Science and Technology, 2021, 23(9): 144-151. |

| [8] | WU Zishuai, LI Hu, HUANG Qiuyao, CHEN Chuanhua, LUO Qunchang, ZHOU Xinmin, WU Jiaju, LIU Guanglin. Influences of Nitrogen Fertilizer Application Rate and Planting Density on the Yield and Rice Quality of Guiyu 11 [J]. Journal of Agricultural Science and Technology, 2021, 23(8): 154-162. |

| [9] | WENG Wenan, CHENG Shuang, LI Shaoping, TIAN Jinyu, TAO Yu, HU Qun, HU Yajie, GUO Baowei, WEI Haiyan, XING Zhipeng, ZHANG Hongcheng. Effects of One-off Nitrogen Basal Fertilization on Yield of Direct Seeding Conventional Japonica Rice Under Different Panicle Formation Types [J]. Journal of Agricultural Science and Technology, 2021, 23(8): 163-172. |

| [10] | JIANG Xuehai, LUO Deqiang, LI Min, JI Guangmei, JIANG Mingjin, LI Lijiang, Li Ganghua, ZHOU Weijia, ZHANG Jiafeng. Influences of Planting Density on Yield and Nitrogen Use Efficiency in New Indica Hybrid Rice Varieties by Bowl-Seedling-Mechanical-Transplanting [J]. Journal of Agricultural Science and Technology, 2021, 23(8): 173-184. |

| [11] | ZHOU Xuan, KANG Xingrong, PENG Jianwei, YANG Xiangdong, ZHONG Xuemei, HU Wenfeng, LONG Junyou. Effects of Reduction Application of Polyurethane Coated Urea on Growth, Yield and Economic Benefit of Double-cropping Early Rice [J]. Journal of Agricultural Science and Technology, 2021, 23(7): 153-161. |

| [12] | LUO Youyi, WANG Weiqin, ZHENG Huabin, LIU Gongyi, CHAO Ying, XU Cai, ZHENG Zhigang, LI Xueqian, WEI Yinlan, TANG Qiyuan. Influences of Different Mechanical and Orderly Planting Methods on Growth Characteristics and Yield of rice [J]. Journal of Agricultural Science and Technology, 2021, 23(7): 162-171. |

| [13] | LIU Yuan, ZHANG Xiuyan, XU Miaoyun, ZHENG Hongyan, ZOU Junjie, ZHANG Lan, WANG Lei. Global Small RNA Transcriptome Profiling of Rice Under Drought Stress [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 23-32. |

| [14] | LIU Dezhu, ZHOU Yong, ZHANG Guozhong, ZHANG Mengyue, KE Huibin, YANG Quanjun. Design and Experiment of Pneumatic Double-side Fertilizer Devices for Ratoon Rice [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 77-85. |

| [15] | JIANG Shukun, WANG Lizhi, YANG Xianli, CHI liyong, LI Zhongjie, LI Mingxian, ZHANG Xijuan, ZHAO Qian, LI Rui, JIANG Hui, LI Wenhua . Effect of Increasing Temperature in Different Growth Stages on Rice Yield and Quality in Cold Regions [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 130-139. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号