Journal of Agricultural Science and Technology ›› 2024, Vol. 26 ›› Issue (8): 112-121.DOI: 10.13304/j.nykjdb.2023.0029

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Xiuquan ZHANG( ), Wanping FENG, Jiawei WANG, Haiyan SONG, Decong ZHENG(

), Wanping FENG, Jiawei WANG, Haiyan SONG, Decong ZHENG( )

)

Received:2023-01-11

Accepted:2023-03-22

Online:2024-08-15

Published:2024-08-12

Contact:

Decong ZHENG

通讯作者:

郑德聪

作者简介:张秀全 E-mail:zhangxiuq1980@126.com;

基金资助:CLC Number:

Xiuquan ZHANG, Wanping FENG, Jiawei WANG, Haiyan SONG, Decong ZHENG. Design and Performance of a Kneading Threshing Device for Sorghum[J]. Journal of Agricultural Science and Technology, 2024, 26(8): 112-121.

张秀全, 冯晚平, 王嘉伟, 宋海燕, 郑德聪. 揉搓式高粱脱粒装置的设计与性能试验[J]. 中国农业科技导报, 2024, 26(8): 112-121.

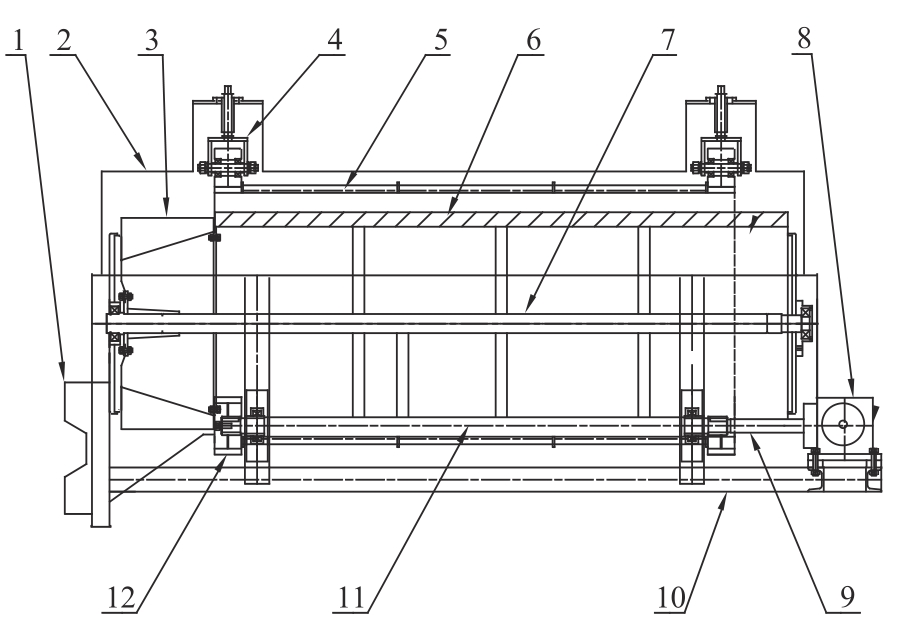

Fig. 1 Structure of kneading sorghum threshing deviceNote: 1—Feeding entrance; 2—Top cover; 3—Screw feeding device; 4—Grid roller pressing device; 5—Grid roller; 6—Rasp bar threshing roller;7—Threshing drum spindle; 8—Reducer; 9—Discharging gap;10—Machine frame; 11—Friction wheel drive shaft; 12—Friction wheel.

| 参数Parameter | 数值Value |

|---|---|

| 株高 Plant height/cm | 145~153 |

| 籽粒平均含水率 Grain average moisture content/% | 11.85 |

| 茎秆平均含水率/% Stem average moisture content/% | 40.04 |

| 谷草比 Grain to grass ratio | 1.34∶1.00 |

| 千粒重 Thousand weight/g | 22.6 |

Table 1 Main properties of buckwheat

| 参数Parameter | 数值Value |

|---|---|

| 株高 Plant height/cm | 145~153 |

| 籽粒平均含水率 Grain average moisture content/% | 11.85 |

| 茎秆平均含水率/% Stem average moisture content/% | 40.04 |

| 谷草比 Grain to grass ratio | 1.34∶1.00 |

| 千粒重 Thousand weight/g | 22.6 |

水平 Level | 因素 Factor | ||

|---|---|---|---|

x1:喂入量 Feed amount/(kg·s-1) | x2:纹杆滚筒转速 Rasp bar roller speed/(r·min-1) | x3:栅格滚筒转速 Grid roller speed/(r·min-1) | |

| +1.682 | 67.05 | 484.1 | 1.364 0 |

| +1 | +50.00 | 450.0 | 1.000 0 |

| 0 | +25.00 | 400.0 | 0.800 0 |

| -1 | 0 | 350.0 | 0.600 0 |

| -1.682 | 17.05 | 315.9 | 0.463 6 |

| Δ | 25.00 | 50.0 | 0.200 0 |

Table 2 Factor level

水平 Level | 因素 Factor | ||

|---|---|---|---|

x1:喂入量 Feed amount/(kg·s-1) | x2:纹杆滚筒转速 Rasp bar roller speed/(r·min-1) | x3:栅格滚筒转速 Grid roller speed/(r·min-1) | |

| +1.682 | 67.05 | 484.1 | 1.364 0 |

| +1 | +50.00 | 450.0 | 1.000 0 |

| 0 | +25.00 | 400.0 | 0.800 0 |

| -1 | 0 | 350.0 | 0.600 0 |

| -1.682 | 17.05 | 315.9 | 0.463 6 |

| Δ | 25.00 | 50.0 | 0.200 0 |

序号 Serial number | 因素水平Factor level | y1:夹带损失率Entrainment loss rate/% | y2:籽粒破碎率 Grain breakage rate/% | ||

|---|---|---|---|---|---|

x1:喂入量 Feed amount | x2:纹杆滚筒转速 Rasp bar roller speed | x3:栅格滚筒转速 Grid roller speed | |||

| 1 | 1 | 1 | 1 | 2.34 | 0.39 |

| 2 | 1 | 1 | -1 | 2.64 | 0.31 |

| 3 | 1 | -1 | 1 | 2.41 | 0.29 |

| 4 | 1 | -1 | -1 | 2.07 | 0.24 |

| 5 | -1 | 1 | 1 | 0.74 | 0.53 |

| 6 | -1 | 1 | -1 | 1.73 | 0.51 |

| 7 | -1 | -1 | 1 | 2.15 | 0.35 |

| 8 | -1 | -1 | -1 | 1.98 | 0.28 |

| 9 | 1.682 | 0 | 0 | 2.80 | 0.22 |

| 10 | -1.682 | 0 | 0 | 1.34 | 0.41 |

| 11 | 0 | 1.682 | 0 | 1.44 | 0.51 |

| 12 | 0 | -1.682 | 0 | 2.86 | 0.34 |

| 13 | 0 | 0 | 1.682 | 1.76 | 0.43 |

| 14 | 0 | 0 | -1.682 | 1.62 | 0.41 |

| 15 | 0 | 0 | 0 | 1.56 | 0.22 |

| 16 | 0 | 0 | 0 | 1.01 | 0.24 |

| 17 | 0 | 0 | 0 | 1.04 | 0.23 |

| 18 | 0 | 0 | 0 | 0.96 | 0.19 |

| 19 | 0 | 0 | 0 | 1.03 | 0.22 |

| 20 | 0 | 0 | 0 | 0.95 | 0.24 |

Table 3 Experimental plan and results

序号 Serial number | 因素水平Factor level | y1:夹带损失率Entrainment loss rate/% | y2:籽粒破碎率 Grain breakage rate/% | ||

|---|---|---|---|---|---|

x1:喂入量 Feed amount | x2:纹杆滚筒转速 Rasp bar roller speed | x3:栅格滚筒转速 Grid roller speed | |||

| 1 | 1 | 1 | 1 | 2.34 | 0.39 |

| 2 | 1 | 1 | -1 | 2.64 | 0.31 |

| 3 | 1 | -1 | 1 | 2.41 | 0.29 |

| 4 | 1 | -1 | -1 | 2.07 | 0.24 |

| 5 | -1 | 1 | 1 | 0.74 | 0.53 |

| 6 | -1 | 1 | -1 | 1.73 | 0.51 |

| 7 | -1 | -1 | 1 | 2.15 | 0.35 |

| 8 | -1 | -1 | -1 | 1.98 | 0.28 |

| 9 | 1.682 | 0 | 0 | 2.80 | 0.22 |

| 10 | -1.682 | 0 | 0 | 1.34 | 0.41 |

| 11 | 0 | 1.682 | 0 | 1.44 | 0.51 |

| 12 | 0 | -1.682 | 0 | 2.86 | 0.34 |

| 13 | 0 | 0 | 1.682 | 1.76 | 0.43 |

| 14 | 0 | 0 | -1.682 | 1.62 | 0.41 |

| 15 | 0 | 0 | 0 | 1.56 | 0.22 |

| 16 | 0 | 0 | 0 | 1.01 | 0.24 |

| 17 | 0 | 0 | 0 | 1.04 | 0.23 |

| 18 | 0 | 0 | 0 | 0.96 | 0.19 |

| 19 | 0 | 0 | 0 | 1.03 | 0.22 |

| 20 | 0 | 0 | 0 | 0.95 | 0.24 |

评价指标 Evaluation index | 变异来源 Sources of variation | 平方和 Sum of squares | 自由度 df | F值 F value | P值 P value |

|---|---|---|---|---|---|

y1:夹带损失率 Entrainment loss rate | 回归Regression | 7.62 | 8 | 14.36 | <0.000 1 |

| 剩余Residual | 0.73 | 11 | — | — | |

| 误差Error | 0.27 | 5 | — | — | |

| 总和 Cortotal | 8.35 | 19 | — | — | |

y2:籽粒破碎率 Grain breakage rate | 回归Regression | 0.22 | 7 | 38.55 | <0.000 1 |

| 剩余Residual | 0.009 6 | 12 | — | — | |

| 误差Error | 0.001 7 | 5 | — | — | |

| 总和Cortotal | 0.23 | 19 | — | — |

Table 4 Variance analysis of entrainment loss rate test results

评价指标 Evaluation index | 变异来源 Sources of variation | 平方和 Sum of squares | 自由度 df | F值 F value | P值 P value |

|---|---|---|---|---|---|

y1:夹带损失率 Entrainment loss rate | 回归Regression | 7.62 | 8 | 14.36 | <0.000 1 |

| 剩余Residual | 0.73 | 11 | — | — | |

| 误差Error | 0.27 | 5 | — | — | |

| 总和 Cortotal | 8.35 | 19 | — | — | |

y2:籽粒破碎率 Grain breakage rate | 回归Regression | 0.22 | 7 | 38.55 | <0.000 1 |

| 剩余Residual | 0.009 6 | 12 | — | — | |

| 误差Error | 0.001 7 | 5 | — | — | |

| 总和Cortotal | 0.23 | 19 | — | — |

评价指标 Evaluation index | 因素 factors | 平方和 Sum of squares | 自由度 Df | F值 F value | P值 P value |

|---|---|---|---|---|---|

y1:夹带损失率 Entrainment loss rate | x1 | 2.06 | 1 | 32.20 | 0.000 2** |

| x2 | 0.91 | 1 | 14.27 | 0.003 6** | |

| x3 | 0.02 | 1 | 0.33 | 0.580 5 | |

| x1x2 | 0.58 | 1 | 9.09 | 0.013 0* | |

| x1x3 | 0.09 | 1 | 1.39 | 0.265 6 | |

| x2x3 | 0.40 | 1 | 6.27 | 0.031 2* | |

| x12 | 1.69 | 1 | 26.32 | 0.000 4** | |

| x22 | 1.98 | 1 | 30.87 | 0.000 2** | |

| x32 | 0.63 | 1 | 9.76 | 0.010 8* | |

y2:籽粒破碎率 Grain breakage rate | x1 | 0.004 | 1 | 3.67 | 0.084 4 |

| x2 | 0.078 | 1 | 61.01 | <0.000 1** | |

| x3 | 0.042 | 1 | 32.91 | 0.000 2** | |

| x1x2 | 0.000 05 | 1 | 0.04 | 0.847 5 | |

| x1x3 | 0.000 2 | 1 | 0.16 | 0.701 3 | |

| x2x3 | 0.007 | 1 | 5.61 | 0.039 4* | |

| x12 | 0.050 | 1 | 38.57 | 0.000 1** | |

| x22 | 0.088 | 1 | 68.42 | <0.000 1** | |

| x32 | 0.006 | 1 | 5.18 | 0.046 0* |

Table 5 Variance analysis of Grain breakage rate test result

评价指标 Evaluation index | 因素 factors | 平方和 Sum of squares | 自由度 Df | F值 F value | P值 P value |

|---|---|---|---|---|---|

y1:夹带损失率 Entrainment loss rate | x1 | 2.06 | 1 | 32.20 | 0.000 2** |

| x2 | 0.91 | 1 | 14.27 | 0.003 6** | |

| x3 | 0.02 | 1 | 0.33 | 0.580 5 | |

| x1x2 | 0.58 | 1 | 9.09 | 0.013 0* | |

| x1x3 | 0.09 | 1 | 1.39 | 0.265 6 | |

| x2x3 | 0.40 | 1 | 6.27 | 0.031 2* | |

| x12 | 1.69 | 1 | 26.32 | 0.000 4** | |

| x22 | 1.98 | 1 | 30.87 | 0.000 2** | |

| x32 | 0.63 | 1 | 9.76 | 0.010 8* | |

y2:籽粒破碎率 Grain breakage rate | x1 | 0.004 | 1 | 3.67 | 0.084 4 |

| x2 | 0.078 | 1 | 61.01 | <0.000 1** | |

| x3 | 0.042 | 1 | 32.91 | 0.000 2** | |

| x1x2 | 0.000 05 | 1 | 0.04 | 0.847 5 | |

| x1x3 | 0.000 2 | 1 | 0.16 | 0.701 3 | |

| x2x3 | 0.007 | 1 | 5.61 | 0.039 4* | |

| x12 | 0.050 | 1 | 38.57 | 0.000 1** | |

| x22 | 0.088 | 1 | 68.42 | <0.000 1** | |

| x32 | 0.006 | 1 | 5.18 | 0.046 0* |

评价指标 Evaluation index | x1:喂入量 Feed amount | x2:纹杆滚筒转速 Rasp bar roller speed | x3:栅格滚筒转速 Grid roller speed |

|---|---|---|---|

| y1:夹带损失率Entrainment loss rate | 2.52 | 2.76 | 1.46 |

| y2:籽粒破碎率Grain breakage rate | 1.78 | 2.41 | 2.32 |

Table 6 Contribution rate of each factor to the test index

评价指标 Evaluation index | x1:喂入量 Feed amount | x2:纹杆滚筒转速 Rasp bar roller speed | x3:栅格滚筒转速 Grid roller speed |

|---|---|---|---|

| y1:夹带损失率Entrainment loss rate | 2.52 | 2.76 | 1.46 |

| y2:籽粒破碎率Grain breakage rate | 1.78 | 2.41 | 2.32 |

Fig. 6 Effect of double factors on entrainment loss rateA: Rasp bar roller speed and feed amount; B: Grid roller speed and feed amount; C: Grid roller speed and rasp bar roller speed

Fig. 7 Effect of double factors on kernel breakageA: Rasp bar roller speed and feed amount; B: Grid roller speed and feed amount; C: Grid roller speed and rasp bar roller speed

| 1 | 陈朝儒,王智,马强,等.甜高粱茎汁及茎渣同步糖化发酵工艺优化[J].农业工程学报.2016,32(3):253-258. |

| CHEN C R, WANG Z, MA Q, et al.. Optimization of ethanol production from bagasse and juice of sweet sorghum stem by simultaneous saccharification and fermentation [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(3): 253-258. | |

| 2 | 杨森,王石垒,张雷,等.甜高粱茎秆残渣生料多菌种固态发酵生产蛋白饲料[J].农业工程学报.2015,31(15):309-314. |

| YANG S, WANG S L, ZHANG L, et al.. Producing protein feedstuff by multiple strains solid-state fermentation with raw sweet sorghum stalk residue [J]. Trans. Chin. Soc. Agric. Eng., 2015, 31(15): 309-314. | |

| 3 | 韩立朴,马凤娇,谢光辉,等.甜高粱生产要素特征、成本及能源效率分析[J].中国农业大学学报,2012,17(6):62-75. |

| HAN L P, MA F J, XIE G H, et al.. Analysis of sweet sorghum’s characteristic of production factor, cost and energy efficiency [J]. J. China Agric. Univ., 2012,17(6): 62-75. | |

| 4 | CAO W X, SUN C, LIU R H, et al.. Comparison of the effects of five pretreatment methods on enhancing the enzymatic digestibility and ethanol production from sweet sorghum bagasse [J]. Bioresour. Technol., 2012, 111: 215-221. |

| 5 | 王家胜,王东伟,尚书旗,等. 4LZZ-1.0型小区稻麦联合收割机的研制及试验[J].农业工程学报,2016,32(18):19-25. |

| WANG J S, WANG D W, SHANG S Q, et al.. Development and experiment on 4LZZ-1.0 type plot grain combine [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(18): 19-25. | |

| 6 | 陈艳普,滕悦江,郭飞扬,等.联合收割机纵轴流脱粒系统研究进展[J].中国农机化学报,2019,40(9):13-19. |

| CHEN Y P, TENG Y J, GUO F Y, et al.. Research progress on longitudinal axial flow threshing system of combine harvester [J]. J. Chin. Agric. Mech., 2019, 40(9): 13-19. | |

| 7 | 孙志强,唐兴隆,贺桂春,等.高粱联合收割机改进试验与研究[J].农业开发与装备,2016(10):104-105. |

| SUN Z Q, TANG X L, HE G C, et al.. Experiment and research on improvement of sorghum combine [J]. Agric. Dev. Equip., 2016(10): 104-105. | |

| 8 | 滕悦江,金诚谦, 陈艳普,等. 稻麦联合收获机分段式脱粒装置设计与优化[J].农业工程学报,2020,36(12): 1-12. |

| TENG Y J, JIN C Q, CHEN Y P, et al.. Design and optimization of segmented threshing device of combine harvester for rice and wheat [J]. Trans. Chin. Soc. Agric. Eng., 2020,36(12): 1-12. | |

| 9 | 梁振伟,李耀明,赵湛,等.纵轴流联合收获机籽粒夹带损失监测方法及传感器研制[J].农业工程学报,2014,30(3):18-26. |

| LIANG Z W, LI Y M, ZHAO Z, et al.. Monitoring method and sensor for grain seoaration loss on axial flow combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2014, 30(3): 18-26. | |

| 10 | 钟挺,胡志超,顾峰玮,等.4LZ-1.0Q 型稻麦联合收获机脱粒清选部件试验与优化[J].农业机械学报,2012,43(10):76-81. |

| ZHONG T, HU Z C, GU F W, et al.. Optimization and experiment for threshing and cleaning parts of 4LZ-1.0Q cereal combine harvester [J]. Trans. Chin. Soc. Agric. Mach., 2012, 43(10): 76-81. | |

| 11 | 张东明,衣淑娟,陶桂香,等. 谷子轴流脱粒与分离试验台的研制[J].农业化研究,2019, 41(11): 62-67. |

| ZHANG D M, YI S J, TAO G X, et al.. Development of millet axial-flow threshing and separating test bed [J]. J. Agric. Mech. Res., 2019, 41(11): 62-67. | |

| 12 | 徐立章,李耀明,王成红,等.切纵流双滚筒联合收获机脱粒分离装置[J].农业机械学报,2014,45(2):105-108, 135. |

| XU L Z, LI Y M, WANG C H, et al.. A combinational threshing and separating unit of combine harvester with a transverse tangential and an axial rotor [J]. Trans. Chin. Soc. Agric. Mach., 2014, 45(2): 105-108, 135. | |

| 13 | 邸志峰,崔中凯,张华,等. 纹杆块与钉齿组合式轴流玉米脱粒滚筒的设计与试验[J]. 农业工程学报, 2018, 34(1):28-34. |

| DI Z F, CUI Z K, ZHANG H, et al.. Design and experiment of rasp bar and nail tooth combined axial flow corn threshing cylinder [J]. Trans. Chin. Soc. Agric. Eng., 2018, 34(1): 28-34. | |

| 14 | 侯守印,陈海涛.立式轴流大豆种子脱粒机参数优化[J].农业工程学报,2012, 28(5): 19-25. |

| HOU S Y, CHEN H T. Parameters optimization of vertical axial flow thresher for soybean breeding [J]. Trans. Chin. Soc. Agric. Eng., 2012, 28(5): 19-25. | |

| 15 | 郝玉伟,段斌,余永昌.室内大豆单株种子脱粒机设计[J].农业工程,2014,4(1):94-97. |

| HAO Y W, DUAN B, YU Y C. Design of indoor thresher for soybean sheller [J]. Agric. Eng., 2014, 4(1): 94-97. | |

| 16 | 李毅念,陈俊生,丁启朔,等.轴流式和切流式机械脱粒对稻谷损伤及加工品质的影响[J].农业工程学报,2017,33(15):41-48. |

| LI Y N, CHEN J S, DING Q S, et al.. Effects of axial flow and tangential flow mechanical threshing on rice damage and milling quality [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(15): 41-48. | |

| 17 | 李耀刚.一种高粱联合收获装置设计与试验[J].农业工程,2017,7(2):118-121. |

| LI Y G. Design and test on a kind of sorghum combined harvesting device [J]. Agric. Eng., 2017, 7(2): 118-121. | |

| 18 | 钱震杰,金诚谦,袁文胜,等. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J].吉林大学学报(工学版),2021,51(3):1121-1130. |

| QIAN Z J, JIN C Q, YUAN W S, et al.. Frictional impact dynamics model of threshing process between flexible teeth and grains [J]. J. Jilin Univ. (Eng. Tech.), 2021,51(3):1121-1130. | |

| 19 | 金诚谦,郭飞扬,徐金山.大豆联合收获机作业参数优化[J].农业工程学报,2019,35(13):10-22. |

| JIN C Q, GUO F Y, XU J S. Optimization of working parameters of soybean combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2019, 35(13): 10-22. | |

| 20 | 黄小娜,张卫国,党威龙,等.荞麦收获机械研究现状及发展趋势[J].农业机械,2018,850(10):65-71. |

| HUANG X N, ZHANG W G, DANG W L, et al.. Research status and development trend of buckwheat harvesting machinery [J]. Agric. Mach., 2018, 850(10): 154-156. | |

| 21 | 王金双,熊永森,徐中伟,等.纵轴流联合收获机关键部件改进设计与试验[J].农业工程学报,2017,33(10):25-31. |

| WANG J S, XIONG Y S, XU Z W, et al.. Improved design and test of key components for longitudinal axial flow combine harvester [J]. Trans. Chin. Soc. Agric. Eng., 2017, 33(10): 25-31. | |

| 22 | 唐忠,李耀明,梁振伟. 纵轴流脱粒装置水稻最佳脱粒分离参数预测与控制[J]. 农业工程学报,2016,32(22):70-76. |

| TANG Z, LI Y M, LIANG Z W. Optimal parameters prediction and control of rice threshing for longitudinal axial threshing apparatus [J]. Trans. Chin. Soc. Agric. Eng., 2016, 32(22): 70-76. | |

| 23 | 邓军,张琦,马兴,等. 脱粒机试验方法: [S].北京:中国标准出版社,2017. |

| 24 | 董殿文, 刘继明, 常智发,等. 高粱: [S]. 北京:中国标准出版社,2007. |

| 25 | 何冯光,邓干然,崔振德,等. 自走式木薯茎叶青贮饲料收获机作业性能研究[J]. 中国农业科技导报,2022,24(8):109-115. |

| HE F G, DENG G R, CUI Z D, et al.. Operating performance of self-propelled silage cassava stem and leaf harvester [J]. J. Agric. Sci. Technol., 2022, 24(8): 109-115. |

| [1] | Yu FENG, Shujin QIU, Xiangyang YUAN, Qingliang CUI, Zhiqiang JI. Research on Compression Mechanical Characteristics of Sorghum Grains [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 102-110. |

| [2] | Zhidan WANG, Jili LIU, Na WU. Effects of Fenlong Tillage on Photosynthetic Physiological Characteristics and Yield of Sweet Sorghum [J]. Journal of Agricultural Science and Technology, 2022, 24(1): 148-156. |

| [3] | CUI Jianghui§, YANG Puyuan§, CHANG Jinhua*. Identification and Expression Analysis Under Abiotic Stress of GRF Gene Family in Sorghum [J]. Journal of Agricultural Science and Technology, 2021, 23(4): 37-46. |

| [4] | WANG Zhiheng, YANG Xiuliu, ZOU Fang, HUANG Siqi, ZHOU Wuyan, XU Zhongwei, WEI Yuqing*. Effects of Salt and Drought Cross Stress on Germination and Physiological Characteristics of Sweet Sorghum Seeds [J]. Journal of Agricultural Science and Technology, 2021, 23(2): 37-49. |

| [5] | FAN Na, PENG Zhidong, BAI Wenbin*, ZHAO Jianwu. Influences of Microbial Agents on Soil Enzyme Activity and Sorghum Growth [J]. Journal of Agricultural Science and Technology, 2021, 23(2): 185-192. |

| [6] | HAO Zhenggang, ZHAO Huijun, WEI Yuqing*, ZENG Zhouqi, WANG Zhiheng. Physiological and Biochemical Responses of Sweet Sorghum to Cadmium Stress and Its Cadmium Accumulation [J]. Journal of Agricultural Science and Technology, 2021, 23(1): 30-42. |

| [7] | WANG Zhiheng, HUANG Siqi, ZOU Fang, YANG Xiuliu, WEI Yuqing*. Effects of Temperature and NaCl on Seed Germination and Seedling Antioxidant Enzyme Activities of Sweet Sorghum [J]. Journal of Agricultural Science and Technology, 2020, 22(9): 42-51. |

| [8] |

ZOU Fang, YANG Xiuliu, HUANG Siqi, WANG Zhiheng, WEI Yuqing*.

Effect of Exogenous Spermine on Growth and Physiological and Biochemical Indexes of Sweet Sorghum Seedlings

under Drought Stress

[J]. Journal of Agricultural Science and Technology, 2020, 22(4): 44-52.

|

| [9] | LIU Chenyang1, ZHANG Huijie2, XIN Xiangfei1*. Analysis of the Development Characteristics and Trends of Sorghum Industry in China [J]. Journal of Agricultural Science and Technology, 2020, 22(10): 1-9. |

| [10] | REN Fuli1,2, PAN Yinghong3, ZHANG Xiaoxiao2, PU Weijun2, MU Yongying3, LI Yubin2, ZHANG Hua1*, ZHU Li2*. Comprehensive Evaluation Method for Sorghum Salt Tolerance Based on Multilevel Phenotypic Analysis [J]. Journal of Agricultural Science and Technology, 2019, 21(6): 152-162. |

| [11] | OU Jiashun1,2, LIU Dawei1,2,3, LI Xu1,2,3, XIE Fangping1,2,3*, WANG Xiushan1,2, XIE Chao1,2. Design and Test of High Self-purification Threshing Device for Small Rice Combine Harvester [J]. Journal of Agricultural Science and Technology, 2017, 19(9): 63-69. |

| [12] | WANG Dong§, WANG Chen§, MA Le, LI Hanxiao, CHEN Jibao*. Establishment of Regeneration System Using Sweet Sorghum Seed as Explant [J]. Journal of Agricultural Science and Technology, 2017, 19(12): 119-125. |

| [13] | LI Xiao-dong, FANG Xian-fa, HAN Zeng-de*, ZHANG Zi-rui, LIU Gui-ming, CUI Jun-we. Dynamic Simulation of Sweet Sorghum Cutting Based on ANSYS/LS-DYNA [J]. , 2015, 17(3): 70-76. |

| [14] | HAN Yu\|cui1, YE Kai2, HOU Sheng\|lin1, TU Zhen\|dong2, LV Peng1, DU Rui\|heng1,. Progress on Molecular Biology of Salinity Tolerance in Sorghum [J]. , 2014, 16(4): 65-70. |

| [15] | LI Na-na1*, WU Qiu-ping2*, ZHANG Xiao-dong1, DONG Shu-ting2, LIU Peng2, ZHANG Ji. Studies on Correlation between Sugar Output and Dry Matter Production of 30 Sweet Sorghum Varieties [J]. , 2011, 13(4): 104-109. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号