中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (7): 101-110.DOI: 10.13304/j.nykjdb.2024.0052

• 智慧农业 农机装备 • 上一篇

奚小波( ), 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏(

), 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏( )

)

收稿日期:2024-01-19

接受日期:2024-05-09

出版日期:2025-07-15

发布日期:2025-07-11

通讯作者:

张瑞宏

作者简介:奚小波 E-mail: xxbctg@126.com;

基金资助:

Xiaobo XI( ), Jieyuan DING, Wendi ZHANG, Yangjie SHI, Yifu JIN, Ruihong ZHANG(

), Jieyuan DING, Wendi ZHANG, Yangjie SHI, Yifu JIN, Ruihong ZHANG( )

)

Received:2024-01-19

Accepted:2024-05-09

Online:2025-07-15

Published:2025-07-11

Contact:

Ruihong ZHANG

摘要:

针对果园树干间杂草难去除的问题设计了一种果园中耕避障除草机,包括行间除草机构、株间除草机构、液压避障组件等,可实现行间和株间的中耕除草作业,通过触式弹簧避障杆联动液压缸驱动四连杆机构,实现株间除草机构的避障。利用EDEM软件以除草轮的转速、入土深度、行进速度为指标进行3因素3水平正交仿真试验和作业参数优化,最佳参数组合为:除草轮转速500 r·min-1、入土深度80 mm、前进速度1.2 m·s-1。样机田间试验表明,其除草作业的避障通过率100%,漏耕率3.44%,损伤率0%,平均耕深为80.9 mm,耕深稳定性系数为97.8%,生产率为0.86~1.38 hm2·h-1。研究结果可为果园中耕避障除草机设计提供参考。

中图分类号:

奚小波, 丁杰源, 张文帝, 史扬杰, 金亦富, 张瑞宏. 一种果园中耕避障除草机的设计与试验[J]. 中国农业科技导报, 2025, 27(7): 101-110.

Xiaobo XI, Jieyuan DING, Wendi ZHANG, Yangjie SHI, Yifu JIN, Ruihong ZHANG. Design and Experiment of Orchard Obstacle Avoidance Weeding Cultivator[J]. Journal of Agricultural Science and Technology, 2025, 27(7): 101-110.

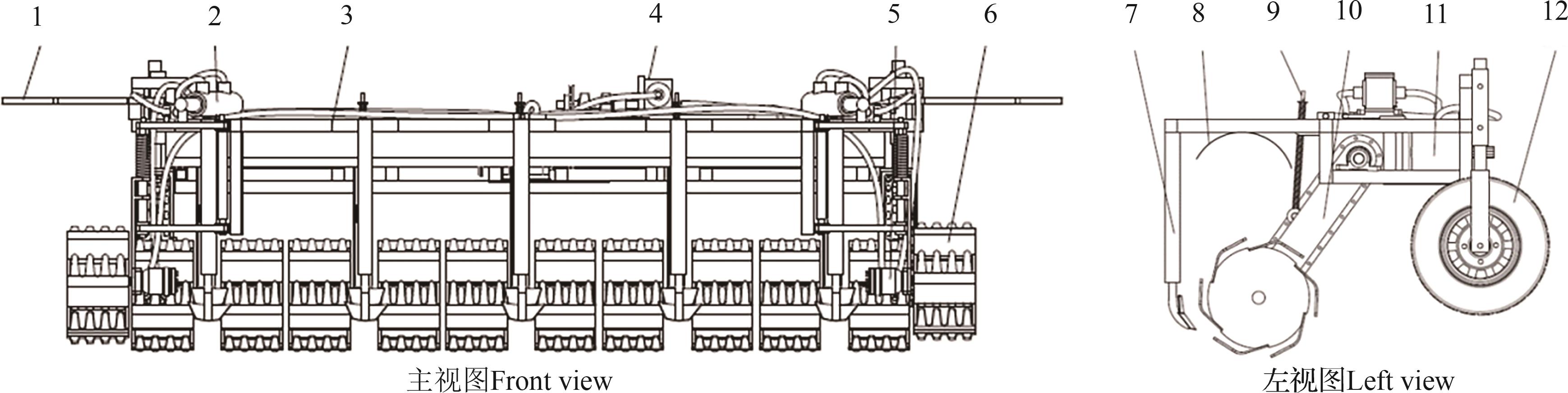

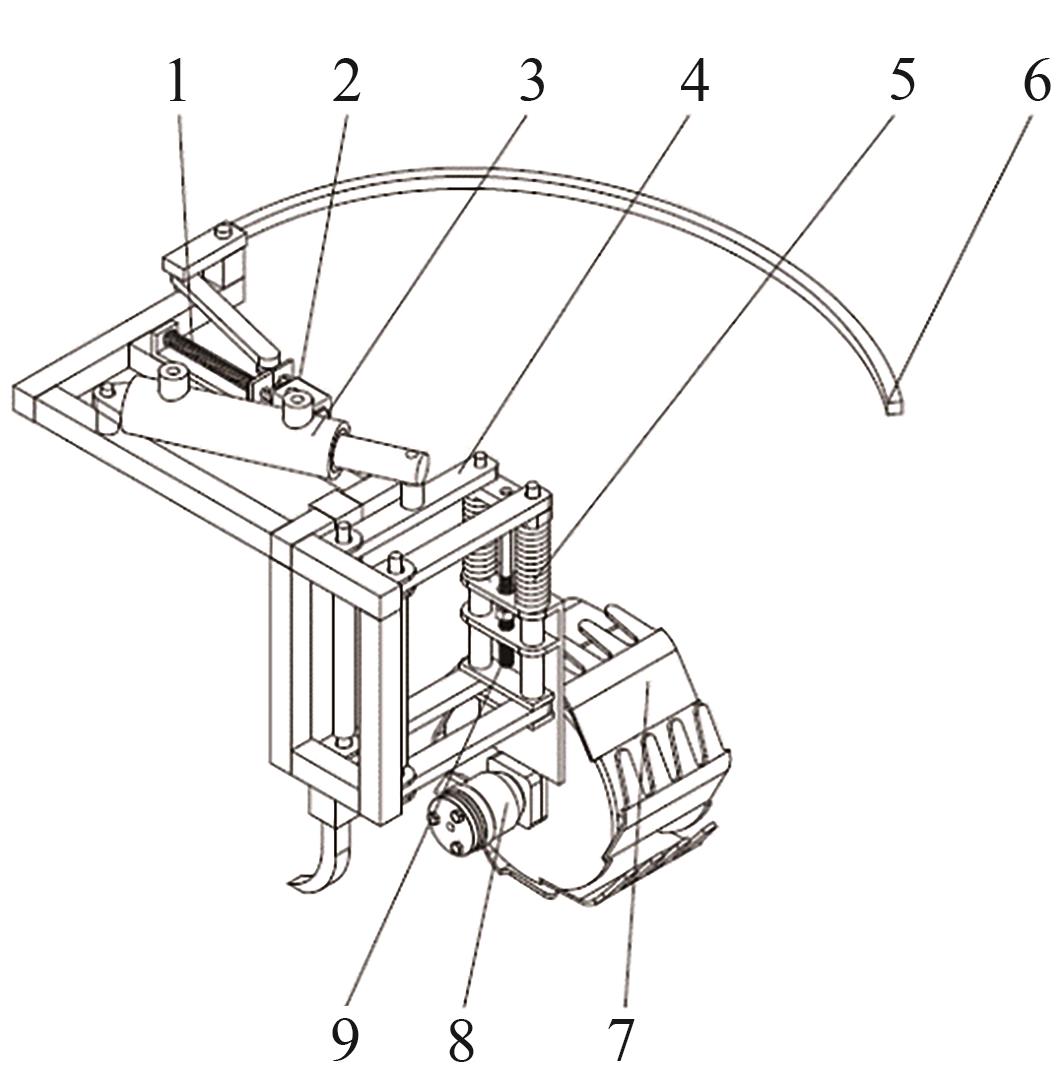

图1 果园中耕避障除草机整体结构注:1—避障杆; 2—液压避障组件; 3—机架; 4—液压阀; 5—液压马达; 6—除草轮; 7—除草铲; 8—挡泥板; 9—弹簧缓冲机构; 10—链轮传动箱; 11—中间齿轮箱; 12—行走轮。

Fig. 1 Overall structure of orchard obstacle avoidance weeding cultivatorNote: 1—Obstacle avoidance pole; 2—Hydraulic obstacle avoidance components; 3—Frame; 4—Hydraulic valve; 5—Hydraulic motor; 6—Weeding wheel; 7—Weeder tine; 8—Mudguard; 9—Spring buffer mechanism; 10—Chain wheel drive box; 11—Intermediate gearbox; 12—Walking wheel.

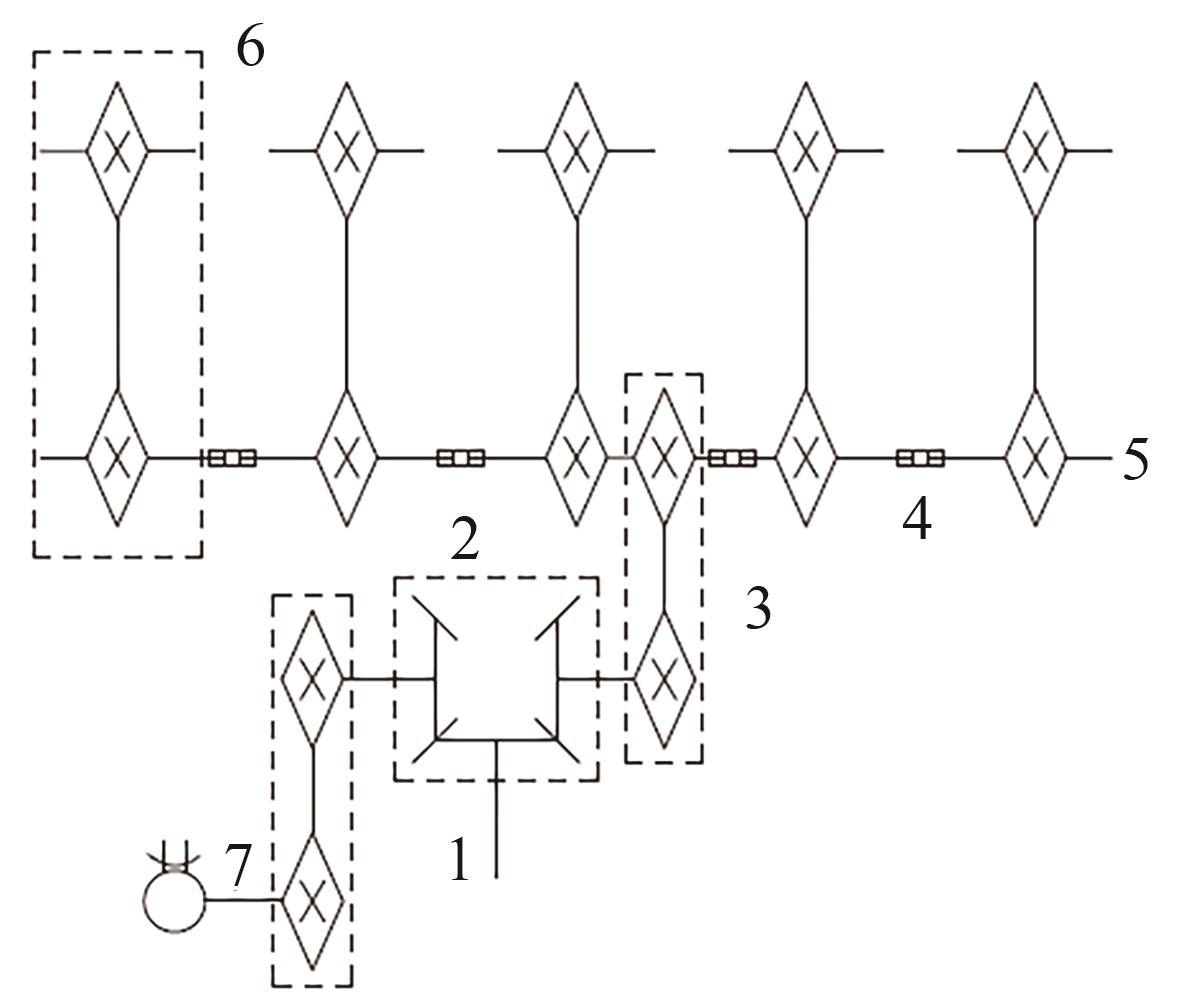

图2 行间除草机构传动注:1—动力输入轴; 2—锥齿轮箱; 3—链轮传动; 4—联轴器;5—主传动轴; 6—除草单体; 7—液压泵。

Fig. 2 Inter-row weeding mechanism transmissionNote: 1—Power-failure detection input shaft; 2—Bevel gear box; 3—Sprocket feed; 4—Coupling; 5—Main driving shaft; 6—Weed removal unit; 7—Hydraulic pump.

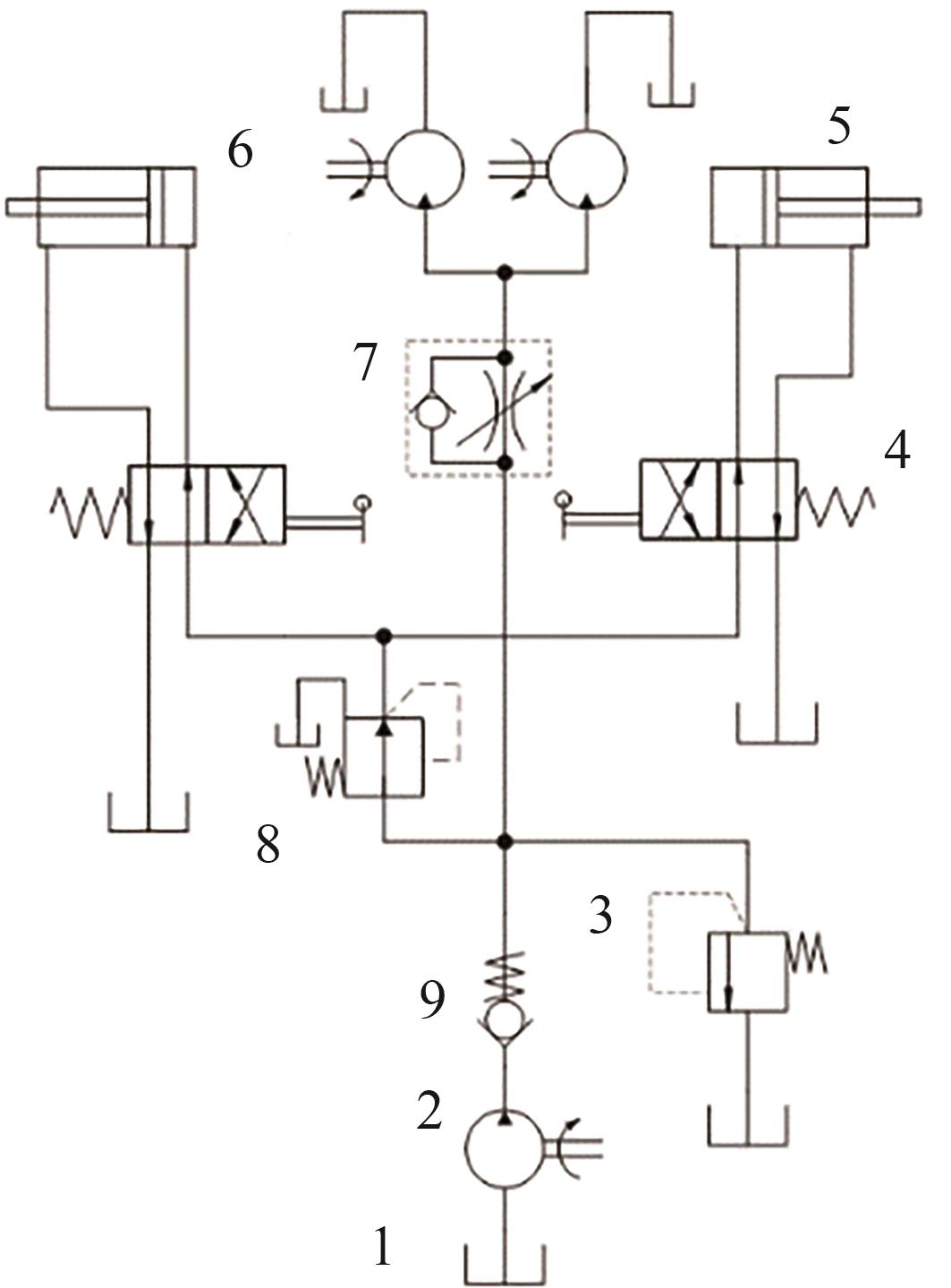

图3 株间除草机构液压系统注:1—液压油箱; 2—液压泵; 3—溢流阀; 4—换向阀; 5—液压油缸; 6—液压马达; 7—调速阀; 8—减压阀; 9—单向阀。

Fig. 3 Intra-row weeding mechanism hydraulic systemNote: 1—Hydraulic reservoir;2—Hydraulic pump;3—Overflow valve;4—Reversing valve;5—Hydraulic cylinder;6—Hydraulic motor;7—Speed-control valve;8—Reducing valve;9—Check valve.

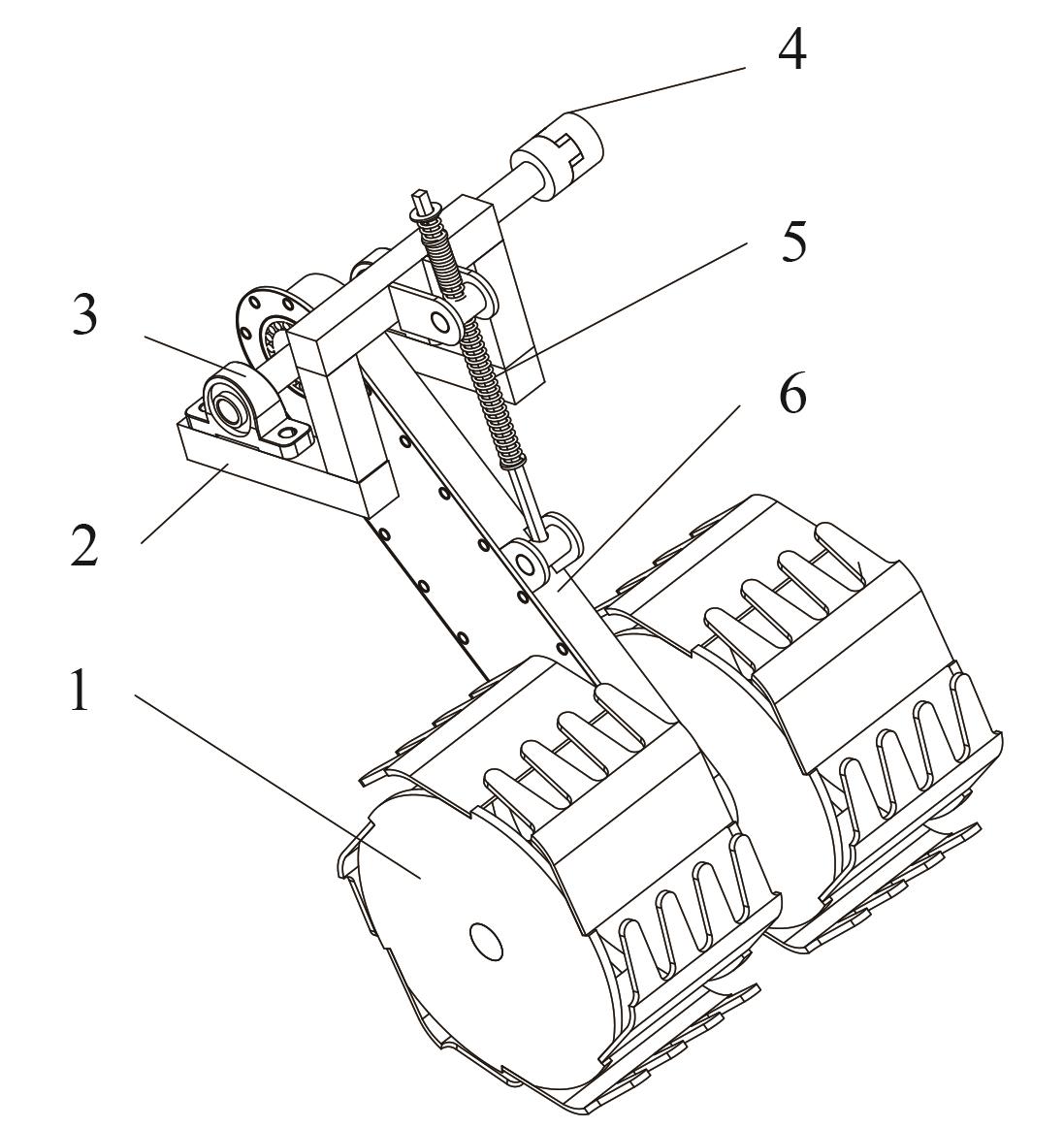

图4 除草单体注:1—除草轮; 2—机架; 3—轴承座; 4—联轴器; 5—弹簧缓冲机构; 6—链轮传动箱。

Fig. 4 Weed removal unitNote: 1—Weeding wheel;2—Frame;3—Bearing seat;4—Coupling;5—Spring buffer mechanism;6—Chain wheel drive box.

图5 避障机构注:1—复位弹簧; 2—换向阀; 3—液压缸; 4—避障连杆; 5—缓冲弹簧; 6—避障杆; 7—除草轮; 8—液压马达; 9—调节杆。

Fig. 5 Obstacle avoidance mechanismNote: 1—Reset spring; 2—Reversing valve; 3—Hydraulic cylinder; 4—Obstacle avoidance connecting rod; 5—Buffer spring; 6—Obstacle avoidance pole; 7—Weeding wheel; 8—Hydraulic motor; 9—Regulating stem.

项目 Item | 数值 Value |

|---|---|

尺寸(长×宽×高) Dimensions (length × width × height)/mm | 2 975×1 438×928 |

与拖拉机连接方式 Coupling mean | 三点悬挂 Trifilar suspension |

配套动力 Matching power/kW | 54.1 |

耕深 Tillage depth/cm | 8 |

作业幅宽 Working width/cm | 300 |

除草轮转速 Weeding wheel rotation speed/(r·min-1) | 500 |

表1 整机性能参数

Table 1 Overall performance parameters

项目 Item | 数值 Value |

|---|---|

尺寸(长×宽×高) Dimensions (length × width × height)/mm | 2 975×1 438×928 |

与拖拉机连接方式 Coupling mean | 三点悬挂 Trifilar suspension |

配套动力 Matching power/kW | 54.1 |

耕深 Tillage depth/cm | 8 |

作业幅宽 Working width/cm | 300 |

除草轮转速 Weeding wheel rotation speed/(r·min-1) | 500 |

项目 Item | 参数 Parameter | 数值 Value |

|---|---|---|

土壤颗粒 Soil particle | 泊松比Poisson ratio | 0.3 |

| 剪切模量Shear modulus/Pa | 6×107 | |

| 密度Density /(kg·m-3) | 1 596 | |

| 颗粒半径Particle radius/mm | 10 | |

| 恢复系数Coefficient of restitution | 0.5 | |

| 静摩擦系数Coefficient of static friction | 0.5 | |

| 动摩擦系数Coefficient of kinetic friction | 0.1 | |

除草轮 Weeding wheel | 泊松比Poisson ratio | 0.31 |

| 剪切模量Shear modulus/Pa | 2×108 | |

| 密度Density/(kg·m-3) | 7 850 | |

| 恢复系数Coefficient of restitution | 0.35 | |

| 静摩擦系数Coefficient of static friction | 0.29 | |

| 动摩擦系数Coefficient of kinetic friction | 0.1 |

表2 离散元仿真参数

Table 2 Discrete element simulation parameters

项目 Item | 参数 Parameter | 数值 Value |

|---|---|---|

土壤颗粒 Soil particle | 泊松比Poisson ratio | 0.3 |

| 剪切模量Shear modulus/Pa | 6×107 | |

| 密度Density /(kg·m-3) | 1 596 | |

| 颗粒半径Particle radius/mm | 10 | |

| 恢复系数Coefficient of restitution | 0.5 | |

| 静摩擦系数Coefficient of static friction | 0.5 | |

| 动摩擦系数Coefficient of kinetic friction | 0.1 | |

除草轮 Weeding wheel | 泊松比Poisson ratio | 0.31 |

| 剪切模量Shear modulus/Pa | 2×108 | |

| 密度Density/(kg·m-3) | 7 850 | |

| 恢复系数Coefficient of restitution | 0.35 | |

| 静摩擦系数Coefficient of static friction | 0.29 | |

| 动摩擦系数Coefficient of kinetic friction | 0.1 |

| 水平Level | A:入土深度 Tillage depth/mm | B:转速 Rotation speed/(r·min-1) | C:行进速度 Forward speed/(m·s-1) |

|---|---|---|---|

| -1 | 20 | 150 | 1.2 |

| 0 | 50 | 360 | 1.4 |

| 1 | 80 | 500 | 1.6 |

表3 试验因素水平表

Table 3 Experimental factor level

| 水平Level | A:入土深度 Tillage depth/mm | B:转速 Rotation speed/(r·min-1) | C:行进速度 Forward speed/(m·s-1) |

|---|---|---|---|

| -1 | 20 | 150 | 1.2 |

| 0 | 50 | 360 | 1.4 |

| 1 | 80 | 500 | 1.6 |

序号 Serial number | 因素水平Factor level | 土壤扰动表面积 Soil disturbance surface area/m2 | ||

|---|---|---|---|---|

A:入土深度 Tillage depth/mm | B:转速 Rotation speed/(r·min-1) | C:行进速度 Forward speed/(m·s-1) | ||

| 1 | 20 | 150 | 1.2 | 0.917 2 |

| 2 | 20 | 360 | 1.4 | 1.782 8 |

| 3 | 20 | 500 | 1.6 | 2.095 4 |

| 4 | 50 | 150 | 1.4 | 0.933 2 |

| 5 | 50 | 360 | 1.6 | 1.613 8 |

| 6 | 50 | 500 | 1.2 | 3.033 4 |

| 7 | 80 | 150 | 1.6 | 1.230 4 |

| 8 | 80 | 360 | 1.2 | 2.709 7 |

| 9 | 80 | 500 | 1.4 | 3.144 0 |

| K1 | 4.795 4 | 3.080 8 | 6.660 3 | |

| K2 | 5.580 4 | 6.106 3 | 5.860 0 | |

| K3 | 7.084 1 | 8.272 8 | 4.939 6 | |

| k1 | 1.598 5 | 1.026 9 | 2.220 1 | |

| k2 | 1.860 1 | 2.035 4 | 1.953 3 | |

| k3 | 2.361 4 | 2.757 6 | 1.646 5 | |

| 极差R | 0.762 9 | 1.730 7 | 0.573 6 | |

影响程度 Influence degree | B>A>C | |||

最优组合 Optimal composition | A3B3C1 | |||

表4 正交试验结果与极差分析

Table 4 Orthogonal experimental results and range analysis

序号 Serial number | 因素水平Factor level | 土壤扰动表面积 Soil disturbance surface area/m2 | ||

|---|---|---|---|---|

A:入土深度 Tillage depth/mm | B:转速 Rotation speed/(r·min-1) | C:行进速度 Forward speed/(m·s-1) | ||

| 1 | 20 | 150 | 1.2 | 0.917 2 |

| 2 | 20 | 360 | 1.4 | 1.782 8 |

| 3 | 20 | 500 | 1.6 | 2.095 4 |

| 4 | 50 | 150 | 1.4 | 0.933 2 |

| 5 | 50 | 360 | 1.6 | 1.613 8 |

| 6 | 50 | 500 | 1.2 | 3.033 4 |

| 7 | 80 | 150 | 1.6 | 1.230 4 |

| 8 | 80 | 360 | 1.2 | 2.709 7 |

| 9 | 80 | 500 | 1.4 | 3.144 0 |

| K1 | 4.795 4 | 3.080 8 | 6.660 3 | |

| K2 | 5.580 4 | 6.106 3 | 5.860 0 | |

| K3 | 7.084 1 | 8.272 8 | 4.939 6 | |

| k1 | 1.598 5 | 1.026 9 | 2.220 1 | |

| k2 | 1.860 1 | 2.035 4 | 1.953 3 | |

| k3 | 2.361 4 | 2.757 6 | 1.646 5 | |

| 极差R | 0.762 9 | 1.730 7 | 0.573 6 | |

影响程度 Influence degree | B>A>C | |||

最优组合 Optimal composition | A3B3C1 | |||

| 指标Index | 机具速度 Machine speed/(m·s-1) | ||

|---|---|---|---|

| 1.2 | 1.4 | 1.6 | |

树木总数 Total number of trees | 20 | 25 | 23 |

避障完成总数 Number of obstacle avoidance | 20 | 25 | 23 |

避障率 Obstacle avoidance percentage/% | 100 | 100 | 100 |

表5 避障通过率测试结果

Table 5 Obstacle avoidance pass rate test results

| 指标Index | 机具速度 Machine speed/(m·s-1) | ||

|---|---|---|---|

| 1.2 | 1.4 | 1.6 | |

树木总数 Total number of trees | 20 | 25 | 23 |

避障完成总数 Number of obstacle avoidance | 20 | 25 | 23 |

避障率 Obstacle avoidance percentage/% | 100 | 100 | 100 |

测试项目 Testing item | 复位弹簧弹性系数 Elastic coefficient of reset spring/(N·mm-1) | |

|---|---|---|

| 20 | 30 | |

树木总数 Total number of trees | 20 | 20 |

避障完成总数 Number of obstacle avoidance | 20 | 20 |

避障率 Obstacle avoidance percentage/% | 100 | 100 |

果树擦伤数 Number of fruit tree abrasions | 0 | 3 |

果树损伤比 Scratch ratio of fruit trees/% | 0 | 15 |

表6 损伤率测试结果

Table 6 Damage rate test results

测试项目 Testing item | 复位弹簧弹性系数 Elastic coefficient of reset spring/(N·mm-1) | |

|---|---|---|

| 20 | 30 | |

树木总数 Total number of trees | 20 | 20 |

避障完成总数 Number of obstacle avoidance | 20 | 20 |

避障率 Obstacle avoidance percentage/% | 100 | 100 |

果树擦伤数 Number of fruit tree abrasions | 0 | 3 |

果树损伤比 Scratch ratio of fruit trees/% | 0 | 15 |

试验序号 Test number | 果园总面积 Total orchard area/m2 | 去除树干后的土地面积 Land area without tree trunks/m2 | 实际耕作面积 Actual tillage area/m2 | 漏耕率 Missed tillage rate/% |

|---|---|---|---|---|

| 1 | 30 | 24 | 23.25 | 3.23 |

| 2 | 30 | 23 | 22.10 | 4.07 |

| 3 | 30 | 25 | 24.40 | 2.46 |

| 4 | 30 | 26 | 24.95 | 4.21 |

| 5 | 30 | 24 | 23.25 | 3.23 |

表7 漏耕率测试结果

Table 7 Missed tillage rate test results

试验序号 Test number | 果园总面积 Total orchard area/m2 | 去除树干后的土地面积 Land area without tree trunks/m2 | 实际耕作面积 Actual tillage area/m2 | 漏耕率 Missed tillage rate/% |

|---|---|---|---|---|

| 1 | 30 | 24 | 23.25 | 3.23 |

| 2 | 30 | 23 | 22.10 | 4.07 |

| 3 | 30 | 25 | 24.40 | 2.46 |

| 4 | 30 | 26 | 24.95 | 4.21 |

| 5 | 30 | 24 | 23.25 | 3.23 |

试验序号 Test number | 平均值 Average/mm | 标准差 Standard deviation/mm | 变异系数 Coefficient of variation/% | 稳定性系数 Stability coefficient/% |

|---|---|---|---|---|

| 1 | 79.5 | 1.68 | 2.11 | 97.89 |

| 2 | 81.2 | 2.28 | 2.81 | 97.19 |

| 3 | 82.0 | 2.00 | 2.49 | 97.51 |

| 4 | 81.0 | 1.14 | 1.40 | 98.60 |

表8 耕深测试结果

Table 8 Tillage depth test results

试验序号 Test number | 平均值 Average/mm | 标准差 Standard deviation/mm | 变异系数 Coefficient of variation/% | 稳定性系数 Stability coefficient/% |

|---|---|---|---|---|

| 1 | 79.5 | 1.68 | 2.11 | 97.89 |

| 2 | 81.2 | 2.28 | 2.81 | 97.19 |

| 3 | 82.0 | 2.00 | 2.49 | 97.51 |

| 4 | 81.0 | 1.14 | 1.40 | 98.60 |

| [1] | 白勇, 王晓燕, 胡光, 等. 非化学方法在农田杂草防治中的应用[J]. 农业机械学报, 2007, 38(4): 191-196. |

| BAI Y, WANG X Y, HU G, et al.. Review of the development in non-chemical weed management [J]. Trans.Chin.Soc.Agric.Mach., 2007, 38(4): 191-196. | |

| [2] | CORDILL C, GRIFT T E.Design and testing of an intra-row mechanical weeding machine for corn [J]. Biosyst.Eng., 2011,110(3): 247-252. |

| [3] | 齐月, 李俊生, 闫冰, 等. 化学除草剂对农田生态系统野生植物多样性的影响[J]. 生物多样性, 2016, 24(2): 228-236. |

| QI Y, LI J S, YAN B, et al.. Impact of herbicides on wild plant diversity in agro-ecosystems:a review [J]. Biodivers. Sci., 2016, 24(2): 228-236. | |

| [4] | 王金峰, 王金武, 闫东伟, 等. 3SCJ-2型水田行间除草机设计与试验[J]. 农业机械学报, 2017, 48(6): 71-78, 202. |

| WANG J F, WANG J W, YAN D W, et al.. Design and experiment of 3SCJ-2 type row weeding machine for paddy field [J]. Trans. Chin. Soc. Agric. Mach., 2017, 48(6): 71-78, 202. | |

| [5] | REBICH R A, COUPE R H, THURMAN E M. Herbicide concentrations in the Mississippi River Basin—the importance of chloroacetanilide herbicide degradates [J]. Sci. Total Environ., 2004, 321(1/2/3): 189-199. |

| [6] | 张晋, 陈伟, 朱继平, 等. 果园自动避障中耕除草管理机设计与试验[J]. 中国农机化学报, 2020, 41(8): 40-49. |

| ZHANG J, CHEN W, ZHU J P, et al.. Design and experiment of automatic obstacle avoidance cultivation weeding management machine [J]. J. Chin. Agric. Mech., 2020, 41(8): 40-49. | |

| [7] | 朱站伟, 汤智辉, 何义川, 等. 果园株间除草自动避障装置的设计与试验[J]. 农机化研究, 2020, 42(6): 147-153. |

| ZHU Z W, TANG Z H, HE Y C, et al.. Design and experiment of automatic obstacle avoidance device for weeding between plants [J]. J. Agric. Mech. Res., 2020, 42(6): 147-153. | |

| [8] | 陈平录, 许静, 翟因敏, 等. 丘陵山区低矮树型果园立式微耕机的设计与试验[J]. 机械设计与制造, 2021(2):299-303. |

| CHEN P L, XU J, ZHAI Y M, et al.. Design and experimental study of vertical micro-cultivator for low trees in hilly orchard [J]. Mach. Des. Manuf., 2021(2): 299-303. | |

| [9] | 鲍秀兰, 严煜, 毛金城, 等. 果园割草机器人甩刀设计与分析[J]. 华中农业大学学报, 2020, 39(6): 136-143. |

| BAO X L, YAN Y, MAO J C, et al.. Design and analyses of swinging blade for orchard mowing robot [J]. J. Huazhong Agric. Univ., 2020, 39(6): 136-143. | |

| [10] | 付作立, 王德成, 李卫, 等. 双圆盘式苜蓿旋转切割器设计与试验[J]. 农业机械学报, 2018, 49(): 214-220. |

| FU Z L, WANG D C, LI W, et al.. Design and experiment of two-disc rotary mower of alfalfa [J]. Trans. Chin. Soc. Agric. Mach., 2018, 49(S1): 214-220. | |

| [11] | 王永烁, 康建明, 彭强吉, 等. 果树株间避障除草机设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2410-2420. |

| WANG Y S, KANG J M, PENG Q J, et al.. Design and experiment of obstacle avoidance weeding machine for fruit trees [J]. J. Jilin Univ. (Eng. Technol.), 2023, 53(8): 2410-2420. | |

| [12] | SCARFONE A, PICCHIO R, DEL GIUDICE A, et al.. Semi-automatic guidance vs . manual guidance in agriculture: a comparison of work performance in wheat sowing [J/OL]. Electronics, 2021, 10(7): 825 [2024-12-30]. . |

| [13] | 高文杰, 张锋伟, 戴飞, 等. 果园机械化装备研究进展与展望[J]. 林业机械与木工设备, 2021, 49(12): 9-20. |

| GAO W J, ZHANG F W, DAI F, et al.. Research progress and prospects of orchard mechanized equipment [J]. For. Mach. Woodwork. Equip., 2021, 49(12): 9-20. | |

| [14] | 吕金庆, 刘金妮, 赵治明, 等. 马铃薯碎土整地联合作业机设计与试验[J]. 农业机械学报, 2023, 54(8): 19-29. |

| LYU J Q, LIU J N, ZHAO Z M, et al.. Design and test of key components of potato soil-crushing site preparation machine [J]. Trans. Chin. Soc. Agric. Mach., 2023, 54(8): 19-29. | |

| [15] | 杨启志, 杨鑫宇, 赫明胜, 等. 葡萄分层旋抛式清土起藤机高效旋抛刀设计与试验[J]. 农业工程学报, 2022, 38(24): 44-51. |

| YANG Q Z, YANG X Y, HE M S, et al.. Design and experiment of the rotary throwing knife of wine grape cleaning machine [J]. Trans. Chin. Soc. Agric. Eng., 2022, 38(24): 44-51. | |

| [16] | 张帅磊. 深松铲错位布置对土壤扰动影响的仿真与试验研究[D]. 杨凌: 西北农林科技大学, 2018. |

| ZHANG S L. Simulations and experiments of soil disturbance as affected by the dislocation arrangement of subsoilers [D]. Yangling: Northwest A&F University, 2018. | |

| [17] | 崔宏伟. 水田除草机自动避苗控制系统研究[D]. 广州: 华南农业大学, 2017. |

| CUI H W. Study on control system with automatic avoiding rice seedlings ofweeder for paddy [D]. Guangzhou: South China Agricultural University, 2017. | |

| [18] | 丁艳, 朱继平, 袁栋, 等. 旋耕机: [S]. 北京:中国标准出版社, 2017. |

| [19] | 李宝筏. 农业机械学[M]. 北京: 中国农业出版社, 2003:1-438. |

| [20] | 朱站伟. 果园株间除草自动避障装置的设计与试验研究[D]. 石河子: 石河子大学, 2020. |

| ZHU Z W.Design and experimental study of an automatic obstacle avoidance device between weeds in orchards [D]. Shihezi: Shihezi University, 2020. | |

| [21] | 中国农机研究院. 农业机械设计手册[M]. 北京: 中国农业科学技术出版社, 2007: 1-1885. |

| [22] | 沈启扬, 雷哓晖, 马拯胞, 等. F. US-UFO型果园避障割草机试验研究[J]. 中国农机化学报, 2021, 42(10): 65-71, 77. |

| SHEN Q Y, LEI X H, MA Z B, et al.. Experimental study on F. US-UFO mower for avoiding obstacles in orchards [J]. J. Chin. Agric. Mech., 2021, 42(10): 65-71, 77. | |

| [23] | 杨毅, 弋晓康, 何义川, 等. 主干型果园株间避障割草机的设计与试验[J]. 塔里木大学学报, 2023, 35(4): 78-87. |

| YANG Y, YI X K, HE Y C, et al.. Design and experiment of obstacle avoidance mower for trunk orchards [J]. J. Tarim Univ., 2023, 35(4): 78-87. | |

| [24] | 李雪军, 王鹏飞, 丁顺荣, 等. 基于虚拟正交试验果园垄面割草机侧刀盘切割性能分析[J]. 中国农业科技导报, 2020, 22(9): 113-121. |

| LI X J, WANG P F, DING S R, et al.. Cutting performance of side cutter head of orchard mower based on virtual orthogonal test [J]. J. Agric. Sci. Technol., 2020, 22(9): 113-121. |

| [1] | 许静, 李晗, 陈平录, 罗江旎, 唐承露, 刘木华. 油茶茶枯离散元模型参数标定与试验[J]. 中国农业科技导报, 2025, 27(3): 112-121. |

| [2] | 冯长龙, 黄春光, 宁辰阳, 李树平, 陈科锦. 植树机挖坑机构螺旋式钻头性能特性优化研究[J]. 中国农业科技导报, 2025, 27(2): 89-98. |

| [3] | 田祥州, 贺福强, 陈发江, 詹璐歆. 基于休止角标定不同含水率木粉离散元参数[J]. 中国农业科技导报, 2025, 27(1): 118-128. |

| [4] | 顿国强, 王雷, 纪欣鑫, 姜新波, 赵宇, 郭娜. 金乡紫皮蒜种离散元参数标定与试验验证[J]. 中国农业科技导报, 2024, 26(8): 131-139. |

| [5] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [6] | 李明, 董帅, 庞永强, 燕洁华, 叶汪忠. 风沙土混拌刀具的改良设计与试验[J]. 中国农业科技导报, 2024, 26(4): 87-96. |

| [7] | 黄元昊, 全腊珍, 胡广发, 全伟, 石方刚. 多种材料与不同含水率土壤的离散元接触参数标定[J]. 中国农业科技导报, 2024, 26(3): 98-109. |

| [8] | 陈林, 余南辉, 王立宗, 范吉军, 雷港, 刘晓鹏, 周龙, 周劲. 米糠和碎米的接触参数测量与离散元仿真标定[J]. 中国农业科技导报, 2024, 26(2): 127-136. |

| [9] | 杨大芳, 李飞翔, 葛越锋, 李奕辰. 基于离散元法的外槽轮排肥器排肥性能研究[J]. 中国农业科技导报, 2024, 26(12): 88-97. |

| [10] | 王洪波, 樊志鹏, 乌兰图雅, 王春光, 马哲. 揉碎玉米秸秆螺旋输送仿真离散元模型参数标定[J]. 中国农业科技导报, 2023, 25(3): 96-106. |

| [11] | 于淼, 周海宾, 丁京涛, 程红胜, 沈玉君, 范盛远, 张曦, 王健, 徐鹏翔, 程琼仪. 基于EDEM的餐厨垃圾组成颗粒间接触参数标定[J]. 中国农业科技导报, 2023, 25(12): 111-120. |

| [12] | 马紫涛, 赵智豪, 全伟, 石方刚, 高晨, 吴明亮. 基于EDEM的水稻残茬秸秆离散元仿真参数标定[J]. 中国农业科技导报, 2023, 25(11): 103-113. |

| [13] | 单发科, 康朔, 朱建锡, 王永维, 王俊. 基于EDEM的粉垄和旋耕作业混肥效果研究[J]. 中国农业科技导报, 2023, 25(11): 90-102. |

| [14] | 周婷, 孙松林, 朱海英, 彭才望. 含水率对黑水虻生物转化猪粪有机肥黏结流动的影响[J]. 中国农业科技导报, 2023, 25(10): 126-136. |

| [15] | 李飞翔, 王鹏, 王云飞, 葛越锋, 唐凯怿, 李得志. 基于堆积试验的玉米包衣种子离散元参数标定[J]. 中国农业科技导报, 2022, 24(7): 97-107. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号