中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (2): 192-200.DOI: 10.13304/j.nykjdb.2023.0857

• 生物制造 资源生态 • 上一篇

张如艳1( ), 李绅昊1, 朱奇鹏2, 冯太纲1, 李红波2, 邢泽炳2, 羡瑜1(

), 李绅昊1, 朱奇鹏2, 冯太纲1, 李红波2, 邢泽炳2, 羡瑜1( )

)

收稿日期:2023-11-22

接受日期:2024-03-08

出版日期:2025-02-15

发布日期:2025-02-14

通讯作者:

羡瑜

作者简介:张如艳 E-mail:3439672507@qq.com;

基金资助:

Ruyan ZHANG1( ), Shenhao LI1, Qipeng ZHU2, Taigang FENG1, Hongbo LI2, Zebing XING2, Yu XIAN1(

), Shenhao LI1, Qipeng ZHU2, Taigang FENG1, Hongbo LI2, Zebing XING2, Yu XIAN1( )

)

Received:2023-11-22

Accepted:2024-03-08

Online:2025-02-15

Published:2025-02-14

Contact:

Yu XIAN

摘要:

为实现园林绿化废弃物高值化利用,拓宽木塑复合材料的使用范围,以园林绿化废弃物和聚乳酸为原料、生物炭为增强剂,选取杨木粉含量、模压温度、模压压力和保压时间4个因素进行Box-Benhnken试验,运用响应面法对木塑复合材料的模压工艺参数进行优化,并分析生物炭含量对复合材料物理力学性能的影响。结果表明,试验最优工艺参数为杨木粉含量41.31%,模压温度170 ℃,模压压力11.49 MPa,保压时间10 min;添加生物炭可较好地改善木粉和聚乳酸界面相容性,提高复合材料的力学性能,随着生物炭含量的增加,复合材料的力学性能先上升后下降,当生物炭含量为2.0%时,弯曲强度、弯曲模量和冲击强度分别为32.00 MPa、3.20 GPa和3.47 kJ·m-2,吸水率最小,显气孔率最低,复合材料的综合力学性能最佳。以上研究结果为生物炭改善木塑复合材料性能提供依据。

中图分类号:

张如艳, 李绅昊, 朱奇鹏, 冯太纲, 李红波, 邢泽炳, 羡瑜. 生物炭含量对园林绿化废弃物/聚乳酸复合材料物理力学性能影响[J]. 中国农业科技导报, 2025, 27(2): 192-200.

Ruyan ZHANG, Shenhao LI, Qipeng ZHU, Taigang FENG, Hongbo LI, Zebing XING, Yu XIAN. Effect of Biochar Content on Physical and Mechanical Properties of Garden Greening Waste/polylactic Acid Composites[J]. Journal of Agricultural Science and Technology, 2025, 27(2): 192-200.

| 因素 Factor | 编码水平 Coding level | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| A:杨木粉含量Poplar wood powder content/% | 30 | 40 | 50 |

| B:模压温度 Molding temperature/℃ | 160 | 170 | 180 |

| C:模压压力Molding pressure/MPa | 6 | 9 | 12 |

| D:保压时间Holding time/min | 10 | 13 | 16 |

表 1 响应面试验设计因素水平表

Table 1 Response surface experimental design factor level table

| 因素 Factor | 编码水平 Coding level | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| A:杨木粉含量Poplar wood powder content/% | 30 | 40 | 50 |

| B:模压温度 Molding temperature/℃ | 160 | 170 | 180 |

| C:模压压力Molding pressure/MPa | 6 | 9 | 12 |

| D:保压时间Holding time/min | 10 | 13 | 16 |

试验号 Number | A:杨木粉含量 Poplar wood powder content/% | B:模压温度 Molding temperature/℃ | C:模压压力 Molding pressure/MPa | D:保压时间 Holding time/min | Y1:弯曲强度 Flexural strength/MPa | Y2:冲击强度 Impact strength/(kJ·m-²) |

|---|---|---|---|---|---|---|

| 1 | 40 | 170 | 9 | 13 | 24.40 | 2.80 |

| 2 | 40 | 160 | 6 | 13 | 29.00 | 4.06 |

| 3 | 30 | 180 | 9 | 13 | 21.40 | 2.13 |

| 4 | 50 | 160 | 9 | 13 | 23.50 | 2.18 |

| 5 | 50 | 180 | 9 | 13 | 26.20 | 2.37 |

| 6 | 40 | 170 | 9 | 13 | 22.00 | 2.55 |

| 7 | 30 | 170 | 6 | 13 | 20.80 | 2.45 |

| 8 | 40 | 170 | 6 | 10 | 25.40 | 3.71 |

| 9 | 40 | 180 | 9 | 16 | 20.60 | 2.29 |

| 10 | 30 | 170 | 9 | 16 | 22.00 | 2.10 |

| 11 | 50 | 170 | 12 | 13 | 23.40 | 2.16 |

| 12 | 40 | 180 | 6 | 13 | 17.80 | 2.58 |

| 13 | 50 | 170 | 9 | 10 | 28.40 | 2.31 |

| 14 | 40 | 160 | 9 | 16 | 29.20 | 3.36 |

| 15 | 40 | 170 | 12 | 10 | 29.00 | 3.60 |

| 16 | 40 | 180 | 12 | 13 | 29.30 | 3.02 |

| 17 | 40 | 160 | 12 | 13 | 32.00 | 3.98 |

| 18 | 40 | 170 | 9 | 13 | 28.40 | 3.31 |

| 19 | 40 | 170 | 6 | 16 | 27.60 | 2.73 |

| 20 | 30 | 170 | 9 | 10 | 27.20 | 2.06 |

| 21 | 30 | 170 | 12 | 13 | 24.80 | 2.23 |

| 22 | 50 | 170 | 9 | 16 | 25.00 | 2.36 |

| 23 | 40 | 180 | 9 | 10 | 22.60 | 2.61 |

| 24 | 40 | 170 | 9 | 13 | 27.40 | 2.99 |

| 25 | 40 | 170 | 12 | 16 | 24.00 | 2.61 |

| 26 | 30 | 160 | 9 | 13 | 30.00 | 2.34 |

| 27 | 40 | 170 | 9 | 13 | 24.20 | 3.21 |

| 28 | 40 | 160 | 9 | 10 | 30.80 | 3.06 |

| 29 | 50 | 170 | 6 | 13 | 26.20 | 2.01 |

表 2 响应面试验设计和结果

Table 2 Response surface experimental design and results

试验号 Number | A:杨木粉含量 Poplar wood powder content/% | B:模压温度 Molding temperature/℃ | C:模压压力 Molding pressure/MPa | D:保压时间 Holding time/min | Y1:弯曲强度 Flexural strength/MPa | Y2:冲击强度 Impact strength/(kJ·m-²) |

|---|---|---|---|---|---|---|

| 1 | 40 | 170 | 9 | 13 | 24.40 | 2.80 |

| 2 | 40 | 160 | 6 | 13 | 29.00 | 4.06 |

| 3 | 30 | 180 | 9 | 13 | 21.40 | 2.13 |

| 4 | 50 | 160 | 9 | 13 | 23.50 | 2.18 |

| 5 | 50 | 180 | 9 | 13 | 26.20 | 2.37 |

| 6 | 40 | 170 | 9 | 13 | 22.00 | 2.55 |

| 7 | 30 | 170 | 6 | 13 | 20.80 | 2.45 |

| 8 | 40 | 170 | 6 | 10 | 25.40 | 3.71 |

| 9 | 40 | 180 | 9 | 16 | 20.60 | 2.29 |

| 10 | 30 | 170 | 9 | 16 | 22.00 | 2.10 |

| 11 | 50 | 170 | 12 | 13 | 23.40 | 2.16 |

| 12 | 40 | 180 | 6 | 13 | 17.80 | 2.58 |

| 13 | 50 | 170 | 9 | 10 | 28.40 | 2.31 |

| 14 | 40 | 160 | 9 | 16 | 29.20 | 3.36 |

| 15 | 40 | 170 | 12 | 10 | 29.00 | 3.60 |

| 16 | 40 | 180 | 12 | 13 | 29.30 | 3.02 |

| 17 | 40 | 160 | 12 | 13 | 32.00 | 3.98 |

| 18 | 40 | 170 | 9 | 13 | 28.40 | 3.31 |

| 19 | 40 | 170 | 6 | 16 | 27.60 | 2.73 |

| 20 | 30 | 170 | 9 | 10 | 27.20 | 2.06 |

| 21 | 30 | 170 | 12 | 13 | 24.80 | 2.23 |

| 22 | 50 | 170 | 9 | 16 | 25.00 | 2.36 |

| 23 | 40 | 180 | 9 | 10 | 22.60 | 2.61 |

| 24 | 40 | 170 | 9 | 13 | 27.40 | 2.99 |

| 25 | 40 | 170 | 12 | 16 | 24.00 | 2.61 |

| 26 | 30 | 160 | 9 | 13 | 30.00 | 2.34 |

| 27 | 40 | 170 | 9 | 13 | 24.20 | 3.21 |

| 28 | 40 | 160 | 9 | 10 | 30.80 | 3.06 |

| 29 | 50 | 170 | 6 | 13 | 26.20 | 2.01 |

| 源项Source | 平方和 Sum of squares | 自由度Degree of freedom | 均方差 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 7.52 | 14 | 0.54 | 3.25 | 0.017 6 |

| A | 3.63 | 1 | 3.63 | 0.63 | 0.440 3 |

| B | 127.40 | 1 | 127.40 | 22.14 | 0.000 3 |

| C | 15.08 | 1 | 15.08 | 2.62 | 0.127 8 |

| D | 13.13 | 1 | 13.13 | 2.28 | 0.153 2 |

| AB | 31.92 | 1 | 31.92 | 5.55 | 0.033 6 |

| AC | 6.38 | 1 | 6.38 | 1.11 | 0.310 3 |

| AD | 0.14 | 1 | 0.14 | 0.02 | 0.878 0 |

| BC | 19.14 | 1 | 19.14 | 3.33 | 0.089 6 |

| BD | 0.39 | 1 | 0.39 | 0.07 | 0.798 2 |

| CD | 4.73 | 1 | 4.73 | 0.82 | 0.379 9 |

| A2 | 5.04 | 1 | 5.04 | 0.88 | 0.365 3 |

| B2 | 1.58 | 1 | 1.58 | 0.27 | 0.608 3 |

| C2 | 9.12×10-3 | 1 | 9.12×10-3 | 1.59×10-3 | 0.968 8 |

| D2 | 0.17 | 1 | 0.17 | 0.03 | 0.865 5 |

| 残差Residual | 80.54 | 14 | 5.75 | ||

| 失拟误差Lack of fit | 62.08 | 10 | 6.21 | 1.35 | 0.416 1 |

| 纯误差Pure error | 18.46 | 4 | 4.61 | ||

| 总离差Cor total | 310.80 | 28 |

表3 响应面法优化试验的弯曲强度方差分析

Table 3 Analysis of variance of flexural strength for response surface method optimization tests

| 源项Source | 平方和 Sum of squares | 自由度Degree of freedom | 均方差 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 7.52 | 14 | 0.54 | 3.25 | 0.017 6 |

| A | 3.63 | 1 | 3.63 | 0.63 | 0.440 3 |

| B | 127.40 | 1 | 127.40 | 22.14 | 0.000 3 |

| C | 15.08 | 1 | 15.08 | 2.62 | 0.127 8 |

| D | 13.13 | 1 | 13.13 | 2.28 | 0.153 2 |

| AB | 31.92 | 1 | 31.92 | 5.55 | 0.033 6 |

| AC | 6.38 | 1 | 6.38 | 1.11 | 0.310 3 |

| AD | 0.14 | 1 | 0.14 | 0.02 | 0.878 0 |

| BC | 19.14 | 1 | 19.14 | 3.33 | 0.089 6 |

| BD | 0.39 | 1 | 0.39 | 0.07 | 0.798 2 |

| CD | 4.73 | 1 | 4.73 | 0.82 | 0.379 9 |

| A2 | 5.04 | 1 | 5.04 | 0.88 | 0.365 3 |

| B2 | 1.58 | 1 | 1.58 | 0.27 | 0.608 3 |

| C2 | 9.12×10-3 | 1 | 9.12×10-3 | 1.59×10-3 | 0.968 8 |

| D2 | 0.17 | 1 | 0.17 | 0.03 | 0.865 5 |

| 残差Residual | 80.54 | 14 | 5.75 | ||

| 失拟误差Lack of fit | 62.08 | 10 | 6.21 | 1.35 | 0.416 1 |

| 纯误差Pure error | 18.46 | 4 | 4.61 | ||

| 总离差Cor total | 310.80 | 28 |

| 源项Source | 平方和 Sum of squares | 自由度Degree of freedom | 均方差 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 2.48 | 14 | 0.18 | 4.76 | 0.003 1 |

| A | 3.00×10-4 | 1 | 3.00×10-4 | 8.05×10-3 | 0.929 8 |

| B | 0.09 | 1 | 0.09 | 2.51 | 0.135 2 |

| C | 3.33×10-3 | 1 | 3.33×10-3 | 0.09 | 0.769 3 |

| D | 0.08 | 1 | 0.08 | 2.24 | 0.157 0 |

| AB | 3.60×10-3 | 1 | 3.60×10-3 | 0.10 | 0.760 5 |

| AC | 5.63×10-3 | 1 | 5.63×10-3 | 0.15 | 0.703 5 |

| AD | 0.02 | 1 | 0.02 | 0.64 | 0.435 4 |

| BC | 0.07 | 1 | 0.07 | 1.88 | 0.191 4 |

| BD | 0.12 | 1 | 0.12 | 3.19 | 0.095 6 |

| CD | 4.00×10-4 | 1 | 4.00×10-4 | 0.01 | 0.918 9 |

| A2 | 0.35 | 1 | 0.35 | 9.30 | 0.008 6 |

| B2 | 1.93 | 1 | 1.93 | 51.93 | <0.000 1 |

| C2 | 0.06 | 1 | 0.06 | 1.61 | 0.225 2 |

| D2 | 0.02 | 1 | 0.02 | 0.55 | 0.470 9 |

| 残差Residual | 0.52 | 14 | 0.04 | ||

| 失拟误差Lack of fit | 0.48 | 10 | 0.05 | 4.96 | 0.068 2 |

| 纯误差Pure error | 0.04 | 4 | 9.73×10-3 | ||

| 总离差Cor total | 3 | 28 |

表4 响应面法优化试验的冲击强度方差分析

Table 4 Analysis of variance of impact strength for response surface method optimization test

| 源项Source | 平方和 Sum of squares | 自由度Degree of freedom | 均方差 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 2.48 | 14 | 0.18 | 4.76 | 0.003 1 |

| A | 3.00×10-4 | 1 | 3.00×10-4 | 8.05×10-3 | 0.929 8 |

| B | 0.09 | 1 | 0.09 | 2.51 | 0.135 2 |

| C | 3.33×10-3 | 1 | 3.33×10-3 | 0.09 | 0.769 3 |

| D | 0.08 | 1 | 0.08 | 2.24 | 0.157 0 |

| AB | 3.60×10-3 | 1 | 3.60×10-3 | 0.10 | 0.760 5 |

| AC | 5.63×10-3 | 1 | 5.63×10-3 | 0.15 | 0.703 5 |

| AD | 0.02 | 1 | 0.02 | 0.64 | 0.435 4 |

| BC | 0.07 | 1 | 0.07 | 1.88 | 0.191 4 |

| BD | 0.12 | 1 | 0.12 | 3.19 | 0.095 6 |

| CD | 4.00×10-4 | 1 | 4.00×10-4 | 0.01 | 0.918 9 |

| A2 | 0.35 | 1 | 0.35 | 9.30 | 0.008 6 |

| B2 | 1.93 | 1 | 1.93 | 51.93 | <0.000 1 |

| C2 | 0.06 | 1 | 0.06 | 1.61 | 0.225 2 |

| D2 | 0.02 | 1 | 0.02 | 0.55 | 0.470 9 |

| 残差Residual | 0.52 | 14 | 0.04 | ||

| 失拟误差Lack of fit | 0.48 | 10 | 0.05 | 4.96 | 0.068 2 |

| 纯误差Pure error | 0.04 | 4 | 9.73×10-3 | ||

| 总离差Cor total | 3 | 28 |

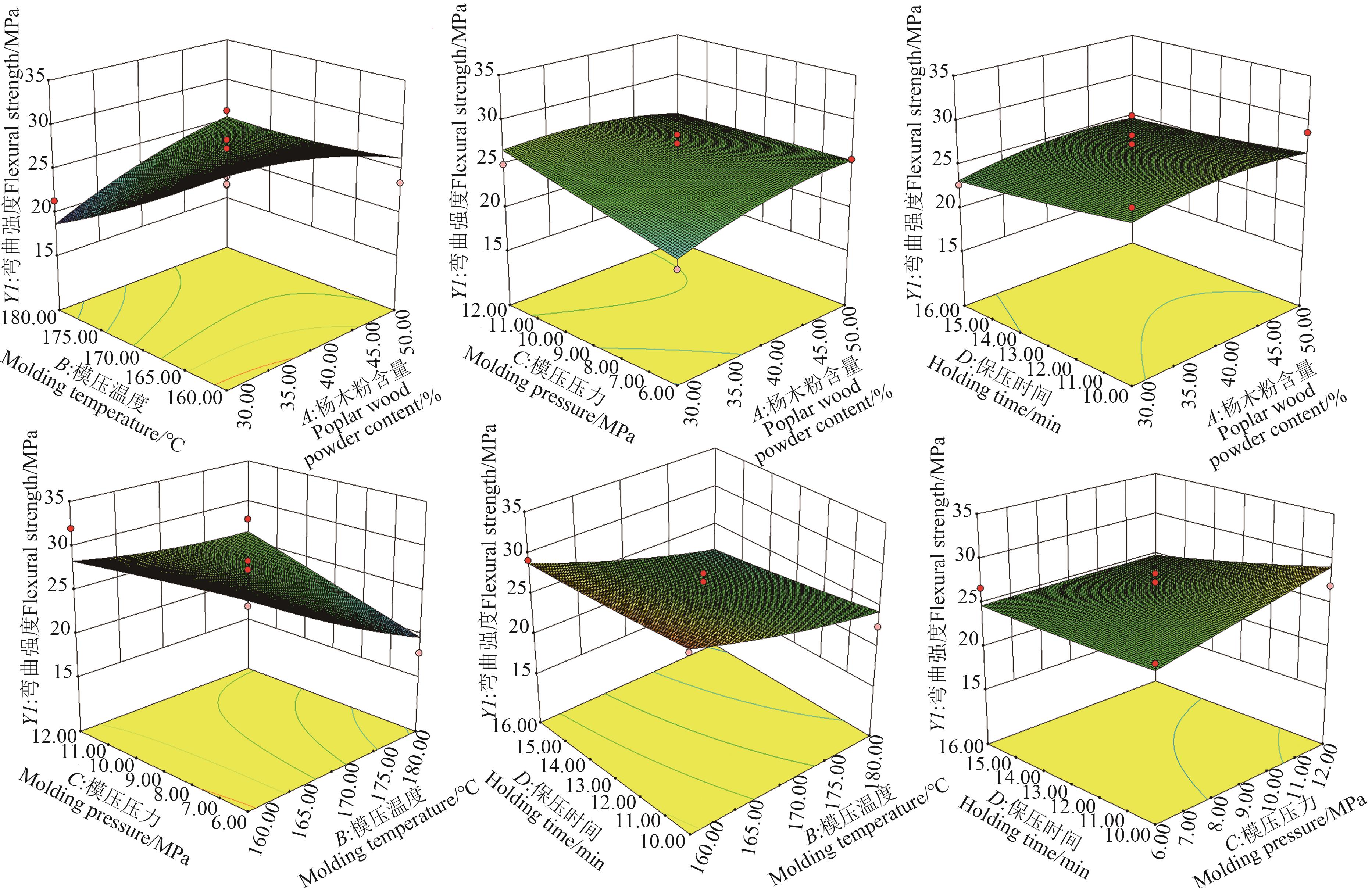

图 1 杨木粉含量、模压温度、模压压力和保压时间对复合材料弯曲强度交互影响的三维响应面

Fig. 1 Three-dimensional response surface of the interaction effects of poplar wood powder content, molding temperature, molding pressure and holding time on the flexural strength of composites

图 2 杨木粉含量、模压温度、模压压力和保压时间对复合材料冲击强度交互影响的三维响应面

Fig. 2 Three-dimensional response surface of the interaction effect of poplar wood powder content, molding temperature, molding pressure and holding time on the impact strength of composites

图4 生物炭增强杨木粉/PLA复合材料微观结构A: CK; B: BC 0.5%; C:BC 1.0%; D: BC 2.0%;E: BC 3%;F: BC 4.0%

Fig. 4 Microstructure of biochar-reinforced poplar wood powder/PLA composites

| 1 | 鞠艳艳,丁元君,邵前前,等.城市园林废弃物生物质炭性质及其应用潜力[J].林业科学,2020,56(8):107-120. |

| JU Y Y, DING Y J, SHAO Q Q, et al.. Properties and application potential of biochar from urban green wastes [J]. Sci. Silvae Sin., 2020,56(8):107-120. | |

| 2 | CHOI J, YANG I, KIM S S, et al.. Upcycling plastic waste into high value-added carbonaceous materials [J/OL].Macromol. Rapid Commun.,2022,43(1):e2100467 [2023-10-22].. |

| 3 | BASALP D, TIHMINLIOGLU F, SOFUOGLU S C,et al.. Utilization of municipal plastic and wood waste in industrial manufacturing of wood plastic composites [J]. Waste Biomass Valoriz., 2020,11(10):5419-5430. |

| 4 | 孙小虎,刘毫,周子惠.建筑装饰装修工程中的木塑复合材料及其应用[J].合成材料老化与应用,2022,51(5):143-145. |

| SUN X H, LIU H, ZHOU Z H. Wood plastic composite material and its application in building decoration engineering [J]. Synth. Mater. Aging Appl., 2022,51(5):143-145. | |

| 5 | KHALID M Y, RASHID A A L, ARIF Z U, et al.. Natural fiber reinforced composites: sustainable materials for emerging applications [J/OL]. Results Eng., 2021, 11: 100263 [2023-10-22]. . |

| 6 | 张显,蔡明,孙宝忠.植物纤维增强复合材料的湿热老化研究进展[J].材料导报,2022,36(5):222-232. |

| ZHANG X, CAI M, SUN B Z. Research progress of hygrothermal aging of plant fiber reinforced composites [J]. Mater. Rep., 2022,36(5):222-232. | |

| 7 | 刘彬,李彬,王怀栋,等.木塑复合材料应用现状及发展趋势[J].工程塑料应用,2017,45(1):137-141. |

| LIU B, LI B, WANG H D,et al.. Application status and development trend of wood plastic composite [J].Eng. Plast. Appl., 2017,45(1):137-141. | |

| 8 | BORAN TORUN S, PESMAN E, DONMEZ CAVDAR A. Effect of alkali treatment on composites made from recycled polyethylene and chestnut cupula [J]. Polym. Compos., 2019,40(11):4442-4451. |

| 9 | ZHOU Y H, FAN M Z, CHEN L H. Interface and bonding mechanisms of plant fibre composites:an overview [J]. Compos. Part B Eng., 2016,101:31-45. |

| 10 | YI S M, XU S H, LI Y, et al.. Synergistic toughening effects of grafting modification and elastomer-olefin block copolymer addition on the fracture resistance of wood particle/polypropylene/elastomer composites [J/OL].Mater. Des.,2019,181:107918 [2023-10-22]. . |

| 11 | XIAN Y, FENG T G, LI H B, et al.. The influence of nano-CaCO3 on the mechanical and dynamic thermo-mechanical properties of core-shell structured wood plastic composites [J/OL]. Forests, 2023, 14(2):257 [2023-10-22]. . |

| 12 | ZHANG Q F, LEI H W, CAI H Z, et al.. Improvement on the properties of microcrystalline cellulose/polylactic acid composites by using activated biochar [J/OL]. J. Clean. Prod., 2020,252:119898[2023-10-22]. . |

| 13 | 张庆法,徐航,任夏瑾,等.农林废物生物炭/高密度聚乙烯复合材料的制备与性能[J].复合材料学报,2021,38(2):398-405. |

| ZHANG Q F, XU H, REN X J, et al.. Preparation and properties of agroforestry wastes biochar/high density polyethylene composites [J]. Acta Mater. Compos. Sin., 2021,38(2):398-405. | |

| 14 | 张庆法, 杨科研, 蔡红珍, 等. 稻壳/高密度聚乙烯复合材料与稻壳炭/高密度聚乙烯复合材料性能对比[J]. 复合材料学报, 2018, 35(11): 3044-3050. |

| ZHANG Q F, YANG K Y, CAI H Z, et al.. Comparison of properties between rice husk/high density polyethylene and rice husk biochar/high density polyethylene composites [J]. Acta. Mater. Compos. Sin., 2018, 35(11): 3044-3050. | |

| 15 | ZOUARI M, DEVALLANCE D B, MARROT L.Effect of biochar addition on mechanical properties,thermal stability,and water resistance of hemp-polylactic acid (PLA) composites [J/OL].Materials, 2022,15(6):2271[2023-10-22].. |

| 16 | WEI M Q, LI Q B, JIANG T,et al..Improvement on the mechanical properties of maleic anhydride/polylactic acid composites with Pinus sylvestris-char [J/OL].Mater. Today Commun., 2023,34:105278 [2023-10-22].. |

| 17 | DONNELLY T A.Response-surface experimental design [J].IEEE Potentials,1992,11(1):19-21. |

| 18 | ASTM International. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials: [S]. New York:American National Standards Institute,2010. |

| 19 | ASTM International. Standard test method for determining the charpy impact resistance of notched specimens of plastics: [S]. New York: American National Standards Institute,2010. |

| 20 | ASTM International. Standard test method for water absorption of rigid cellular plastics: [S]. New York: American National Standards Institute,2012. |

| 21 | TRAN P, NGUYEN Q T, LAU K T. Fire performance of polymer-based composites for maritime infrastructure [J]. Compos. Part B Eng., 2018,155:31-48. |

| 22 | SHAH A U R, IMDAD A, SADIQ A,et al..Mechanical,thermal,and fire retardant properties of rice husk biochar reinforced recycled high-density polyethylene composite material [J/OL].Polymers,2023,15(8):1827 [2023-10-22].. |

| 23 | 魏俞涌,张庆法,盛奎川.生物炭对玉米醇溶蛋白/聚丙烯复合材料力学性能的影响[J].中国农业科技导报,2022,24(10):161-168. |

| WEI Y Y, ZHANG Q F, SHENG K C. Effect of biochar on mechanical properties of zein/polypropylene composites [J]. J. Agric. Sci. Technol., 2022,24(10):161-168. | |

| 24 | ARRIGO R, BARTOLI M, MALUCELLI G. Poly(lactic acid)-biochar biocomposites:effect of processing and filler content on rheological,thermal,and mechanical properties [J/OL]. Polymers,2020, 12(4):892 [2023-10-22]. . |

| 25 | DAS C, TAMRAKAR S, KIZILTAS A,et al..Incorporation of biochar to improve mechanical,thermal and electrical properties of polymer composites [J/OL]. Polymers,2021,13(16):2663 [2023-10-22]. . |

| 26 | BARDHA A, PRASHER S, VILLARTA J, et al.. Nut shell and grain husk waste biochar as carbon black replacements in styrene-butadiene rubber composites and improvements through steam activation [J/OL]. Ind .Crops Prod., 2023,203:117180 [2023-10-22]. . |

| 27 | ADENIYI A G, IWUOZOR K O, EMENIKE E C, et al.. Mechanical and microstructural properties of bio-composite produced from recycled polystyrene/chicken feather biochar [J/OL]. J. Renewable Energy Environ., 2023,11(3): 1553 [2023-10-22]. . |

| [1] | 郗婧怡, 王双庆, 白一彤, 姚秀利, 黄碧璇, 李青怡, 范丽清, 黄世臣, 孙明国. 响应面法优化黑水虻处理餐厨垃圾工艺参数研究[J]. 中国农业科技导报, 2025, 27(1): 241-249. |

| [2] | 傅丽君, 林潇雨, 林建华, 沈慧男, 吴勇镇. 红松茸牛肉酱加工工艺及货架期研究[J]. 中国农业科技导报, 2024, 26(6): 148-158. |

| [3] | 张岚雄, 郑威, 陈源桉, 沈婧, 邹双全, 伍建榕, 倪林. 樟叶总木脂素提取工艺及其抑菌活性研究[J]. 中国农业科技导报, 2024, 26(5): 138-147. |

| [4] | 刘东玲, 司皓, 郑宝江, 张玉红. 响应面法优化酶解辅助-超声提取菥蓂中的黑芥子苷[J]. 中国农业科技导报, 2024, 26(4): 225-233. |

| [5] | 李琦, 张树林, 张达娟, 贾滢暄, 王泽斌. 响应面法改良牟氏角毛藻培养基[J]. 中国农业科技导报, 2023, 25(8): 225-233. |

| [6] | 赵秀英, 黄晴雯, 曹浩杰, 王杰, 李瑞姣, 聂冬霞, 韩铮, 赵志辉. 响应面法优化禾谷镰刀菌产脱氧雪腐镰刀菌烯醇及其衍生物的液体培养条件[J]. 中国农业科技导报, 2023, 25(7): 222-233. |

| [7] | 李绍波, 张阔, 王佳, 李建平, 刘树腾. 基于CFD的风送喷雾装置风筒参数优化[J]. 中国农业科技导报, 2023, 25(12): 93-102. |

| [8] | 王凯强, 杨雪, 李常风, 段晓, 彭晴, 乔宇, 石波. 响应面法优化低聚木糖诱导大豆抗毒素合成条件[J]. 中国农业科技导报, 2022, 24(10): 208-217. |

| [9] | 戴阳军1,胡舰1,2,周莹2,左波1,石怡雪1. Plackett-Burman设计及响应面法优化无花果干复合酶解工艺[J]. 中国农业科技导报, 2018, 20(7): 146-153. |

| [10] | 陈金娥,刘慧,赵志刚,张海容*. 响应面法优化超声波提取三七根多糖工艺研究[J]. 中国农业科技导报, 2018, 20(4): 138-146. |

| [11] | 徐澜1,张鹏飞1,雷丽霞1,张海容2,王创云3. 响应面法优化微波辅助提取吴茱萸多糖工艺[J]. 中国农业科技导报, 2016, 18(4): 174-180. |

| [12] | 熊夏宇,曾新安*,王满生,张智宏. 响应面法优化脉冲电场辅助提取油菜花粉中黄酮类物质工艺研究[J]. 中国农业科技导报, 2015, 17(5): 88-93. |

| [13] | 辛崇博,孜力汗,刘晨光,白凤武*. 响应面法优化玉米芯同步糖化发酵预处理条件[J]. , 2013, 15(5): 173-180. |

| [14] | 王金玲1,刘晓平2,高玮华1,赵凤艳3,吕长山3. 解磷巨大芽胞杆菌液体发酵的培养基优化[J]. , 2013, 15(2): 185-192. |

| [15] | 张宁,刘爽,刘冬莲*. 超声波协同固体酸水解花生壳制备乙酰丙酸的研究[J]. , 2013, 15(1): 164-169. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号