中国农业科技导报 ›› 2025, Vol. 27 ›› Issue (3): 112-121.DOI: 10.13304/j.nykjdb.2023.0687

• 智慧农业 农机装备 • 上一篇

许静1( ), 李晗2, 陈平录1(

), 李晗2, 陈平录1( ), 罗江旎1, 唐承露1, 刘木华1

), 罗江旎1, 唐承露1, 刘木华1

收稿日期:2023-09-14

接受日期:2024-03-18

出版日期:2025-03-15

发布日期:2025-03-14

通讯作者:

陈平录

作者简介:许静E-mail:xujing0085@jxau.edu.cn;

基金资助:

Jing XU1( ), Han LI2, Pinglu CHEN1(

), Han LI2, Pinglu CHEN1( ), Jiangni LUO1, Chenglu TANG1, Muhua LIU1

), Jiangni LUO1, Chenglu TANG1, Muhua LIU1

Received:2023-09-14

Accepted:2024-03-18

Online:2025-03-15

Published:2025-03-14

Contact:

Pinglu CHEN

摘要:

准确获取油茶茶枯有机肥的离散元仿真模型参数是运用仿真手段优化设计油茶茶枯施肥装置的关键。以含水率为2.88%的油茶茶枯为研究对象,选用EDEM软件中的“Hertz-Mindlin with JKR”作为接触模型,以圆筒提升法物理实验堆积角度为响应目标,通过响应面法优化标定了油茶茶枯有机肥的仿真参数。首先通过接触摩擦试验并结合GEMM材料库得出其他难以测量的参数,如COSM的泊松比和剪切模量,进而为Plackett-Burman试验提供选择水平。通过Plackett-Burman试验从油茶茶枯有关的9个参数中筛选出了3个对堆积角影响较为显著的参数:茶枯-茶枯静摩擦系数、茶枯-不锈钢静摩擦系数、茶枯-茶枯滚动摩擦系数。根据最陡爬坡试验结果确定显著性参数最优值区间,进一步以茶枯有机肥堆积角为响应值,基于Box-Behnken试验获得堆积角与显著性参数的二阶回归模型。以物理试验测得的堆积角度35.42°为响应目标对回归方程寻求最优解,得到最佳参数组合为:茶枯-茶枯静摩擦系数1.01,茶枯-不锈钢静摩擦系数0.34,茶枯-茶枯滚动摩擦系数0.20。采用最优解进行堆积和模孔压缩仿真试验,仿真堆积角与物理试验结果的相对误差为2.96%,且堆积形状具有高度相似性,仿真挤压力与实际模孔压缩试验的挤压力相对误差为1.79%,验证了所标定的参数的准确性。研究结果可为分析茶枯有机肥与施肥装置间复杂的相互作用并设计出高效精准茶枯有机肥施肥机提供理论参考。

中图分类号:

许静, 李晗, 陈平录, 罗江旎, 唐承露, 刘木华. 油茶茶枯离散元模型参数标定与试验[J]. 中国农业科技导报, 2025, 27(3): 112-121.

Jing XU, Han LI, Pinglu CHEN, Jiangni LUO, Chenglu TANG, Muhua LIU. Calibration and Validation of Discrete Element Model for Camelliaoleifera Seed Meal[J]. Journal of Agricultural Science and Technology, 2025, 27(3): 112-121.

摩擦系数 Coefficient of friction | 茶枯 Seed meal | ||||

|---|---|---|---|---|---|

静摩擦系数 Static friction coefficient | 0.215 | 0.415 | 0.297 | 0.257 | 0.250 |

滚动摩擦系数 Static friction coefficient | 0.242 | 0.311 | 0.347 | 0.278 | 0.244 |

表1 茶枯与不锈钢之间的静摩擦系数及滚动摩擦系数

Table 1 Static friction coefficient and rolling friction coefficient between seed meal and stainless steel

摩擦系数 Coefficient of friction | 茶枯 Seed meal | ||||

|---|---|---|---|---|---|

静摩擦系数 Static friction coefficient | 0.215 | 0.415 | 0.297 | 0.257 | 0.250 |

滚动摩擦系数 Static friction coefficient | 0.242 | 0.311 | 0.347 | 0.278 | 0.244 |

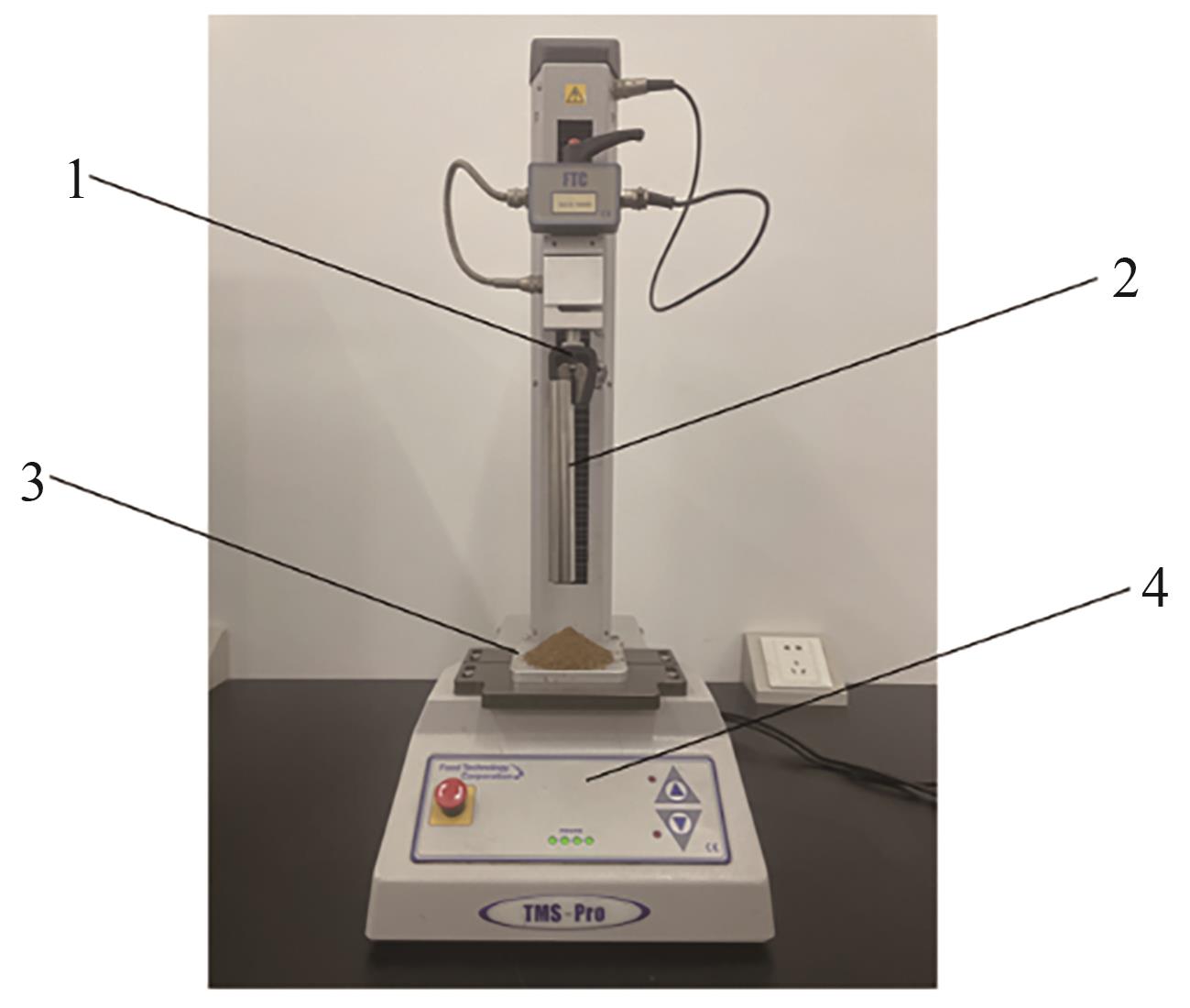

图1 茶枯堆积角物理试验注:1—夹持装置;2—不锈钢圆筒;3—不锈钢底座;4—质构检测仪。

Fig. 1 Physical experiment of resting angle of seed mealNote:1—Clamping device; 2—Stainless steel cylinder; 3—Stainless steel base; 4—Texture tester.

参数符号 Parameter symbol | 参数 Parameter | 参数水平 Parameter level | ||

|---|---|---|---|---|

| -1 | 0 | 1 | ||

| X1 | 茶枯泊松比 Poisson’s ratio of COSM | 0.30 | 0.35 | 0.4 |

| X2 | 茶枯剪切模量/MPa Shear modulus of COSM/MPa | 10 | 160 | 310 |

| X3 | 茶枯-茶枯碰撞恢复系数 Collision recovery coefficient of COSM-COSM | 0.35 | 0.55 | 0.75 |

| X4 | 茶枯-不锈钢碰撞恢复系数 Collision recovery coefficient of COSM-stainless steel | 0.10 | 0.35 | 0.6 |

| X5 | 茶枯-茶枯静摩擦系数 Static friction coefficient of COSM-COSM | 0.44 | 0.80 | 1.16 |

| X6 | 茶枯-不锈钢静摩擦系数 Static friction coefficient of COSM-stainless steel | 0.215 | 0.315 | 0.415 |

| X7 | 茶枯-茶枯滚动摩擦系数 Coefficient of rolling friction of COSM-COSM | 0.050 | 0.175 | 0.300 |

| X8 | 茶枯-不锈钢滚动摩擦系数 Coefficient of rolling friction of COSM-stainless steel | 0.242 0 | 0.294 5 | 0.347 0 |

| X9 | JKR表面能/(J·m-2) JKR surface energy/(J·m-2) | 0 | 1.75 | 3.50 |

表2 参数水平

Table 2 Parameter level

参数符号 Parameter symbol | 参数 Parameter | 参数水平 Parameter level | ||

|---|---|---|---|---|

| -1 | 0 | 1 | ||

| X1 | 茶枯泊松比 Poisson’s ratio of COSM | 0.30 | 0.35 | 0.4 |

| X2 | 茶枯剪切模量/MPa Shear modulus of COSM/MPa | 10 | 160 | 310 |

| X3 | 茶枯-茶枯碰撞恢复系数 Collision recovery coefficient of COSM-COSM | 0.35 | 0.55 | 0.75 |

| X4 | 茶枯-不锈钢碰撞恢复系数 Collision recovery coefficient of COSM-stainless steel | 0.10 | 0.35 | 0.6 |

| X5 | 茶枯-茶枯静摩擦系数 Static friction coefficient of COSM-COSM | 0.44 | 0.80 | 1.16 |

| X6 | 茶枯-不锈钢静摩擦系数 Static friction coefficient of COSM-stainless steel | 0.215 | 0.315 | 0.415 |

| X7 | 茶枯-茶枯滚动摩擦系数 Coefficient of rolling friction of COSM-COSM | 0.050 | 0.175 | 0.300 |

| X8 | 茶枯-不锈钢滚动摩擦系数 Coefficient of rolling friction of COSM-stainless steel | 0.242 0 | 0.294 5 | 0.347 0 |

| X9 | JKR表面能/(J·m-2) JKR surface energy/(J·m-2) | 0 | 1.75 | 3.50 |

序号 No. | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | 堆积角 Repose angle/(°) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | -1 | 1 | -1 | -1 | -1 | 1 | 1 | 1 | 30.41 |

| 2 | 1 | 1 | -1 | 1 | -1 | -1 | -1 | 1 | 1 | 7.02 |

| 3 | -1 | 1 | 1 | -1 | 1 | -1 | -1 | -1 | 1 | 14.76 |

| 4 | 1 | -1 | 1 | 1 | -1 | 1 | -1 | -1 | -1 | 5.43 |

| 5 | 1 | 1 | -1 | 1 | 1 | -1 | 1 | -1 | -1 | 41.24 |

| 6 | 1 | 1 | 1 | -1 | 1 | 1 | -1 | 1 | -1 | 27.61 |

| 7 | -1 | 1 | 1 | 1 | -1 | 1 | 1 | -1 | 1 | 48.23 |

| 8 | -1 | -1 | 1 | 1 | 1 | -1 | 1 | 1 | -1 | 41.35 |

| 9 | -1 | -1 | -1 | 1 | 1 | 1 | -1 | 1 | 1 | 38.10 |

| 10 | 1 | -1 | -1 | -1 | 1 | 1 | 1 | -1 | 1 | 55.66 |

| 11 | -1 | 1 | -1 | -1 | -1 | 1 | 1 | 1 | -1 | 44.57 |

| 12 | -1 | 1 | 1 | 1 | -1 | 1 | 1 | -1 | 1 | 48.23 |

| 13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 37.65 |

表3 Plackett-Burman试验方案及结果

Table 3 Plackett-burman test protocol and results

序号 No. | X1 | X2 | X3 | X4 | X5 | X6 | X7 | X8 | X9 | 堆积角 Repose angle/(°) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | -1 | 1 | -1 | -1 | -1 | 1 | 1 | 1 | 30.41 |

| 2 | 1 | 1 | -1 | 1 | -1 | -1 | -1 | 1 | 1 | 7.02 |

| 3 | -1 | 1 | 1 | -1 | 1 | -1 | -1 | -1 | 1 | 14.76 |

| 4 | 1 | -1 | 1 | 1 | -1 | 1 | -1 | -1 | -1 | 5.43 |

| 5 | 1 | 1 | -1 | 1 | 1 | -1 | 1 | -1 | -1 | 41.24 |

| 6 | 1 | 1 | 1 | -1 | 1 | 1 | -1 | 1 | -1 | 27.61 |

| 7 | -1 | 1 | 1 | 1 | -1 | 1 | 1 | -1 | 1 | 48.23 |

| 8 | -1 | -1 | 1 | 1 | 1 | -1 | 1 | 1 | -1 | 41.35 |

| 9 | -1 | -1 | -1 | 1 | 1 | 1 | -1 | 1 | 1 | 38.10 |

| 10 | 1 | -1 | -1 | -1 | 1 | 1 | 1 | -1 | 1 | 55.66 |

| 11 | -1 | 1 | -1 | -1 | -1 | 1 | 1 | 1 | -1 | 44.57 |

| 12 | -1 | 1 | 1 | 1 | -1 | 1 | 1 | -1 | 1 | 48.23 |

| 13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 37.65 |

参数 Parameter | 标准化效应 Standardization effect | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value | 显著性排序 Significance sort |

|---|---|---|---|---|---|---|

| X1 | -3.97 | 47.28 | 1 | 2.14 | 0.281 | 5 |

| X2 | 1.38 | 5.74 | 1 | 0.26 | 0.661 | 8 |

| X3 | -3.83 | 44.01 | 1 | 1.99 | 0.294 | 6 |

| X4 | 0.70 | 1.46 | 1 | 0.07 | 0.822 | 9 |

| X5 | 13.15 | 518.50 | 1 | 23.43 | 0.040 | 3 |

| X6 | 13.44 | 541.90 | 1 | 24.48 | 0.038 | 2 |

| X7 | 27.39 | 2 251.18 | 1 | 101.72 | 0.010 | 1 |

| X8 | 3.26 | 31.88 | 1 | 1.44 | 0.353 | 7 |

| X9 | 4.97 | 74.00 | 1 | 3.34 | 0.209 | 4 |

表4 Plackett-Burman试验参数显著性分析

Table 4 Plackett-burman test parameters significance analysis

参数 Parameter | 标准化效应 Standardization effect | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value | 显著性排序 Significance sort |

|---|---|---|---|---|---|---|

| X1 | -3.97 | 47.28 | 1 | 2.14 | 0.281 | 5 |

| X2 | 1.38 | 5.74 | 1 | 0.26 | 0.661 | 8 |

| X3 | -3.83 | 44.01 | 1 | 1.99 | 0.294 | 6 |

| X4 | 0.70 | 1.46 | 1 | 0.07 | 0.822 | 9 |

| X5 | 13.15 | 518.50 | 1 | 23.43 | 0.040 | 3 |

| X6 | 13.44 | 541.90 | 1 | 24.48 | 0.038 | 2 |

| X7 | 27.39 | 2 251.18 | 1 | 101.72 | 0.010 | 1 |

| X8 | 3.26 | 31.88 | 1 | 1.44 | 0.353 | 7 |

| X9 | 4.97 | 74.00 | 1 | 3.34 | 0.209 | 4 |

试验序号 Test No. | 参数 Parameter | 堆积角 Repose angle/(°) | 相对误差 Relative errors/% | |||

|---|---|---|---|---|---|---|

| X5 | X6 | X7 | 仿真值 Simulation values | 试验值 Test values | ||

| 1 | 0.440 | 0.215 | 0.05 | 12.51 | 35.42 | 64.68 |

| 2 | 0.584 | 0.255 | 0.10 | 18.70 | 35.42 | 47.20 |

| 3 | 0.728 | 0.295 | 0.15 | 26.95 | 35.42 | 23.91 |

| 4 | 0.872 | 0.335 | 0.20 | 36.63 | 35.42 | 3.42 |

| 5 | 1.016 | 0.375 | 0.25 | 43.65 | 35.42 | 23.24 |

| 6 | 1.160 | 0.415 | 0.30 | 54.31 | 35.42 | 53.33 |

表5 最陡爬坡试验方案及结果

Table 5 The program and results of the steepest climbing test

试验序号 Test No. | 参数 Parameter | 堆积角 Repose angle/(°) | 相对误差 Relative errors/% | |||

|---|---|---|---|---|---|---|

| X5 | X6 | X7 | 仿真值 Simulation values | 试验值 Test values | ||

| 1 | 0.440 | 0.215 | 0.05 | 12.51 | 35.42 | 64.68 |

| 2 | 0.584 | 0.255 | 0.10 | 18.70 | 35.42 | 47.20 |

| 3 | 0.728 | 0.295 | 0.15 | 26.95 | 35.42 | 23.91 |

| 4 | 0.872 | 0.335 | 0.20 | 36.63 | 35.42 | 3.42 |

| 5 | 1.016 | 0.375 | 0.25 | 43.65 | 35.42 | 23.24 |

| 6 | 1.160 | 0.415 | 0.30 | 54.31 | 35.42 | 53.33 |

序号 No. | X5 | X6 | X7 | 堆积角 Repose angle/(°) |

|---|---|---|---|---|

| 1 | 0.728 | 0.295 | 0.20 | 35.73 |

| 2 | 1.016 | 0.295 | 0.20 | 34.20 |

| 3 | 0.728 | 0.375 | 0.20 | 42.07 |

| 4 | 1.016 | 0.375 | 0.20 | 37.19 |

| 5 | 0.728 | 0.335 | 0.15 | 34.49 |

| 6 | 1.016 | 0.335 | 0.15 | 33.02 |

| 7 | 0.728 | 0.335 | 0.25 | 42.04 |

| 8 | 1.016 | 0.335 | 0.25 | 39.91 |

| 9 | 0.872 | 0.295 | 0.15 | 30.92 |

| 10 | 0.872 | 0.375 | 0.15 | 40.45 |

| 11 | 0.872 | 0.295 | 0.25 | 43.52 |

| 12 | 0.872 | 0.375 | 0.25 | 42.65 |

| 13 | 0.872 | 0.335 | 0.20 | 37.40 |

| 14 | 0.872 | 0.335 | 0.20 | 37.81 |

| 15 | 0.872 | 0.335 | 0.20 | 37.71 |

| 16 | 0.872 | 0.335 | 0.20 | 38.05 |

| 17 | 0.872 | 0.335 | 0.20 | 38.09 |

表6 Box-Behnken试验设计及结果

Table 6 Box-behnken experimental design and result

序号 No. | X5 | X6 | X7 | 堆积角 Repose angle/(°) |

|---|---|---|---|---|

| 1 | 0.728 | 0.295 | 0.20 | 35.73 |

| 2 | 1.016 | 0.295 | 0.20 | 34.20 |

| 3 | 0.728 | 0.375 | 0.20 | 42.07 |

| 4 | 1.016 | 0.375 | 0.20 | 37.19 |

| 5 | 0.728 | 0.335 | 0.15 | 34.49 |

| 6 | 1.016 | 0.335 | 0.15 | 33.02 |

| 7 | 0.728 | 0.335 | 0.25 | 42.04 |

| 8 | 1.016 | 0.335 | 0.25 | 39.91 |

| 9 | 0.872 | 0.295 | 0.15 | 30.92 |

| 10 | 0.872 | 0.375 | 0.15 | 40.45 |

| 11 | 0.872 | 0.295 | 0.25 | 43.52 |

| 12 | 0.872 | 0.375 | 0.25 | 42.65 |

| 13 | 0.872 | 0.335 | 0.20 | 37.40 |

| 14 | 0.872 | 0.335 | 0.20 | 37.81 |

| 15 | 0.872 | 0.335 | 0.20 | 37.71 |

| 16 | 0.872 | 0.335 | 0.20 | 38.05 |

| 17 | 0.872 | 0.335 | 0.20 | 38.09 |

方差来源 Source of variance | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|

| R2=0.9932;R2adj=0.9845;CV=1.17%;精密度(adep precision)=36.824 0 | ||||

| 模型Model | 201.21 | 9 | 113.95 | <0.000 1 |

| X5 | 12.53 | 1 | 63.84 | <0.000 1 |

| X6 | 40.46 | 1 | 206.19 | <0.000 1 |

| X7 | 106.87 | 1 | 544.71 | <0.000 1 |

| X5X6 | 2.81 | 1 | 14.30 | 0.006 9 |

| X5X7 | 0.11 | 1 | 0.555 0 | 0.480 5 |

| X6X7 | 27.04 | 1 | 137.82 | <0.000 1 |

| X52 | 6.76 | 1 | 34.46 | 0.000 6 |

| X62 | 2.39 | 1 | 12.16 | 0.010 2 |

| X72 | 2.83 | 1 | 14.44 | 0.006 7 |

| 残差Residual | 1.37 | 7 | ||

| 失拟项 Lack of fit | 1.06 | 3 | 4.50 | 0.090 2 |

| 纯误差 Pure error | 0.31 | 4 | ||

| 总和Sum | 202.58 | 16 | ||

表7 Box-Behnken二次回归模型方差分析

Table 7 Box-behnken quadratic regression model analysis of variance

方差来源 Source of variance | 均方和 Sum of mean squares | 自由度 Degree of freedom | F值 F value | P值 P value |

|---|---|---|---|---|

| R2=0.9932;R2adj=0.9845;CV=1.17%;精密度(adep precision)=36.824 0 | ||||

| 模型Model | 201.21 | 9 | 113.95 | <0.000 1 |

| X5 | 12.53 | 1 | 63.84 | <0.000 1 |

| X6 | 40.46 | 1 | 206.19 | <0.000 1 |

| X7 | 106.87 | 1 | 544.71 | <0.000 1 |

| X5X6 | 2.81 | 1 | 14.30 | 0.006 9 |

| X5X7 | 0.11 | 1 | 0.555 0 | 0.480 5 |

| X6X7 | 27.04 | 1 | 137.82 | <0.000 1 |

| X52 | 6.76 | 1 | 34.46 | 0.000 6 |

| X62 | 2.39 | 1 | 12.16 | 0.010 2 |

| X72 | 2.83 | 1 | 14.44 | 0.006 7 |

| 残差Residual | 1.37 | 7 | ||

| 失拟项 Lack of fit | 1.06 | 3 | 4.50 | 0.090 2 |

| 纯误差 Pure error | 0.31 | 4 | ||

| 总和Sum | 202.58 | 16 | ||

| 1 | 陆思羽,胡冬南,郭晓敏,等.4个油茶品种的果实生长动态及经济性状比较[J].经济林研究,2020,38(2):46-52. |

| LU S Y, HU D N, GUO X M, et al.. Comparison of fruit growth dynamics and economic characteristics of four Camellia oleifera clones [J]. Non-Wood For. Res., 2020,38(2): 46-52. | |

| 2 | 赖鹏英,肖志红,李培旺,等.油茶资源利用及产业发展现状[J].生物质化学工程,2021,55(1):23-30. |

| LAI P Y, XIAO Z H, LI P W, et al.. Research on utilization of Camellia oleifera Abel.Resources and industrial development status [J]. Biomass Chem. Eng., 2021,55(1):23-30. | |

| 3 | 樊庆山,刁其玉,毕研亮,等.新型植物饼粕类饲料在反刍动物生产中的应用[J].家畜生态学报,2018,39(2):79-85. |

| FAN Q S, DIAO Q Y, BI Y L, et al.. Application of new plant cake feeds in ruminant animal production [J]. J. Domest. Anim. Ecol., 2018,39(2):79-85. | |

| 4 | 练杰,金青哲,王兴国.油茶籽粕微生物发酵研究进展[J].中国油脂,2012,37(7):24-26. |

| LIAN J, JIN Q Z, WANG X G. Research advance in microbial fermentation of oil-tea camellia seed meal [J]. China Oils Fats, 2012,37(7):24-26. | |

| 5 | 郑钰铟,胡素萍,陈辉,等.油茶饼粕生物炭和有机肥对土壤酶活性的影响[J].森林与环境学报,2018,38(3):348-354. |

| ZHENG Y Y, HU S P, CHEN H, et al.. Effects of Camellia cake biochar and organic fertilizer on soil enzymatic activities [J]. J. For. Environ., 2018,38(3):348-354. | |

| 6 | 朱飞凡.油茶饼粕的农业应用价值与方法[J].食品安全导刊,2021(34):190-192. |

| ZHU F F. Agricultural application value and method of Camellia oil cake [J]. China Food Saf. Mag., 2021(34):190-192. | |

| 7 | 渠心静,赵冠宇,耿蕊,等.油茶茶枯分解及养分释放规律[J].经济林研究,2019,37(4):104-111. |

| QU X J, ZHAO G Y, GENG R, et al.. Decomposition and nutrient releasing pattern in Camellia oleifera seed meal [J]. Non-Wood For. Res., 2019,37(4):104-111. | |

| 8 | 查钱慧,洪文泓,谭莎,等.油茶饼粕有机肥对番茄生长表观及生理指标的影响[J].安徽农业大学学报,2015,42(3):458-462. |

| ZHA Q H, HONG W H, TAN S, et al.. Effects of camellia cake organic fertilizer on the growth and physiological characteristics of Lycopersicon esculentum Mill [J]. J. Anhui Agric. Univ., 2015,42(3):458-462. | |

| 9 | 冯少平,黄婷,张晖,等.油茶饼粕有机肥对马占相思和窿缘桉幼苗生长的影响[J].亚热带植物科学,2021,50(5):366-370. |

| FENG S P, HUANG T, ZHANG H, et al.. Oil-tea cake organic fertilizer on growth of Acacia mangium and Eucalyptus exserta seedlings [J]. Subtrop. Plant Sci., 2021,50(5):366-370. | |

| 10 | 张晖,吴雪辉,董斌,等.不同比例油茶饼粕自然发酵过程中的养分变化及微生物群落比较[J].经济林研究,2022,40(2):40-47. |

| ZHANG H, WU X H, DONG B, et al.. Comparison of nutrient changes and bacterial community during natural fermentation of Camellia oleifera oil-tea cake with different proportions [J]. Non-Wood For. Res., 2022,40(2):40-47. | |

| 11 | 王金峰,付佐栋,翁武雄,等.圆锥盘推板式水田侧深施肥双行排肥器设计与试验[J].农业机械学报,2023,54(2):53-62, 106. |

| WANG J F, FU Z D, WENG W X, et al.. Design and experiment of conical-disc push plate double-row fertilizer apparatus for side-deep fertilization in paddy field [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(2):53-62, 106. | |

| 12 | 袁全春,徐丽明,马帅,等.有机肥深施机肥块破碎刀设计与试验[J].农业工程学报,2020,36(9):44-51. |

| YUAN Q C, XU L M, MA S, et al.. Design and test of sawtooth fertilizer block crushing blade of organic fertilizer deep applicator [J]. Trans. Chin. Soc. Agric. Eng., 2020,36(9):44-51. | |

| 13 | 廖庆喜,陈勇,张青松,等.油菜侧深穴施肥装置设计与试验[J].农业机械学报,2023,54(2):41-52. |

| LIAO Q X, CHEN Y, ZHANG Q S, et al.. Design and experiment of side deep hole fertilization device for rapeseed [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(2):41-52. | |

| 14 | 张兆国,薛浩田,王一驰,等.基于离散元法的三七仿生挖掘铲设计与试验[J].农业机械学报,2022,53(5):100-111. |

| ZHANG Z G, XUE H T, WANG Y C, et al.. Design and experiment of Panax notoginseng bionic excavating shovel based on EDEM [J]. Trans. Chin. Soc. Agric. Mach., 2022,53(5):100-111. | |

| 15 | 丁文波,朱继平,陈伟,等.基于EDEM的青稞接触参数仿真标定[J].中国农机化学报,2021,42(9):114-121. |

| DING W B, ZHU J P, CHEN W, et al.. Simulation calibration of highland barley contact parameters based on EDEM [J]. J. Chin. Agric. Mech., 2021,42(9): 114-121. | |

| 16 | KOVACS A. Modelling of maize plant by the discrete element method [D]. Budapest: Budapest University of Technology and Economics, 2019. |

| 17 | PETINGCO M C, CASADA M E, MAGHIRANG R G. Discrete element method simulation of wheat bulk density as affected by grain drop height and kernel size distribution [J]. J. ASABE, 2022,65(3):555-566. |

| 18 | LI X Y, DU Y F, LIU L, et al.. Parameter calibration of corncob based on DEM [J/OL]. Adv. Powder Technol., 2022,33(8):103699 [2024-07-16]. . |

| 19 | 彭才望,许道军,贺喜,等.黑水虻处理的猪粪有机肥离散元仿真模型参数标定[J].农业工程学报,2020,36(17):212-218. |

| PENG C W, XU D J, HE X, et al.. Parameter calibration of discrete element simulation model for pig manure organic fertilizer treated with Hermetia illucen [J]. Trans. Chin. Soc. Agric. Eng., 2020,36(17):212-218. | |

| 20 | 罗帅,袁巧霞, GOUDA Shaban,等.基于JKR粘结模型的蚯蚓粪基质离散元法参数标定[J].农业机械学报,2018,49(4):343-350. |

| LUO S, YUAN Q X, GOUDA S B, et al.. Parameters calibration of vermicomposting nursery substrate with discrete element method based on JKR contact model [J]. Trans. Chin. Soc. Agric. Mach., 2018,49(4):343-350. | |

| 21 | 王韦韦,蔡丹艳,谢进杰,等.玉米秸秆粉料致密成型离散元模型参数标定[J].农业机械学报,2021,52(3):127-134. |

| WANG W W, CAI D Y, XIE J J, et al.. Parameters calibration of discrete element model for corn stalk powder compression simulation [J]. Trans. Chin. Soc. Agric. Mach., 2021,52(3):127-134. | |

| 22 | 韩树杰,戚江涛,坎杂,等.新疆果园深施散体厩肥离散元参数标定研究[J].农业机械学报,2021,52(4):101-108. |

| HAN S J, QI J T, KAN Z, et al.. Parameters calibration of discrete element for deep application of bulk manure in Xinjiang orchard [J]. Trans. Chin. Soc. Agric. Mach., 2021,52(4):101-108. | |

| 23 | 牛智有,孔宪锐,沈柏胜,等.颗粒饲料破损离散元仿真参数标定[J].农业机械学报,2022,53(7):132-140, 207. |

| NIU Z Y, KONG X R, SHEN B S, et al.. Parameters calibration of discrete element simulation for pellet feed attrition [J]. Trans. Chin. Soc. Agric. Mach., 2022,53(7):132-140, 207. | |

| 24 | 宋占华,李浩,闫银发,等.桑园土壤非等径颗粒离散元仿真模型参数标定与试验[J].农业机械学报,2022,53(6):21-33. |

| SONG Z H, LI H, YAN Y F, et al.. Calibration method of contact characteristic parameters of soil in mulberry field based on unequal-diameter particles DEM theory [J]. Trans. Chin. Soc. Agric. Mach., 2022,53(6):21-33. | |

| 25 | 张喜瑞,胡旭航,刘俊孝,等.香蕉秸秆离散元仿真粘结模型参数标定与试验[J].农业机械学报,2023,54(5):121-130. |

| ZHANG X R, HU X H, LIU J X, et al.. Calibration and verification of bonding parameters of banana straw simulation model based on discrete element method [J]. Trans. Chin. Soc. Agric. Mach.,2023,54(5):121-130. | |

| 26 | 戚江涛,蒙贺伟,坎杂,等.基于EDEM的双螺旋奶牛饲喂装置给料性能分析与试验[J].农业工程学报,2017,33(24):65-71. |

| QI J T, MENG H W, KAN Z, et al.. Analysis and test of feeding performance of dual-spiral cow feeding device based on EDEM [J]. Trans. Chin. Soc. Agric. Eng., 2017,33(24):65-71. | |

| 27 | MA G G, SUN Z J, MA H, et al.. Calibration of contact parameters for moist bulk of shotcrete based on EDEM [J/OL]. Adv. Materials Sci. Eng., 2022(1):6072303 [2024-07-16]. . |

| 28 | 问小江,方飞飞,刘应科,等.基于煤粉堆积角的EDEM颗粒接触参数标定[J].中国安全科学报,2020,30(7):114-119. |

| WEN X J, FANG F F, LIU Y K, et al.. Research on stacking angle of coal particles and parameter calibration on EDEM [J]. China Safety Sci. J., 2020,30(7):114-119. | |

| 29 | XIA R, LI B, WANG X W, et al.. Measurement and calibration of the discrete element parameters of wet bulk coal [J].Measurement, 2019,142:84-95. |

| 30 | 郝建军,魏文波,黄鹏程,等.油葵籽粒离散元参数标定与试验验证[J].农业工程学报,2021,37(12):36-44. |

| HAO J J, WEI W B, HUANG P C, et al.. Calibration and experimental verification of discrete element parameters of oil sunflower seeds [J]. Trans. Chin. Soc. Agric. Eng., 2021,37(12):36-44. | |

| 31 | 田辛亮,丛旭,齐江涛,等.黑土区玉米秸秆-土壤混料离散元模型参数标定[J].农业机械学报,2021,52(10):100-108, 242. |

| TIAN X L, CONG X, QI J T, et al.. Parameter calibration of discrete element model for corn straw-soil mixture in black soil areas [J]. Trans. Chin. Soc. Agric. Mach., 2021,52(10):100-108, 242. | |

| 32 | 廖宜涛,廖庆喜,周宇,等.饲料油菜薹期收获茎秆破碎离散元仿真参数标定[J].农业机械学报,2020,51(6):73-82. |

| LIAO Y T, LIAO Q X, ZHOU Y, et al.. Parameters calibration of discrete element model of fodder rape crop harvest in bolting stage [J]. Trans. Chin. Soc. Agric. Mach., 2020,51(6):73-82. | |

| 33 | 曾长女,金南南,谷贺,等.基于数字图像测量技术的豆粕剪切变形特性[J].农业工程学报,2020,36(5):310-317. |

| ZENG C N, JIN N N, GU H, et al..Analysis of triaxial shear characteristics of soybean meal based on digital image measurement technology [J]. Trans. Chin. Soc. Agric. Eng., 2020,36(5):310-317. | |

| 34 | 丁辛亭,李凯,郝伟,等.基于RSM和GA-BP-GA优化的油茶籽仿真参数标定[J].农业机械学报,2023,54(2):139-150. |

| DING X T, LI K, HAO W, et al.. Calibration of simulation parameters of Camellia oleifera seeds based on RSM and GA-BP-GA optimization [J]. Trans. Chin. Soc. Agric. Mach., 2023,54(2):139-150. | |

| 35 | 廖配.撞击式油茶果破壳装置的设计与试验[D].长沙:湖南农业大学,2019. |

| LIAO P. The design and experiment of the impact device for breaking the shell of Camellia oleifera fruit [D]. Changsha: Hunan Agricultural University,2019. |

| [1] | 冯长龙, 黄春光, 宁辰阳, 李树平, 陈科锦. 植树机挖坑机构螺旋式钻头性能特性优化研究[J]. 中国农业科技导报, 2025, 27(2): 89-98. |

| [2] | 田祥州, 贺福强, 陈发江, 詹璐歆. 基于休止角标定不同含水率木粉离散元参数[J]. 中国农业科技导报, 2025, 27(1): 118-128. |

| [3] | 顿国强, 王雷, 纪欣鑫, 姜新波, 赵宇, 郭娜. 金乡紫皮蒜种离散元参数标定与试验验证[J]. 中国农业科技导报, 2024, 26(8): 131-139. |

| [4] | 王兴松, 王娜, 杜宇, 周鹏, 王戈, 贾孟, 徐照丽, 白羽祥. 有机肥对玉溪植烟土壤有机质组分和微生物群落结构的影响[J]. 中国农业科技导报, 2024, 26(8): 201-212. |

| [5] | 顿国强, 吴星澎, 纪欣鑫, 张福利, 纪文义, 杨永振. 双摆盘式大豆小区排种器的仿真优化[J]. 中国农业科技导报, 2024, 26(6): 82-90. |

| [6] | 韩秀丽, 李嘉伟, 张杰, 郭艳杰, 张丽娟, 吉艳芝. 生物有机肥替代化肥对葡萄生长与土壤肥力的影响[J]. 中国农业科技导报, 2024, 26(4): 195-205. |

| [7] | 李明, 董帅, 庞永强, 燕洁华, 叶汪忠. 风沙土混拌刀具的改良设计与试验[J]. 中国农业科技导报, 2024, 26(4): 87-96. |

| [8] | 黄元昊, 全腊珍, 胡广发, 全伟, 石方刚. 多种材料与不同含水率土壤的离散元接触参数标定[J]. 中国农业科技导报, 2024, 26(3): 98-109. |

| [9] | 陈林, 余南辉, 王立宗, 范吉军, 雷港, 刘晓鹏, 周龙, 周劲. 米糠和碎米的接触参数测量与离散元仿真标定[J]. 中国农业科技导报, 2024, 26(2): 127-136. |

| [10] | 梁永进, 朱睿璇, 韦贝蕾, 袁小迈, 成武洋, 彭博, 王梓廷, 韦建玉. 有机肥配施对我国烟叶品质影响的整合分析[J]. 中国农业科技导报, 2024, 26(12): 164-175. |

| [11] | 杨大芳, 李飞翔, 葛越锋, 李奕辰. 基于离散元法的外槽轮排肥器排肥性能研究[J]. 中国农业科技导报, 2024, 26(12): 88-97. |

| [12] | 张伟健, 冯景翊, 李悦, 何婉莹, 车延静, 王紫颖, 白雪燕, 谷思玉. 内-外源有机质对黑土磷素吸附及有效性的影响[J]. 中国农业科技导报, 2024, 26(11): 180-190. |

| [13] | 高静娟, 朱晨宇, 柯玉琴, 郑朝元, 李春英, 李文卿. 烟稻轮作条件下有机肥施用时期对烤烟碳氮代谢的影响[J]. 中国农业科技导报, 2023, 25(9): 157-165. |

| [14] | 张晨阳, 徐明岗, 王斐, 李然, 孙楠. 施用有机肥对我国大豆产量及土壤养分的影响[J]. 中国农业科技导报, 2023, 25(8): 148-156. |

| [15] | 王艳成, 张纪月, 冯帅奇, 梁雪, 张振, 董微巍, 姬文秀. 外源促生菌联合有机肥对干旱胁迫下参地土壤性状及人参抗逆性影响[J]. 中国农业科技导报, 2023, 25(8): 196-202. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号