Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (3): 122-132.DOI: 10.13304/j.nykjdb.2023.0691

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Changlong FENG( ), Chenyang NING(

), Chenyang NING( ), Yixin ZHU, Shuping LI, Chunguang HUANG

), Yixin ZHU, Shuping LI, Chunguang HUANG

Received:2023-09-16

Accepted:2023-11-28

Online:2025-03-15

Published:2025-03-14

Contact:

Chenyang NING

通讯作者:

宁辰阳

作者简介:冯长龙E-mail:changlong_feng0919@126.com;

基金资助:CLC Number:

Changlong FENG, Chenyang NING, Yixin ZHU, Shuping LI, Chunguang HUANG. Research on Design and Optimization of Ring Winding Mechanism for Trunk Bandages[J]. Journal of Agricultural Science and Technology, 2025, 27(3): 122-132.

冯长龙, 宁辰阳, 朱艺鑫, 李树平, 黄春光. 树干绷带环形缠绕机构设计与优化研究[J]. 中国农业科技导报, 2025, 27(3): 122-132.

材料 Material | 比热容 Specific heat J/(kg·K) | 导热系数Thermal conductivity | 密度 Density g/cm3 |

|---|---|---|---|

空气 Air | ∞ | 0.041 | 1.29×10-3 |

绷带 Bandage | 1.25 | 0.28 | 1.15 |

树干 Trunk | 2.4 | 0.3 | 0.76 |

树皮 Bark | 1.25 | 0.19 | 0.386 |

Table 1 EDEM particle parameters[12]

材料 Material | 比热容 Specific heat J/(kg·K) | 导热系数Thermal conductivity | 密度 Density g/cm3 |

|---|---|---|---|

空气 Air | ∞ | 0.041 | 1.29×10-3 |

绷带 Bandage | 1.25 | 0.28 | 1.15 |

树干 Trunk | 2.4 | 0.3 | 0.76 |

树皮 Bark | 1.25 | 0.19 | 0.386 |

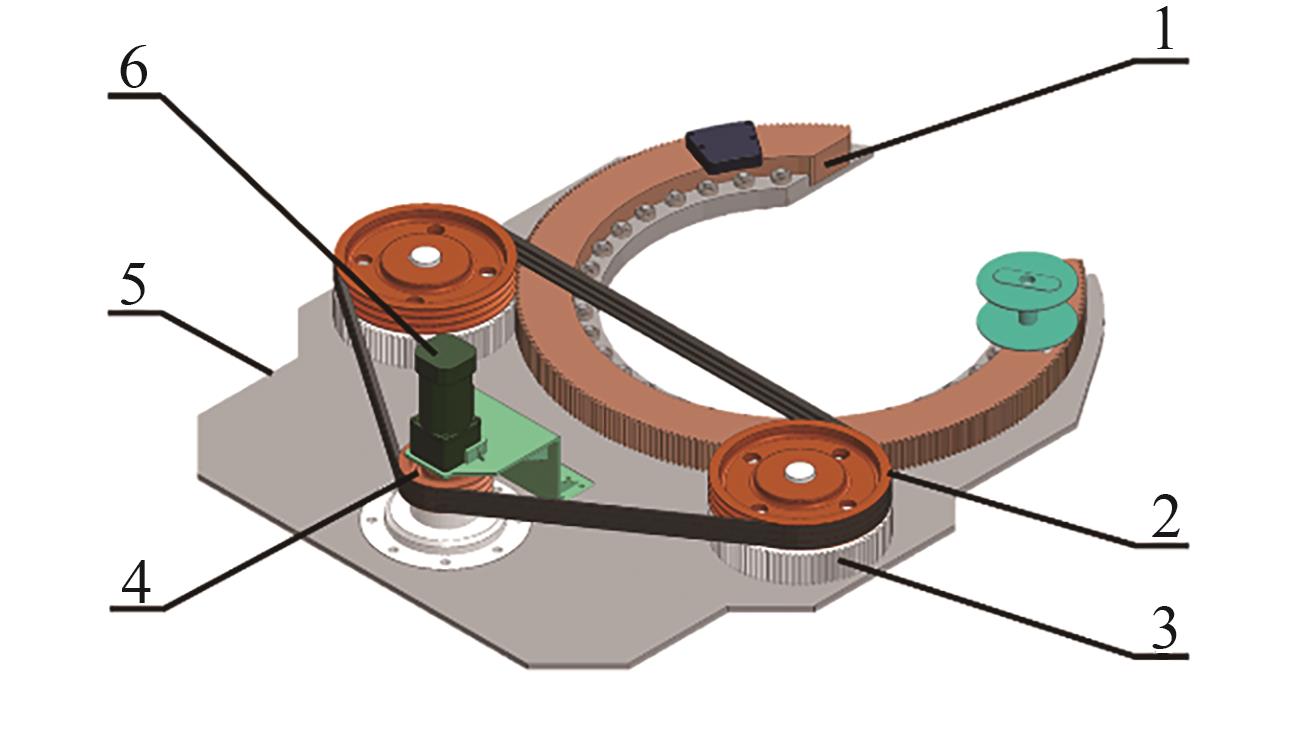

Fig. 1 Winding mechanism modelNote:1—C shape rotation ring; 2—Driven V-belt wheel; 3—Driving gear; 4—Active V belt wheel; 5—Bearing platform; 6—Drive motor.

部件1 Component 1 | 部件2 Component 2 | 约束类型 Constraint type |

|---|---|---|

| 主动齿轮 Driving gear | 承载平台 Bearing platform | 转动副 Revolute joint |

C形转动环 C-shaped rotating ring | 承载平台 Bearing platform | 转动副 Revolute joint |

承载平台 Bearing platform | 大地 Ground | 固定副 Fixed joint |

Table 2 Kinematic restraint pairs of winding mechanism

部件1 Component 1 | 部件2 Component 2 | 约束类型 Constraint type |

|---|---|---|

| 主动齿轮 Driving gear | 承载平台 Bearing platform | 转动副 Revolute joint |

C形转动环 C-shaped rotating ring | 承载平台 Bearing platform | 转动副 Revolute joint |

承载平台 Bearing platform | 大地 Ground | 固定副 Fixed joint |

接触名称 Contact name | 部件1 Component 1 | 部件2 Component 2 | 接触类型 Contact type |

|---|---|---|---|

碰撞 Impact | C形转动环 C-shaped rotating ring | 主动齿轮 Driving gear | 柔性体对刚体 Flexible body To Rigid body |

碰撞 Impact | C形转动环 C-shaped rotating ring | 承载平台 Bearing platform | 柔性体对刚体 Flexible body To Rigid body |

碰撞 Impact | 主动齿轮 Driving gear | 承载平台 Bearing platform | 刚体对刚体 Rigid body To Rigid body |

Table 3 Contact types of winding mechanism

接触名称 Contact name | 部件1 Component 1 | 部件2 Component 2 | 接触类型 Contact type |

|---|---|---|---|

碰撞 Impact | C形转动环 C-shaped rotating ring | 主动齿轮 Driving gear | 柔性体对刚体 Flexible body To Rigid body |

碰撞 Impact | C形转动环 C-shaped rotating ring | 承载平台 Bearing platform | 柔性体对刚体 Flexible body To Rigid body |

碰撞 Impact | 主动齿轮 Driving gear | 承载平台 Bearing platform | 刚体对刚体 Rigid body To Rigid body |

参数 Parameter | 值 Value |

|---|---|

接触刚度 Contact stiffness | 3.51×1011 |

碰撞系数 Impact coefficient | 1.5 |

阻尼系数 Damping coefficient | 50 |

穿透深度 Penetrating coefficient | 0.1 |

静摩擦系数 Static friction coefficient | 0.1 |

Table 4 Basic parameters of dynamic simulation

参数 Parameter | 值 Value |

|---|---|

接触刚度 Contact stiffness | 3.51×1011 |

碰撞系数 Impact coefficient | 1.5 |

阻尼系数 Damping coefficient | 50 |

穿透深度 Penetrating coefficient | 0.1 |

静摩擦系数 Static friction coefficient | 0.1 |

水平 Level | A:环宽 Ring width/mm | B:环厚 Ring thickness/mm | C:模数 Module number |

|---|---|---|---|

| -1 | 100 | 70 | 4 |

| 0 | 150 | 106 | 6 |

| 1 | 200 | 141 | 8 |

Table 5 Test factor level

水平 Level | A:环宽 Ring width/mm | B:环厚 Ring thickness/mm | C:模数 Module number |

|---|---|---|---|

| -1 | 100 | 70 | 4 |

| 0 | 150 | 106 | 6 |

| 1 | 200 | 141 | 8 |

编号 ID | 水平 Level | S:应力 Stress /MPa | M:质量 Mass/kg | ||

|---|---|---|---|---|---|

A:环宽 Ring width | B:环厚 Ring thickness | C:模数 Module | |||

| 1 | -1 | -1 | 0 | 24.40 | 46.48 |

| 2 | 1 | -1 | 0 | 1.51 | 106.83 |

| 3 | -1 | 1 | 0 | 4.64 | 93.63 |

| 4 | 1 | 1 | 0 | 3.66 | 215.19 |

| 5 | -1 | 0 | -1 | 7.51 | 71.13 |

| 6 | 1 | 0 | -1 | 6.14 | 161.00 |

| 7 | -1 | 0 | 1 | 17.30 | 66.20 |

| 8 | 1 | 0 | 1 | 17.70 | 154.85 |

| 9 | 0 | -1 | -1 | 5.87 | 72.77 |

| 10 | 0 | 1 | -1 | 3.98 | 146.58 |

| 11 | 0 | -1 | 1 | 13.70 | 70.60 |

| 12 | 0 | 1 | 1 | 7.84 | 142.21 |

| 13 | 0 | 0 | 0 | 5.37 | 108.22 |

| 14 | 0 | 0 | 0 | 5.37 | 108.22 |

| 15 | 0 | 0 | 0 | 5.37 | 108.22 |

| 16 | 0 | 0 | 0 | 5.37 | 108.22 |

| 17 | 0 | 0 | 0 | 5.37 | 108.22 |

Table 6 Simulation test scheme and results

编号 ID | 水平 Level | S:应力 Stress /MPa | M:质量 Mass/kg | ||

|---|---|---|---|---|---|

A:环宽 Ring width | B:环厚 Ring thickness | C:模数 Module | |||

| 1 | -1 | -1 | 0 | 24.40 | 46.48 |

| 2 | 1 | -1 | 0 | 1.51 | 106.83 |

| 3 | -1 | 1 | 0 | 4.64 | 93.63 |

| 4 | 1 | 1 | 0 | 3.66 | 215.19 |

| 5 | -1 | 0 | -1 | 7.51 | 71.13 |

| 6 | 1 | 0 | -1 | 6.14 | 161.00 |

| 7 | -1 | 0 | 1 | 17.30 | 66.20 |

| 8 | 1 | 0 | 1 | 17.70 | 154.85 |

| 9 | 0 | -1 | -1 | 5.87 | 72.77 |

| 10 | 0 | 1 | -1 | 3.98 | 146.58 |

| 11 | 0 | -1 | 1 | 13.70 | 70.60 |

| 12 | 0 | 1 | 1 | 7.84 | 142.21 |

| 13 | 0 | 0 | 0 | 5.37 | 108.22 |

| 14 | 0 | 0 | 0 | 5.37 | 108.22 |

| 15 | 0 | 0 | 0 | 5.37 | 108.22 |

| 16 | 0 | 0 | 0 | 5.37 | 108.22 |

| 17 | 0 | 0 | 0 | 5.37 | 108.22 |

| 来源Source | 应力 Stress | 质量 Mass | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

平方和 Sum of square | 自由度Freedom | 均方 Mean square | F | P | 显著性 Significance | 平方和 Sum of square | 自由度 Freedom | 均方 Mean square | F | P | 显著性 Significance | |

模型 Model | 522.38 | 9 | 58.04 | 4.55 | 0.029 2 | * | 28 712.42 | 9 | 3 190.27 | 1 334.12 | <0.000 1 | ** |

| A | 77.13 | 1 | 77.13 | 6.04 | 0.043 6 | * | 16 238.72 | 1 | 16 238.72 | 6 790.80 | <0.000 1 | ** |

| B | 80.39 | 1 | 80.39 | 6.30 | 0.040 4 | * | 11 319.86 | 1 | 11 319.86 | 4 733.80 | <0.000 1 | ** |

| C | 136.46 | 1 | 136.46 | 10.69 | 0.013 7 | * | 38.81 | 1 | 38.81 | 16.23 | 0.005 0 | ** |

| AB | 120.01 | 1 | 120.01 | 9.40 | 0.018 2 | * | 936.67 | 1 | 936.67 | 391.70 | <0.000 1 | ** |

| AC | 0.78 | 1 | 0.78 | 0.06 | 0.811 5 | 0.372 1 | 1 | 0.37 | 0.16 | 0.705 0 | ||

| BC | 3.94 | 1 | 3.94 | 0.31 | 0.595 8 | 1.21 | 1 | 1.21 | 0.51 | 0.499 9 | ||

| A2 | 59.17 | 1 | 59.17 | 4.63 | 0.068 3 | 166.25 | 1 | 166.25 | 69.53 | <0.000 1 | ** | |

| B2 | 1.35 | 1 | 1.35 | 0.11 | 0.754 5 | 4.46 | 1 | 4.46 | 1.86 | 0.214 5 | ||

| C2 | 39.01 | 1 | 39.01 | 3.06 | 0.124 0 | 6.15 | 1 | 6.15 | 2.57 | 0.152 8 | ||

残差 Residual | 89.37 | 7 | 12.77 | 16.74 | 7 | 2.39 | ||||||

失拟项 Lack of fit | 89.37 | 3 | 29.79 | 2.33 | >0.05 | 16.74 | 3 | 5.58 | 2.34 | >0.05 | ||

纯误差 Pure error | 0 | 4 | 0 | 0 | 4 | 0 | ||||||

| R2 | 0.853 9 | 0.999 4 | ||||||||||

调整R2 Adjusted R2 | 0.666 1 | 0.999 8 | ||||||||||

Table 7 Results of variance analysis

| 来源Source | 应力 Stress | 质量 Mass | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

平方和 Sum of square | 自由度Freedom | 均方 Mean square | F | P | 显著性 Significance | 平方和 Sum of square | 自由度 Freedom | 均方 Mean square | F | P | 显著性 Significance | |

模型 Model | 522.38 | 9 | 58.04 | 4.55 | 0.029 2 | * | 28 712.42 | 9 | 3 190.27 | 1 334.12 | <0.000 1 | ** |

| A | 77.13 | 1 | 77.13 | 6.04 | 0.043 6 | * | 16 238.72 | 1 | 16 238.72 | 6 790.80 | <0.000 1 | ** |

| B | 80.39 | 1 | 80.39 | 6.30 | 0.040 4 | * | 11 319.86 | 1 | 11 319.86 | 4 733.80 | <0.000 1 | ** |

| C | 136.46 | 1 | 136.46 | 10.69 | 0.013 7 | * | 38.81 | 1 | 38.81 | 16.23 | 0.005 0 | ** |

| AB | 120.01 | 1 | 120.01 | 9.40 | 0.018 2 | * | 936.67 | 1 | 936.67 | 391.70 | <0.000 1 | ** |

| AC | 0.78 | 1 | 0.78 | 0.06 | 0.811 5 | 0.372 1 | 1 | 0.37 | 0.16 | 0.705 0 | ||

| BC | 3.94 | 1 | 3.94 | 0.31 | 0.595 8 | 1.21 | 1 | 1.21 | 0.51 | 0.499 9 | ||

| A2 | 59.17 | 1 | 59.17 | 4.63 | 0.068 3 | 166.25 | 1 | 166.25 | 69.53 | <0.000 1 | ** | |

| B2 | 1.35 | 1 | 1.35 | 0.11 | 0.754 5 | 4.46 | 1 | 4.46 | 1.86 | 0.214 5 | ||

| C2 | 39.01 | 1 | 39.01 | 3.06 | 0.124 0 | 6.15 | 1 | 6.15 | 2.57 | 0.152 8 | ||

残差 Residual | 89.37 | 7 | 12.77 | 16.74 | 7 | 2.39 | ||||||

失拟项 Lack of fit | 89.37 | 3 | 29.79 | 2.33 | >0.05 | 16.74 | 3 | 5.58 | 2.34 | >0.05 | ||

纯误差 Pure error | 0 | 4 | 0 | 0 | 4 | 0 | ||||||

| R2 | 0.853 9 | 0.999 4 | ||||||||||

调整R2 Adjusted R2 | 0.666 1 | 0.999 8 | ||||||||||

| 1 | 杨凝薇,王丽,郭倩,等.12个果桑品种在保定地区自然越冬过程中的生理生化响应[J].干旱区资源与环境,2023,37(8):153-161. |

| YANG N W, WANG L, GUO Q, et al.. Physiological and biochemical responses of 12 mulberry varieties during natural overwintering in Baoding city [J]. J. Arid Land Resour. Environ., 2023,37(8):153-161. | |

| 2 | 黄金凤,闫忠业,王冬梅,等.辽宁熊岳地区苹果树冻害调查分析[J].中国果树,2020(5):127-129. |

| HUANG J F, YAN Z Y, WANG D M, et al.. Investigation and analysis on freezing injury of apple trees in Xiongyue, Liaoning province [J]. China Fruits, 2020(5):127-129. | |

| 3 | 王芳,王淇,赵曦阳.低温胁迫下植物的表型及生理响应机制研究进展[J].分子植物育种,2019,17(15):5144-5153. |

| WANG F, WANG Q, ZHAO X Y. Research progress of phenotype and physiological response mechanism of plants under low temperature stress [J]. Mol. Plant Breeding, 2019,17(15):5144-5153. | |

| 4 | 乌凤章,王贺新,徐国辉,等.木本植物低温胁迫生理及分子机制研究进展[J].林业科学,2015,51(7):116-128. |

| WU F Z, WANG H X, XU G H, et al.. Research progress on the physiological and molecular mechanisms of woody plants under low temperature stress [J]. Sci. Silvae Sin., 2015,51(7):116-128. | |

| 5 | 宋南,周砚玺,李运琦,等.植物绷带包裹树干引起的温度响应及其对树木越冬影响的分析[J].辽宁林业科技,2012(5):23-25. |

| 6 | 周建,杨立峰.广玉兰幼树冬季防寒技术研究[J].北方园艺,2012(12):76-78. |

| ZHOU J, YANG L F. Study on cold-resistant technologies of Magnolia grandiflora L. seedlings in winter [J]. North. Hortic., 2012(12):76-78. | |

| 7 | 史耀耀,李海宁,余强,等.数控布带缠绕机设计与控制技术研究[J].中国机械工程,2008,19(12):1433-1436. |

| SHI Y Y, LI H N, YU Q, et al.. Design and control technology study of the NC tape winding machine [J].China Mech. Eng., 2008,19(12):1433-1436. | |

| 8 | 吴晓,陈梓昶,戴鹏飞,等.一种胶带缠绕机构的设计及力学分析[J].机械设计与研究,2021,37(3):194-197. |

| WU X, CHEN Z C, DAI P F, et al.. Design and mechanical analysis of a tape winding mechanism [J]. Mach. Des. Res., 2021,37(3):194-197. | |

| 9 | 张慧敏,薛琛,郭兴召.基于工业机器人的线束自动缠绕机构运动特性研究[J].机床与液压,2020,48(9):5-9. |

| ZHANG H M, XUE C, GUO X Z. Research on motion characteristics of an automatic winding mechanism of wire harness based on industrial robot [J]. Mach. Tool Hydraul., 2020,48(9):5-9. | |

| 10 | DENG B, SHI Y Y, YU T, et al.. Influence mechanism and optimization analysis of technological parameters for the composite prepreg tape winding process [J/OL]. Polym (Basel.), 2020,12(8):1843 [2024-07-15]. . |

| 11 | 戴丽玲,李云霞,孙学强.基于粒子群算法的新型机械臂圆弧导轨优化设计[J].机床与液压,2017,45(15):39-43, 9. |

| DAI L L, LI Y X, SUN X Q. Optimization and design of a new-style circle guide rail used in mechanical arm based on particle swarm optimization [J]. Mach.Tool Hydraul., 2017,45(15):39-43, 9. | |

| 12 | 中华人民共和国有色金属行业标准. 有色金属加工企业工业炉热平衡测试与计算方法(汇编): (1-10)-92[S].北京:中国有色金属工业总公司,1992. |

| 13 | 成大先.机械设计手册[M].第6版.北京:化学工业出版社,2017:1-456. |

| 14 | 邱海飞.机械系统柔性建模方法与仿真研究[J].机械传动,2016,40(12):169-172. |

| QIU H F. Research of the flexible modeling and its application of mechanical drive system [J]. J. Mech. Transm., 2016,40(12):169-172. | |

| 15 | 潘毅,许妍妍,樊智敏.双渐开线齿轮柔性多体动力学分析[J].机电工程,2022,39(8):1088-1095. |

| PAN Y, XU Y Y, FAN Z M. Flexible multi-body dynamics analysis of double involute gear [J]. J. Mech. Electron. Eng., 2022,39(8):1088-1095. | |

| 16 | 王鹏,包道日娜,吴胜胜,等.基于静力学分析的新型变桨风力机关键齿轮参数优化[J].太阳能学报,2023,44(7):456-462. |

| WANG P, BAO D R N, WU S S, et al.. Optimization of key gear parameters of new variable pitch wind turbine based on static analysis [J]. Acta Energiae Solaris Sin., 2023,44(7):456-462. | |

| 17 | 郭超凡,李粤,姚德宇,等.仿生香蕉秸秆粉碎装置关键部件作业参数优化与试验[J].中国农机化学报,2022,43(1):93-100. |

| GUO C F, LI Y, YAO D Y, et al.. Optimization and experiment of operating parameters of key components of bionic banana straw crushing devices [J]. J. Chin. Agric. Mech., 2022,43(1):93-100. | |

| 18 | MOSLEMI A, SEYYED-ESFAHANI M. Robust optimization of multistage process: response surface and multi-response optimization approaches [J]. Int. J. Nonlin. Sci. Num., 2022, 23(2): 163-175. |

| [1] | Ruyan ZHANG, Shenhao LI, Qipeng ZHU, Taigang FENG, Hongbo LI, Zebing XING, Yu XIAN. Effect of Biochar Content on Physical and Mechanical Properties of Garden Greening Waste/polylactic Acid Composites [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 192-200. |

| [2] | Changlong FENG, Chunguang HUANG, Chenyang NING, Shuping LI, Kejin CHEN. Optimization of Performance and Characteristics of Spiral Drill Bit Excavation Mechanism for Planting Machine [J]. Journal of Agricultural Science and Technology, 2025, 27(2): 89-98. |

| [3] | Jingyi XI, Shuangqing WANG, Yitong BAI, Xiuli YAO, Bixuan HUANG, Qingyi LI, Liqing FAN, Shichen HUANG, Mingguo SUN. Study on Optimization of Processing Parameters Using Hermetia illucens Larva to Treat Food Waste by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 241-249. |

| [4] | Lijun FU, Xiaoyu LIN, Jianhua LIN, Huinan SHEN, Yongzhen WU. Research on Processing Technology and Shelf Life of Red Matsutake Beef Sauce [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 148-158. |

| [5] | Dongling LIU, Hao SI, Baojiang ZHENG, Yuhong ZHANG. Optimization of Enzyme Assisted-ultrasonic Extraction of Sinigrin in Thlaspi arvense Seeds by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 225-233. |

| [6] | Xiuying ZHAO, Qingwen HUANG, Haojie CAO, Jie WANG, Ruijiao LI, Dongxia NIE, Zheng HAN, Zhihui ZHAO. Optimization of Liquid Culture Conditions for the Production of Deoxynivalenol and Its Derivatives by Fusarium graminearum Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 222-233. |

| [7] | Tingting SHI, Yulan LIAO, Xuyou PENG, Chenyu YUAN. Design and Optimization of Single Row In-line Cassava Planter [J]. Journal of Agricultural Science and Technology, 2022, 24(6): 115-122. |

| [8] | Kaiqiang WANG, Xue YANG, Changfeng LI, Xiao DUAN, Qing PENG, Yu QIAO, Bo SHI. Optimization of Glyceollins Synthesis Condition Induced by Xylooligosaccharides Based on Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2022, 24(10): 208-217. |

| [9] | GUO Huihui, LIN Congfa, JIANG Yuanbin, LI Zhigang. Optimization of Protocorm Proliferation Medium of Dendrobium huoshanense by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2020, 22(3): 173-180. |

| [10] | LIANG Zhaochao, GUO Xianwei, SONG Yanjuan, MA Tianfu, WANG Feng, WANG Liyan, JING Ruiyong*. Extraction Process of Polysaccharide in Agaricus bisporus Optimized by Response Surface Method and Its Antioxidant Activity in vitro [J]. Journal of Agricultural Science and Technology, 2019, 21(8): 161-168. |

| [11] | WU Qi1,2,3§, ZHANG Yuhui1,2§, SU Rongrong1,2, SUN Bo1,3, WU Qiuyun1,2, XIA Zhilan1,2*. Optimization of Submerged Fermentation Medium of Agaricus blazei Murrill for Mycelial Biomass Accumulation Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2019, 21(3): 152-160. |

| [12] | LI Jinfeng, LIU Xianxi, ZHANG Kaixing*. Grain Combine Harvester Cutter and Whole Machine Smoothness Simulation Analysis Based on ADAMS [J]. Journal of Agricultural Science and Technology, 2019, 21(1): 62-69. |

| [13] | DAI Yangjun1, HU Jian1,2, ZHOU Ying2, ZUO Bo1, SHI Yixue1. Optimization of Compound Enzymolysis Process of Dried Figs by Plackett-Burman Design and Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2018, 20(7): 146-153. |

| [14] | CHEN Xinyao, DONG Xing, CHEN Jingjie, QIN Tao, LI Jian*, HUANG Yifan*. Optimization of Extraction Process for Crude Polysaccharide from Hericium Erinaceus by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2017, 19(3): 131-136. |

| [15] | XIE Feng, GUO Jin-bing, LIAO Na, LIU Yun-dong, GUAN Cheng-jun*. Kinematics Simulation Analysis of the Sugarcane #br# Harvester Cutter based on Adams [J]. Journal of Agricultural Science and Technology, 2016, 18(4): 87-92. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号