Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (2): 192-200.DOI: 10.13304/j.nykjdb.2023.0857

• BIO-MANUFACTURING & RESOURCE AND ECOLOGY • Previous Articles

Ruyan ZHANG1( ), Shenhao LI1, Qipeng ZHU2, Taigang FENG1, Hongbo LI2, Zebing XING2, Yu XIAN1(

), Shenhao LI1, Qipeng ZHU2, Taigang FENG1, Hongbo LI2, Zebing XING2, Yu XIAN1( )

)

Received:2023-11-22

Accepted:2024-03-08

Online:2025-02-15

Published:2025-02-14

Contact:

Yu XIAN

张如艳1( ), 李绅昊1, 朱奇鹏2, 冯太纲1, 李红波2, 邢泽炳2, 羡瑜1(

), 李绅昊1, 朱奇鹏2, 冯太纲1, 李红波2, 邢泽炳2, 羡瑜1( )

)

通讯作者:

羡瑜

作者简介:张如艳 E-mail:3439672507@qq.com;

基金资助:CLC Number:

Ruyan ZHANG, Shenhao LI, Qipeng ZHU, Taigang FENG, Hongbo LI, Zebing XING, Yu XIAN. Effect of Biochar Content on Physical and Mechanical Properties of Garden Greening Waste/polylactic Acid Composites[J]. Journal of Agricultural Science and Technology, 2025, 27(2): 192-200.

张如艳, 李绅昊, 朱奇鹏, 冯太纲, 李红波, 邢泽炳, 羡瑜. 生物炭含量对园林绿化废弃物/聚乳酸复合材料物理力学性能影响[J]. 中国农业科技导报, 2025, 27(2): 192-200.

| 因素 Factor | 编码水平 Coding level | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| A:杨木粉含量Poplar wood powder content/% | 30 | 40 | 50 |

| B:模压温度 Molding temperature/℃ | 160 | 170 | 180 |

| C:模压压力Molding pressure/MPa | 6 | 9 | 12 |

| D:保压时间Holding time/min | 10 | 13 | 16 |

Table 1 Response surface experimental design factor level table

| 因素 Factor | 编码水平 Coding level | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| A:杨木粉含量Poplar wood powder content/% | 30 | 40 | 50 |

| B:模压温度 Molding temperature/℃ | 160 | 170 | 180 |

| C:模压压力Molding pressure/MPa | 6 | 9 | 12 |

| D:保压时间Holding time/min | 10 | 13 | 16 |

试验号 Number | A:杨木粉含量 Poplar wood powder content/% | B:模压温度 Molding temperature/℃ | C:模压压力 Molding pressure/MPa | D:保压时间 Holding time/min | Y1:弯曲强度 Flexural strength/MPa | Y2:冲击强度 Impact strength/(kJ·m-²) |

|---|---|---|---|---|---|---|

| 1 | 40 | 170 | 9 | 13 | 24.40 | 2.80 |

| 2 | 40 | 160 | 6 | 13 | 29.00 | 4.06 |

| 3 | 30 | 180 | 9 | 13 | 21.40 | 2.13 |

| 4 | 50 | 160 | 9 | 13 | 23.50 | 2.18 |

| 5 | 50 | 180 | 9 | 13 | 26.20 | 2.37 |

| 6 | 40 | 170 | 9 | 13 | 22.00 | 2.55 |

| 7 | 30 | 170 | 6 | 13 | 20.80 | 2.45 |

| 8 | 40 | 170 | 6 | 10 | 25.40 | 3.71 |

| 9 | 40 | 180 | 9 | 16 | 20.60 | 2.29 |

| 10 | 30 | 170 | 9 | 16 | 22.00 | 2.10 |

| 11 | 50 | 170 | 12 | 13 | 23.40 | 2.16 |

| 12 | 40 | 180 | 6 | 13 | 17.80 | 2.58 |

| 13 | 50 | 170 | 9 | 10 | 28.40 | 2.31 |

| 14 | 40 | 160 | 9 | 16 | 29.20 | 3.36 |

| 15 | 40 | 170 | 12 | 10 | 29.00 | 3.60 |

| 16 | 40 | 180 | 12 | 13 | 29.30 | 3.02 |

| 17 | 40 | 160 | 12 | 13 | 32.00 | 3.98 |

| 18 | 40 | 170 | 9 | 13 | 28.40 | 3.31 |

| 19 | 40 | 170 | 6 | 16 | 27.60 | 2.73 |

| 20 | 30 | 170 | 9 | 10 | 27.20 | 2.06 |

| 21 | 30 | 170 | 12 | 13 | 24.80 | 2.23 |

| 22 | 50 | 170 | 9 | 16 | 25.00 | 2.36 |

| 23 | 40 | 180 | 9 | 10 | 22.60 | 2.61 |

| 24 | 40 | 170 | 9 | 13 | 27.40 | 2.99 |

| 25 | 40 | 170 | 12 | 16 | 24.00 | 2.61 |

| 26 | 30 | 160 | 9 | 13 | 30.00 | 2.34 |

| 27 | 40 | 170 | 9 | 13 | 24.20 | 3.21 |

| 28 | 40 | 160 | 9 | 10 | 30.80 | 3.06 |

| 29 | 50 | 170 | 6 | 13 | 26.20 | 2.01 |

Table 2 Response surface experimental design and results

试验号 Number | A:杨木粉含量 Poplar wood powder content/% | B:模压温度 Molding temperature/℃ | C:模压压力 Molding pressure/MPa | D:保压时间 Holding time/min | Y1:弯曲强度 Flexural strength/MPa | Y2:冲击强度 Impact strength/(kJ·m-²) |

|---|---|---|---|---|---|---|

| 1 | 40 | 170 | 9 | 13 | 24.40 | 2.80 |

| 2 | 40 | 160 | 6 | 13 | 29.00 | 4.06 |

| 3 | 30 | 180 | 9 | 13 | 21.40 | 2.13 |

| 4 | 50 | 160 | 9 | 13 | 23.50 | 2.18 |

| 5 | 50 | 180 | 9 | 13 | 26.20 | 2.37 |

| 6 | 40 | 170 | 9 | 13 | 22.00 | 2.55 |

| 7 | 30 | 170 | 6 | 13 | 20.80 | 2.45 |

| 8 | 40 | 170 | 6 | 10 | 25.40 | 3.71 |

| 9 | 40 | 180 | 9 | 16 | 20.60 | 2.29 |

| 10 | 30 | 170 | 9 | 16 | 22.00 | 2.10 |

| 11 | 50 | 170 | 12 | 13 | 23.40 | 2.16 |

| 12 | 40 | 180 | 6 | 13 | 17.80 | 2.58 |

| 13 | 50 | 170 | 9 | 10 | 28.40 | 2.31 |

| 14 | 40 | 160 | 9 | 16 | 29.20 | 3.36 |

| 15 | 40 | 170 | 12 | 10 | 29.00 | 3.60 |

| 16 | 40 | 180 | 12 | 13 | 29.30 | 3.02 |

| 17 | 40 | 160 | 12 | 13 | 32.00 | 3.98 |

| 18 | 40 | 170 | 9 | 13 | 28.40 | 3.31 |

| 19 | 40 | 170 | 6 | 16 | 27.60 | 2.73 |

| 20 | 30 | 170 | 9 | 10 | 27.20 | 2.06 |

| 21 | 30 | 170 | 12 | 13 | 24.80 | 2.23 |

| 22 | 50 | 170 | 9 | 16 | 25.00 | 2.36 |

| 23 | 40 | 180 | 9 | 10 | 22.60 | 2.61 |

| 24 | 40 | 170 | 9 | 13 | 27.40 | 2.99 |

| 25 | 40 | 170 | 12 | 16 | 24.00 | 2.61 |

| 26 | 30 | 160 | 9 | 13 | 30.00 | 2.34 |

| 27 | 40 | 170 | 9 | 13 | 24.20 | 3.21 |

| 28 | 40 | 160 | 9 | 10 | 30.80 | 3.06 |

| 29 | 50 | 170 | 6 | 13 | 26.20 | 2.01 |

| 源项Source | 平方和 Sum of squares | 自由度Degree of freedom | 均方差 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 7.52 | 14 | 0.54 | 3.25 | 0.017 6 |

| A | 3.63 | 1 | 3.63 | 0.63 | 0.440 3 |

| B | 127.40 | 1 | 127.40 | 22.14 | 0.000 3 |

| C | 15.08 | 1 | 15.08 | 2.62 | 0.127 8 |

| D | 13.13 | 1 | 13.13 | 2.28 | 0.153 2 |

| AB | 31.92 | 1 | 31.92 | 5.55 | 0.033 6 |

| AC | 6.38 | 1 | 6.38 | 1.11 | 0.310 3 |

| AD | 0.14 | 1 | 0.14 | 0.02 | 0.878 0 |

| BC | 19.14 | 1 | 19.14 | 3.33 | 0.089 6 |

| BD | 0.39 | 1 | 0.39 | 0.07 | 0.798 2 |

| CD | 4.73 | 1 | 4.73 | 0.82 | 0.379 9 |

| A2 | 5.04 | 1 | 5.04 | 0.88 | 0.365 3 |

| B2 | 1.58 | 1 | 1.58 | 0.27 | 0.608 3 |

| C2 | 9.12×10-3 | 1 | 9.12×10-3 | 1.59×10-3 | 0.968 8 |

| D2 | 0.17 | 1 | 0.17 | 0.03 | 0.865 5 |

| 残差Residual | 80.54 | 14 | 5.75 | ||

| 失拟误差Lack of fit | 62.08 | 10 | 6.21 | 1.35 | 0.416 1 |

| 纯误差Pure error | 18.46 | 4 | 4.61 | ||

| 总离差Cor total | 310.80 | 28 |

Table 3 Analysis of variance of flexural strength for response surface method optimization tests

| 源项Source | 平方和 Sum of squares | 自由度Degree of freedom | 均方差 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 7.52 | 14 | 0.54 | 3.25 | 0.017 6 |

| A | 3.63 | 1 | 3.63 | 0.63 | 0.440 3 |

| B | 127.40 | 1 | 127.40 | 22.14 | 0.000 3 |

| C | 15.08 | 1 | 15.08 | 2.62 | 0.127 8 |

| D | 13.13 | 1 | 13.13 | 2.28 | 0.153 2 |

| AB | 31.92 | 1 | 31.92 | 5.55 | 0.033 6 |

| AC | 6.38 | 1 | 6.38 | 1.11 | 0.310 3 |

| AD | 0.14 | 1 | 0.14 | 0.02 | 0.878 0 |

| BC | 19.14 | 1 | 19.14 | 3.33 | 0.089 6 |

| BD | 0.39 | 1 | 0.39 | 0.07 | 0.798 2 |

| CD | 4.73 | 1 | 4.73 | 0.82 | 0.379 9 |

| A2 | 5.04 | 1 | 5.04 | 0.88 | 0.365 3 |

| B2 | 1.58 | 1 | 1.58 | 0.27 | 0.608 3 |

| C2 | 9.12×10-3 | 1 | 9.12×10-3 | 1.59×10-3 | 0.968 8 |

| D2 | 0.17 | 1 | 0.17 | 0.03 | 0.865 5 |

| 残差Residual | 80.54 | 14 | 5.75 | ||

| 失拟误差Lack of fit | 62.08 | 10 | 6.21 | 1.35 | 0.416 1 |

| 纯误差Pure error | 18.46 | 4 | 4.61 | ||

| 总离差Cor total | 310.80 | 28 |

| 源项Source | 平方和 Sum of squares | 自由度Degree of freedom | 均方差 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 2.48 | 14 | 0.18 | 4.76 | 0.003 1 |

| A | 3.00×10-4 | 1 | 3.00×10-4 | 8.05×10-3 | 0.929 8 |

| B | 0.09 | 1 | 0.09 | 2.51 | 0.135 2 |

| C | 3.33×10-3 | 1 | 3.33×10-3 | 0.09 | 0.769 3 |

| D | 0.08 | 1 | 0.08 | 2.24 | 0.157 0 |

| AB | 3.60×10-3 | 1 | 3.60×10-3 | 0.10 | 0.760 5 |

| AC | 5.63×10-3 | 1 | 5.63×10-3 | 0.15 | 0.703 5 |

| AD | 0.02 | 1 | 0.02 | 0.64 | 0.435 4 |

| BC | 0.07 | 1 | 0.07 | 1.88 | 0.191 4 |

| BD | 0.12 | 1 | 0.12 | 3.19 | 0.095 6 |

| CD | 4.00×10-4 | 1 | 4.00×10-4 | 0.01 | 0.918 9 |

| A2 | 0.35 | 1 | 0.35 | 9.30 | 0.008 6 |

| B2 | 1.93 | 1 | 1.93 | 51.93 | <0.000 1 |

| C2 | 0.06 | 1 | 0.06 | 1.61 | 0.225 2 |

| D2 | 0.02 | 1 | 0.02 | 0.55 | 0.470 9 |

| 残差Residual | 0.52 | 14 | 0.04 | ||

| 失拟误差Lack of fit | 0.48 | 10 | 0.05 | 4.96 | 0.068 2 |

| 纯误差Pure error | 0.04 | 4 | 9.73×10-3 | ||

| 总离差Cor total | 3 | 28 |

Table 4 Analysis of variance of impact strength for response surface method optimization test

| 源项Source | 平方和 Sum of squares | 自由度Degree of freedom | 均方差 Mean square | F值 F value | P值 P value |

|---|---|---|---|---|---|

| 模型Model | 2.48 | 14 | 0.18 | 4.76 | 0.003 1 |

| A | 3.00×10-4 | 1 | 3.00×10-4 | 8.05×10-3 | 0.929 8 |

| B | 0.09 | 1 | 0.09 | 2.51 | 0.135 2 |

| C | 3.33×10-3 | 1 | 3.33×10-3 | 0.09 | 0.769 3 |

| D | 0.08 | 1 | 0.08 | 2.24 | 0.157 0 |

| AB | 3.60×10-3 | 1 | 3.60×10-3 | 0.10 | 0.760 5 |

| AC | 5.63×10-3 | 1 | 5.63×10-3 | 0.15 | 0.703 5 |

| AD | 0.02 | 1 | 0.02 | 0.64 | 0.435 4 |

| BC | 0.07 | 1 | 0.07 | 1.88 | 0.191 4 |

| BD | 0.12 | 1 | 0.12 | 3.19 | 0.095 6 |

| CD | 4.00×10-4 | 1 | 4.00×10-4 | 0.01 | 0.918 9 |

| A2 | 0.35 | 1 | 0.35 | 9.30 | 0.008 6 |

| B2 | 1.93 | 1 | 1.93 | 51.93 | <0.000 1 |

| C2 | 0.06 | 1 | 0.06 | 1.61 | 0.225 2 |

| D2 | 0.02 | 1 | 0.02 | 0.55 | 0.470 9 |

| 残差Residual | 0.52 | 14 | 0.04 | ||

| 失拟误差Lack of fit | 0.48 | 10 | 0.05 | 4.96 | 0.068 2 |

| 纯误差Pure error | 0.04 | 4 | 9.73×10-3 | ||

| 总离差Cor total | 3 | 28 |

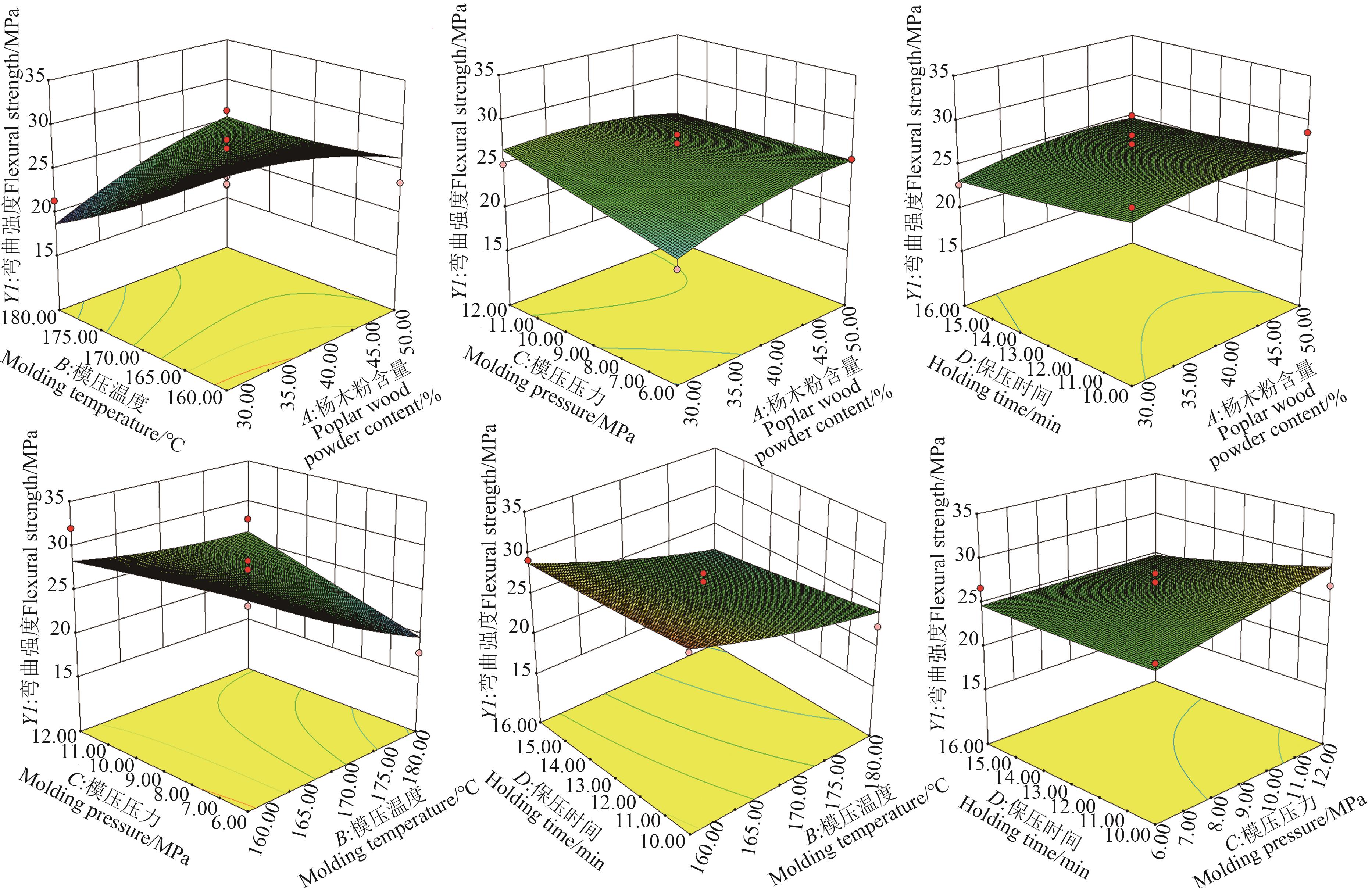

Fig. 1 Three-dimensional response surface of the interaction effects of poplar wood powder content, molding temperature, molding pressure and holding time on the flexural strength of composites

Fig. 2 Three-dimensional response surface of the interaction effect of poplar wood powder content, molding temperature, molding pressure and holding time on the impact strength of composites

| 1 | 鞠艳艳,丁元君,邵前前,等.城市园林废弃物生物质炭性质及其应用潜力[J].林业科学,2020,56(8):107-120. |

| JU Y Y, DING Y J, SHAO Q Q, et al.. Properties and application potential of biochar from urban green wastes [J]. Sci. Silvae Sin., 2020,56(8):107-120. | |

| 2 | CHOI J, YANG I, KIM S S, et al.. Upcycling plastic waste into high value-added carbonaceous materials [J/OL].Macromol. Rapid Commun.,2022,43(1):e2100467 [2023-10-22].. |

| 3 | BASALP D, TIHMINLIOGLU F, SOFUOGLU S C,et al.. Utilization of municipal plastic and wood waste in industrial manufacturing of wood plastic composites [J]. Waste Biomass Valoriz., 2020,11(10):5419-5430. |

| 4 | 孙小虎,刘毫,周子惠.建筑装饰装修工程中的木塑复合材料及其应用[J].合成材料老化与应用,2022,51(5):143-145. |

| SUN X H, LIU H, ZHOU Z H. Wood plastic composite material and its application in building decoration engineering [J]. Synth. Mater. Aging Appl., 2022,51(5):143-145. | |

| 5 | KHALID M Y, RASHID A A L, ARIF Z U, et al.. Natural fiber reinforced composites: sustainable materials for emerging applications [J/OL]. Results Eng., 2021, 11: 100263 [2023-10-22]. . |

| 6 | 张显,蔡明,孙宝忠.植物纤维增强复合材料的湿热老化研究进展[J].材料导报,2022,36(5):222-232. |

| ZHANG X, CAI M, SUN B Z. Research progress of hygrothermal aging of plant fiber reinforced composites [J]. Mater. Rep., 2022,36(5):222-232. | |

| 7 | 刘彬,李彬,王怀栋,等.木塑复合材料应用现状及发展趋势[J].工程塑料应用,2017,45(1):137-141. |

| LIU B, LI B, WANG H D,et al.. Application status and development trend of wood plastic composite [J].Eng. Plast. Appl., 2017,45(1):137-141. | |

| 8 | BORAN TORUN S, PESMAN E, DONMEZ CAVDAR A. Effect of alkali treatment on composites made from recycled polyethylene and chestnut cupula [J]. Polym. Compos., 2019,40(11):4442-4451. |

| 9 | ZHOU Y H, FAN M Z, CHEN L H. Interface and bonding mechanisms of plant fibre composites:an overview [J]. Compos. Part B Eng., 2016,101:31-45. |

| 10 | YI S M, XU S H, LI Y, et al.. Synergistic toughening effects of grafting modification and elastomer-olefin block copolymer addition on the fracture resistance of wood particle/polypropylene/elastomer composites [J/OL].Mater. Des.,2019,181:107918 [2023-10-22]. . |

| 11 | XIAN Y, FENG T G, LI H B, et al.. The influence of nano-CaCO3 on the mechanical and dynamic thermo-mechanical properties of core-shell structured wood plastic composites [J/OL]. Forests, 2023, 14(2):257 [2023-10-22]. . |

| 12 | ZHANG Q F, LEI H W, CAI H Z, et al.. Improvement on the properties of microcrystalline cellulose/polylactic acid composites by using activated biochar [J/OL]. J. Clean. Prod., 2020,252:119898[2023-10-22]. . |

| 13 | 张庆法,徐航,任夏瑾,等.农林废物生物炭/高密度聚乙烯复合材料的制备与性能[J].复合材料学报,2021,38(2):398-405. |

| ZHANG Q F, XU H, REN X J, et al.. Preparation and properties of agroforestry wastes biochar/high density polyethylene composites [J]. Acta Mater. Compos. Sin., 2021,38(2):398-405. | |

| 14 | 张庆法, 杨科研, 蔡红珍, 等. 稻壳/高密度聚乙烯复合材料与稻壳炭/高密度聚乙烯复合材料性能对比[J]. 复合材料学报, 2018, 35(11): 3044-3050. |

| ZHANG Q F, YANG K Y, CAI H Z, et al.. Comparison of properties between rice husk/high density polyethylene and rice husk biochar/high density polyethylene composites [J]. Acta. Mater. Compos. Sin., 2018, 35(11): 3044-3050. | |

| 15 | ZOUARI M, DEVALLANCE D B, MARROT L.Effect of biochar addition on mechanical properties,thermal stability,and water resistance of hemp-polylactic acid (PLA) composites [J/OL].Materials, 2022,15(6):2271[2023-10-22].. |

| 16 | WEI M Q, LI Q B, JIANG T,et al..Improvement on the mechanical properties of maleic anhydride/polylactic acid composites with Pinus sylvestris-char [J/OL].Mater. Today Commun., 2023,34:105278 [2023-10-22].. |

| 17 | DONNELLY T A.Response-surface experimental design [J].IEEE Potentials,1992,11(1):19-21. |

| 18 | ASTM International. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials: [S]. New York:American National Standards Institute,2010. |

| 19 | ASTM International. Standard test method for determining the charpy impact resistance of notched specimens of plastics: [S]. New York: American National Standards Institute,2010. |

| 20 | ASTM International. Standard test method for water absorption of rigid cellular plastics: [S]. New York: American National Standards Institute,2012. |

| 21 | TRAN P, NGUYEN Q T, LAU K T. Fire performance of polymer-based composites for maritime infrastructure [J]. Compos. Part B Eng., 2018,155:31-48. |

| 22 | SHAH A U R, IMDAD A, SADIQ A,et al..Mechanical,thermal,and fire retardant properties of rice husk biochar reinforced recycled high-density polyethylene composite material [J/OL].Polymers,2023,15(8):1827 [2023-10-22].. |

| 23 | 魏俞涌,张庆法,盛奎川.生物炭对玉米醇溶蛋白/聚丙烯复合材料力学性能的影响[J].中国农业科技导报,2022,24(10):161-168. |

| WEI Y Y, ZHANG Q F, SHENG K C. Effect of biochar on mechanical properties of zein/polypropylene composites [J]. J. Agric. Sci. Technol., 2022,24(10):161-168. | |

| 24 | ARRIGO R, BARTOLI M, MALUCELLI G. Poly(lactic acid)-biochar biocomposites:effect of processing and filler content on rheological,thermal,and mechanical properties [J/OL]. Polymers,2020, 12(4):892 [2023-10-22]. . |

| 25 | DAS C, TAMRAKAR S, KIZILTAS A,et al..Incorporation of biochar to improve mechanical,thermal and electrical properties of polymer composites [J/OL]. Polymers,2021,13(16):2663 [2023-10-22]. . |

| 26 | BARDHA A, PRASHER S, VILLARTA J, et al.. Nut shell and grain husk waste biochar as carbon black replacements in styrene-butadiene rubber composites and improvements through steam activation [J/OL]. Ind .Crops Prod., 2023,203:117180 [2023-10-22]. . |

| 27 | ADENIYI A G, IWUOZOR K O, EMENIKE E C, et al.. Mechanical and microstructural properties of bio-composite produced from recycled polystyrene/chicken feather biochar [J/OL]. J. Renewable Energy Environ., 2023,11(3): 1553 [2023-10-22]. . |

| [1] | Jingyi XI, Shuangqing WANG, Yitong BAI, Xiuli YAO, Bixuan HUANG, Qingyi LI, Liqing FAN, Shichen HUANG, Mingguo SUN. Study on Optimization of Processing Parameters Using Hermetia illucens Larva to Treat Food Waste by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2025, 27(1): 241-249. |

| [2] | Lijun FU, Xiaoyu LIN, Jianhua LIN, Huinan SHEN, Yongzhen WU. Research on Processing Technology and Shelf Life of Red Matsutake Beef Sauce [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 148-158. |

| [3] | Dongling LIU, Hao SI, Baojiang ZHENG, Yuhong ZHANG. Optimization of Enzyme Assisted-ultrasonic Extraction of Sinigrin in Thlaspi arvense Seeds by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 225-233. |

| [4] | Xiuying ZHAO, Qingwen HUANG, Haojie CAO, Jie WANG, Ruijiao LI, Dongxia NIE, Zheng HAN, Zhihui ZHAO. Optimization of Liquid Culture Conditions for the Production of Deoxynivalenol and Its Derivatives by Fusarium graminearum Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 222-233. |

| [5] | Kaiqiang WANG, Xue YANG, Changfeng LI, Xiao DUAN, Qing PENG, Yu QIAO, Bo SHI. Optimization of Glyceollins Synthesis Condition Induced by Xylooligosaccharides Based on Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2022, 24(10): 208-217. |

| [6] | GUO Huihui, LIN Congfa, JIANG Yuanbin, LI Zhigang. Optimization of Protocorm Proliferation Medium of Dendrobium huoshanense by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2020, 22(3): 173-180. |

| [7] | LIANG Zhaochao, GUO Xianwei, SONG Yanjuan, MA Tianfu, WANG Feng, WANG Liyan, JING Ruiyong*. Extraction Process of Polysaccharide in Agaricus bisporus Optimized by Response Surface Method and Its Antioxidant Activity in vitro [J]. Journal of Agricultural Science and Technology, 2019, 21(8): 161-168. |

| [8] | WU Qi1,2,3§, ZHANG Yuhui1,2§, SU Rongrong1,2, SUN Bo1,3, WU Qiuyun1,2, XIA Zhilan1,2*. Optimization of Submerged Fermentation Medium of Agaricus blazei Murrill for Mycelial Biomass Accumulation Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2019, 21(3): 152-160. |

| [9] | DAI Yangjun1, HU Jian1,2, ZHOU Ying2, ZUO Bo1, SHI Yixue1. Optimization of Compound Enzymolysis Process of Dried Figs by Plackett-Burman Design and Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2018, 20(7): 146-153. |

| [10] | CHEN Xinyao, DONG Xing, CHEN Jingjie, QIN Tao, LI Jian*, HUANG Yifan*. Optimization of Extraction Process for Crude Polysaccharide from Hericium Erinaceus by Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2017, 19(3): 131-136. |

| [11] | XU Lan1, ZHANG Peng-fei1, LEI Li-xia1, ZHANG Hai-rong2, WANG Chuang-yun3. A Microwave-assisted Procedure for the Extraction Polysaccharide from Evodia rutaecarpa Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2016, 18(4): 174-180. |

| [12] | XIONG Xia-yu, ZENG Xin-an*| WANG Man-sheng, ZHANG Zhi-hong. Studies on Optimization of Extraction Technology Assisted by Pulsed Electric Field of Total Flavonolds from Rape Pollen Using Response Surface Methodology [J]. Journal of Agricultural Science and Technology, 2015, 17(5): 88-93. |

| [13] | XIN Chongbo, ZI Lihan, LIU Chenguang, BAI Fengwu*. Response Surface Methodology Application for Optimizing Corncobs Pretreatment Conditions During Simultaneous Saccharification and Ethanol Fermentation [J]. , 2013, 15(5): 173-180. |

| [14] | WANG Jin-ling1, LIU Xiao-ping2, GAO Wei-hua1, ZHAO Feng-yan3, LV Chang-shan3. Medium Optimization for Phosphate-solubilizing Bacteria Bacillus Megaterium in Submerged Fermentation [J]. , 2013, 15(2): 185-192. |

| [15] | WANG Liang1,2, LI Shu1,2, MAO Zhonggui1,2*, ZHAO Fulin3. Optimization of Fermentation Medium for εPolylysine Production by Recombinant Streptomyces sp. FEEL1 [J]. , 2013, 15(1): 76-83. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号