Journal of Agricultural Science and Technology ›› 2025, Vol. 27 ›› Issue (4): 120-132.DOI: 10.13304/j.nykjdb.2023.0913

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Huapeng HU( ), Xukun ZHANG(

), Xukun ZHANG( ), Jiajun CHEN, Yangyang PAN, Peilin YANG, Zhi LU

), Jiajun CHEN, Yangyang PAN, Peilin YANG, Zhi LU

Received:2023-12-11

Accepted:2024-03-04

Online:2025-04-15

Published:2025-04-15

Contact:

Xukun ZHANG

胡华鹏( ), 张绪坤(

), 张绪坤( ), 谌佳君, 潘杨杨, 杨佩林, 鲁志

), 谌佳君, 潘杨杨, 杨佩林, 鲁志

通讯作者:

张绪坤

作者简介:胡华鹏E-mail:1781354105@qq.com;

基金资助:CLC Number:

Huapeng HU, Xukun ZHANG, Jiajun CHEN, Yangyang PAN, Peilin YANG, Zhi LU. Structural Optimization and Moisture Content Simulation of Tea Residue Dual Axis Stirring Dryer[J]. Journal of Agricultural Science and Technology, 2025, 27(4): 120-132.

胡华鹏, 张绪坤, 谌佳君, 潘杨杨, 杨佩林, 鲁志. 茶渣双轴搅拌干燥机结构优化及含水率模拟分析[J]. 中国农业科技导报, 2025, 27(4): 120-132.

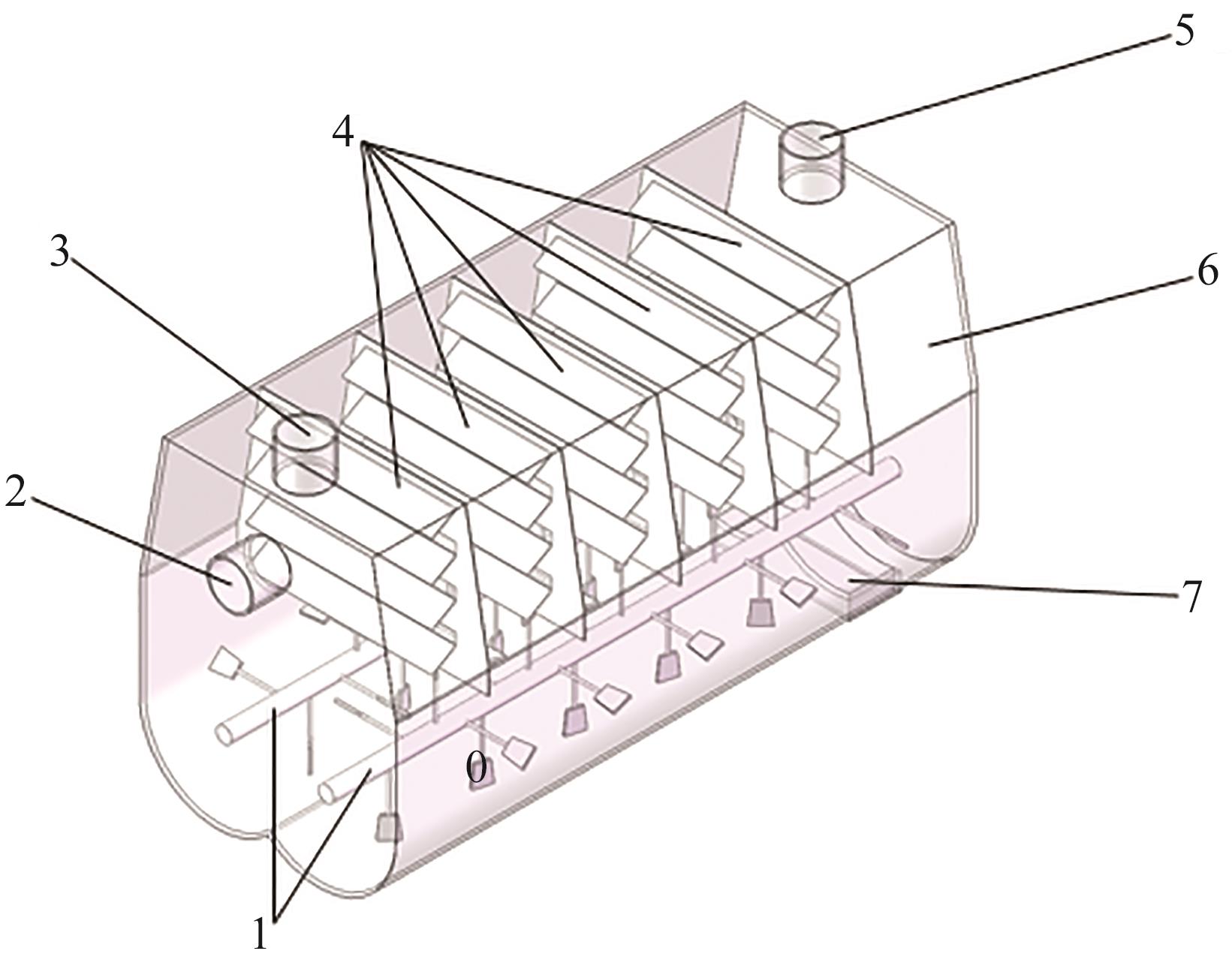

Fig. 1 Three dimensional model of dual axis stirring dryerNote:1—Mixing shaft; 2—Air inlet; 3—Feed inlet; 4—Guide grille; 5—Air outlet; 6—Machine wall; 7—Discharge port.

| 参数 Parameter | 数值 Value |

|---|---|

| 空气进口温度 Temperature at air inlet /℃ | 200~500 |

| 空气进口速度 Velocity at air inlet/(m·s-1) | 1 |

| 出口类型 Type of outlet | 压力出口Pressure outlet |

| 出口压力 Pressure of outlet/Pa | 103 125 |

| 物料进口温度 Temperature at materiel inlet/℃ | 20 |

| 主轴转速 Spindle speed/(r·min-1) | 300~600 |

| 物料进口含水率 Moisture content of material inlet/% | 84 |

| 物料出口含水率 Moisture content of material outlet/% | <14 |

| 物料密度 Material density/ (kg·m-2) | 367 |

| 绝干物料比热容 Specific heat capacity of absolute dry material/(kg·K-1) | 1.63[ |

| 物料导热系数 Material thermal conductivity/(W·m-1·K-1) | 0.0362[ |

Table 1 The main parameters of numerical simulation

| 参数 Parameter | 数值 Value |

|---|---|

| 空气进口温度 Temperature at air inlet /℃ | 200~500 |

| 空气进口速度 Velocity at air inlet/(m·s-1) | 1 |

| 出口类型 Type of outlet | 压力出口Pressure outlet |

| 出口压力 Pressure of outlet/Pa | 103 125 |

| 物料进口温度 Temperature at materiel inlet/℃ | 20 |

| 主轴转速 Spindle speed/(r·min-1) | 300~600 |

| 物料进口含水率 Moisture content of material inlet/% | 84 |

| 物料出口含水率 Moisture content of material outlet/% | <14 |

| 物料密度 Material density/ (kg·m-2) | 367 |

| 绝干物料比热容 Specific heat capacity of absolute dry material/(kg·K-1) | 1.63[ |

| 物料导热系数 Material thermal conductivity/(W·m-1·K-1) | 0.0362[ |

| 格栅数量 Number of grilles | 格栅间距 Spacing of the grilles/mm |

|---|---|

| 0 | — |

| 1 | — |

| 2 | 2 060 |

| 3 | 2 065 |

| 4 | 1 350 |

| 5 | 1 030 |

| 6 | 820 |

Table 2 Layout of each diversion grid

| 格栅数量 Number of grilles | 格栅间距 Spacing of the grilles/mm |

|---|---|

| 0 | — |

| 1 | — |

| 2 | 2 060 |

| 3 | 2 065 |

| 4 | 1 350 |

| 5 | 1 030 |

| 6 | 820 |

| 1 | 仇方方,杨晓萍.茶渣肥料的应用[J].福建茶叶,2011,33(6):21-23. |

| 2 | 丁其欢,武珊珊,钱杨杨,等.中国茶渣综合利用研究现状[J].热带农业科学, 2021, 41(8):66-70. |

| DING Q H, WU S S, QIAN Y Y, et al.. Comprehensive utilization of tea residues in China [J]. Chin. J. Trop. Agric., 2021, 41(8):66-70. | |

| 3 | 李娟,活泼,杨海燕.茶叶中非水溶性蛋白质提取工艺及功能性质的研究[J].浙江农业科学,2006,47(2):150-153. |

| LI J, HUO P, YANG H Y. Study on extraction technology and functional properties of water insoluble tea protein [J]. J. Zhejiang Agric. Sci., 2006, 47(2):150-153. | |

| 4 | KRISHNAPILLAI S. Effect of waste tea(tea fluff) on growth of young tea plants (Camellia sinensis L.) [J]. Cancer Res., 1981, 69(8):3347-3355. |

| 5 | 谢枫,金玲莉,涂娟,等.茶废弃物综合利用研究进展[J].中国农学通报,2015,31(1):140-145. |

| XIE F, JIN L L, TU J, et al.. Comprehensive utilization of tea waste:a review [J]. Chin. Agric. Sci. Bull., 2015, 31(1):140-145. | |

| 6 | 黄梦姣.茶渣深加工综合利用及咀嚼片的工艺研究[D].西安:陕西科技大学,2018. |

| HUANG M J. Extraction of apple pomace cellulose and study on preparation of its derivatives [D].Xi’an: Shaanxi University of Science and Technology, 2018. | |

| 7 | KHAN N, MUKHTAR H. Tea polyphenols in promotion of human health [J/OL].Nutrients, 2018, 11(1):39 [2024-10-08].. |

| 8 | 吴俊.废弃茶渣在养猪业中的应用[J].当代畜牧, 2018, 1(18):9-10. |

| WU J. Application of waste tea residue in pig industry [J]. Contemporary Anim. Husbandry, 2018, 1(18):9-10. | |

| 9 | 沈瀚.农产品加工机械[M].北京:中国大地出版社,2009:56-57. |

| 10 | WU Z H, MUJUMDAR A S. CFD modeling of the gas-particle flow behavior in spouted beds [J]. Powder Technol., 2008,183(2):260-272. |

| 11 | WANG Y, WILLIAMS K C, JONES M G, et al.. CFD simulation of gas-solid flow in dense phase bypass pneumatic convey. using the Euler-Euler model [J]. Appl. Mech. Mater., 2010, 26-28:1190-1194. |

| 12 | TAREK J J, MADHUMITA B R. Drying of sludge in a pneumatic dryer using computational fluid dynamics [J].Drying Technol., 2011, 29(3):308-322. |

| 13 | AMIRI A F, NAZARI M, SHAHMARDAN M M. Numerical investigation of heat transfer of CuO nanofluid using eeulerian-eulerian two phase model [J]. Int. J. Mech. Eng. Appl., 2017, 5(5):259-268. |

| 14 | CAMMARATA L, LETTIERI P, MICALE G, et al.. 2D and 3D CFD simulations of bubbling fluidized beds using eulerian-eulerian models [J/OL]. Int. J. Chem. Reactor Eng., 2003, 1(1):1083 [2024-10-08]. . |

| 15 | 秦长江,胡自化,张荣,等.双轴桨叶式干燥机气固两相流的数值模拟[J].有色金属工程,2017,7(3):64-72. |

| QIN C J, HU Z H, ZHANG R, et al.. Numerical simulation of gas-solid two-phase flow of biaxial paddle dryer [J]. Nonferrous Met. Eng., 2017, 7(3):64-72. | |

| 16 | 任景春,刘东玲,李延国,等.直通热风顺流式双轴搅拌干燥机的研究[J].农机化研究,2010,32(7):124-126, 134. |

| REN J C, LIU D L, LI Y G, et al.. The research on drying machine of straight-through hot air and biaxial mixing [J]. J. Agric. Mech. Res., 2010, 32(7):124-126, 134. | |

| 17 | 朱雨,董金善,赵悦,等.双轴螺旋桨叶干燥机内污泥含水率数值模拟[J].石油化工设备,2021,50(6):47-52. |

| ZHU Y, DONG J S, ZHAO Y, et al.. Numerical simulation of sludge moisture content in a twin-shaft propeller dryer [J]. Petro Chem. Equip., 2021, 50(6):47-52. | |

| 18 | 陈庆光,徐忠,张永建.RNGκ-ε模式在工程湍流数值计算中的应用[J].力学季刊,2003,24(1):88-95. |

| CHEN Q G, XU Z, ZHANG Y J. Application of RNG κ-ε models in numerical simulations of engineering turbulent flows[J]. Chin. Q. Mech., 2003, 24(1):88-95. | |

| 19 | 王福军.计算流体动力学分析:CFD软件原理与应用[M].北京:清华大学出版社,2004:113-139. |

| 20 | 隋洪涛,李鹏飞,马世虎,等.精通CFD动网格工程仿真与案例实战[M].北京:人民邮电出版社,2013:11-15. |

| 21 | 赵晨.茶叶炒干抛光机组的设计与试验[D].合肥:安徽农业大学, 2023. |

| ZHAO C. Design and test of tea drying polishing machine [D]. Hefei: Anhui Agricultural University, 2023. | |

| 22 | 殷鸿范.茶叶导热系数的研究[J].农业工程学报, 1986, 1(4):51-57. |

| YIN H F. Study on thermal conductivity of teas [J]. Trans. Chin. Soc. Agric. Eng., 1986, 1(4):51-57. |

| [1] | Guoliang ZHONG, Lin WAN, Gang CHE, Hao TANG, Tianqi QU, Qilin ZHANG. Influence of Drying Parameters on Hot Air Drying Rate and Energy Consumption of Rice [J]. Journal of Agricultural Science and Technology, 2025, 27(3): 95-103. |

| [2] | Dawei LIU, Feng QIN, Qian LIAO, Xiushan WANG, Fangping XIE, Tiehui LI. Optimization and Experimental Study of Drying Process Parameters for Rice in Hot-air Drying [J]. Journal of Agricultural Science and Technology, 2024, 26(8): 93-102. |

| [3] | Zhaoyang YANG, Peng XU, Tiejian YUAN, Xiaoqiong LI, Donggen PENG, Zhentao ZHANG, Junling YANG, Chuangchuang DING, Jizhou ZHU. Study on Low Temperature Drying Characteristics and Quality of Hybrid Broussonetia papyrifera [J]. Journal of Agricultural Science and Technology, 2024, 26(11): 157-170. |

| [4] | Zimin CHEN, Jiangting MO, Guangsheng CHEN, Xiaoxuan GUO, Xianwen ZHU. Analysis and Optimization of the Airflow Field in a Head-air Heat Pump Dryer Based on Fluent [J]. Journal of Agricultural Science and Technology, 2024, 26(10): 135-144. |

| [5] | Yaqiang HU, Ya YUAN, Luwei YANG, Xuelai ZHANG, Shaopeng QIU, Xinyao YU. Study on Hot Air Drying System for Implantable Alfalfa Bales [J]. Journal of Agricultural Science and Technology, 2023, 25(7): 105-112. |

| [6] | Yilin YANG, Junxiong DING, Xiaohua WU, Peng WANG, Dongliang SUN, Xinyao YU, Zhentao ZHANG, Dong LI. Optimization of Hot-air Drying Process Parameters of Lentinus edodes Based on Response Surface [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 154-164. |

| [7] | Tingting SHI, Yulan LIAO, Xuyou PENG, Chenyu YUAN. Design and Optimization of Single Row In-line Cassava Planter [J]. Journal of Agricultural Science and Technology, 2022, 24(6): 115-122. |

| [8] | Pinglu CHEN, Shihua XIAO, Jing XU, Muhua LIU. CFD-DEM Simulation of Paddy Drying in Lifting Screw Conveyor of Harvester [J]. Journal of Agricultural Science and Technology, 2022, 24(5): 93-101. |

| [9] | Wenbin GUO, Yao LI, Zhanghua HUANG, Jianqiang DU, Shanzhu QIAN, Zemin HE, Jingjing GAO. Physical Field Analysis and Structure Optimization of Solar Hot Air Dryer Based on COMSOL [J]. Journal of Agricultural Science and Technology, 2022, 24(10): 90-98. |

| [10] | ZHONG Runeng, ZHENG Qinhong, YAO Bin, XIANG Tai . Numerical Simulation for Effective Dielectric Properties of Cereal Grain Materials [J]. Journal of Agricultural Science and Technology, 2021, 23(9): 103-111. |

| [11] | PENG Donggen, NIE Jiangtao, SUN Wanfu. Application of Grain In-bin Drying Based on Liquid Desiccant Dehumidification Driven by Heat Pump [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 67-76. |

| [12] | ZHOU Shuxian, SHI Yixin, JIANG Ping. Design and Test Verification of Two-stage Jet Mixer Based on CFD [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 86-96. |

| [13] | SHI Yangjie, XI Xiaobo, YUAN Rican, SHAN Xiang, ZHANG Qi, ZHAO Qidong, ZHANG Ruihong. Design and Experiment of Microwave Vacuum Drying Equipment with CO2 Cold Trap [J]. Journal of Agricultural Science and Technology, 2021, 23(6): 97-104. |

| [14] | DENG Yige, DING Songshuang, ZHU Jiaming, TIAN Yuli, QIAO Baoming, SHI Xiangdong. Effect of Drying Density on Change of Main Nitrogen Compounds in Drying Process of Cigar Tobacco [J]. Journal of Agricultural Science and Technology, 2021, 23(5): 168-175. |

| [15] | YANG Taotao, ZHOU Xingyu, LU Xiaoli, QIAN Shanhua, YU Jinghu. Particle Molding Simulation and Structural Parameter Optimization of Pellet Mill Based on Orthogonal Experiment [J]. Journal of Agricultural Science and Technology, 2021, 23(10): 90-96. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号