Journal of Agricultural Science and Technology ›› 2023, Vol. 25 ›› Issue (7): 105-112.DOI: 10.13304/j.nykjdb.2022.0044

• INTELLIGENT AGRICULTURE & AGRICULTURAL MACHINERY • Previous Articles

Yaqiang HU1,2( ), Ya YUAN1(

), Ya YUAN1( ), Luwei YANG1, Xuelai ZHANG2, Shaopeng QIU1, Xinyao YU1

), Luwei YANG1, Xuelai ZHANG2, Shaopeng QIU1, Xinyao YU1

Received:2022-01-17

Accepted:2022-05-05

Online:2023-07-15

Published:2023-08-25

Contact:

Ya YUAN

胡亚强1,2( ), 苑亚1(

), 苑亚1( ), 杨鲁伟1, 章学来2, 邱少鹏1, 于馨尧1

), 杨鲁伟1, 章学来2, 邱少鹏1, 于馨尧1

通讯作者:

苑亚

作者简介:胡亚强 E-mail:914153497@qq.com;

基金资助:CLC Number:

Yaqiang HU, Ya YUAN, Luwei YANG, Xuelai ZHANG, Shaopeng QIU, Xinyao YU. Study on Hot Air Drying System for Implantable Alfalfa Bales[J]. Journal of Agricultural Science and Technology, 2023, 25(7): 105-112.

胡亚强, 苑亚, 杨鲁伟, 章学来, 邱少鹏, 于馨尧. 植入式苜蓿草捆热风干燥系统的研究[J]. 中国农业科技导报, 2023, 25(7): 105-112.

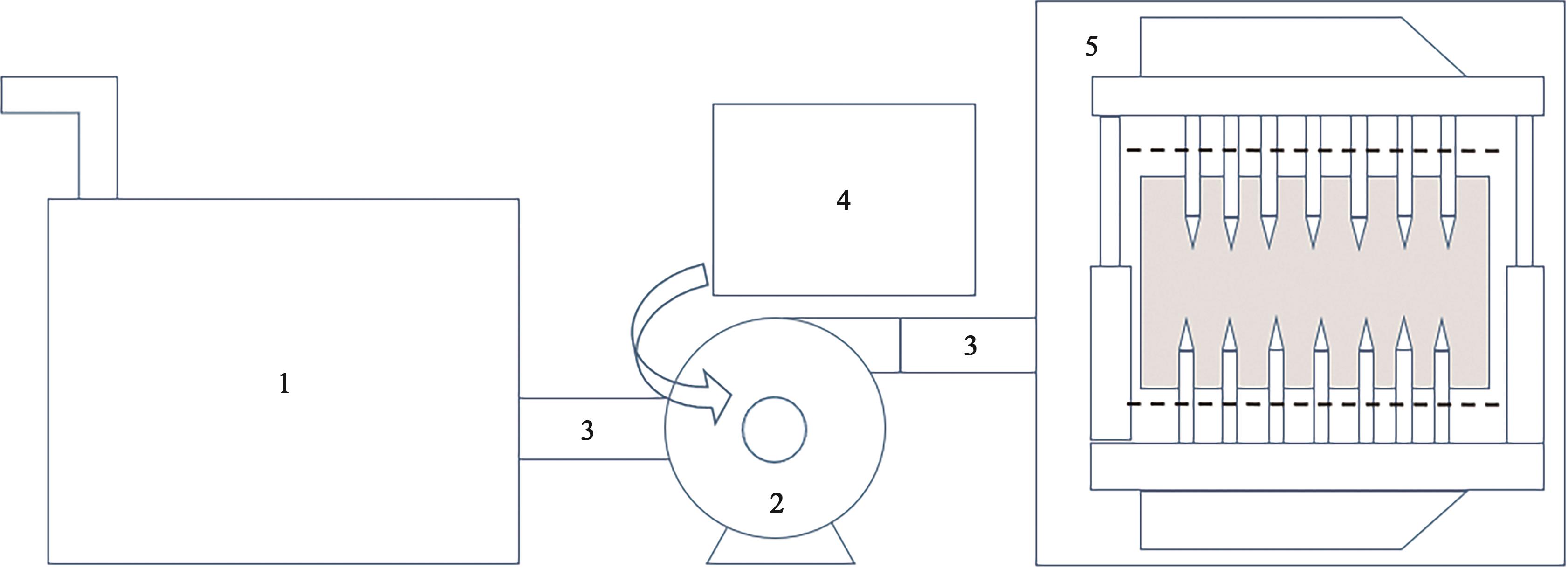

Fig. 1 Flow of implantable hot air drying systemNote:1—Biomass hot-blast stove; 2—High temperature centrifugal fan; 3—Flue Pipe; 4—Diesel engine; 5—Implantable dryer.

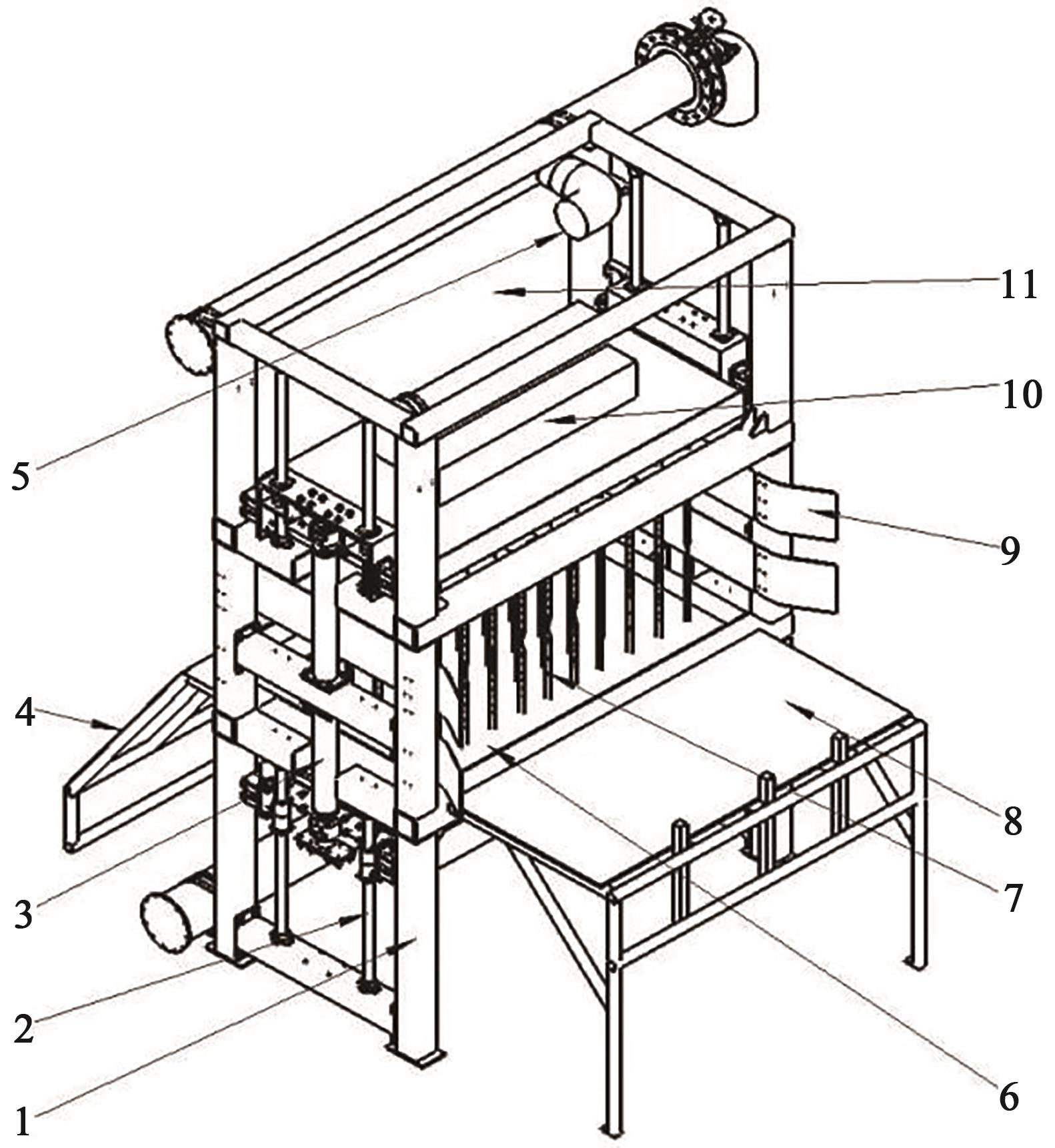

Fig. 2 Acupuncture implantable dryerNote:1—Support column; 2—Guide column; 3—Hydraulic system; 4—Blanking platform; 5—Air inlet; 6—Air duct guide plate;7—Needle tube; 8—Loading platform; 9—Bale guide plate; 10—Reinforcing column; 11—Upper stabilizing barn.

等级 Level | 粗蛋白 CP/% | 酸性洗涤纤维 ADF/% | 中性洗涤纤维 NDF/% | 总可消化养分 TDN/% | 相对饲喂价值 RFV |

|---|---|---|---|---|---|

特级 Extraordinary level | >22.0 | <27.0 | <34.0 | >62.0 | >185.0 |

优质级 High quality level | 20.1~22.0 | 27.1~29.0 | 34.0~36.1 | 60.5~62.0 | 170.1~185.0 |

良好级 Good level | 18.1~20.0 | 29.1~32.1 | 36.0~40.1 | 58.1~60.4 | 150.1~170.0 |

普通级 Ordinary level | 16.1~18.0 | 32.0~35.1 | 40.0~44.1 | 56.1~58.0 | 100.1~150.0 |

经济级 Economic level | ≤16.0 | ≥35.0 | ≥44.0 | ≤56.0 | ≤100.0 |

Table 1 American alfalfa hay quality inspection indicators and grading guidelines[16]

等级 Level | 粗蛋白 CP/% | 酸性洗涤纤维 ADF/% | 中性洗涤纤维 NDF/% | 总可消化养分 TDN/% | 相对饲喂价值 RFV |

|---|---|---|---|---|---|

特级 Extraordinary level | >22.0 | <27.0 | <34.0 | >62.0 | >185.0 |

优质级 High quality level | 20.1~22.0 | 27.1~29.0 | 34.0~36.1 | 60.5~62.0 | 170.1~185.0 |

良好级 Good level | 18.1~20.0 | 29.1~32.1 | 36.0~40.1 | 58.1~60.4 | 150.1~170.0 |

普通级 Ordinary level | 16.1~18.0 | 32.0~35.1 | 40.0~44.1 | 56.1~58.0 | 100.1~150.0 |

经济级 Economic level | ≤16.0 | ≥35.0 | ≥44.0 | ≤56.0 | ≤100.0 |

| 指标 Index | 干燥前样品 Sample before drying | 干燥后样品 Sample after drying | 自然晾晒样品 Natural drying samples |

|---|---|---|---|

| 粗蛋白Crude protein, CP/% | 20.3 | 20.2 | 18.2 |

| 酸性洗涤不溶蛋白Acid deter⁃ gent insoluble crude protein, ADICP/% | 1.4 | 1.3 | 1.4 |

| 有效粗蛋白Available protein, AP/% | 18.9 | 17.9 | 16.8 |

| 酸性洗涤纤维Acid detergent fiber,ADF/% | 28.2 | 27.5 | 33.7 |

| 中性洗涤纤维Neutral detergent fiber,NDF/% | 35.72 | 35.61 | 40.68 |

| 木质素Lingnin/% | 6.5 | 6.5 | 7.3 |

| 非纤维碳水化合物Non-fiber carbohydrate, NFC/% | 29.40 | 31.09 | 28.66 |

| 淀粉Starch/% | 1.6 | 2.1 | 0.7 |

| 水溶性碳水化合物Water-soluble carbohydrates,WSC/% | 10.8 | 11.9 | 6.6 |

| 单糖Monosaccharide,MSC/% | 8.1 | 8.3 | 5.3 |

| 脂肪Fat/% | 2.7 | 2.6 | 1.8 |

| 灰分Ash/% | 10.88 | 10.50 | 9.66 |

| 总可消化养分Tatal digestive nutrition,TDN/% | 61 | 61 | 58 |

| 相对饲用价值Relative feed value,RFV | 172 | 170 | 142 |

Table 2 Index measurement before and after drying in different ways

| 指标 Index | 干燥前样品 Sample before drying | 干燥后样品 Sample after drying | 自然晾晒样品 Natural drying samples |

|---|---|---|---|

| 粗蛋白Crude protein, CP/% | 20.3 | 20.2 | 18.2 |

| 酸性洗涤不溶蛋白Acid deter⁃ gent insoluble crude protein, ADICP/% | 1.4 | 1.3 | 1.4 |

| 有效粗蛋白Available protein, AP/% | 18.9 | 17.9 | 16.8 |

| 酸性洗涤纤维Acid detergent fiber,ADF/% | 28.2 | 27.5 | 33.7 |

| 中性洗涤纤维Neutral detergent fiber,NDF/% | 35.72 | 35.61 | 40.68 |

| 木质素Lingnin/% | 6.5 | 6.5 | 7.3 |

| 非纤维碳水化合物Non-fiber carbohydrate, NFC/% | 29.40 | 31.09 | 28.66 |

| 淀粉Starch/% | 1.6 | 2.1 | 0.7 |

| 水溶性碳水化合物Water-soluble carbohydrates,WSC/% | 10.8 | 11.9 | 6.6 |

| 单糖Monosaccharide,MSC/% | 8.1 | 8.3 | 5.3 |

| 脂肪Fat/% | 2.7 | 2.6 | 1.8 |

| 灰分Ash/% | 10.88 | 10.50 | 9.66 |

| 总可消化养分Tatal digestive nutrition,TDN/% | 61 | 61 | 58 |

| 相对饲用价值Relative feed value,RFV | 172 | 170 | 142 |

| 编号 Number | 干燥前质量 Quality before drying | 干燥后质量 Quality after drying | 水分蒸发量 Water evaporation |

|---|---|---|---|

| 1#草捆1# bale | 568 | 494 | 74 |

| 2#草捆2# bale | 549 | 466 | 83 |

| 3#草捆3# bale | 532 | 455 | 77 |

Table 3 Bale mass change

| 编号 Number | 干燥前质量 Quality before drying | 干燥后质量 Quality after drying | 水分蒸发量 Water evaporation |

|---|---|---|---|

| 1#草捆1# bale | 568 | 494 | 74 |

| 2#草捆2# bale | 549 | 466 | 83 |

| 3#草捆3# bale | 532 | 455 | 77 |

| 1 | 郭婷,薛彪,白娟,等.刍议中国牧草产业发展现状——以苜蓿、燕麦为例[J].草业科学,2019,36(5):1466-1473. |

| GUO T, XUE B, BAI J, et al.. Discussion of the present situation of China's forage grass industry development: an example using alfalfa and oats [J]. Pratac. Sci., 2019, 36(5): 1466-1473. | |

| 2 | 孙志华,赵俊金,许海涛,等.2019年我国苜蓿产业形势分析[J].中国奶牛,2019(10):58-60. |

| SUN Z H, ZHAO J J, XU H T, et al.. Analysis of China's alfalfa industry in 2019 [J]. China Dairy Cattle, 2019(10):58-60. | |

| 3 | 郑先哲,王忠江,金长江.牧草干燥理论与设备[M]. 北京:中国农业出版社,2009:3-9. |

| 4 | 贾婷婷,赵苗苗,吴哲,等.雨淋及干燥方式对紫花苜蓿干草品质的影响[J].草地学报,2017,25(06):1362-1367. |

| JIA T T, ZHAO M M, WU Z, et al.. Effect of raining and drying method on the quality of Alfalfa hay [J]. Acta Agrestia Sin., 2017,25(6): 1362-1367. | |

| 5 | 郑先哲,蒋亦元. 苜蓿干燥特性试验研究[J]. 农业工程学报,2005,21(1):159-162. |

| ZHENG X Z, JIANG Y Y. Experimental study on the drying process characteristics of alfalfa [J]. Trans. Chin. Soc. Agric. Eng., 2005, 21(1):159-162. | |

| 6 | 石欣,王芳,张静,等.苜蓿主要营养成分预测模型的建立及分析[J].饲料研究,2021(21):108-110. |

| SHI X, WANG F, ZHANG J, et al.. Establishment and analysis of prediction model for main nutrient components of alfalfa [J]. Feed Res., 2021(21):108-110. | |

| 7 | 中华人民共和国农业部. 农业部关于印发《全国种植业结构调整规划 (2016—2020年)》的通知[EB/OL].[2021-12-20].. |

| 8 | 荷斯坦网.2020年进口干草统计.(2021-01-01)[2021-12-20]. . |

| 9 | 杨世昆,杜建强.太阳能草捆干燥设备设计与试验[J].农业机械学报,2011,42(4):81-86. |

| YANG S K, DU J Q. Design and experiment of bale drying machinery using solar energy [J]. Trans. Chin. Soc. Agric. Mach., 2011,42(4):81-86. | |

| 10 | 钱珊珠,杨哲.苜蓿草捆太阳能干燥特性试验研究[J].农机化研究,2017,39(2):158-161. |

| QIAN S Z, YANG Z. Testing study on solar drying characteristics of alfalfa bale [J]. J. Agric. Mechan. Res., 2017,39(2):158-161. | |

| 11 | ROMÁN D, HENSEL O. Numerical simulations and experimental measurements on the distribution of air and drying of round hay bales [J]. Biosys. Eng., 2014, 122: 1-15. |

| 12 | KHALID A, GAADI A. Impact of raking and baling patterns on alfalfa hay dry matter and quality losses [J]. Saudi J. Biol. Sci., 2018,25(6):1040-1048. |

| 13 | 李海龙,车刚,万霖,等.方捆苜蓿热风循环干燥工艺实验研究[J].中国农业科技导报,2019,21(8):82- 89. |

| LI H L, CHE G, WAN L, et al.. Bundle alfalfa experimental study on hot air circulation drying process [J]. J. Agric. Sci. Technol., 2019,21(8):82-89. | |

| 14 | 杨鲁伟,孙椰望,魏娟,等. 牧草烘干装置: CN112710134A[P].2021-04-27. |

| 15 | 李宏宇,杨茁萌,仇学军,等.美国二次压缩苜蓿草捆的取样与样品前处理方法[J].中国奶牛,2019(2):54-59. |

| LI H Y, YANG Z M, QIU X J, et al.. Sampling and sample pretreatment of American secondary compressed alfalfa bales [J]. China Dairy Cattle, 2019(2):54-59. | |

| 16 | 陶莎,王玉庭,张峭.国内苜蓿草供需现状及中美贸易摩擦带来的影响与对策[J].畜牧与饲料科学,2019,40(10):46-50. |

| TAO S, WANG Y T, ZHANG Q. Situation of domestic alfalfa market and the impact from sino-US trade frictions and its countermeasures [J]. Anim. Husbandry Feed Sci., 2019,40(10):46-50. |

| [1] | Dongmeng ZHANG, Dongping YAO, Jun WU, Qiuhong LUO, Wen ZHUANG, Xionglun LIU, Qiyun DENG, Bin BAI. Effect of Natural Low Temperature on Cooking and Eating Quality of Rice During Grain Filling Stage [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 144-153. |

| [2] | Yilin YANG, Junxiong DING, Xiaohua WU, Peng WANG, Dongliang SUN, Xinyao YU, Zhentao ZHANG, Dong LI. Optimization of Hot-air Drying Process Parameters of Lentinus edodes Based on Response Surface [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 154-164. |

| [3] | Shijiang ZHU, Hu LI, Wen XU, Yating FENG. Effects of Soil Moisture Content on Fruit Quality in Citrus Orchards Within Three Gorges Reservoir Area [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 201-207. |

| [4] | Zhongxiu RAO, Jimin SUN, Na ZHANG, Longtao LI, Chunhua DONG, Zengping YANG, Fengqiu HUANG. Impacts from Adding Artemisia argyi Straw into Substrates on Growth and Quality of Pleurotus ostreatus [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 208-215. |

| [5] | Yongyan LIU, Zhengxiong SONG, Jiawei JIN, Jing WANG, Min XU, Junxue ZHOU, Zhanmin LI, Shimin ZHAO, Yunpeng FU, Xiaoyan DAI. Effects of Molybdenum and Zinc Nutrition on Physiological Characteristics and Quality of Flue-cured Tobacco [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 216-224. |

| [6] | Xiangdong WANG, Daqi LIANG, Yanzhi MA. Comparison and Comprehensive Evaluation of Fruit and Seed Kernel Quality of Sour Jujube (Ziziphus acidojujuba C.Y. Cheng et M.J.Liu) from Different Producing Areas [J]. Journal of Agricultural Science and Technology, 2023, 25(6): 50-58. |

| [7] | Lu TIAN, Xiaoxia GUO, Wenbin SU, Chunyan HUANG, Zhi LI, Peng ZHANG, Caiyuan JIAN, Jia LIU, Dejuan KONG, Kang HAN. Effects of Microbial Fertilizer on Growth, Yield and Quality of Continuous Cropping Sugar Beet [J]. Journal of Agricultural Science and Technology, 2023, 25(5): 192-203. |

| [8] | Zhengran SUN, Cuiping ZHANG, Jinli ZHANG, Hao WU, Xiuyan LIU, Zhenkai WANG, Yuzhen YANG, Daohua HE. Effects of Chemical Detopping on Cotton Plant Growth in Guanzhong Cotton Region [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 167-177. |

| [9] | Wenjun ZHAO, Jizhou YANG, Mei YIN, Jianfeng CHEN, Kaizheng XUE, Baowen HU, Libo FU, Wei WANG, Zhiyuan WANG, Yanxian YANG, Hua CHEN. Effects of Combined Application of Green Manure with Reduced Nitrogen Fertilizer on Yield and Quality of Flue-cured Tobacco [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 189-196. |

| [10] | Xiangdong WANG, Yue SONG, Yanzhi MA. Quality Comparison and Comprehensive Evaluation of Different Zingiber officinale Rosc. Varieties [J]. Journal of Agricultural Science and Technology, 2023, 25(4): 56-66. |

| [11] | Nali XU, Huixia YU, Mingming YAO, Yanqing WANG, Qingfeng LI, Caixia LIU, Gang SUN, Jiajing CHEN, Jiaohui LONG, Zhangjun WANG. Analysis of Genetic Diversity Based on SSR and SRAP Markers and Agronomic Traits of Wheat Resources [J]. Journal of Agricultural Science and Technology, 2023, 25(3): 30-46. |

| [12] | Ze TENG, Yuxia ZHANG, Weidong CHEN, Baiming CONG, Yonglei TIAN, Qingxin ZHANG, Yongliang ZHANG, Dongru WANG. Effect of Chitosan on Alfalfa’s Cold Resistance and Content of Cold-resistant Protective Substances [J]. Journal of Agricultural Science and Technology, 2023, 25(2): 192-198. |

| [13] | Weixin DONG, Dongxiao LI, Yuechen ZHANG. Effects of Different Nitrogen Levels on Physiological Parameters, Yield and Quality of Maize [J]. Journal of Agricultural Science and Technology, 2023, 25(1): 142-152. |

| [14] | Geng LI, Yuanyuan ZHAO, Yuyuan CHENG, Jiang WU, Weidong DUAN, Guangting YIN, Qian LI, Chen CHEN, Fei ZHENG, Yuan LIU, Hongzhi SHI. Effects of Different Organic-inorganic Nitrogen Ratios on Soil Carbon and Nitrogen and Upper Leaf Quality in Nanyang Tobacco Area [J]. Journal of Agricultural Science and Technology, 2023, 25(1): 175-186. |

| [15] | Yuanwei CHEN, Huabin ZHENG, Weiqin WANG, Na KUANG, Youyi LUO, Dan ZOU, Qiyuan TANG. Effect of Mowing Treatment on the Main Season Whole Plant Biomass and Silage Quality and Yield in Regeneration Season of Ratooning Rice [J]. Journal of Agricultural Science and Technology, 2022, 24(8): 161-171. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号