Journal of Agricultural Science and Technology ›› 2024, Vol. 26 ›› Issue (11): 157-170.DOI: 10.13304/j.nykjdb.2023.0755

• FOOD QUALITY & PROCESSING AND STORAGE • Previous Articles

Zhaoyang YANG1,2( ), Peng XU2,3, Tiejian YUAN2, Xiaoqiong LI2(

), Peng XU2,3, Tiejian YUAN2, Xiaoqiong LI2( ), Donggen PENG1(

), Donggen PENG1( ), Zhentao ZHANG2, Junling YANG2, Chuangchuang DING2, Jizhou ZHU4

), Zhentao ZHANG2, Junling YANG2, Chuangchuang DING2, Jizhou ZHU4

Received:2023-10-16

Accepted:2024-03-04

Online:2024-11-15

Published:2024-11-19

Contact:

Xiaoqiong LI,Donggen PENG

杨朝阳1,2( ), 徐鹏2,3, 苑铁键2, 李晓琼2(

), 徐鹏2,3, 苑铁键2, 李晓琼2( ), 彭冬根1(

), 彭冬根1( ), 张振涛2, 杨俊玲2, 丁闯闯2, 朱纪洲4

), 张振涛2, 杨俊玲2, 丁闯闯2, 朱纪洲4

通讯作者:

李晓琼,彭冬根

作者简介:杨朝阳 E-mail:953822978@qq.com

基金资助:CLC Number:

Zhaoyang YANG, Peng XU, Tiejian YUAN, Xiaoqiong LI, Donggen PENG, Zhentao ZHANG, Junling YANG, Chuangchuang DING, Jizhou ZHU. Study on Low Temperature Drying Characteristics and Quality of Hybrid Broussonetia papyrifera[J]. Journal of Agricultural Science and Technology, 2024, 26(11): 157-170.

杨朝阳, 徐鹏, 苑铁键, 李晓琼, 彭冬根, 张振涛, 杨俊玲, 丁闯闯, 朱纪洲. 杂交构树低温干燥特性及品质研究[J]. 中国农业科技导报, 2024, 26(11): 157-170.

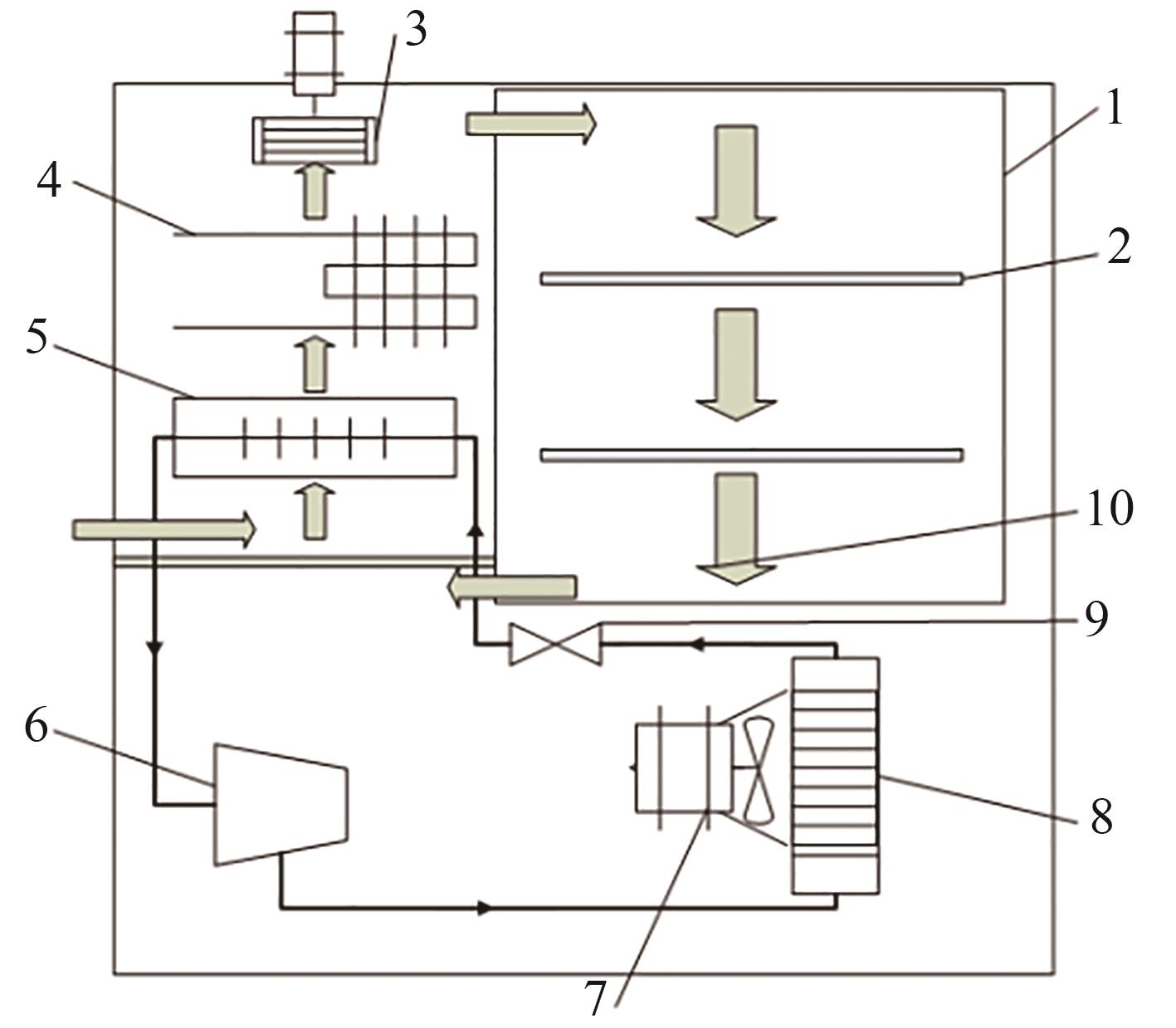

Fig. 1 Hot air drying equipmentNote:1—Drying box;2—Partition board; 3—Fan; 4—Electric heater; 5—Evaporator; 6—Compressor; 7—Condenser fan; 8— Condenser;9—Expansion valve; 10—Hot air flow.

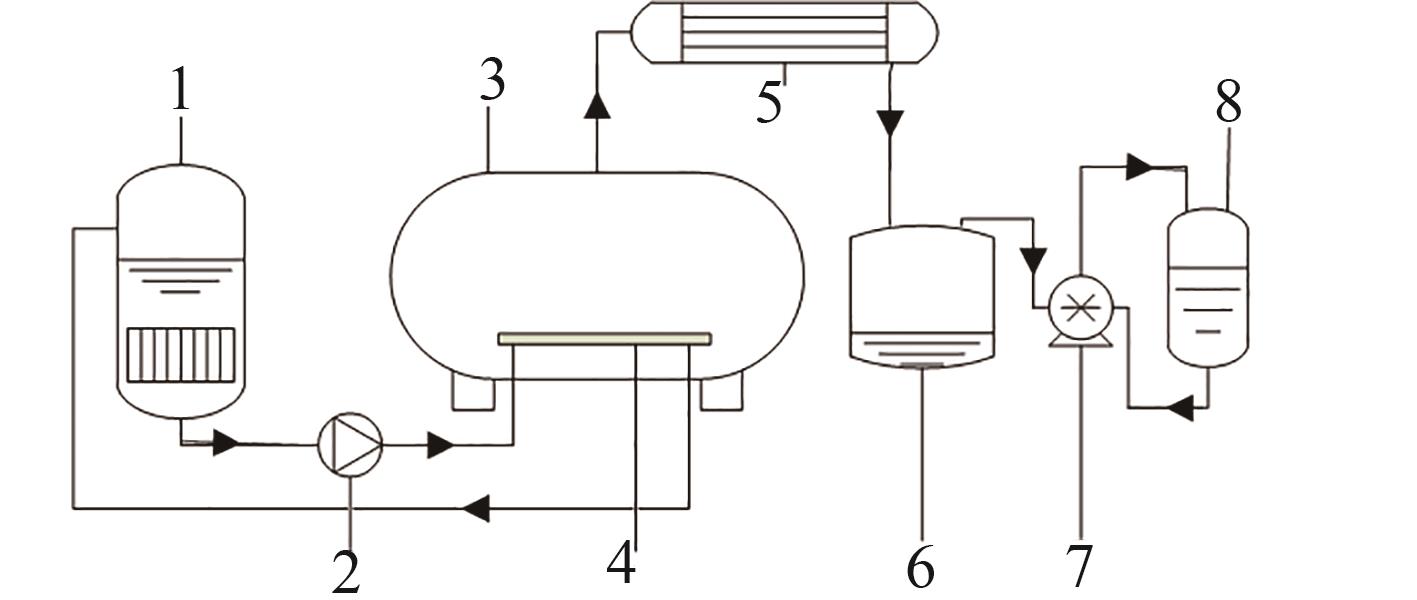

Fig. 2 Vacuum drying systemNote:1—Heat source tank;2—Hot water pump;3—Vacuum drying chamber;4—Heat conduction plate;5—Heat exchanger;6—Condensate water tank;7—Vacuum pump;8—Circulation water tank.

干燥工况 Drying condition | 干燥工艺 Drying process | 厚度 Thickness/cm | 温度 Temperature/℃ | 压力 Pressure/kPa |

|---|---|---|---|---|

| 1 | 热风干燥HAD | 2 | 60 | 常压 Atmospheric pressure |

| 2 | 70 | |||

| 3 | 80 | |||

| 4 | 3 | 60 | ||

| 5 | 70 | |||

| 6 | 80 | |||

| 7 | 4 | 60 | ||

| 8 | 70 | |||

| 9 | 80 | |||

| 10 | 真空干燥VD | 2 | 60 | 40 |

| 11 | 20 | |||

| 12 | 70 | 40 | ||

| 13 | 20 | |||

| 14 | 80 | 40 | ||

| 15 | 20 |

Table 1 Experimental design

干燥工况 Drying condition | 干燥工艺 Drying process | 厚度 Thickness/cm | 温度 Temperature/℃ | 压力 Pressure/kPa |

|---|---|---|---|---|

| 1 | 热风干燥HAD | 2 | 60 | 常压 Atmospheric pressure |

| 2 | 70 | |||

| 3 | 80 | |||

| 4 | 3 | 60 | ||

| 5 | 70 | |||

| 6 | 80 | |||

| 7 | 4 | 60 | ||

| 8 | 70 | |||

| 9 | 80 | |||

| 10 | 真空干燥VD | 2 | 60 | 40 |

| 11 | 20 | |||

| 12 | 70 | 40 | ||

| 13 | 20 | |||

| 14 | 80 | 40 | ||

| 15 | 20 |

干燥模型 Drying model | 模型公式 Formulation |

|---|---|

| A. Sander | MR=exp[-(t/k)a] |

| Henderson and Pabis | MR=a exp(-kt) |

| Logarithmic | MR=a exp(-kt) + b |

| Newton/Lewis | MR=exp(-kt) |

| Page | MR=exp(-kta) |

| Third-degree polynomial model | MR=a+bt+kt2+k0t3 |

Table 2 Drying model

干燥模型 Drying model | 模型公式 Formulation |

|---|---|

| A. Sander | MR=exp[-(t/k)a] |

| Henderson and Pabis | MR=a exp(-kt) |

| Logarithmic | MR=a exp(-kt) + b |

| Newton/Lewis | MR=exp(-kt) |

| Page | MR=exp(-kta) |

| Third-degree polynomial model | MR=a+bt+kt2+k0t3 |

干燥模型 Drying model | 干燥工况 Drying condation | 拟合参数的优度 Goodness of fit paramenter | 模型系数Model coefficient | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 平方误差和SSE/(×10-3) | 决定系数 R2 | 均方根误差RMSE | a | b | k | k0/ (×10-4) | |||

| Page | HAD, 60 ℃, 2 cm | 3.190 | 0.995 6 | 0.023 1 | 1.380 81 | 0.159 78 | |||

| HAD, 70 ℃, 2 cm | 1.800 | 0.997 5 | 0.019 0 | 1.457 87 | 0.213 97 | ||||

| HAD, 80 ℃, 2 cm | 1.220 | 0.998 0 | 0.175 0 | 1.445 46 | 0.242 81 | ||||

| HAD, 60 ℃, 3 cm | 8.350 | 0.990 3 | 0.030 5 | 1.366 16 | 0.079 35 | ||||

| HAD,70 ℃, 3 cm | 2.950 | 0.996 7 | 0.018 1 | 1.234 64 | 0.138 34 | ||||

| HAD, 80 ℃, 3 cm | 1.410 | 0.997 9 | 0.015 3 | 1.286 11 | 0.162 25 | ||||

| HAD, 60 ℃, 4 cm | 1.580 | 0.998 7 | 0.010 6 | 1.174 86 | 0.085 39 | ||||

| HAD, 70 ℃, 4 cm | 1.920 | 0.997 9 | 0.013 9 | 1.196 86 | 0.111 43 | ||||

| HAD, 80 ℃, 4 cm | 1.710 | 0.998 1 | 0.013 8 | 1.220 08 | 0.127 80 | ||||

| VD, 60 ℃, 40 kPa, 2 cm | 4.160 | 0.996 0 | 0.019 4 | 1.339 04 | 0.072 20 | ||||

| VD, 60 ℃, 20 kPa, 2 cm | 1.860 | 0.997 5 | 0.015 3 | 1.252 48 | 0.109 96 | ||||

| VD, 70 ℃, 40 kPa, 2 cm | 3.260 | 0.996 4 | 0.019 0 | 1.357 89 | 0.089 78 | ||||

| VD, 70 ℃, 20 kPa, 2 cm | 1.810 | 0.997 7 | 0.015 0 | 1.258 36 | 0.123 95 | ||||

| VD, 80 ℃, 40 kPa, 2 cm | 3.130 | 0.995 6 | 0.021 1 | 1.271 99 | 0.130 40 | ||||

| VD, 80 ℃, 20 kPa, 2 cm | 2.480 | 0.996 8 | 0.018 8 | 1.273 48 | 0.150 06 | ||||

| Logarithmic | HAD, 60 ℃, 2 cm | 0.406 | 0.999 4 | 0.009 01 | 2.097 44 | -1.094 39 | 0.090 84 | ||

| HAD, 70 ℃, 2 cm | 0.387 | 0.999 5 | 0.009 84 | 2.082 71 | -1.076 04 | 0.119 98 | |||

| HAD, 80 ℃, 2 cm | 0.299 | 0.999 5 | 0.009 98 | 2.202 59 | -1.197 10 | 0.121 50 | |||

| HAD, 60 ℃, 3 cm | 0.715 | 0.999 2 | 0.009 45 | 3.127 44 | -2.133 57 | 0.033 46 | |||

| HAD,70 ℃, 3 cm | 0.185 | 0.999 8 | 0.004 81 | 1.455 33 | -0.456 43 | 0.109 97 | |||

| HAD, 80 ℃, 3 cm | 0.261 | 0.999 6 | 0.007 22 | 1.568 38 | -0.562 06 | 0.122 31 | |||

| HAD, 60 ℃, 4 cm | 0.582 | 0.999 5 | 0.006 69 | 1.228 46 | -0.218 93 | 0.088 65 | |||

| HAD, 70 ℃, 4 cm | 0.084 | 0.999 9 | 0.003 05 | 1.326 62 | -0.323 95 | 0.100 87 | |||

| HAD, 80 ℃, 4 cm | 0.190 | 0.999 8 | 0.004 88 | 1.337 43 | -0.331 35 | 0.116 05 | |||

| VD, 60 ℃, 40 kPa, 2 cm | 0.211 | 0.999 8 | 0.004 59 | 1.956 24 | -0.953 00 | 0.052 88 | |||

| VD, 60 ℃, 20 kPa, 2 cm | 0.118 | 0.999 8 | 0.004 10 | 1.636 30 | -0.634 97 | 0.081 48 | |||

| VD, 70 ℃, 40 kPa, 2 cm | 0.252 | 0.999 7 | 0.005 61 | 2.007 24 | -1.002 39 | 0.061 92 | |||

| VD, 70 ℃, 20 kPa, 2 cm | 0.083 | 0.999 9 | 0.003 44 | 1.553 49 | -0.551 42 | 0.096 30 | |||

| VD, 80 ℃, 40 kPa, 2 cm | 0.047 | 0.999 9 | 0.002 81 | 1.763 08 | -0.765 48 | 0.085 81 | |||

| VD, 80 ℃, 20 kPa, 2 cm | 0.012 | 0.999 9 | 0.001 40 | 1.579 12 | -0.578 93 | 0.110 61 | |||

| Lewes | HAD, 60 ℃, 2 cm | 22.810 | 0.968 8 | 0.057 1 | 0.265 94 | ||||

| HAD, 70 ℃, 2 cm | 25.460 | 0.964 8 | 0.065 1 | 0.357 94 | |||||

| HAD, 80 ℃, 2 cm | 19.970 | 0.967 3 | 0.063 2 | 0.380 57 | |||||

| HAD, 60 ℃, 3 cm | 32.630 | 0.962 2 | 0.057 1 | 0.152 00 | |||||

| HAD,70 ℃, 3 cm | 14.620 | 0.983 7 | 0.038 2 | 0.203 06 | |||||

| HAD, 80 ℃, 3 cm | 13.460 | 0.980 3 | 0.043 8 | 0.240 81 | |||||

| HAD, 60 ℃, 4 cm | 12.230 | 0.989 9 | 0.028 6 | 0.122 78 | |||||

| HAD, 70 ℃, 4 cm | 11.450 | 0.987 7 | 0.032 2 | 0.158 81 | |||||

Table 3 Results of drying kinetics fitting of hybrid Broussonetia papyrifera

干燥模型 Drying model | 干燥工况 Drying condation | 拟合参数的优度 Goodness of fit paramenter | 模型系数Model coefficient | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 平方误差和SSE/(×10-3) | 决定系数 R2 | 均方根误差RMSE | a | b | k | k0/ (×10-4) | |||

| Page | HAD, 60 ℃, 2 cm | 3.190 | 0.995 6 | 0.023 1 | 1.380 81 | 0.159 78 | |||

| HAD, 70 ℃, 2 cm | 1.800 | 0.997 5 | 0.019 0 | 1.457 87 | 0.213 97 | ||||

| HAD, 80 ℃, 2 cm | 1.220 | 0.998 0 | 0.175 0 | 1.445 46 | 0.242 81 | ||||

| HAD, 60 ℃, 3 cm | 8.350 | 0.990 3 | 0.030 5 | 1.366 16 | 0.079 35 | ||||

| HAD,70 ℃, 3 cm | 2.950 | 0.996 7 | 0.018 1 | 1.234 64 | 0.138 34 | ||||

| HAD, 80 ℃, 3 cm | 1.410 | 0.997 9 | 0.015 3 | 1.286 11 | 0.162 25 | ||||

| HAD, 60 ℃, 4 cm | 1.580 | 0.998 7 | 0.010 6 | 1.174 86 | 0.085 39 | ||||

| HAD, 70 ℃, 4 cm | 1.920 | 0.997 9 | 0.013 9 | 1.196 86 | 0.111 43 | ||||

| HAD, 80 ℃, 4 cm | 1.710 | 0.998 1 | 0.013 8 | 1.220 08 | 0.127 80 | ||||

| VD, 60 ℃, 40 kPa, 2 cm | 4.160 | 0.996 0 | 0.019 4 | 1.339 04 | 0.072 20 | ||||

| VD, 60 ℃, 20 kPa, 2 cm | 1.860 | 0.997 5 | 0.015 3 | 1.252 48 | 0.109 96 | ||||

| VD, 70 ℃, 40 kPa, 2 cm | 3.260 | 0.996 4 | 0.019 0 | 1.357 89 | 0.089 78 | ||||

| VD, 70 ℃, 20 kPa, 2 cm | 1.810 | 0.997 7 | 0.015 0 | 1.258 36 | 0.123 95 | ||||

| VD, 80 ℃, 40 kPa, 2 cm | 3.130 | 0.995 6 | 0.021 1 | 1.271 99 | 0.130 40 | ||||

| VD, 80 ℃, 20 kPa, 2 cm | 2.480 | 0.996 8 | 0.018 8 | 1.273 48 | 0.150 06 | ||||

| Logarithmic | HAD, 60 ℃, 2 cm | 0.406 | 0.999 4 | 0.009 01 | 2.097 44 | -1.094 39 | 0.090 84 | ||

| HAD, 70 ℃, 2 cm | 0.387 | 0.999 5 | 0.009 84 | 2.082 71 | -1.076 04 | 0.119 98 | |||

| HAD, 80 ℃, 2 cm | 0.299 | 0.999 5 | 0.009 98 | 2.202 59 | -1.197 10 | 0.121 50 | |||

| HAD, 60 ℃, 3 cm | 0.715 | 0.999 2 | 0.009 45 | 3.127 44 | -2.133 57 | 0.033 46 | |||

| HAD,70 ℃, 3 cm | 0.185 | 0.999 8 | 0.004 81 | 1.455 33 | -0.456 43 | 0.109 97 | |||

| HAD, 80 ℃, 3 cm | 0.261 | 0.999 6 | 0.007 22 | 1.568 38 | -0.562 06 | 0.122 31 | |||

| HAD, 60 ℃, 4 cm | 0.582 | 0.999 5 | 0.006 69 | 1.228 46 | -0.218 93 | 0.088 65 | |||

| HAD, 70 ℃, 4 cm | 0.084 | 0.999 9 | 0.003 05 | 1.326 62 | -0.323 95 | 0.100 87 | |||

| HAD, 80 ℃, 4 cm | 0.190 | 0.999 8 | 0.004 88 | 1.337 43 | -0.331 35 | 0.116 05 | |||

| VD, 60 ℃, 40 kPa, 2 cm | 0.211 | 0.999 8 | 0.004 59 | 1.956 24 | -0.953 00 | 0.052 88 | |||

| VD, 60 ℃, 20 kPa, 2 cm | 0.118 | 0.999 8 | 0.004 10 | 1.636 30 | -0.634 97 | 0.081 48 | |||

| VD, 70 ℃, 40 kPa, 2 cm | 0.252 | 0.999 7 | 0.005 61 | 2.007 24 | -1.002 39 | 0.061 92 | |||

| VD, 70 ℃, 20 kPa, 2 cm | 0.083 | 0.999 9 | 0.003 44 | 1.553 49 | -0.551 42 | 0.096 30 | |||

| VD, 80 ℃, 40 kPa, 2 cm | 0.047 | 0.999 9 | 0.002 81 | 1.763 08 | -0.765 48 | 0.085 81 | |||

| VD, 80 ℃, 20 kPa, 2 cm | 0.012 | 0.999 9 | 0.001 40 | 1.579 12 | -0.578 93 | 0.110 61 | |||

| Lewes | HAD, 60 ℃, 2 cm | 22.810 | 0.968 8 | 0.057 1 | 0.265 94 | ||||

| HAD, 70 ℃, 2 cm | 25.460 | 0.964 8 | 0.065 1 | 0.357 94 | |||||

| HAD, 80 ℃, 2 cm | 19.970 | 0.967 3 | 0.063 2 | 0.380 57 | |||||

| HAD, 60 ℃, 3 cm | 32.630 | 0.962 2 | 0.057 1 | 0.152 00 | |||||

| HAD,70 ℃, 3 cm | 14.620 | 0.983 7 | 0.038 2 | 0.203 06 | |||||

| HAD, 80 ℃, 3 cm | 13.460 | 0.980 3 | 0.043 8 | 0.240 81 | |||||

| HAD, 60 ℃, 4 cm | 12.230 | 0.989 9 | 0.028 6 | 0.122 78 | |||||

| HAD, 70 ℃, 4 cm | 11.450 | 0.987 7 | 0.032 2 | 0.158 81 | |||||

干燥模型 Drying model | 干燥工况 Drying condation | 拟合参数的优度 Goodness of fit paramenter | 模型系数Model coefficient | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 平方误差和SSE/(×10-3) | 决定系数 R2 | 均方根误差RMSE | a | b | k | k0/ (×10-4) | |||

| Lewes | HAD, 80 ℃, 4 cm | 12.670 | 0.986 0 | 0.035 6 | 0.185 08 | ||||

| VD, 60 ℃, 40 kPa, 2 cm | 30.370 | 0.970 6 | 0.050 3 | 0.138 11 | |||||

| VD, 60 ℃, 20 kPa, 2 cm | 13.220 | 0.982 0 | 0.038 3 | 0.167 40 | |||||

| VD, 70 ℃, 40 kPa, 2 cm | 27.740 | 0.969 4 | 0.052 6 | 0.166 92 | |||||

| VD, 70 ℃, 20 kPa, 2 cm | 14.200 | 0.982 1 | 0.039 7 | 0.188 29 | |||||

| VD, 80 ℃, 40 kPa, 2 cm | 15.020 | 0.978 8 | 0.043 4 | 0.198 05 | |||||

| VD, 80 ℃, 20 kPa, 2 cm | 15.050 | 0.980 3 | 0.043 4 | 0.225 07 | |||||

| Henderson and Pabis | HAD, 60 ℃, 2 cm | 18.860 | 0.974 2 | 0.056 0 | 1.052 06 | 0.280 83 | |||

| HAD, 70 ℃, 2 cm | 21.730 | 0.969 9 | 0.066 0 | 1.053 60 | 0.376 44 | ||||

| HAD, 80 ℃, 2 cm | 17.310 | 0.971 7 | 0.065 8 | 1.046 01 | 0.398 33 | ||||

| HAD, 60 ℃, 3 cm | 26.910 | 0.968 8 | 0.054 7 | 1.054 21 | 0.162 23 | ||||

| HAD,70 ℃, 3 cm | 11.780 | 0.986 9 | 0.036 2 | 1.040 86 | 0.212 01 | ||||

| HAD, 80 ℃, 3 cm | 10.670 | 0.984 4 | 0.042 2 | 1.043 05 | 0.252 77 | ||||

| HAD, 60 ℃, 4 cm | 8.340 | 0.993 1 | 0.024 4 | 1.040 80 | 0.128 63 | ||||

| HAD, 70 ℃, 4 cm | 8.790 | 0.990 5 | 0.029 6 | 1.037 03 | 0.165 76 | ||||

| HAD, 80 ℃, 4 cm | 9.560 | 0.989 4 | 0.032 6 | 1.041 77 | 0.193 83 | ||||

| VD, 60 ℃, 40 kPa, 2 cm | 23.150 | 0.977 6 | 0.045 8 | 1.058 48 | 0.147 74 | ||||

| VD, 60 ℃, 20 kPa, 2 cm | 10.370 | 0.985 9 | 0.036 1 | 1.039 65 | 0.175 80 | ||||

| VD, 70 ℃, 40 kPa, 2 cm | 21.420 | 0.976 4 | 0.048 8 | 1.058 14 | 0.178 30 | ||||

| VD, 70 ℃, 20 kPa, 2 cm | 11.160 | 0.985 9 | 0.037 4 | 1.041 92 | 0.197 59 | ||||

| VD, 80 ℃, 40 kPa, 2 cm | 12.420 | 0.982 5 | 0.042 1 | 1.039 58 | 0.207 54 | ||||

| VD, 80 ℃, 20 kPa, 2 cm | 12.330 | 0.983 8 | 0.042 0 | 1.041 41 | 0.235 55 | ||||

| Third-degree polynomial model | HAD, 60 ℃, 2 cm | 0.402 | 0.999 5 | 0.010 0 | 1.003 40 | -0.191 54 | 0.009 00 | -2.626 38 | |

| HAD, 70 ℃, 2 cm | 0.059 | 0.999 9 | 0.004 44 | 1.001 05 | -0.218 47 | -0.003 82 | 21.500 00 | ||

| HAD, 80 ℃, 2 cm | 0.049 | 0.999 9 | 0.004 93 | 1.000 96 | -0.235 02 | -0.005 97 | 29.800 00 | ||

| HAD, 60 ℃, 3 cm | 0.610 | 0.999 3 | 0.00934 | 0.998 24 | -0.111 97 | 0.003 73 | -1.525 58 | ||

| HAD,70 ℃, 3 cm | 0.140 | 0.999 8 | 0.004 48 | 1.001 22 | -0.164 90 | 0.010 16 | -3.639 05 | ||

| HAD, 80 ℃, 3 cm | 0.212 | 0.999 7 | 0.007 28 | 1.004 00 | -0.184 00 | 0.008 17 | -0.196 88 | ||

| HAD, 60 ℃, 4 cm | 0.529 | 0.999 6 | 0.006 64 | 1.006 94 | -0.105 28 | 0.003 89 | -0.579 12 | ||

| HAD, 70 ℃, 4 cm | 0.077 | 0.999 9 | 0.003 11 | 1.001 05 | -0.130 66 | 0.005 68 | -1.024 05 | ||

| HAD, 80 ℃, 4 cm | 0.174 | 0.999 8 | 0.004 98 | 1.005 39 | -0.153 08 | 0.008 01 | -1.874 45 | ||

| VD, 60 ℃, 40 kPa, 2 cm | 0.074 | 0.999 9 | 0.002 9 | 0.998 30 | -0.096 26 | 0.001 00 | 0.618 73 | ||

| VD, 60 ℃, 20 kPa, 2 cm | 0.039 | 0.999 9 | 0.002 54 | 0.997 73 | -0.125 91 | 0.003 07 | 0.585 90 | ||

| VD, 70 ℃, 40 kPa, 2 cm | 0.040 | 0.999 9 | 0.002 39 | 0.998 83 | -0.113 06 | 0.000 56 | 1.683 43 | ||

| VD, 70 ℃, 20 kPa, 2 cm | 0.014 | 0.999 9 | 0.001 53 | 0.998 76 | -0.141 89 | 0.004 50 | 0.341 37 | ||

| VD, 80 ℃, 40 kPa, 2 cm | 0.037 | 0.999 9 | 0.002 70 | 0.998 88 | -0.154 25 | 0.007 42 | -2.354 61 | ||

| VD, 80 ℃, 20 kPa, 2 cm | 0.012 | 0.999 9 | 0.001 54 | 0.999 72 | -0.173 02 | 0.008 80 | -2.058 89 | ||

Table 3 Results of drying kinetics fitting of hybrid Broussonetia papyrifera

干燥模型 Drying model | 干燥工况 Drying condation | 拟合参数的优度 Goodness of fit paramenter | 模型系数Model coefficient | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 平方误差和SSE/(×10-3) | 决定系数 R2 | 均方根误差RMSE | a | b | k | k0/ (×10-4) | |||

| Lewes | HAD, 80 ℃, 4 cm | 12.670 | 0.986 0 | 0.035 6 | 0.185 08 | ||||

| VD, 60 ℃, 40 kPa, 2 cm | 30.370 | 0.970 6 | 0.050 3 | 0.138 11 | |||||

| VD, 60 ℃, 20 kPa, 2 cm | 13.220 | 0.982 0 | 0.038 3 | 0.167 40 | |||||

| VD, 70 ℃, 40 kPa, 2 cm | 27.740 | 0.969 4 | 0.052 6 | 0.166 92 | |||||

| VD, 70 ℃, 20 kPa, 2 cm | 14.200 | 0.982 1 | 0.039 7 | 0.188 29 | |||||

| VD, 80 ℃, 40 kPa, 2 cm | 15.020 | 0.978 8 | 0.043 4 | 0.198 05 | |||||

| VD, 80 ℃, 20 kPa, 2 cm | 15.050 | 0.980 3 | 0.043 4 | 0.225 07 | |||||

| Henderson and Pabis | HAD, 60 ℃, 2 cm | 18.860 | 0.974 2 | 0.056 0 | 1.052 06 | 0.280 83 | |||

| HAD, 70 ℃, 2 cm | 21.730 | 0.969 9 | 0.066 0 | 1.053 60 | 0.376 44 | ||||

| HAD, 80 ℃, 2 cm | 17.310 | 0.971 7 | 0.065 8 | 1.046 01 | 0.398 33 | ||||

| HAD, 60 ℃, 3 cm | 26.910 | 0.968 8 | 0.054 7 | 1.054 21 | 0.162 23 | ||||

| HAD,70 ℃, 3 cm | 11.780 | 0.986 9 | 0.036 2 | 1.040 86 | 0.212 01 | ||||

| HAD, 80 ℃, 3 cm | 10.670 | 0.984 4 | 0.042 2 | 1.043 05 | 0.252 77 | ||||

| HAD, 60 ℃, 4 cm | 8.340 | 0.993 1 | 0.024 4 | 1.040 80 | 0.128 63 | ||||

| HAD, 70 ℃, 4 cm | 8.790 | 0.990 5 | 0.029 6 | 1.037 03 | 0.165 76 | ||||

| HAD, 80 ℃, 4 cm | 9.560 | 0.989 4 | 0.032 6 | 1.041 77 | 0.193 83 | ||||

| VD, 60 ℃, 40 kPa, 2 cm | 23.150 | 0.977 6 | 0.045 8 | 1.058 48 | 0.147 74 | ||||

| VD, 60 ℃, 20 kPa, 2 cm | 10.370 | 0.985 9 | 0.036 1 | 1.039 65 | 0.175 80 | ||||

| VD, 70 ℃, 40 kPa, 2 cm | 21.420 | 0.976 4 | 0.048 8 | 1.058 14 | 0.178 30 | ||||

| VD, 70 ℃, 20 kPa, 2 cm | 11.160 | 0.985 9 | 0.037 4 | 1.041 92 | 0.197 59 | ||||

| VD, 80 ℃, 40 kPa, 2 cm | 12.420 | 0.982 5 | 0.042 1 | 1.039 58 | 0.207 54 | ||||

| VD, 80 ℃, 20 kPa, 2 cm | 12.330 | 0.983 8 | 0.042 0 | 1.041 41 | 0.235 55 | ||||

| Third-degree polynomial model | HAD, 60 ℃, 2 cm | 0.402 | 0.999 5 | 0.010 0 | 1.003 40 | -0.191 54 | 0.009 00 | -2.626 38 | |

| HAD, 70 ℃, 2 cm | 0.059 | 0.999 9 | 0.004 44 | 1.001 05 | -0.218 47 | -0.003 82 | 21.500 00 | ||

| HAD, 80 ℃, 2 cm | 0.049 | 0.999 9 | 0.004 93 | 1.000 96 | -0.235 02 | -0.005 97 | 29.800 00 | ||

| HAD, 60 ℃, 3 cm | 0.610 | 0.999 3 | 0.00934 | 0.998 24 | -0.111 97 | 0.003 73 | -1.525 58 | ||

| HAD,70 ℃, 3 cm | 0.140 | 0.999 8 | 0.004 48 | 1.001 22 | -0.164 90 | 0.010 16 | -3.639 05 | ||

| HAD, 80 ℃, 3 cm | 0.212 | 0.999 7 | 0.007 28 | 1.004 00 | -0.184 00 | 0.008 17 | -0.196 88 | ||

| HAD, 60 ℃, 4 cm | 0.529 | 0.999 6 | 0.006 64 | 1.006 94 | -0.105 28 | 0.003 89 | -0.579 12 | ||

| HAD, 70 ℃, 4 cm | 0.077 | 0.999 9 | 0.003 11 | 1.001 05 | -0.130 66 | 0.005 68 | -1.024 05 | ||

| HAD, 80 ℃, 4 cm | 0.174 | 0.999 8 | 0.004 98 | 1.005 39 | -0.153 08 | 0.008 01 | -1.874 45 | ||

| VD, 60 ℃, 40 kPa, 2 cm | 0.074 | 0.999 9 | 0.002 9 | 0.998 30 | -0.096 26 | 0.001 00 | 0.618 73 | ||

| VD, 60 ℃, 20 kPa, 2 cm | 0.039 | 0.999 9 | 0.002 54 | 0.997 73 | -0.125 91 | 0.003 07 | 0.585 90 | ||

| VD, 70 ℃, 40 kPa, 2 cm | 0.040 | 0.999 9 | 0.002 39 | 0.998 83 | -0.113 06 | 0.000 56 | 1.683 43 | ||

| VD, 70 ℃, 20 kPa, 2 cm | 0.014 | 0.999 9 | 0.001 53 | 0.998 76 | -0.141 89 | 0.004 50 | 0.341 37 | ||

| VD, 80 ℃, 40 kPa, 2 cm | 0.037 | 0.999 9 | 0.002 70 | 0.998 88 | -0.154 25 | 0.007 42 | -2.354 61 | ||

| VD, 80 ℃, 20 kPa, 2 cm | 0.012 | 0.999 9 | 0.001 54 | 0.999 72 | -0.173 02 | 0.008 80 | -2.058 89 | ||

干燥模型 Drying model | 干燥工况 Drying condation | 拟合参数的优度 Goodness of fit paramenter | 模型系数Model coefficient | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 平方误差和SSE/(×10-3) | 决定系数 R2 | 均方根误差RMSE | a | b | k | k0/ (×10-4) | |||

| A. Sande | HAD, 60 ℃, 2 cm | 3.190 | 0.995 6 | 0.023 1 | 1.380 86 | 3.774 03 | |||

| HAD, 70 ℃, 2 cm | 1.800 | 0.997 5 | 0.019 0 | 1.458 42 | 2.879 60 | ||||

| HAD, 80 ℃, 2 cm | 1.220 | 0.998 0 | 0.017 4 | 1.445 88 | 2.662 52 | ||||

| HAD, 60 ℃, 3 cm | 8.350 | 0.990 3 | 0.030 5 | 1.368 20 | 6.389 19 | ||||

| HAD,70 ℃, 3 cm | 2.950 | 0.996 7 | 0.018 1 | 1.235 14 | 4.963 45 | ||||

| HAD, 80 ℃, 3 cm | 1.410 | 0.997 9 | 0.015 3 | 1.286 64 | 4.112 37 | ||||

| HAD, 60 ℃, 4 cm | 1.580 | 0.998 7 | 0.010 6 | 1.175 30 | 8.119 44 | ||||

| HAD, 70 ℃, 4 cm | 1.920 | 0.997 9 | 0.013 9 | 1.197 38 | 6.255 46 | ||||

| HAD, 80 ℃, 4 cm | 1.710 | 0.998 1 | 0.013 8 | 1.220 66 | 5.398 91 | ||||

| VD, 60 ℃, 40 kPa, 2 cm | 4.160 | 0.996 0 | 0.019 4 | 1.339 04 | 7.119 51 | ||||

| VD, 60 ℃, 20 kPa, 2 cm | 1.860 | 0.997 5 | 0.015 3 | 1.253 16 | 5.827 04 | ||||

| VD, 70 ℃, 40 kPa, 2 cm | 3.260 | 0.996 4 | 0.019 0 | 1.359 05 | 5.900 30 | ||||

| VD, 70 ℃, 20 kPa, 2 cm | 1.810 | 0.997 7 | 0.015 0 | 1.259 05 | 5.254 80 | ||||

| VD, 80 ℃, 40 kPa, 2 cm | 3.130 | 0.995 6 | 0.021 1 | 1.272 92 | 4.960 34 | ||||

| VD, 80 ℃, 20 kPa, 2 cm | 2.480 | 0.996 8 | 0.018 8 | 1.274 27 | 4.434 25 | ||||

Table 3 Results of drying kinetics fitting of hybrid Broussonetia papyrifera

干燥模型 Drying model | 干燥工况 Drying condation | 拟合参数的优度 Goodness of fit paramenter | 模型系数Model coefficient | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 平方误差和SSE/(×10-3) | 决定系数 R2 | 均方根误差RMSE | a | b | k | k0/ (×10-4) | |||

| A. Sande | HAD, 60 ℃, 2 cm | 3.190 | 0.995 6 | 0.023 1 | 1.380 86 | 3.774 03 | |||

| HAD, 70 ℃, 2 cm | 1.800 | 0.997 5 | 0.019 0 | 1.458 42 | 2.879 60 | ||||

| HAD, 80 ℃, 2 cm | 1.220 | 0.998 0 | 0.017 4 | 1.445 88 | 2.662 52 | ||||

| HAD, 60 ℃, 3 cm | 8.350 | 0.990 3 | 0.030 5 | 1.368 20 | 6.389 19 | ||||

| HAD,70 ℃, 3 cm | 2.950 | 0.996 7 | 0.018 1 | 1.235 14 | 4.963 45 | ||||

| HAD, 80 ℃, 3 cm | 1.410 | 0.997 9 | 0.015 3 | 1.286 64 | 4.112 37 | ||||

| HAD, 60 ℃, 4 cm | 1.580 | 0.998 7 | 0.010 6 | 1.175 30 | 8.119 44 | ||||

| HAD, 70 ℃, 4 cm | 1.920 | 0.997 9 | 0.013 9 | 1.197 38 | 6.255 46 | ||||

| HAD, 80 ℃, 4 cm | 1.710 | 0.998 1 | 0.013 8 | 1.220 66 | 5.398 91 | ||||

| VD, 60 ℃, 40 kPa, 2 cm | 4.160 | 0.996 0 | 0.019 4 | 1.339 04 | 7.119 51 | ||||

| VD, 60 ℃, 20 kPa, 2 cm | 1.860 | 0.997 5 | 0.015 3 | 1.253 16 | 5.827 04 | ||||

| VD, 70 ℃, 40 kPa, 2 cm | 3.260 | 0.996 4 | 0.019 0 | 1.359 05 | 5.900 30 | ||||

| VD, 70 ℃, 20 kPa, 2 cm | 1.810 | 0.997 7 | 0.015 0 | 1.259 05 | 5.254 80 | ||||

| VD, 80 ℃, 40 kPa, 2 cm | 3.130 | 0.995 6 | 0.021 1 | 1.272 92 | 4.960 34 | ||||

| VD, 80 ℃, 20 kPa, 2 cm | 2.480 | 0.996 8 | 0.018 8 | 1.274 27 | 4.434 25 | ||||

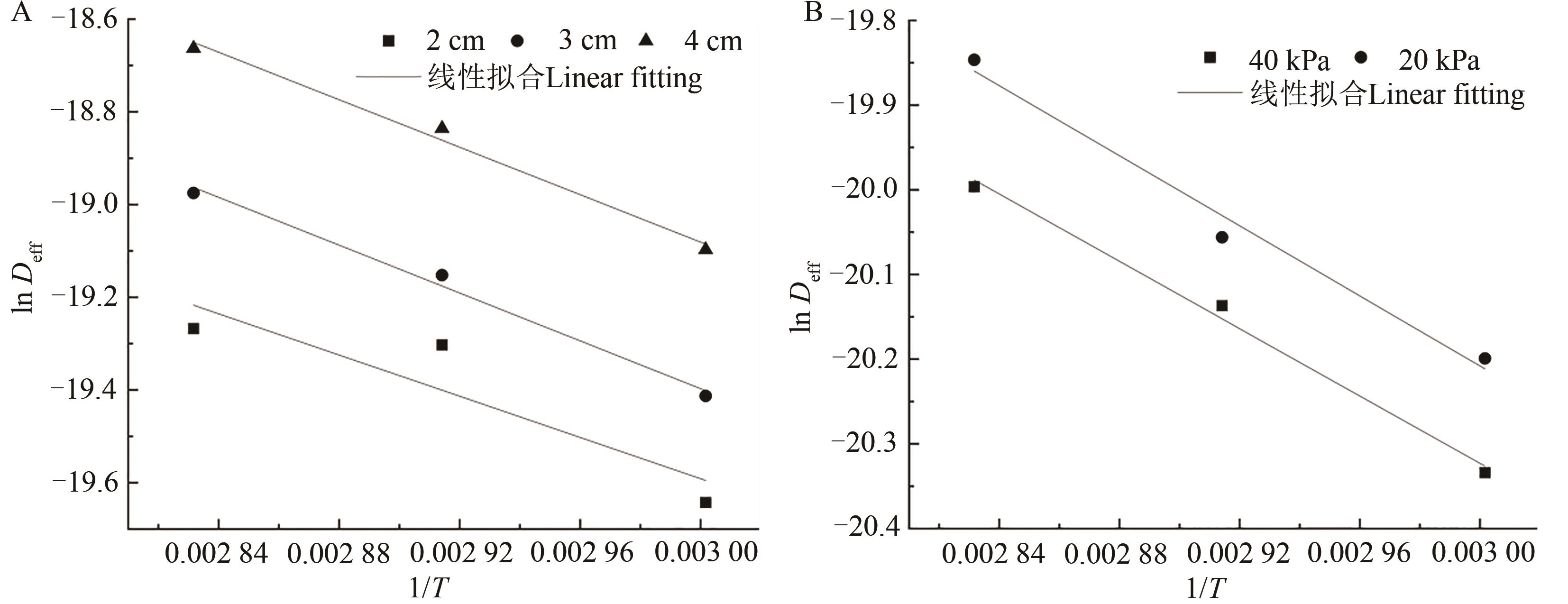

干燥工况 Drying condition | 活化能 Ea(kJ·mol-1) | 决定系数 R2 | 拟合方程 Fitting equation |

|---|---|---|---|

| HAD, 2 cm | 18.49 | 0.832 3 | ln(Deff)=-2 224.295 85/T-12.918 55 |

| HAD, 3 cm | 21.45 | 0.991 4 | ln(Deff)=-2 580.006 04/T-11.657 22 |

| HAD, 4 cm | 21.29 | 0.989 9 | ln(Deff)=-2 560.481 51/T-11.399 72 |

| VD, 40 kPa | 16.53 | 0.993 6 | ln(Deff)=-1 988.773 27/T-14.356 74 |

| VD, 20 kPa | 17.20 | 0.984 3 | ln(Deff)=-2 069.290 23/T-14.000 18 |

Table 4 Ea values under different working conditions of hybrid Broussonetia papyrifera

干燥工况 Drying condition | 活化能 Ea(kJ·mol-1) | 决定系数 R2 | 拟合方程 Fitting equation |

|---|---|---|---|

| HAD, 2 cm | 18.49 | 0.832 3 | ln(Deff)=-2 224.295 85/T-12.918 55 |

| HAD, 3 cm | 21.45 | 0.991 4 | ln(Deff)=-2 580.006 04/T-11.657 22 |

| HAD, 4 cm | 21.29 | 0.989 9 | ln(Deff)=-2 560.481 51/T-11.399 72 |

| VD, 40 kPa | 16.53 | 0.993 6 | ln(Deff)=-1 988.773 27/T-14.356 74 |

| VD, 20 kPa | 17.20 | 0.984 3 | ln(Deff)=-2 069.290 23/T-14.000 18 |

Fig. 7 Fitting relationship between ln(Deff) and 1/T based on Arrhenius relationA: Hot air drying;B: Vacuum drying. Deff—Water effective diffusion coefficient;T—Temperature

| 干燥工况Drying condition | L* :明度 Lightness | a* :红/绿色度 Red/green degree | b* :黄/蓝色度 Yellow/blue degree | ΔE:色差 Chromatic aberration |

|---|---|---|---|---|

| 新鲜Fresh | 24.72±2.52 d | 2.91±0.48 b | 13.89±1.96 ab | - |

| 60 ℃, 2 cm | 29.28±1.07 a | 3.05±0.26 b | 15.22±0.66 ab | 4.77±1.21 ab |

| 70 ℃, 2 cm | 22.52±0.62 e | 3.04±0.40 b | 12.59±0.32 b | 2.61±0.53 c |

| 80 ℃, 2 cm | 26.98±0.67 c | 4.11±0.67 a | 16.44±2.05 a | 3.74±1.92 abc |

| 60 ℃, 3 cm | 23.66±0.78 de | 2.90±0.18 b | 12.69±0.97 b | 1.71±1.01 c |

| 70 ℃, 3 cm | 26.84±0.67 c | 3.11±0.11 b | 13.68±0.34 b | 2.16±0.67 c |

| 80 ℃, 3 cm | 29.53±1.09 a | 2.97±0.55 b | 14.34±1.48 ab | 5.03±0.82 a |

| 60 ℃, 4 cm | 29.09±0.87 ab | 4.17±0.61 a | 15.03±1.70 ab | 4.87±1.18 ab |

| 70 ℃, 4 cm | 27.94±0.98 abc | 3.14±0.30 b | 14.73±0.45 ab | 3.35±1.04 abc |

| 80 ℃, 4 cm | 27.16±0.19 bc | 3.28±0.70 b | 14.45±1.78 ab | 2.93±0.62 bc |

Table 5 Color of hybrid Broussonetia papyrifera underdifferent hot air drying parameters

| 干燥工况Drying condition | L* :明度 Lightness | a* :红/绿色度 Red/green degree | b* :黄/蓝色度 Yellow/blue degree | ΔE:色差 Chromatic aberration |

|---|---|---|---|---|

| 新鲜Fresh | 24.72±2.52 d | 2.91±0.48 b | 13.89±1.96 ab | - |

| 60 ℃, 2 cm | 29.28±1.07 a | 3.05±0.26 b | 15.22±0.66 ab | 4.77±1.21 ab |

| 70 ℃, 2 cm | 22.52±0.62 e | 3.04±0.40 b | 12.59±0.32 b | 2.61±0.53 c |

| 80 ℃, 2 cm | 26.98±0.67 c | 4.11±0.67 a | 16.44±2.05 a | 3.74±1.92 abc |

| 60 ℃, 3 cm | 23.66±0.78 de | 2.90±0.18 b | 12.69±0.97 b | 1.71±1.01 c |

| 70 ℃, 3 cm | 26.84±0.67 c | 3.11±0.11 b | 13.68±0.34 b | 2.16±0.67 c |

| 80 ℃, 3 cm | 29.53±1.09 a | 2.97±0.55 b | 14.34±1.48 ab | 5.03±0.82 a |

| 60 ℃, 4 cm | 29.09±0.87 ab | 4.17±0.61 a | 15.03±1.70 ab | 4.87±1.18 ab |

| 70 ℃, 4 cm | 27.94±0.98 abc | 3.14±0.30 b | 14.73±0.45 ab | 3.35±1.04 abc |

| 80 ℃, 4 cm | 27.16±0.19 bc | 3.28±0.70 b | 14.45±1.78 ab | 2.93±0.62 bc |

| 干燥工况Drying condition | L* :明度 Lightness | a* :红/绿色度 Red/green degree | b* :黄/蓝色度 Yellow/blue degree | ΔE:色差 Chromatic aberration |

|---|---|---|---|---|

| 新鲜Fresh | 19.63±0.31 d | 6.10±0.23 a | 13.51±0.49 c | — |

| 60 ℃, 40 kPa, 2 cm | 27.00±0.19 b | 6.22±0.31 a | 16.01±0.21 ab | 7.80±0.12 b |

| 60 ℃, 20 kPa, 2 cm | 23.69±0.40 c | 6.03±0.91 a | 15.61±0.45 b | 4.64±0.39 c |

| 70 ℃, 40 kPa, 2 cm | 30.48±2.66 a | 6.63±0.27 a | 17.59±0.71 a | 11.61±2.75 a |

| 70 ℃, 20 kPa, 2 cm | 28.85±0.24 ab | 6.57±1.12 a | 17.05±1.80 ab | 10.01±0.95 ab |

| 80 ℃, 40 kPa, 2 cm | 29.09±0.40 a | 6.08±0.34 a | 16.11±0.97 ab | 9.84±0.63 ab |

| 80 ℃, 20 kPa, 2 cm | 29.40±0.78 a | 6.40±0.69 a | 16.46±0.32 ab | 10.23±0.83 a |

Table 6 Color of hybrid Broussonetia papyrifera underdifferent vacuum drying parameters

| 干燥工况Drying condition | L* :明度 Lightness | a* :红/绿色度 Red/green degree | b* :黄/蓝色度 Yellow/blue degree | ΔE:色差 Chromatic aberration |

|---|---|---|---|---|

| 新鲜Fresh | 19.63±0.31 d | 6.10±0.23 a | 13.51±0.49 c | — |

| 60 ℃, 40 kPa, 2 cm | 27.00±0.19 b | 6.22±0.31 a | 16.01±0.21 ab | 7.80±0.12 b |

| 60 ℃, 20 kPa, 2 cm | 23.69±0.40 c | 6.03±0.91 a | 15.61±0.45 b | 4.64±0.39 c |

| 70 ℃, 40 kPa, 2 cm | 30.48±2.66 a | 6.63±0.27 a | 17.59±0.71 a | 11.61±2.75 a |

| 70 ℃, 20 kPa, 2 cm | 28.85±0.24 ab | 6.57±1.12 a | 17.05±1.80 ab | 10.01±0.95 ab |

| 80 ℃, 40 kPa, 2 cm | 29.09±0.40 a | 6.08±0.34 a | 16.11±0.97 ab | 9.84±0.63 ab |

| 80 ℃, 20 kPa, 2 cm | 29.40±0.78 a | 6.40±0.69 a | 16.46±0.32 ab | 10.23±0.83 a |

Fig. 8 Nutritional quality of hybrid Broussonetia papyrifera under hot air drying conditionNote:Different lowercase letters in same index indicate significant differences at P<0.05 level. Number of drying condition is same as Table 1.

Fig. 9 Nutritional quality of hybrid Broussonetia papyrifera under vacuum drying conditionNote:Different lowercase letters in same index indicate significant differences at P<0.05 level. Number of drying condition is same as Table 1.

| 1 | LIAO S X, DENG Z H, CUI K, et al.. Genetic diversity of Broussonetia papyrifera populations in southwest China [J]. Genet. Mol. Res., 2014, 13(3): 7553-7563. |

| 2 | 李华西.构树及其开发利用[J]. 河北林业, 2007(1): 36-37. |

| 3 | SUN W T, HUANG Y, WU C R, et al.. Addition of lactic acid bacteria can promote the quality and feeding value of Broussonetia papyrifera (Paper Mulberry) silage [J/OL]. Fermentation, 2022, 8(1):25 [2023-09-16]. . |

| 4 | 张红,陈凤鸣,黄兴国,等.构树叶的营养价值及其在动物生产中的应用研究进展[J].动物营养学报,2020,32(9):4086-4092. |

| ZHANG H, CHEN F M, HUANG X G, et al.. Nutritional value of Broussonetia papyrifera leaf and its application in animal production [J]. Chin. J. Anim. Nutr., 2020, 32(9): 4086-4092. | |

| 5 | 陈光吉,熊先勤,何润霞,等.全株构树青贮在务川黑牛日粮中饲用价值评价[J].中国农业科学,2021,54(19):4218-4228. |

| CHEN G J, XIONG X Q, HE R X, et al.. Evaluation of feeding value for whole Broussonetia papyrifera silage in diet of Wuchuan black beef cattle [J]. Sci. Agric. Sin., 2021, 54(19): 4218-4228. | |

| 6 | XIONG Y, GUO C Z, WANG L, et al.. Effects of paper mulberry silage on the growth performance, rumen microbiota and muscle fatty acid composition in Hu lambs [J/OL]. Fermentation, 2021, 7(4):286 [2023-09-16]. . |

| 7 | FARAHMANDFAR R, TIRGARIAN B, DEHGHAN B, et al.. Comparison of different drying methods on bitter orange (Citrus aurantium L.) peel waste: changes in physical (density and color) and essential oil (yield, composition, antioxidant and antibacterial) properties of powders [J]. J. Food Meas. Chract., 2020, 14(2): 862-875. |

| 8 | NGUYEN V T, VUONG Q V, BOWYER M C, et al.. Effects of different drying methods on bioactive compound yield and antioxidant capacity of Phyllanthus amarus [J]. Dry. Technol., 2015, 33(8):1006-1017. |

| 9 | 路明德. 发展稻谷机械烘干 减少自然晾晒损失[J]. 民营科技, 2017(1):262, 265. |

| 10 | 陈亮. 农产品干燥新工艺发展[J]. 山西农经, 2017(16): 35-36. |

| 11 | ORIKASA T, WU L, SHIINA T, et al.. Drying characteristicsof kiwifruit during hot air drying [J]. J. Food Eng., 2008, 85(2): 303-308. |

| 12 | HAZAL Z C T, SELMA C K, ESRA A, et al.. Ultrasound‐assisted vacuum drying as alternative drying method to increase drying rate and bioactive compounds retention of raspberry [J/OL]. J. Food Process. Pres., 2021, 45(12):e16044 [2023-09-16]. . |

| 13 | 陶盛昌,李文佳,邱健健, 等. 食药用真菌干燥技术研究进展[J].保鲜与加工,2019,19 (1):171-178. |

| TAO S C, LI W J, QIU J J, et al.. Advances on drying technology of edible-medicinal fungus [J]. Storage Process, 2019, 19 (1):171-178. | |

| 14 | 韩兴鹏. 干燥方式对猴头菇品质及抗氧化活性的影响[D]. 哈尔滨: 东北林业大学,2018. |

| HAN X P. The effect of drying methods on quality and antioxidant activity of Hericium erinaceus [D]. Harbin: Northeast Forestry University, 2018. | |

| 15 | 杨双喜,马尧,张海红,等.干燥方式对黄花菜粉营养、色泽及氨基酸含量的影响[J]. 中国食品学报, 2022, 22(10):232-241. |

| YANG S X, MA Y, ZHANG H H, et al... Effects of drying methods on the nutrition, color and amino acid content of daylily powder [J]. J. Chin. Inst. Food Sci. Technol., 2022, 22(10):232-241. | |

| 16 | 李巧菲,张宏图,彭桂兰,等. 豇豆热风干燥特性及工艺优化[J]. 食品工业科技, 2023, 44(6): 253-260. |

| LI Q F, ZHANG H T, PENG G L, et al.. Hot air drying characteristics and process optimization of cowpea [J]. Sci. Technol. Food Ind., 2023, 44(6): 253-260. | |

| 17 | KIM M, KERR W L. Vacuum-belt drying of rabbiteye blueberry (Vaccinium ashei) slurries: influence of drying conditions on physical and quality properties of blueberry powder [J]. Food Bioproc. Technol., 2013, 6(11): 3227-3237. |

| 18 | 彭小伟,彭雅兰,何旭华,等.不同干燥方式对玉竹干燥动力学特征及品质的影响[J].中南林业科技大学学报,2022,42(11):164-172. |

| PENG X W, PENG Y L, HE X H, et al.. Effects of different drying methods on the drying dynamic characteristics and quality of Polygonatum odoratum [J]. J. Cent. South Univ. For. Technol., 2022, 42(11):164-172. | |

| 19 | 唐亮. 饲粮中构树叶粉对生长肥育猪生产性能、胴体品质、血清生化指标及养分消化率的影响[D]. 南宁: 广西大学, 2008. |

| TANG L. Effect of leaves of Broussonetia papyrifera used in diet on performance, carcess quality, serum biochemical parameters, and apparent digestibility of dietary nutrients in growing-finishing pigs [D]. Nanning: Guangxi University, 2008. | |

| 20 | ZHENG X Z, JIANG Y Y, PAN Z L. Drying and quality characteristics of different components of alfalfa [J/OL]. Agric. Food Sci., 2005, 23(2):19929 [2023-09-16]. . |

| 21 | BILANSKI W K, LEE J H A, HALYK R M. High-temperature drying of alfalfa stems [J]. Can. J. Plant Sci., 1965, 45(5): 471-476. |

| 22 | LEONOR J M, LUIZ C G, MOACIR C E, et al.. Qualidade de grãos de aveia sob secagem intermitente em altas temperaturas quality of oat grains under intermittent drying at high temperatures [J]. Ciência Rural, 2007, 37(5):1268-1273. |

| 23 | 胡亚强, 苑亚, 杨鲁伟,等. 苜蓿薄层干燥特性及颜色和品质[J]. 草业科学, 2022, 39(9): 1861-1868. |

| HU Y Q, YUAN Y, YANG L W, et al.. Study on thin layer drying characteristics and color and quality of alfalfa [J]. Pratac. Sci., 2022, 39(9): 1861-1868. | |

| 24 | 尚平,关亚鹏,张丽媛,等.热风干燥桑叶的干燥特性、活性成分含量及抗氧化能力研究[J].食品研究与开发,2022,43(1):52-59. |

| SHANG P, GUAN Y P, ZHANG L Y, et al.. Study of the drying characteristics, active component content and an-tioxidant capacity of hot-air-drying mulberry leaves [J]. Food Res. Dev., 2022, 43(1):52-59. | |

| 25 | 孟祥绍,党斌,张文刚,等.不同干燥方式对荨麻叶营养成分及抗氧化活性的影响[J].食品工业,2023, 44(8):161-166. |

| MENG X S, DANG B, ZHANG W G, et al.. Effects of different drying methods on nutritional components and antioxidant activity of nettle leaves [J]. Food Ind., 2023, 44(8):161-166. | |

| 26 | 中华人民共和国国家卫生和计划生育委员会. 食品安全国家标准 食品中水分的测定: [S]. 北京:中国标准出版社,2016. |

| 27 | XU P, PENG X Y, YANG J L, et al.. Effect of vacuum drying and pulsed vacuum drying on drying kinetics and quality of bitter orange (Citrus aurantium L.) slices [J/OL]. J. Food Process. Pres., 2021, 45(12):e16098 [2023-09-16]. . |

| 28 | GUO H L, CHEN Y, XU W, et al.. Assessment of drying kinetics, textural and aroma attributes of Mentha haplocalyx leaves during the hot air thin-layer drying process [J/OL]. Foods, 2022, 11(6):784 [2023-09-16]. . |

| 29 | WANG N, YANG S Y, ZHANG Y F, et al.. Drying kinetics and quality characteristics of daylily dried by mid-infrared [J]. Int. J. Food Eng., 2021, 17(12):969-979. |

| 30 | DOYMAZ I. Thin‐layer drying of spinach leaves in a convective dryer [J]. J. Food Process Eng., 2009, 32(1): 112-125. |

| 31 | XU P, ZHANG Z T, PENG X Y, et al.. Study on vacuum drying kinetics and processing of the Lonicera japonica Thunb. aqueous extracts [J/OL]. LWT, 2022, 167:113868 [2023-09-16]. . |

| 32 | GOMES F P, RESENDE O, SOUSA E P D, et al.. Application of mathematical models and thermodynamic properties in the drying of jambu leaves [J/OL]. Agriculture, 2022, 12(8):1252 [2023-09-16]. . |

| 33 | YANG K W, WANG D, VIDYARTHI S K, et al.. Pulsed vacuum drying of Persimmon slices: drying kinetics, physicochemical properties, microstructure and antioxidant capacity [J/OL]. Plants, 2022, 11(19):2500 [2023-09-16]. . |

| 34 | 肖志明,樊霞,马东霞,等. 饲料中粗蛋白的测定 凯氏定氮法: [S]. 北京:中国标准出版社,2018. |

| 35 | 武润仙,杨林,何一帆,等. 饲料中粗灰分的测定: [S]. 北京:中国标准出版社,2007. |

| 36 | 张凤枰,张芸,张茹,等. 饲料中中性洗涤纤维(NDF)的测定: [S]. 北京:中国标准出版社,2022. |

| 37 | 中华人民共和国农业农村部. 饲料中酸性洗涤纤维的测定: [S]. 北京:中国标准出版社,2022. |

| 38 | SINGH B, PANESAR P S, NANDA V. Utilization of carrot pomace for the preparation of a value added product [J]. World J. Dairy Food Sci., 2006, 1(1): 22-27. |

| 39 | AREPALLY D, RAVULA S R, MALIK G K, et al.. Mathematical modelling, energy and exergy analysis of tomato slices in a mixed mode natural convection solar dryer [J]. Chem. Sci. Int. J., 2017, 20(4): 1-11. |

| 40 | LIU H, JIAO J H, TIAN Y, et al.. Drying kinetics of Pleurotus eryngii slices during hot air drying [J]. Open Phys., 2022, 20(1):265-273. |

| 41 | BUZRUL S. Reassessment of thin-layer drying models for foods:a critical short communication [J/OL]. Processes, 2022, 10(1):118 [2023-09-16]. . |

| 42 | GONELI A L D, NASU A K, GANCEDO R, et al.. Cinética de secagem de folhas de erva baleeira (Cordia verbenacea DC.) [J]. Rev. Bras. Plant. Med., 2014, 16: 434-443. |

| 43 | 于昊. 木质素降解菌的筛选及其产酶条件的优化[D]. 扬州:扬州大学, 2022. |

| YU H. Screening of lignin-degrading bacteria and optimizationof enzyme production conditions [D]. Yangzhou: Yangzhou University, 2022. | |

| 44 | 刘德成. 冷冻-红外分段组合干燥红枣片干燥特性及品质研究[D]. 石河子: 石河子大学, 2022. |

| LIU D C. Study on drying characteristics and quality of sequentialfreeze-infrared drying jujube slices [D]. Shihezi: Shihezi University, 2022. | |

| 45 | AGREGAN R, LORENZO J M, KUMAR M, et al.. Anaerobic digestion of lignocellulose components: challenges and novel approaches [J/OL]. Energies, 2022, 15(22): 8413 [2023-09-16]. . |

| 46 | 杨苏茂,熊康宁,刘兴宜,等.晾晒方式对构树失水速率及饲用价值的影响[J].草业科学,2018,35(5):1170-1178. |

| YANG S M, XIONG K N, LIU X Y, et al.. Effect of different drying methods on water loss rate and nutritional value of Broussonetia papyrifera [J]. Pratac. Sci., 2018, 12(5): 1170-1178. | |

| 47 | 王安娜,王赟,彭小伟,等.不同干燥方式对竹叶花椒叶品质的影响[J].中国农业科学,2023,56(18):3655-3669. |

| WANG A N, WANG Y, PENG X W, et al.. Effects of different drying methods on the quality characteristics of dried Zanthoxylum armatum leaves [J]. Sci. Agric. Sin., 2023, 56(18): 3655-3669. | |

| 48 | 赵哲.颗粒堆积多孔介质干燥过程模拟及试验研究[D]. 西安: 陕西科技大学, 2015. |

| ZHAO Z. Simulation and experimental research on drying of grain packing porous media [D]. Xi’an: Shaanxi University of Science & Technology, 2015. | |

| 49 | TIAN Y T, ZHAO Y T, HUANG J J, et al.. Effects of different drying methods on the product quality and volatile compounds of whole shiitake mushrooms [J]. Food Chem., 2016, 197: 714-722. |

| [1] | Lanting XIANG, Shuhui SONG, Lijuan LIU, Xiaoling SHE, Jiahua ZHOU, Baogang WANG, Hong CHANG, Chao ZHANG, Daqi FU, Yunxiang WANG. Effect of Different Storage Temperatures on Quality of Jingcai 1 Watermelon [J]. Journal of Agricultural Science and Technology, 2024, 26(9): 137-145. |

| [2] | Lei JI, Tianhong LIU, Ying WANG, Xiao LI, Hongyan LI, Xiaodong JIANG, Yuanqin SUN, Shuaizhong ZHANG. Effect of Glycosylation on Quality and Volatile Flavor Characteristics of rainbow trout (Oncorhynchus mykiss) Floss [J]. Journal of Agricultural Science and Technology, 2024, 26(9): 159-172. |

| [3] | Zhefeng XU, Chunshuo LIU, Xudong LIAO, Jiahong SUI, Yuqiu CHEN, Changbao CHEN, Tao ZHANG, Lina WEI. Effects of Ecological Factors on Quality Difference Between Forestland Ginseng and Farmland Ginseng [J]. Journal of Agricultural Science and Technology, 2024, 26(9): 213-223. |

| [4] | Bo PANG, Shengmei LI, Yanlin LI, Tao YANG, Weiwei LIANG, Ru ZHANG, Yajie HUANG, Dan REN, Jinxin CUI, Jing LI, Jingjing MA, Wenwei GAO. Genetic Diversity Analysis in 192 Gossypium hirsutum L. F1 Hybrids [J]. Journal of Agricultural Science and Technology, 2024, 26(8): 34-50. |

| [5] | Shijian BAI, Jinge HU, Chao LI, Junshe CAI. Effects of 3 Trellis Systems on Cultivation Characters and Berry Quality of ‘Xinyu’ Grape [J]. Journal of Agricultural Science and Technology, 2024, 26(8): 63-73. |

| [6] | Liang SUN, Yi XU, Qin CAI, Jinghao GUO, Can ZHAO, Baowei GUO, Zhipeng XING, Zhongyang HUO, Hongcheng ZHANG, Yajie HU. Research Progress on Effects of Medium and Trace Elements on Yield and Quality of Rice [J]. Journal of Agricultural Science and Technology, 2024, 26(8): 9-19. |

| [7] | Xianyin SUN, Qiuhuan MU, Yong MI, Guangde LYU, Xiaolei QI, Yingying SUN, Xundong YIN, Ruixia WANG, Ke WU, Zhaoguo QIAN, Yan ZHAO, Minggang GAO. Classification and Evaluation of New Wheat Lines Based on GT Biplot [J]. Journal of Agricultural Science and Technology, 2024, 26(7): 14-24. |

| [8] | Shenghai HUANG, Xiujun TANG, Xiaoxu JIA, Lina MA, Yinyin LIU, Yushi GAO. Development Status of Pre-prepared Poultry Meat Dishes Industry, Influencing Factors and Promotion Strategies of Its Quality and Safety [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 133-140. |

| [9] | Wei YUE, Hui WANG, Xi CHEN, Xinchun ZHAN, Xinmin RUAN. Study on Comprehensive Evaluation Method of Rice Quality in Anhui Province [J]. Journal of Agricultural Science and Technology, 2024, 26(6): 141-147. |

| [10] | Dengyang LU, Panpan TONG, Min YAN, Jingkai BAO, Mingzhe LIU, Yilei XIA, Cuiyun WU. Identification and Evaluation of Korla Pear Bud Sport with Larger Fruit Size [J]. Journal of Agricultural Science and Technology, 2024, 26(5): 52-64. |

| [11] | Limin GAO, Zechen GU, Xuefei GONG, Lianming CUI, Dongsen GUO, Ying ZHOU, Lin WANG, Qishun WEI. Effects of Grass Growing on the Productivity of Orchard-Soil System in China: A Meta-Analysis [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 184-194. |

| [12] | Xiuli HAN, Jiawei LI, Jie ZHANG, Yanjie GUO, Lijuan ZHANG, Yanzhi JI. Effects of Bio-organic Fertilizer Replacing Part of Chemical Fertilizer on Grape Growth and Soil Fertility [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 195-205. |

| [13] | Ying XU, Yue REN, Yuzhu SHA, Xiaoning PU, Xinyu GUO, Liangwei YAO, Pengyang SHAO, Jiqing WANG, Shaobin LI, Xiu LIU. Characteristics Analysis of Meat Fatty Acids of Tibetan Sheep at Different Altitudes Under Natural Grazing Conditions [J]. Journal of Agricultural Science and Technology, 2024, 26(4): 67-76. |

| [14] | Tongyu ZHANG, Ying GOU, Qi LI, Li YANG. Effects of Ginseng Rust Rot on Ginseng Quality and Soil Related Factors [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 124-133. |

| [15] | Furong CHEN, Weiyi XIONG, Jiao YIN, Xiaozhuo ZHANG, Yu HAN, Yishu DENG. Effects of Microbial Agents on Leaf Vegetable Wastes During Composting [J]. Journal of Agricultural Science and Technology, 2024, 26(3): 146-154. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号