中国农业科技导报 ›› 2024, Vol. 26 ›› Issue (9): 146-158.DOI: 10.13304/j.nykjdb.2022.1036

• 食品质量 加工储运 • 上一篇

王学庆1( ), 张波1(

), 张波1( ), 韩丽婷1, 吕转转1, 陈建军2, 张竹林2, 张军强2, 杜建梅2

), 韩丽婷1, 吕转转1, 陈建军2, 张竹林2, 张军强2, 杜建梅2

收稿日期:2022-11-28

接受日期:2023-05-05

出版日期:2024-09-15

发布日期:2024-09-13

通讯作者:

张波

作者简介:王学庆 E-mail:1339245327@qq.com;

基金资助:

Xueqing WANG1( ), Bo ZHANG1(

), Bo ZHANG1( ), Liting HAN1, Zhuanzhuan LYU1, Jianjun CHEN2, Zhulin ZHANG2, Junqiang ZHANG2, Jianmei DU2

), Liting HAN1, Zhuanzhuan LYU1, Jianjun CHEN2, Zhulin ZHANG2, Junqiang ZHANG2, Jianmei DU2

Received:2022-11-28

Accepted:2023-05-05

Online:2024-09-15

Published:2024-09-13

Contact:

Bo ZHANG

摘要:

为改善酿酒葡萄原料的香气品质,研究不同超高压处理条件对赤霞珠葡萄果实挥发性物质的影响,利用顶空固相微萃取(headspace-solid phase microextraction,HS-SPME)与气相色谱-质谱联用技术(gas chromatography-mass spectrometry,GC-MS),对不同超高压条件处理的葡萄果实挥发性物质进行测定,结合主成分分析与香气轮廓描述对其特征香气进行分析。结果表明,不同处理条件下的果实挥发性物质与对照相比均发生显著变化(P<0.05);主成分分析发现,400 MPa压力操作及25 min的处理时间均与果实中具有草本、果香气味的醛、酮类物质有较高的相关性;香气轮廓分析发现,一定的压力与时间处理可显著提高赤霞珠葡萄的气味强度。以上研究结果为超高压技术在葡萄酒生产中的应用与推广提供了一定的数据参考和技术支持。

中图分类号:

王学庆, 张波, 韩丽婷, 吕转转, 陈建军, 张竹林, 张军强, 杜建梅. 超高压处理对赤霞珠葡萄挥发性物质的影响[J]. 中国农业科技导报, 2024, 26(9): 146-158.

Xueqing WANG, Bo ZHANG, Liting HAN, Zhuanzhuan LYU, Jianjun CHEN, Zhulin ZHANG, Junqiang ZHANG, Jianmei DU. Effects of High Hydrostatic Pressure Processing on Volatile Compounds in Cabernet Sauvignon[J]. Journal of Agricultural Science and Technology, 2024, 26(9): 146-158.

类别 Species | 化合物 Compound | 对照 CK | 压力处理Pressure treatment/MPa | ||||

|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | |||

醇类 Alcohols | 己醇 1-hexanol | 25.16±0.08 bc | 28.76±1.37 a | 27.96±1.10 ab | 26.60±2.09 ab | 16.80±1.34 e | 23.29±0.25 c |

顺-3-己烯醇 (Z)-3-hexenol | 5.50±0.08 c | 5.41±0.22 c | 4.93±0.02 c | 6.50±0.51 a | 4.04±0.26 c | 5.36±0.14 c | |

反-2-己烯醇 (E)-2-hexenol | 31.25±0.68 a | 26.46±1.36 b | 19.56±0.65 c | 27.40±1.65 b | 17.05±1.14 d | 20.71±0.49 c | |

1-辛烯-3-醇 Oct-1-en-3-ol | 1.80±0.04 c | 2.27±0.18 b | 2.59±0.07 a | 1.78±0.25 c | 0.77±0.10 d | 2.81±0.12 a | |

辛醇 1-octanol | 0.92±0.05 a | 0.97±0.01 a | 0.99±0.05 a | 0.79±0.01 b | 0.70±0.06 c | — | |

总计 Total | 64.64±0.93 a | 63.87±3.15 a | 56.04±1.89 b | 63.09±4.49 a | 39.36±2.91 c | 52.17±1.00 b | |

醛类 Aldehydes | 己醛 Hexanal | 372.87±34.52 b | 313.90±5.23 c | 378.96±1.37 b | 370.97±0.22 b | 531.29±18.16 a | 185.80±26.99 d |

顺-3-己烯醛 (Z)-3-hexenal | 2.52±0.37 a | 1.68±0.12 b | 1.54±0.18 b | 1.79±0.08 b | 2.21±0.09 a | 0.81±0.07 c | |

庚醛 Heptanal | 0.52±0.05 b | 0.37±0.00 c | 0.46±0.02 b | 0.61±0.02 a | 0.74±0.09 a | 0.39±0.04 c | |

反-2-己烯醛 (E)-2-hexenal | 710.16±25.49 b | 482.48±5.64 c | 509.52±3.15 c | 717.67±15.12 b | 822.43±20.31 a | 327.03±31.16 d | |

己醛二乙缩醛 1,1-diethoxyhexane | 1.92±0.30 d | 2.14±0.01 cd | 2.47±0.19 c | 3.05±0.15 b | 3.86±0.07 a | 1.20±0.14 e | |

反-2-庚烯醛 (E)-2-heptenal | 1.56±0.06 bc | 0.90±0.01 d | 1.04±0.08 cd | 1.31±0.02 bcd | 2.16±0.56 a | 1.73±0.15 ab | |

反-2-辛烯醛 (E)-2-octenal | 0.53±0.05 b | 0.43±0.04 b | 1.06±0.11 a | 1.11±0.08 a | 1.16±0.14 a | 1.14±0.11 a | |

反, 反-2,4-庚二烯醛 (E,E)-2,4-heptadienal | 0.84±0.03 c | 0.67±0.02 d | 0.74±0.07 cd | 1.07±0.04 b | 1.31±0.07 a | 0.86±0.07 c | |

反-2-壬烯醛 (E)-2-nonenal | 0.83±0.11 b | 0.96±0.05 b | 1.59±0.21 a | 1.02±0.15 b | — | — | |

反-2, 顺-6-壬二 烯醛 (2E,6Z)-nona-2,6-dienal | 0.51±0.09 c | 0.95±0.01 b | 1.38±0.17 a | 0.81±0.08 b | — | — | |

| 总计Total | 1 092.28±61.06 b | 804.48±11.14 d | 898.77±5.55 c | 1 099.41±15.96 b | 1 364.42±39.41 a | 518.96±58.72 e | |

酮类 Ketones | 1-戊烯-3-酮 1-penten-3-one | 1.04±0.32 b | 0.54±0.10 c | 0.56±0.03 c | 0.73±0.03 bc | 1.38±0.09 a | 0.58±0.06 c |

4-甲基-3-戊烯-2-酮 4-methyl-3-penten- 2-one | 53.67±2.65 b | 40.35±0.63 d | 46.17±2.54 c | 53.85±2.19 b | 71.16±4.38 a | 34.40±1.46 e | |

甲基庚烯酮 6-methylhept-5-en-2-one | 0.80±0.04 b | 0.52±0.00 c | 1.06±0.05 a | 0.53±0.01 c | 0.51±0.04 c | 0.50±0.16 c | |

| 佛尔酮 Phorone | 12.24±1.31 bc | 10.63±0.23 c | 14.03±0.46 b | 16.93±1.57 a | 12.72±0.05 b | 7.90±0.02 d | |

异佛尔酮 Isophorone | 4.13±0.16 c | 3.82±0.19 c | 4.76±0.18 b | 4.66±0.11 b | 6.32±0.46 a | 3.06±0.03 d | |

| 总计 Total | 71.88±4.49 bc | 55.85±1.14 d | 66.58±3.25 c | 76.70±3.91 b | 92.09±4.98 a | 46.44±1.73 e | |

酯类 Esters | 顺-3-己烯乙酸酯 (Z)-3-hexenyl acetate | 0.83±0.00 a | — | — | — | — | — |

芳香族 Aromatic | 苯甲醇 Benzyl alcohol | 1.68±0.08 b | 2.29±0.14 a | 2.44±0.10 a | 1.16±0.05 c | 1.66±0.15 b | 1.22±0.21 c |

苯乙醇 Phenylethyl alcohol | 1.98±0.02 c | 3.08±0.16 a | 3.15±0.22 a | 2.11±0.15 bc | 1.81±0.12 c | 2.35±0.16 b | |

苯甲醛 Benzaldehyde | 1.17±0.06 b | 0.71±0.04 c | 0.89±0.04 c | 1.34±0.08 b | 2.40±0.18 a | 0.78±0.13 c | |

| 总计 Total | 4.82±0.16 c | 6.08±0.35 ab | 6.48±0.36 a | 4.61±0.28 c | 5.87±0.45 b | 4.35±0.51 c | |

萜烯类 Terpenes | 柠檬烯 Limonene | 7.66±0.60 a | 3.36±0.06 c | 3.55±0.14 c | 3.35±0.14 c | 5.70±0.24 b | 6.19±0.02 b |

其他 Others | 2, 6-二叔丁基对甲酚 Butylated hydroxytoluene | 68.43±3.06 d | 67.23±0.55 d | 41.25±0.01 e | 96.34±1.22 a | 90.14±3.61 b | 79.62±3.82 c |

1, 3, 5-三甲苯 Mesitylene | 1.42±0.21 b | 1.11±0.10 b | 1.97±0.23 a | 1.90±0.16 a | 1.19±0.02 b | 1.28±0.11 b | |

| 总计 Total | 69.85±3.27 d | 68.34±0.65 d | 43.16±0.24 e | 98.24±1.38 a | 91.33±3.63 b | 80.90±3.93 c | |

表1 不同压力处理下挥发性物质的含量 (μg·L-1)

Table 1 Contents of volatile compounds under different pressure treatments

类别 Species | 化合物 Compound | 对照 CK | 压力处理Pressure treatment/MPa | ||||

|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | |||

醇类 Alcohols | 己醇 1-hexanol | 25.16±0.08 bc | 28.76±1.37 a | 27.96±1.10 ab | 26.60±2.09 ab | 16.80±1.34 e | 23.29±0.25 c |

顺-3-己烯醇 (Z)-3-hexenol | 5.50±0.08 c | 5.41±0.22 c | 4.93±0.02 c | 6.50±0.51 a | 4.04±0.26 c | 5.36±0.14 c | |

反-2-己烯醇 (E)-2-hexenol | 31.25±0.68 a | 26.46±1.36 b | 19.56±0.65 c | 27.40±1.65 b | 17.05±1.14 d | 20.71±0.49 c | |

1-辛烯-3-醇 Oct-1-en-3-ol | 1.80±0.04 c | 2.27±0.18 b | 2.59±0.07 a | 1.78±0.25 c | 0.77±0.10 d | 2.81±0.12 a | |

辛醇 1-octanol | 0.92±0.05 a | 0.97±0.01 a | 0.99±0.05 a | 0.79±0.01 b | 0.70±0.06 c | — | |

总计 Total | 64.64±0.93 a | 63.87±3.15 a | 56.04±1.89 b | 63.09±4.49 a | 39.36±2.91 c | 52.17±1.00 b | |

醛类 Aldehydes | 己醛 Hexanal | 372.87±34.52 b | 313.90±5.23 c | 378.96±1.37 b | 370.97±0.22 b | 531.29±18.16 a | 185.80±26.99 d |

顺-3-己烯醛 (Z)-3-hexenal | 2.52±0.37 a | 1.68±0.12 b | 1.54±0.18 b | 1.79±0.08 b | 2.21±0.09 a | 0.81±0.07 c | |

庚醛 Heptanal | 0.52±0.05 b | 0.37±0.00 c | 0.46±0.02 b | 0.61±0.02 a | 0.74±0.09 a | 0.39±0.04 c | |

反-2-己烯醛 (E)-2-hexenal | 710.16±25.49 b | 482.48±5.64 c | 509.52±3.15 c | 717.67±15.12 b | 822.43±20.31 a | 327.03±31.16 d | |

己醛二乙缩醛 1,1-diethoxyhexane | 1.92±0.30 d | 2.14±0.01 cd | 2.47±0.19 c | 3.05±0.15 b | 3.86±0.07 a | 1.20±0.14 e | |

反-2-庚烯醛 (E)-2-heptenal | 1.56±0.06 bc | 0.90±0.01 d | 1.04±0.08 cd | 1.31±0.02 bcd | 2.16±0.56 a | 1.73±0.15 ab | |

反-2-辛烯醛 (E)-2-octenal | 0.53±0.05 b | 0.43±0.04 b | 1.06±0.11 a | 1.11±0.08 a | 1.16±0.14 a | 1.14±0.11 a | |

反, 反-2,4-庚二烯醛 (E,E)-2,4-heptadienal | 0.84±0.03 c | 0.67±0.02 d | 0.74±0.07 cd | 1.07±0.04 b | 1.31±0.07 a | 0.86±0.07 c | |

反-2-壬烯醛 (E)-2-nonenal | 0.83±0.11 b | 0.96±0.05 b | 1.59±0.21 a | 1.02±0.15 b | — | — | |

反-2, 顺-6-壬二 烯醛 (2E,6Z)-nona-2,6-dienal | 0.51±0.09 c | 0.95±0.01 b | 1.38±0.17 a | 0.81±0.08 b | — | — | |

| 总计Total | 1 092.28±61.06 b | 804.48±11.14 d | 898.77±5.55 c | 1 099.41±15.96 b | 1 364.42±39.41 a | 518.96±58.72 e | |

酮类 Ketones | 1-戊烯-3-酮 1-penten-3-one | 1.04±0.32 b | 0.54±0.10 c | 0.56±0.03 c | 0.73±0.03 bc | 1.38±0.09 a | 0.58±0.06 c |

4-甲基-3-戊烯-2-酮 4-methyl-3-penten- 2-one | 53.67±2.65 b | 40.35±0.63 d | 46.17±2.54 c | 53.85±2.19 b | 71.16±4.38 a | 34.40±1.46 e | |

甲基庚烯酮 6-methylhept-5-en-2-one | 0.80±0.04 b | 0.52±0.00 c | 1.06±0.05 a | 0.53±0.01 c | 0.51±0.04 c | 0.50±0.16 c | |

| 佛尔酮 Phorone | 12.24±1.31 bc | 10.63±0.23 c | 14.03±0.46 b | 16.93±1.57 a | 12.72±0.05 b | 7.90±0.02 d | |

异佛尔酮 Isophorone | 4.13±0.16 c | 3.82±0.19 c | 4.76±0.18 b | 4.66±0.11 b | 6.32±0.46 a | 3.06±0.03 d | |

| 总计 Total | 71.88±4.49 bc | 55.85±1.14 d | 66.58±3.25 c | 76.70±3.91 b | 92.09±4.98 a | 46.44±1.73 e | |

酯类 Esters | 顺-3-己烯乙酸酯 (Z)-3-hexenyl acetate | 0.83±0.00 a | — | — | — | — | — |

芳香族 Aromatic | 苯甲醇 Benzyl alcohol | 1.68±0.08 b | 2.29±0.14 a | 2.44±0.10 a | 1.16±0.05 c | 1.66±0.15 b | 1.22±0.21 c |

苯乙醇 Phenylethyl alcohol | 1.98±0.02 c | 3.08±0.16 a | 3.15±0.22 a | 2.11±0.15 bc | 1.81±0.12 c | 2.35±0.16 b | |

苯甲醛 Benzaldehyde | 1.17±0.06 b | 0.71±0.04 c | 0.89±0.04 c | 1.34±0.08 b | 2.40±0.18 a | 0.78±0.13 c | |

| 总计 Total | 4.82±0.16 c | 6.08±0.35 ab | 6.48±0.36 a | 4.61±0.28 c | 5.87±0.45 b | 4.35±0.51 c | |

萜烯类 Terpenes | 柠檬烯 Limonene | 7.66±0.60 a | 3.36±0.06 c | 3.55±0.14 c | 3.35±0.14 c | 5.70±0.24 b | 6.19±0.02 b |

其他 Others | 2, 6-二叔丁基对甲酚 Butylated hydroxytoluene | 68.43±3.06 d | 67.23±0.55 d | 41.25±0.01 e | 96.34±1.22 a | 90.14±3.61 b | 79.62±3.82 c |

1, 3, 5-三甲苯 Mesitylene | 1.42±0.21 b | 1.11±0.10 b | 1.97±0.23 a | 1.90±0.16 a | 1.19±0.02 b | 1.28±0.11 b | |

| 总计 Total | 69.85±3.27 d | 68.34±0.65 d | 43.16±0.24 e | 98.24±1.38 a | 91.33±3.63 b | 80.90±3.93 c | |

分类 Species | 化合物 Compound | 对照 CK | 时间处理Time treatment/min | ||||

|---|---|---|---|---|---|---|---|

| 5 | 15 | 25 | 35 | 45 | |||

醇类 Alcohols | 己醇 1-hexanol | 25.16±0.08 c | 35.68±0.43 b | 34.16±0.19 b | 36.39±1.37 b | 20.42±0.10 d | 56.90±3.13 a |

顺-3-己烯醇 (Z)-3-hexenol | 5.50±0.08 bc | 5.26±0.16 c | 6.05±0.07 abc | 6.85±0.26 ab | 4.92±0.11 c | 7.26±1.59 a | |

反-2-己烯醇 (E)-2-hexenol | 31.25±0.68 b | 28.97±0.68 bc | 26.70±0.26 c | 27.75±1.35 c | 14.22±0.41 d | 50.14±3.33 a | |

1-辛烯-3-醇 Oct-1-en-3-ol | 1.80±0.04 c | 1.90±0.08 c | 2.44±0.15 b | 2.58±0.04 b | 3.38±0.41 a | 2.40±0.24 b | |

| 辛醇 1-octanol | 0.92±0.05 cd | 0.94±0.04 cd | 0.85±0.03 d | 1.02±0.06 bc | 1.04±0.05 b | 1.22±0.01 a | |

| 总计 Total | 64.64±0.93 b | 72.75±1.39 b | 70.20±0.70 b | 74.59±3.08 b | 43.98±1.08 c | 117.92±8.30 a | |

醛类 Aldehydes | 己醛 Hexanal | 372.87±34.52 b | 388.15±18.70 b | 435.46±24.08 a | 451.35±24.45 a | 270.80±4.60 d | 324.78±2.30 c |

顺-3-己烯醛 (Z)-3-hexenal | 2.52±0.37 b | 2.14±0.05 bc | 1.88±0.13 c | 3.11±0.01 a | 1.15±0.04 d | 1.90±0.33 c | |

| 庚醛 Heptanal | 0.52±0.05 bc | 0.44±0.04 c | 0.73±0.09 b | 1.17±0.15 a | 0.50±0.01 bc | 0.98±0.20 a | |

反-2-己烯醛 (E)-2-hexenal | 710.16±25.49 b | 537.92±13.29 d | 585.53±9.39 b | 866.65±32.66 a | 426.96±13.37 e | 602.13±15.92 b | |

己醛二乙缩醛 1,1-diethoxyhexane | 1.92±0.30 d | 3.68±0.07 b | 4.08±0.47 b | 4.99±0.01 a | 2.82±0.17 c | — | |

反-2-庚烯醛 (E)-2-heptenal | 1.56±0.06 c | 1.11±0.09 d | 1.49±0.25 c | 2.62±0.04 b | 1.54±0.14 c | 3.50±0.23 a | |

反-2-辛烯醛 (E)-2-octenal | 0.53±0.05 d | 0.53±0.08 d | 0.65±0.08 d | 1.36±0.09 b | 0.89±0.11 c | 1.65±0.02 a | |

反, 反-2, 4-庚二 烯醛 (E,E)-2,4-heptadienal | 0.84±0.03 c | 0.63±0.03 d | 0.99±0.07 b | 1.73±0.01 a | 0.88±0.09 c | — | |

反-2-壬烯醛 (E)-2-nonenal | 0.83±0.11 c | 0.81±0.11 c | 1.21±0.18 b | 2.06±0.09 a | 0.70±0.03 c | 2.35±0.22 a | |

反-2, 顺-6-壬二烯醛 (2E,6Z)-nona-2,6-dienal | 0.51±0.09 b | 0.60±0.07 b | 0.77±0.04 b | 1.65±0.07 a | 0.71±0.04 b | 1.53±0.24 a | |

2-甲基丁醛 2-methylbutanal | — | — | — | — | — | 0.96±0.08 a | |

3-甲基丁醛 3-methylbutanal | — | — | — | — | — | 0.82±0.06 a | |

| 总计 Total | 1 092.28±61.07 b | 936.02±32.53 c | 1 032.79±24.78 b | 1 336.69±57.49 a | 706.94±18.60 d | 940.61±19.60 c | |

酮类 Ketones | 1-戊烯-3-酮 1-penten-3-one | 1.04±0.32 ab | 0.79±0.06 b | 0.77±0.08 b | 1.33±0.01 a | 1.28±0.14 a | 1.27±0.39 a |

4-甲基-3-戊烯-2-酮 4-methyl-3-penten-2-one | 53.67±2.65 c | 42.10±1.61 d | 53.06±0.43 c | 92.36±2.48 a | 42.34±1.74 d | 80.42±4.62 b | |

甲基庚烯酮 6-methylhept-5-en-2-one | 0.80±0.04 b | 0.42±0.04 d | 0.67±0.12 bc | 1.41±0.22 a | 0.51±0.03 cd | 1.21±0.08 a | |

佛尔酮 Phorone | 12.24±1.31 bc | 10.69±0.91 c | 10.25±1.23 c | 26.05±2.40 a | 10.32±0.08 c | 14.56±0.28 b | |

异佛尔酮 Isophorone | 4.13±0.16 b | 3.66±0.14 b | 4.29±0.09 b | 5.50±1.10 a | 4.22±0.15 b | 6.53±0.39 a | |

| 总计 Total | 71.88±4.48 c | 57.66±2.76 d | 69.04±1.95 c | 126.65±5.91 a | 58.67±2.14 d | 103.99±5.76 b | |

酯类 Esters | 辛酸乙酯 Ethyl caprylate | — | — | 1.65±0.13 a | 0.86±0.10 c | 1.05±0.02 c | 1.26±0.17 b |

顺-3-己烯乙酸酯 (Z)-3-hexenyl acetate | 0.83±0.00 a | — | — | — | — | — | |

| 总计 Total | 0.83±0.00 d | — | 1.65±0.13 a | 0.86±0.10 cd | 1.05±0.02 c | 1.26±0.17 b | |

芳香族 Aromatic | 苯甲醇 Benzyl alcohol | 1.68±0.08 c | 2.56±0.10 b | 2.85±0.06 b | 2.82±0.21 b | 1.85±0.06 c | 4.76±0.20 a |

苯乙醇 Phenylethyl alcohol | 1.98±0.02 c | 2.78±0.14 ab | 2.40±0.16 ab | 3.25±0.14 b | 2.53±0.14 ab | 4.90±1.03 a | |

苯甲醛 Phenylethyl alcohol | 1.17±0.06 d | 1.34±0.13 d | 2.30±0.24 c | 3.09±0.06 b | 1.40±0.09 d | 6.70±0.21 a | |

| 总计 Total | 4.82±0.16 e | 6.68±0.37 cd | 7.55±0.46 c | 9.16±0.41 b | 5.78±0.29 de | 16.36±1.44 a | |

萜烯类 Terpenes | 柠檬烯 Limonene | 7.66±0.60 a | 4.70±0.38 b | 3.69±0.11 c | 3.72±0.11 c | 3.41±0.04 c | 3.35±0.19 c |

其他 Others | 2, 6-二叔丁基对 甲酚 Butylated hydroxytoluene | 68.43±3.06 d | 107.21±4.65 b | 107.12±2.14 b | 95.31±0.41 c | 131.78±3.14 a | 101.83±3.96 bc |

1, 3, 5-三甲苯 Mesitylene | 1.42±0.21 b | 1.32±0.13 b | 1.09±0.08 b | 1.31±0.13 b | 1.88±0.41 a | 1.25±0.01 b | |

| 总计 Total | 69.85±3.27 d | 108.53±4.78 b | 108.21±2.22 b | 96.62±0.54 c | 133.66±3.55 a | 103.08±3.97 b | |

表2 不同时间处理下挥发性物质的含量 (μg·L-1)

Table 2 Contents of volatile compounds under different time treatments

分类 Species | 化合物 Compound | 对照 CK | 时间处理Time treatment/min | ||||

|---|---|---|---|---|---|---|---|

| 5 | 15 | 25 | 35 | 45 | |||

醇类 Alcohols | 己醇 1-hexanol | 25.16±0.08 c | 35.68±0.43 b | 34.16±0.19 b | 36.39±1.37 b | 20.42±0.10 d | 56.90±3.13 a |

顺-3-己烯醇 (Z)-3-hexenol | 5.50±0.08 bc | 5.26±0.16 c | 6.05±0.07 abc | 6.85±0.26 ab | 4.92±0.11 c | 7.26±1.59 a | |

反-2-己烯醇 (E)-2-hexenol | 31.25±0.68 b | 28.97±0.68 bc | 26.70±0.26 c | 27.75±1.35 c | 14.22±0.41 d | 50.14±3.33 a | |

1-辛烯-3-醇 Oct-1-en-3-ol | 1.80±0.04 c | 1.90±0.08 c | 2.44±0.15 b | 2.58±0.04 b | 3.38±0.41 a | 2.40±0.24 b | |

| 辛醇 1-octanol | 0.92±0.05 cd | 0.94±0.04 cd | 0.85±0.03 d | 1.02±0.06 bc | 1.04±0.05 b | 1.22±0.01 a | |

| 总计 Total | 64.64±0.93 b | 72.75±1.39 b | 70.20±0.70 b | 74.59±3.08 b | 43.98±1.08 c | 117.92±8.30 a | |

醛类 Aldehydes | 己醛 Hexanal | 372.87±34.52 b | 388.15±18.70 b | 435.46±24.08 a | 451.35±24.45 a | 270.80±4.60 d | 324.78±2.30 c |

顺-3-己烯醛 (Z)-3-hexenal | 2.52±0.37 b | 2.14±0.05 bc | 1.88±0.13 c | 3.11±0.01 a | 1.15±0.04 d | 1.90±0.33 c | |

| 庚醛 Heptanal | 0.52±0.05 bc | 0.44±0.04 c | 0.73±0.09 b | 1.17±0.15 a | 0.50±0.01 bc | 0.98±0.20 a | |

反-2-己烯醛 (E)-2-hexenal | 710.16±25.49 b | 537.92±13.29 d | 585.53±9.39 b | 866.65±32.66 a | 426.96±13.37 e | 602.13±15.92 b | |

己醛二乙缩醛 1,1-diethoxyhexane | 1.92±0.30 d | 3.68±0.07 b | 4.08±0.47 b | 4.99±0.01 a | 2.82±0.17 c | — | |

反-2-庚烯醛 (E)-2-heptenal | 1.56±0.06 c | 1.11±0.09 d | 1.49±0.25 c | 2.62±0.04 b | 1.54±0.14 c | 3.50±0.23 a | |

反-2-辛烯醛 (E)-2-octenal | 0.53±0.05 d | 0.53±0.08 d | 0.65±0.08 d | 1.36±0.09 b | 0.89±0.11 c | 1.65±0.02 a | |

反, 反-2, 4-庚二 烯醛 (E,E)-2,4-heptadienal | 0.84±0.03 c | 0.63±0.03 d | 0.99±0.07 b | 1.73±0.01 a | 0.88±0.09 c | — | |

反-2-壬烯醛 (E)-2-nonenal | 0.83±0.11 c | 0.81±0.11 c | 1.21±0.18 b | 2.06±0.09 a | 0.70±0.03 c | 2.35±0.22 a | |

反-2, 顺-6-壬二烯醛 (2E,6Z)-nona-2,6-dienal | 0.51±0.09 b | 0.60±0.07 b | 0.77±0.04 b | 1.65±0.07 a | 0.71±0.04 b | 1.53±0.24 a | |

2-甲基丁醛 2-methylbutanal | — | — | — | — | — | 0.96±0.08 a | |

3-甲基丁醛 3-methylbutanal | — | — | — | — | — | 0.82±0.06 a | |

| 总计 Total | 1 092.28±61.07 b | 936.02±32.53 c | 1 032.79±24.78 b | 1 336.69±57.49 a | 706.94±18.60 d | 940.61±19.60 c | |

酮类 Ketones | 1-戊烯-3-酮 1-penten-3-one | 1.04±0.32 ab | 0.79±0.06 b | 0.77±0.08 b | 1.33±0.01 a | 1.28±0.14 a | 1.27±0.39 a |

4-甲基-3-戊烯-2-酮 4-methyl-3-penten-2-one | 53.67±2.65 c | 42.10±1.61 d | 53.06±0.43 c | 92.36±2.48 a | 42.34±1.74 d | 80.42±4.62 b | |

甲基庚烯酮 6-methylhept-5-en-2-one | 0.80±0.04 b | 0.42±0.04 d | 0.67±0.12 bc | 1.41±0.22 a | 0.51±0.03 cd | 1.21±0.08 a | |

佛尔酮 Phorone | 12.24±1.31 bc | 10.69±0.91 c | 10.25±1.23 c | 26.05±2.40 a | 10.32±0.08 c | 14.56±0.28 b | |

异佛尔酮 Isophorone | 4.13±0.16 b | 3.66±0.14 b | 4.29±0.09 b | 5.50±1.10 a | 4.22±0.15 b | 6.53±0.39 a | |

| 总计 Total | 71.88±4.48 c | 57.66±2.76 d | 69.04±1.95 c | 126.65±5.91 a | 58.67±2.14 d | 103.99±5.76 b | |

酯类 Esters | 辛酸乙酯 Ethyl caprylate | — | — | 1.65±0.13 a | 0.86±0.10 c | 1.05±0.02 c | 1.26±0.17 b |

顺-3-己烯乙酸酯 (Z)-3-hexenyl acetate | 0.83±0.00 a | — | — | — | — | — | |

| 总计 Total | 0.83±0.00 d | — | 1.65±0.13 a | 0.86±0.10 cd | 1.05±0.02 c | 1.26±0.17 b | |

芳香族 Aromatic | 苯甲醇 Benzyl alcohol | 1.68±0.08 c | 2.56±0.10 b | 2.85±0.06 b | 2.82±0.21 b | 1.85±0.06 c | 4.76±0.20 a |

苯乙醇 Phenylethyl alcohol | 1.98±0.02 c | 2.78±0.14 ab | 2.40±0.16 ab | 3.25±0.14 b | 2.53±0.14 ab | 4.90±1.03 a | |

苯甲醛 Phenylethyl alcohol | 1.17±0.06 d | 1.34±0.13 d | 2.30±0.24 c | 3.09±0.06 b | 1.40±0.09 d | 6.70±0.21 a | |

| 总计 Total | 4.82±0.16 e | 6.68±0.37 cd | 7.55±0.46 c | 9.16±0.41 b | 5.78±0.29 de | 16.36±1.44 a | |

萜烯类 Terpenes | 柠檬烯 Limonene | 7.66±0.60 a | 4.70±0.38 b | 3.69±0.11 c | 3.72±0.11 c | 3.41±0.04 c | 3.35±0.19 c |

其他 Others | 2, 6-二叔丁基对 甲酚 Butylated hydroxytoluene | 68.43±3.06 d | 107.21±4.65 b | 107.12±2.14 b | 95.31±0.41 c | 131.78±3.14 a | 101.83±3.96 bc |

1, 3, 5-三甲苯 Mesitylene | 1.42±0.21 b | 1.32±0.13 b | 1.09±0.08 b | 1.31±0.13 b | 1.88±0.41 a | 1.25±0.01 b | |

| 总计 Total | 69.85±3.27 d | 108.53±4.78 b | 108.21±2.22 b | 96.62±0.54 c | 133.66±3.55 a | 103.08±3.97 b | |

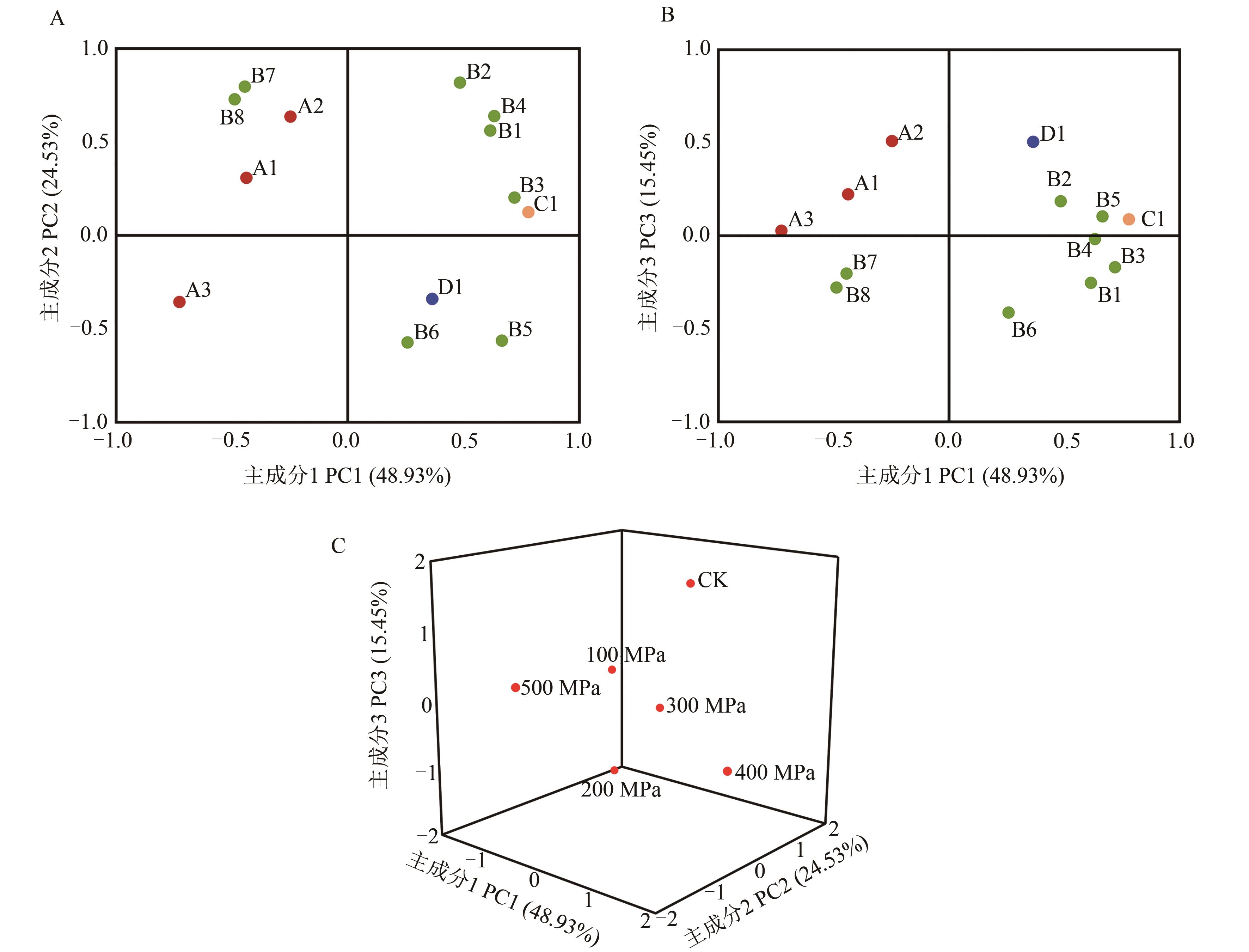

图1 不同HHP压力处理的主成分分析A~B: 载荷图; C:样品分布图。A1—顺-3-己烯醇;A2—反-2-己烯醇;A3—1-辛烯-3-醇;B1—己醛;B2—顺-3-己烯醛;B3—庚醛;B4—反-2-己烯醛;B5—反-2-庚烯醛;B6—反-2-辛烯醛;B7—反-2-壬烯醛;B8—反-2, 顺-6-壬二烯醛;C1—1-戊烯-3-酮;D1—柠檬烯

Fig. 1 Principal components analysis of different HHP pressure treatmentsA~B: Loading plot; C: Sample distribution. A1—(Z)-3-hexenol;A2—(E)-2-hexenol;A3—Oct-1-en-3-ol;B1—Hexanal;B2—(Z)-3-hexenal;B3—Heptanal;B4—(E)-2-hexenal;B5—(E)-2-heptenal;B6—(E)-2-octenal;B7—(E)-2-nonenal;B8—(2E,6Z)-nona-2,6-dienal;C1—1-penten-3-one;D1—Limonene

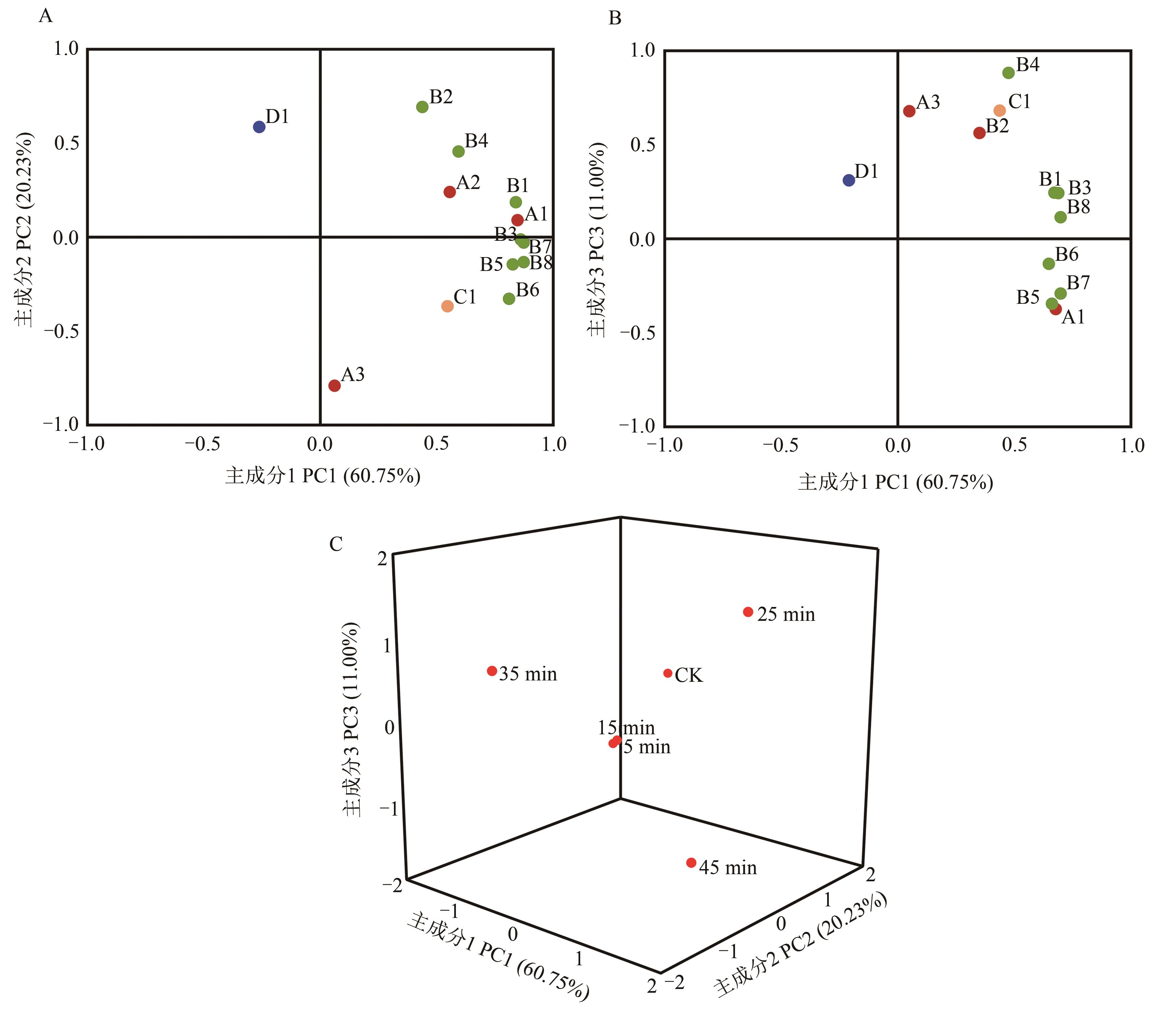

图2 不同HHP时间处理的主成分分析A~B: 载荷图; C:样品分布图。A1—顺-3-己烯醇;A2—反-2-己烯醇;A3—1-辛烯-3-醇;B1—己醛;B2—顺-3-己烯醛;B3—庚醛;B4—反-2-己烯醛;B5—反-2-庚烯醛;B6—反-2-辛烯醛;B7—反-2-壬烯醛;B8—反-2, 顺-6-壬二烯醛;C1—1-戊烯-3-酮;D1—柠檬烯

Fig. 2 Principal components analysis of different HHP time treatmentsA~B: Loading plot; C: Sample distribution. A1—(Z)-3-hexenol;A2—(E)-2-hexenol;A3—Oct-1-en-3-ol;B1—Hexanal;B2—(Z)-3-hexenal;B3—Heptanal;B4—(E)-2-hexenal;B5—(E)-2-heptenal;B6—(E)-2-octenal;B7—(E)-2-nonenal;B8—(2E,6Z)-nona-2,6-dienal;C1—1-penten-3-one;D1—Limonene

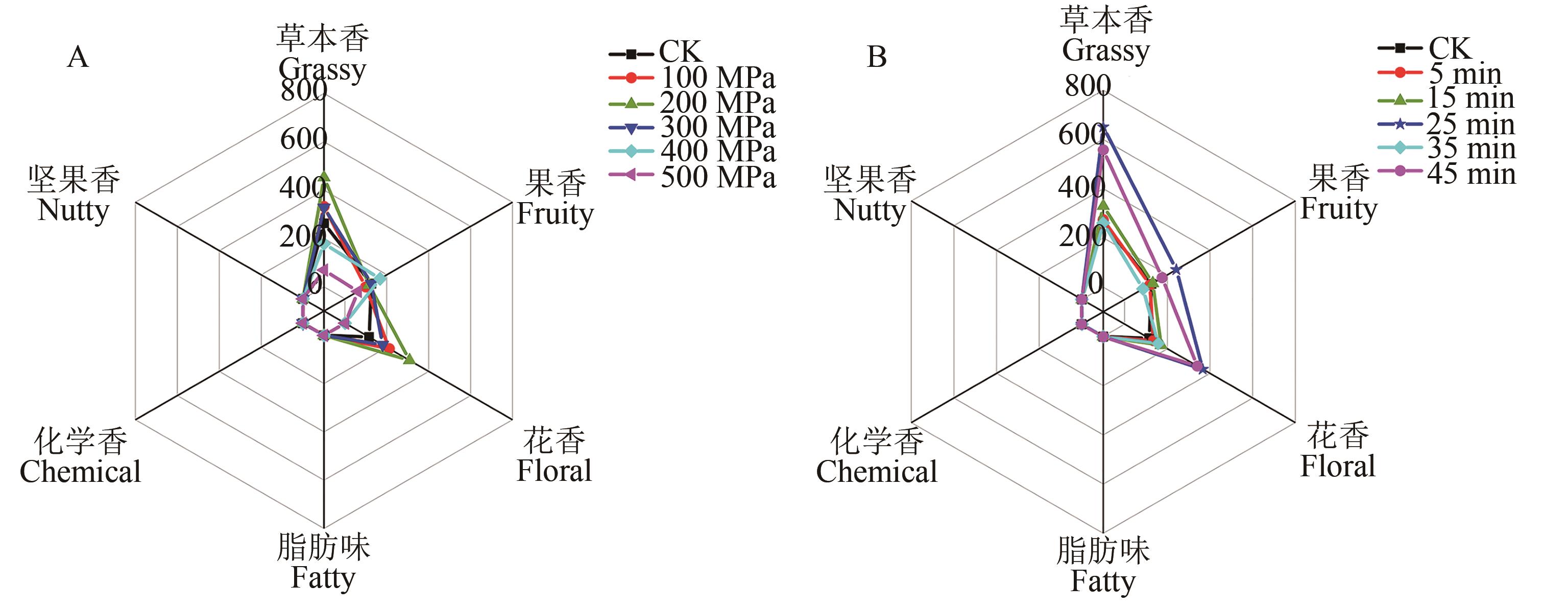

图3 不同HHP压力处理与时间处理的香气轮廓图A:压力处理; B:时间处理

Fig. 3 Aroma profile diagram of different HHP pressure and time treatmentsA: Pressure treatment; B:Time treatment

| CAS | 序号 Number | 化合物 Compound | 阈值 Threshold /(μg·L-1) | 香气描述 Aroma description |

|---|---|---|---|---|

| 928-96-1 | A1 | 顺-3-己烯醇 (Z)-3-hexenol | 3.90 | 草本香 Grassy |

| 928-95-0 | A2 | 反-2-己烯醇 (E)-2-hexenol | 100.00 | 草本香、果香 Grassy, fruity |

| 3391-86-4 | A3 | 1-辛烯-3-醇 Oct-1-en-3-ol | 1.00 | 草本香 Grassy |

| 66-25-1 | B1 | 己醛 Hexanal | 4.50 | 草本香、果香 Grassy, fruity |

| 6789-80-6 | B2 | 顺-3-己烯醛 (Z)-3-hexenal | 0.25 | 草本香 Grassy |

| 111-71-7 | B3 | 庚醛 Heptanal | 3.00 | 脂肪味、果香 Fatty, fruity |

| 6728-26-3 | B4 | 反-2-己烯醛 (E)-2-hexenal | 17.00 | 草本香、果香 Grassy, fruity |

| 18829-55-5 | B5 | 反-2-庚烯醛 (E)-2-heptenal | 4.60 | 草本香、脂肪味 Grassy, fatty |

| 2548-87-0 | B6 | 反-2-辛烯醛 (E)-2-octenal | 3.00 | 脂肪味、果香、坚果香 Fatty, fruity, nutty |

| 18829-56-6 | B7 | 反-2-壬烯醛 (E)-2-nonenal | 0.08 | 草本香 Grassy |

| 557-48-2 | B8 | 反-2, 顺-6-壬二烯醛 (2E,6Z)-nona-2,6-dienal | 0.004 5 | 草本香、花香 Grassy, floral |

| 1629-58-9 | C1 | 1-戊烯-3-酮 1-penten-3-one | 0.90 | 化学香 Chemical |

| 138-86-3 | D1 | 柠檬烯 Limonene | 10.00 | 花香、草本香、果香 Floral, grassy, fruity |

表3 赤霞珠葡萄特征香气物质感官描述

Table 3 Sensory description of aromatic compounds characteristic of Cabernet Sauvignon

| CAS | 序号 Number | 化合物 Compound | 阈值 Threshold /(μg·L-1) | 香气描述 Aroma description |

|---|---|---|---|---|

| 928-96-1 | A1 | 顺-3-己烯醇 (Z)-3-hexenol | 3.90 | 草本香 Grassy |

| 928-95-0 | A2 | 反-2-己烯醇 (E)-2-hexenol | 100.00 | 草本香、果香 Grassy, fruity |

| 3391-86-4 | A3 | 1-辛烯-3-醇 Oct-1-en-3-ol | 1.00 | 草本香 Grassy |

| 66-25-1 | B1 | 己醛 Hexanal | 4.50 | 草本香、果香 Grassy, fruity |

| 6789-80-6 | B2 | 顺-3-己烯醛 (Z)-3-hexenal | 0.25 | 草本香 Grassy |

| 111-71-7 | B3 | 庚醛 Heptanal | 3.00 | 脂肪味、果香 Fatty, fruity |

| 6728-26-3 | B4 | 反-2-己烯醛 (E)-2-hexenal | 17.00 | 草本香、果香 Grassy, fruity |

| 18829-55-5 | B5 | 反-2-庚烯醛 (E)-2-heptenal | 4.60 | 草本香、脂肪味 Grassy, fatty |

| 2548-87-0 | B6 | 反-2-辛烯醛 (E)-2-octenal | 3.00 | 脂肪味、果香、坚果香 Fatty, fruity, nutty |

| 18829-56-6 | B7 | 反-2-壬烯醛 (E)-2-nonenal | 0.08 | 草本香 Grassy |

| 557-48-2 | B8 | 反-2, 顺-6-壬二烯醛 (2E,6Z)-nona-2,6-dienal | 0.004 5 | 草本香、花香 Grassy, floral |

| 1629-58-9 | C1 | 1-戊烯-3-酮 1-penten-3-one | 0.90 | 化学香 Chemical |

| 138-86-3 | D1 | 柠檬烯 Limonene | 10.00 | 花香、草本香、果香 Floral, grassy, fruity |

| 1 | 朱珠芸茜. 新疆‘玫瑰香’葡萄在室温和冷藏条件下品质变化分析[D]. 石河子: 石河子大学, 2020. |

| ZHU Z Y X. Analysis of quality change of Muscat Hamburg Grape from Xinjiang under room temperature and refrigeration conditions [D]. Shihezi: Shihezi University, 2020. | |

| 2 | LIANG Z J, ZHANG P Z, FANG Z X. Modern technologies for extraction of aroma compounds from fruit peels: a review [J]. Criti. Rev. Food Sci. Nutr., 2020, 62(5): 21-24. |

| 3 | 孙蓓, 朱中原, 王龙刚. 超高压技术在食品化工中的重要应用[J]. 化工管理, 2020(34): 131-132. |

| 4 | 谢旭. 高静水压及热处理对蓝莓汁抗氧化性和营养品质影响的研究[D]. 沈阳:沈阳农业大学, 2020. |

| XIE X. Effects of high hydrostatic pressure and thermal processing on the antioxidant and nutritional quality of blueberry juice [D]. Shenyang: Shenyang Agricultural University, 2020. | |

| 5 | WANG F, DU B L, CUI Z W, et al.. Effects of high hydrostatic pressure and thermal processing on bioactive compounds, antioxidant activity, and volatile profile of mulberry juice [J]. Food Sci. Technol. Int., 2017, 23(2): 119-127. |

| 6 | 马永昆, 周日兴, 胡小松. 不同超高压处理压力对哈密瓜汁香气的影响[J]. 食品与发酵工业, 2003,29(11): 14-19. |

| MA Y K, ZHOU R X, HU X S. Effect of ultra high pressure treatment on flavour compounds of hami melon (Cucumis melo L. ) juice [J]. Food Ferment. Ind., 2003,29(11): 14-19. | |

| 7 | CHEN Y J, FENG X P, REN H, et al.. Changes in physicochemical properties and volatiles of kiwifruit pulp beverage treated with high hydrostatic pressure [J/OL]. Foods, 2020, 9(4): 485[2022-10-28].. |

| 8 | ZHANG W T, DONG P, LAO F, et al.. Characterization of the major aroma-active compounds in Keitt mango juice: comparison among fresh, pasteurization and high hydrostatic pressure processing juices [J]. Food Chem., 2019, 289: 215-222. |

| 9 | 潘见, 王海翔, 谢慧明, 等. 超高压处理对鲜榨橙汁中主要香气成分的影响[J]. 农业工程学报, 2009, 25(5): 239-243. |

| PAN J, WANG H X, XIE H M, et al.. Effect of ultra high pressure treatment on main flavour compounds in orange juice [J]. Trans. Chin. Soc. Agric. Eng., 2009, 25(5): 239-243. | |

| 10 | 梁茂雨, 纵伟, 赵光远, 等. 超高压处理对猕猴桃香气成分的影响[J]. 食品工业科技, 2007,28(3): 72-75. |

| LIANG M Y, ZONG W, ZHAO G Y, et al.. Effect of ultra high pressure treatment on flavour compounds in kiwifruit fruit juice [J]. Sci. Technol. Food Ind., 2007,28(3): 72-75. | |

| 11 | SANTOS L M, OLIVEIRA F A, FERREIRA E H, et al.. Application and possible benefits of high hydrostatic pressure or high-pressure homogenization on beer processing: a review [J]. Food Sci. Technol. Int., 2017, 23(7): 561-581. |

| 12 | LI W P, YAO H, CHEN K Q, et al.. Effect of foliar application of fulvic acid antitranspirant on sugar accumulation, phenolic profiles and aroma qualities of Cabernet Sauvignon and Riesling grapes and wines [J/OL]. Food Chem., 2021, 351: 129308 [2022-10-28]. . |

| 13 | GAO X T, WU M H, LI H Q, et al.. Effects of gibberellic acid (GA3) application before anthesis on rachis elongation and berry quality and aroma and flavour compounds in Vitis vinifera L. ‘Cabernet Franc’ and ‘Cabernet Sauvignon’ grapes [J]. J. Sci. Food Agric., 2020, 100(9): 3729-3740. |

| 14 | HE L, REN Z Y, WANG Y, et al.. Variation of growth-to-ripening time interval induced by abscisic acid and synthetic auxin affecting transcriptome and flavor compounds in cabernet sauvignon grape berry [J/OL]. Plants, 2020, 9(5): 630 [2022-10-28]. . |

| 15 | XIE S, LEI Y J, WANG Y J, et al.. Influence of continental climates on the volatile profile of Cabernet Sauvignon grapes from five Chinese viticulture regions [J]. Plant Growth Regul., 2019, 87(1): 83-92. |

| 16 | 张克坤, 王海波, 王孝娣, 等. ‘瑞都香玉’葡萄果实挥发性成分在果实发育过程中的变化[J]. 中国农业科学, 2015, 48(19): 3965-3978. |

| ZHANG K K, WANG H B, WANG X D, et al.. Evolution of volatile compounds during the berry development of 'Ruidu Xiangyu' grape [J]. Sci. Agric. Sin., 2015, 48(19): 3965-3978. | |

| 17 | CAPONE S, TUFARIELLO M, SICILIANO P. Analytical characterisation of Negroamaro red wines by “Aroma Wheels” [J]. Food Chem., 2013, 141(3): 2906-2915. |

| 18 | 纵伟, 李春艳, 张文叶, 等. 超高压处理前后菠萝香气成分的变化[J]. 食品科技, 2007(3): 67-71. |

| ZONG W, LI C Y, ZHANG W Y, et al.. Effect of ultra high pressure treatment on the changes in volatile composition of pineapple [J]. Food Sci. Technol., 2007(3): 67-71. | |

| 19 | 王亚超, 马永昆, 于怀龙, 等. 超高压处理对黄酒中醇水缔合影响的研究[J]. 现代食品科技, 2016, 32(2): 221-226. |

| WANG Y C, MA Y K, YU H L, et al.. Study on the effect of high hydrostatic pressure processing on ethanol-water system for Chinese rise wine [J]. Mod. Food Sci. Technol., 2016, 32(2): 221-226. | |

| 20 | 奚昕琰, 杨淑娜, 王莉, 等. 葡萄新品种‘南太湖特早’果实发育过程中特征香气物质的变化规律[J].浙江大学学报(农业与生命科学版), 2022, 48(2): 154-162. |

| XI X Y, YANG S N, WANG L, et al.. Variation rule of characteristic aroma compounds during the berry development process of a new grape cultivar ‘Nantaihutezao’ [J]. J. Zhejiang Univ. (Agric. Life Sci.), 2022, 48(2): 154-162. | |

| 21 | 赵玉, 詹萍, 王鹏, 等. 猕猴桃中关键香气组分分析[J]. 食品科学, 2021, 42(16): 118-124. |

| ZHAO Y, ZHAN P, WANG P, et al.. Analysis of aroma compounds in kiwifruits [J]. Food Sci., 2021, 42(16): 118-124. | |

| 22 | 安效辉, 苗瀛心, 陈倬, 等. 基于UPLC-Q-TOF-MS分析酵母对葡萄酒中糖苷态香气物质释放的影响[J].食品科学, 2020, 41(12): 158-165. |

| AN X H, MIAO Y X, CHEN Z, et al.. Effects of yeasts on the release of glycosidically bound aroma components from wine analyzed by ultra-high performance liquid chromatography- quadrupole-time-of-flight-mass spectrometry [J]. Food Sci., 2020, 41(12): 158-165. | |

| 23 | 马永昆, 白洁, 魏本喜, 等. 基于SPME-GC-MS的超高压处理黑莓汁香气分析[J]. 农业机械学报, 2011, 42(7): 170-175. |

| MA Y K, BAI J, WEI B X, et al.. Aromatic compounds in blackberry juice after ultrahigh pressure treatment by SPME-GC-MS [J]. Trans. Chin. Soc. Agric. Mach., 2011, 42(7): 170-175. | |

| 24 | GONZALEZ C F, GARCIA P J, RAMIREZ R. Aroma profile of a red plum puree processed by high hydrostatic pressure and analysed by SPME-GC/MS [J]. Innov. Food Sci. Emerg. Technol., 2016, 33: 108-114. |

| 25 | FERREIRA V, RICARDO L. The actual and potential aroma of winemaking grapes [J/OL]. Biomolecules, 2019, 9(12): 818[2022-10-28]. . |

| 26 | YUAN L, LIANG X J, PAN X, et al.. Effects of high hydrostatic pressure combined with vacuum-freeze drying on the aroma-active compounds in blended pumpkin, mango, and jujube juice [J/OL]. Foods, 2021, 10(12): 3151[2022-10-28].. |

| 27 | PAN J, WANG H X, XIE H M, et al.. Effect of ultra high hydrostatic pressure on concentrations of limonene, a terpineol and carvone in navel orange juice [J]. J. Food Proc. Eng., 2011, 34(3): 728-745. |

| 28 | WU Y, DUAN S, ZHAO L, et al.. Aroma characterization based on aromatic series analysis in table grapes [J/OL]. Sci. Rep., 2016, 6(1): 31116 [2022-10-28]. . |

| 29 | 边磊. 超高压处理对黑莓香气、质地特性及过氧化酶的影响[D]. 镇江: 江苏大学, 2009. |

| BIAN L. Effect of ultra high pressure treatment on its aroma components, texture properties and peroxidase in blackberry [D]. Zhenjiang: Jiangsu University, 2009. | |

| 30 | LAMBERT Y, DEMAZEAU G, LARGETEAU A, et al.. Changes in aromatic volatile composition of strawberry after high pressure treatment [J]. Food Chem., 1999, 67(1): 7-16. |

| 31 | PEI L Y, LI J, XU Z L, et al.. Effect of high hydrostatic pressure on aroma components, amino acids, and fatty acids of Hami melon (Cucumis melo L.var. reticulatus naud.) juice [J]. Food Sci. Nutr., 2020, 8(3): 1394-1405. |

| 32 | SUMITANI H, SUEKANE S, NAKATANI A, et al.. Changes in composition of volatile compounds in high pressure treated peach [J]. Agric. Food Chem., 2002, 42(3): 785-790. |

| 33 | PUTNIK P, PAVLIC B, SOJIC B, et al.. Innovative hurdle technologies for the preservation of functional fruit juices [J/OL]. Foods, 2020, 9(6): 699 [2022-10-28]. . |

| 34 | 许文文, 曹霞敏, 胡小松, 等. 超高压对草莓果肉饮料的杀菌效果与品质影响[J]. 食品科学, 2011, 32(23): 28-34. |

| XU W W, CAO X M, HU X S, et al.. Effects of high hydrostatic pressure (HHP) processing on microbial inactivation and quality of strawberry nectar [J]. Food Sci., 2021, 32(23): 28-34. | |

| 35 | 吴梦, 李希, 马永昆, 等.主成分分析超高压对桑椹饮料香气成分的影响[J]. 食品研究与开发, 2017, 38(19): 116-123. |

| WU M, LI X, MA Y K, et al.. Effect of high pressure processing on aroma compounds in mulberry beverage analyzed by principal component [J]. Food Res. Dev., 2017, 38(19): 116-123. |

| [1] | 孙宪印, 牟秋焕, 米勇, 吕广德, 亓晓蕾, 孙盈盈, 尹逊栋, 王瑞霞, 吴科, 钱兆国, 赵岩, 高明刚. 基于GT双标图对小麦新品系的分类评价[J]. 中国农业科技导报, 2024, 26(7): 14-24. |

| [2] | 石玉涛, 谢惠珍, 郑淑琳, 羽观华, 王飞权, 李力, 张渤, 李远华, 罗盛财. 武夷山地方茶树种质生化特性和茶多糖清除超氧阴离子自由基活性分析[J]. 中国农业科技导报, 2024, 26(5): 65-76. |

| [3] | 潘越, 王宝庆, 王季姣, 马勇, 李亚兰. 不同山葡萄品种CO2响应模型拟合及评价[J]. 中国农业科技导报, 2024, 26(4): 58-66. |

| [4] | 曹婷婷, 刘春, 范又维, 马力, 任志雨, 袁素霞, 张军云, 钱遵姚, 杨光炤. 不同氮素供应水平对微型盆栽月季生长发育的影响[J]. 中国农业科技导报, 2024, 26(2): 67-79. |

| [5] | 孟盼盼, 何海燕, 曹钰昕, 张丽欣, 吕清豪, 祁瑞林, 张红瑞. 5个栽培类型药菊分枝期抗旱性综合评价[J]. 中国农业科技导报, 2024, 26(2): 90-99. |

| [6] | 李生梅, 庞博, 耿世伟, 宋武, 李红梅, 马茂森, 张茹, 王新燕, 高文伟. 棉花海陆回交群体盛铃期的光合特性及其生理基础[J]. 中国农业科技导报, 2024, 26(1): 40-51. |

| [7] | 卢倩倩, 阿布都外力·阿不力米提, 侯毅兴, 李志慧, 王爽, 周龙. 复合盐碱胁迫下7个鲜食葡萄品种光合特性研究[J]. 中国农业科技导报, 2023, 25(7): 63-76. |

| [8] | 王爽, 侯毅兴, 冯琳骄, 卢倩倩, 周龙. 干旱胁迫对鲜食葡萄叶片解剖结构的影响[J]. 中国农业科技导报, 2023, 25(6): 40-49. |

| [9] | 贾毅男, 张光弟, 张浩宇, 许昌, 张昆明, 王江龙, 侯晓健. 根区施用硅肥对‘玫瑰香’葡萄果实品质的影响[J]. 中国农业科技导报, 2023, 25(5): 215-223. |

| [10] | 郑淑琳, 石玉涛, 王飞权, 吴邦强, 李远华, 张渤, 叶乃兴. 不同茶树种质资源花器矿质元素含量分析与综合评价[J]. 中国农业科技导报, 2023, 25(4): 178-188. |

| [11] | 郭胜微, 边思文, 丁建文, 张晓辰, 杨兴, 杜锦, 向春阳. 糯玉米萌发期耐低温品种资源的综合评价[J]. 中国农业科技导报, 2023, 25(2): 38-47. |

| [12] | 张月欣, 麻云霞, 马秀枝, 张金旺, 王月林, 俞海生. 大青山不同林龄榆树林的土壤酶和养分特征[J]. 中国农业科技导报, 2023, 25(12): 168-176. |

| [13] | 贾毅男, 万仲武, 许昌, 张光弟, 王江龙, 张昆明, 侯小健, 包文毅, 王玉, 陈卫军. 露地栽培‘大青葡萄’架面不同位置果实品质指标分析[J]. 中国农业科技导报, 2023, 25(12): 44-57. |

| [14] | 刘宇鹏, 陈芳, 古书鸿, 王芳. 贵州不同产地冬荪营养成分及品质评价[J]. 中国农业科技导报, 2023, 25(11): 143-153. |

| [15] | 张会芳, 张建红, 刘海礁, 孙岩, 齐红志, 王楠, 段俊枝, 郭燕, 尹海燕. 近20年黄淮冬麦区南片小麦种质性状演变及其育种价值评价[J]. 中国农业科技导报, 2023, 25(11): 28-41. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802021197号

京公网安备11010802021197号